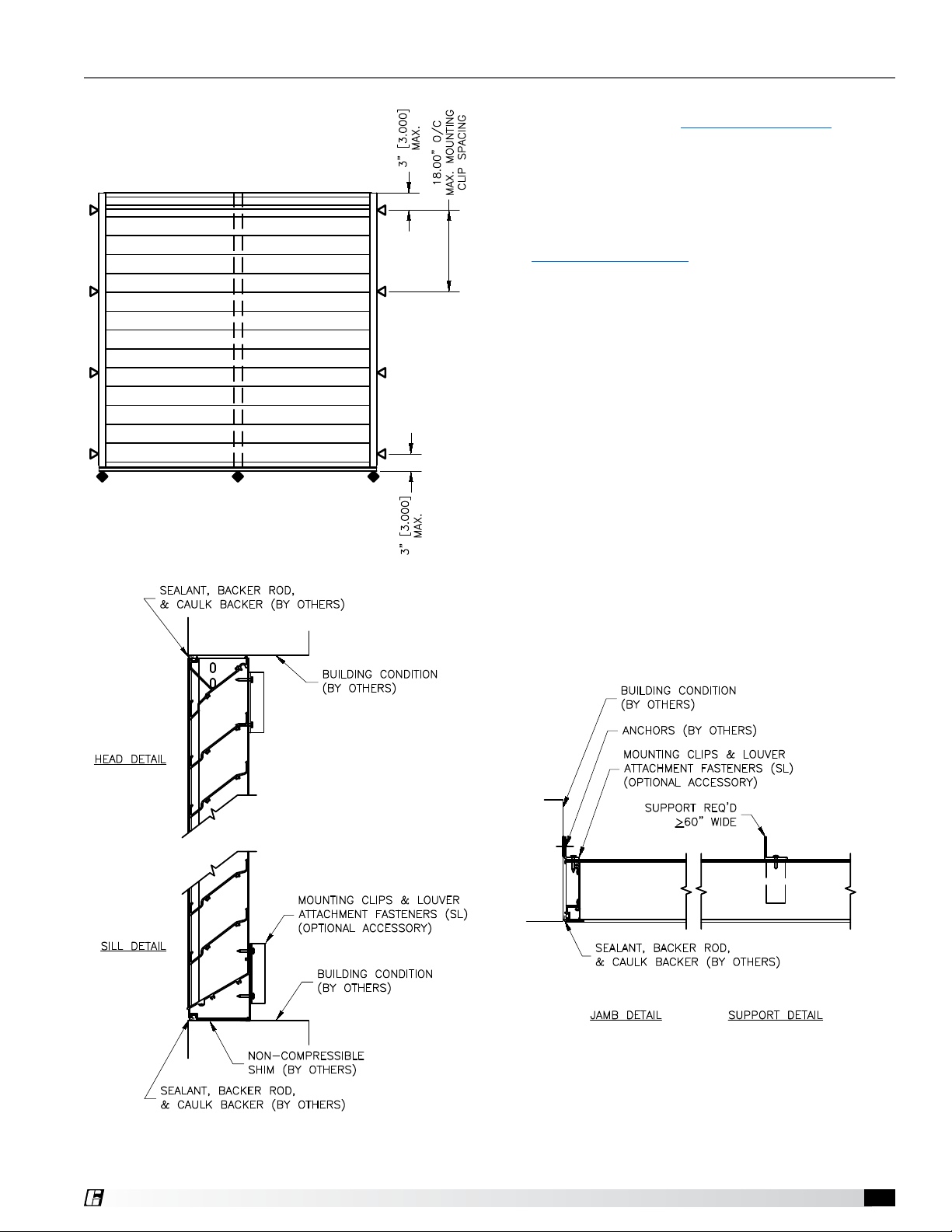

Stationary, Drainable Blade Louver Models8

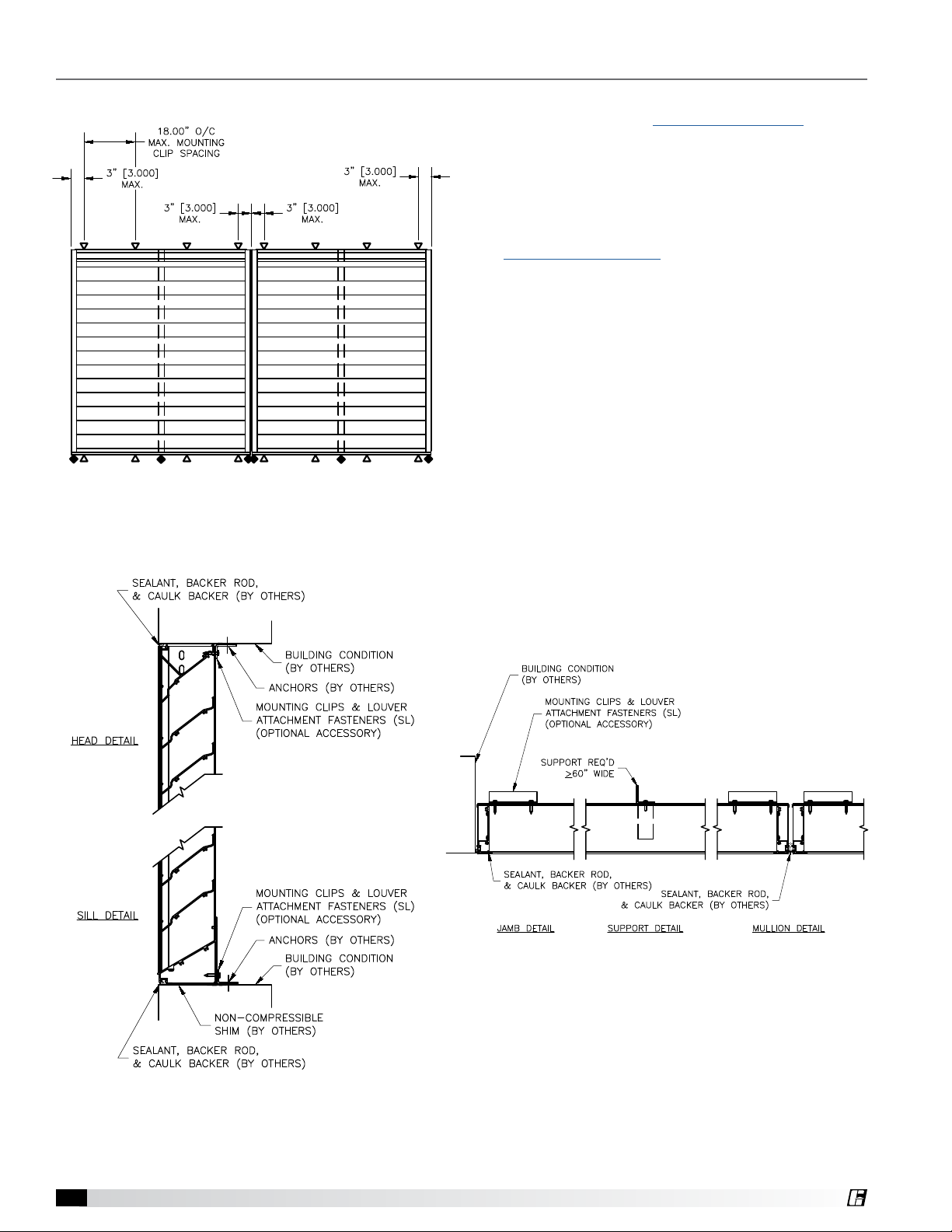

Multiple Section Wide x Multiple Section High Installation

Larger opening sizes require field assembly of multiple louver sections to make up the overall opening size.

Individual louver sections are designed to withstand a 25 psf wind load. Structural reinforcing members

may be required to adequately support and install multiple louver sections within a large opening. Structural

reinforcing members along with any associated installation hardware is not provided by manufacturer unless

indicated otherwise by manufacturer.

1. Locate the shipped loose Alignment Plates for

the jambs. Following the provided Installation,

Operation, and Maintenance Manual instructions

included with the Alignment Plates, connect the

upper and lower louver sections together.

2. If the louver sections are wide enough to require a

blade support angle, the upper louver section and

lower louver section angles will need to be spliced

together. This can be accomplished by following the

provided Installation, Operation, and Maintenance

Manual instructions included with the shipped loose

Splice Angle kit.

3. Locate the optional extended sill, if provided, and

place in the opening. (Extended Sill Details)

4. Locate mounting angles and fasteners required to

attach the louver to the structure. Clip angles and

fasteners are by others unless the optional mounting

angles have been ordered from manufacturer with

the louvers. Anchors to the structure are by others

and are not manufacturer provided.

(Mounting Clip Details)

5. Place the combined left louver section assembly (as

viewed from the exterior) in the opening and shim

around the perimeter to maintain proper spacing for

backer rod and caulk joint.

6. Using the appropriate fasteners, secure the

mounting angles to the back of the louver frame at

the perimeter.

7. Ensure the louvers is level and in the correct

location within the opening and secure the mounting

angles to the structure using the correct anchor (by

others) for the building substrate material.

8. Place the next combined louver section to the

right of the first louver section. Shim around the

perimeter to maintain proper spacing for backer rod

and caulk joint. Repeat steps 6-7 above to secure

the louver to the structure.

9. Follow the same procedure for any additional

sections to the right.

10. Additional structural supports (not designed or

provided by manufacturer) may be required and

will need to be installed behind the louver mullions

at this point. The louvers must be secured to the

structural support using the appropriate mounting

angles and fasteners (by others)

11. Once the louver is secured to the structure, install

backer rod and caulk around the perimeter of the

opening at the front of the louver.

Figure 5.1

Figure 5.2

IOM# 482875