2

Contents

Page

1. Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Standards and specifications . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.1 Normal operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3.2 Special operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Main parameters for panels with circuit-breakers . . . . . . . . . . . 8

2.1.2 Main parameters for panels with NALF switch-disconnector . . 8

2.2 Resistance to internal arc faults . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.1 Dimensions and weights of 12/17,5 kV units . . . . . . . . . . . . . . 9

2.3.2 Dimensions and weights of 24 kV units . . . . . . . . . . . . . . . . . 10

2.3.3 Dimensions and weights of panels with the

NALF 12/17,5 kV switch-disconnectors . . . . . . . . . . . . . . . . 10

2.3.4 Dimensions and weights of panels with the NALF 24 kV

switch-disconnectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

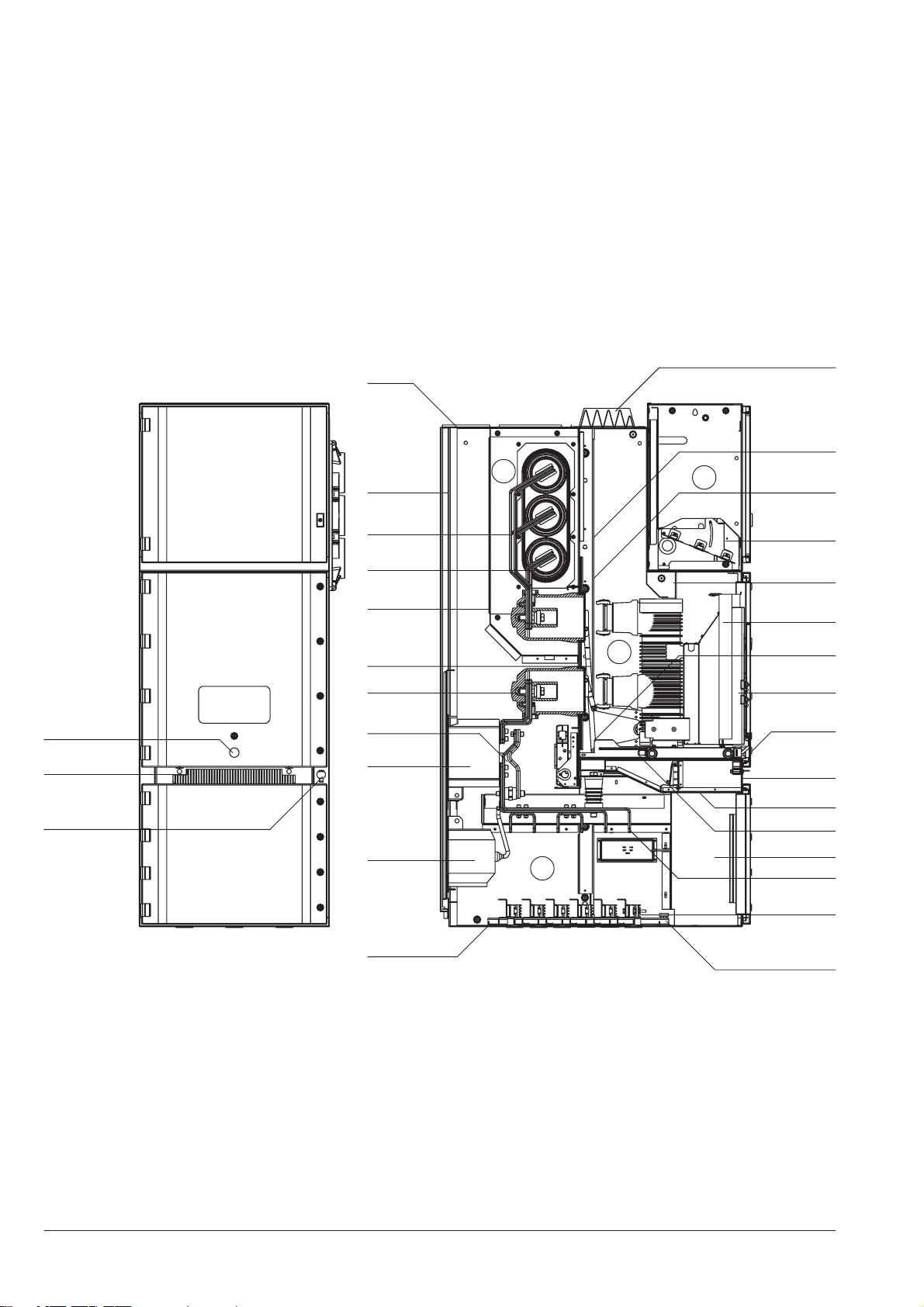

3. Panel design and equipment . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Basic structure and variants . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Enclosure and partitioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2.1 Ventilation of the panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Compartments in the panels . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.1 Busbar compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3.2 Circuit-breaker compartment . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.3 Withdrawable parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3.4 Cable connection compartment . . . . . . . . . . . . . . . . . . . . . . . 16

3.3.5 Control cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.6 Switch-disconnector and cable compartment

in the panel with switch-disconnector . . . . . . . . . . . . . . . . . . 17

3.4 Interlock/protection against erroneous operation . . . . . . . . . . 18

3.4.1 Panel internal interlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.2 Door interlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.3 Interlocks between panels . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.4 Locking devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4.5 Internal interlocking of panel with

switch-disconnector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5 Circuit breaker and contactor plug connector

coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6 Fast recovery device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.7 Ith Limiters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Dispatch and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Condition on delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.4 Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.5 Intermediate storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6 Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6.1 Switchgear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.6.2 Apparatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5. Assembly of the switchgear on site . . . . . . . . . . . . . . . . . 31

5.1 General site requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Foundations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.1 Method of installation A – Installation of the base irons . . . . . 32

5.2.2 Method of installation B – Fixing with anchoring bolts to

concrete floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.3 Method of installation C – Fixing to a raised false . . . . . . . . . 32

5.3 Assembly of the switchgear panels . . . . . . . . . . . . . . . . . . . . 40

5.4 Installation of the bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.1 Bushing of 12/17,5 kV panels . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.2 Bushing of 24 kV panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.5 Fixing of the panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.6 Installation of the busbars . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.6.1 Preparation of the material . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page

5.6.2 Busbar compartment access . . . . . . . . . . . . . . . . . . . . . . . . 48

5.6.3 Busbar installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.7 Installation of the top-mounted boxes . . . . . . . . . . . . . . . . . . 53

5.7.1 Voltage transformers for busbar metering . . . . . . . . . . . . . . . 53

5.7.2 Earthing switch for busbar earthing . . . . . . . . . . . . . . . . . . . 57

5.8 Pressure relief ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.8.1 Standard gas duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.8.2 Compact gas duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.8.3 Compact gas duct with top chimneys . . . . . . . . . . . . . . . . . . 63

5.9 Cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.9.1 Power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.9.2 Control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.10 Earthing the switchgear . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.11 Laying the ring circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.12 Final erection work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6. Operation of the switchgear . . . . . . . . . . . . . . . . . . . . . . . 71

6.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.1.1 Preparatory work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.1.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2 Switching operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2.1 Withdrawable apparatus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.2.2 Circuit-breaker – type VD4 and Vmax . . . . . . . . . . . . . . . . . . 75

6.2.3 Circuit-breaker – type VM1 . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.2.4 Circuit-breaker – type HD4 . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.2.5 Vacuum contactor – type V-contact . . . . . . . . . . . . . . . . . . . 79

6.2.6 Withdrawable metering parts . . . . . . . . . . . . . . . . . . . . . . . . 80

6.2.7 Earthing switch – type EK6 and ST-VG-01 . . . . . . . . . . . . . . 80

6.2.8 Busbar earthing switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6.2.9 Earthing and short-circuiting with earthing module . . . . . . . . 81

6.2.10 NALF type switch-disconnector . . . . . . . . . . . . . . . . . . . . . . 82

6.3 Test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6.3.1 Testing the off-circuit condition . . . . . . . . . . . . . . . . . . . . . . . 84

6.3.2 Current and voltage tests . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.4 Service trucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.4.1 Earthing truck without making capacity . . . . . . . . . . . . . . . . 85

6.4.2 Earthing truck with making capacity . . . . . . . . . . . . . . . . . . . 85

6.4.3 Power cable test truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.4.4 Isolation truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

7.1.1 Intervals for inspection, servicing and repairs . . . . . . . . . . . . 87

7.2 Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.3 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

7.3.1 Maintenance in busbar compartment . . . . . . . . . . . . . . . . . . 89

7.3.2 Maintenance in cable compartment . . . . . . . . . . . . . . . . . . . 90

7.3.3 Maintenance in circuit breaker compartment . . . . . . . . . . . . 94

7.3.4 Maintenance in the low voltage compartment . . . . . . . . . . . . 95

7.4 Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.4.1 Switchgear in general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.4.2 Replacement of complex functional groups . . . . . . . . . . . . . 98

7.5 Testing withdrawable parts . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.5.1 Motor-driven withdrawable parts . . . . . . . . . . . . . . . . . . . . . . 99

7.5.2 Checking correctness of dimensional settings . . . . . . . . . . . 99

7.5.3 Checking auxiliary switch setting on withdrawable parts . . 100

7.5.4 Checking the direction of rotation of the travel motors

on motor-driven withdrawable parts . . . . . . . . . . . . . . . . . . 100

7.5.5 Testing interlock condition . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.6 Tests on the panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.6.1 Auxiliary switch settings on the earthing switch . . . . . . . . . 102

7.7 Spare parts, auxiliary materials and lubricants . . . . . . . . . . 102

7.7.1 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.7.2 Auxiliary materials, lubrificants . . . . . . . . . . . . . . . . . . . . . . 102

7.8 Operating accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8. Product quality and environmental protection . . . . . . . . 104