Remote Racking Operator for AKR BREAKERS

4

Section 3. Description

3-1 Description of Small Frame Remote

Racking Operator – 800A-2000A AKR

Breakers

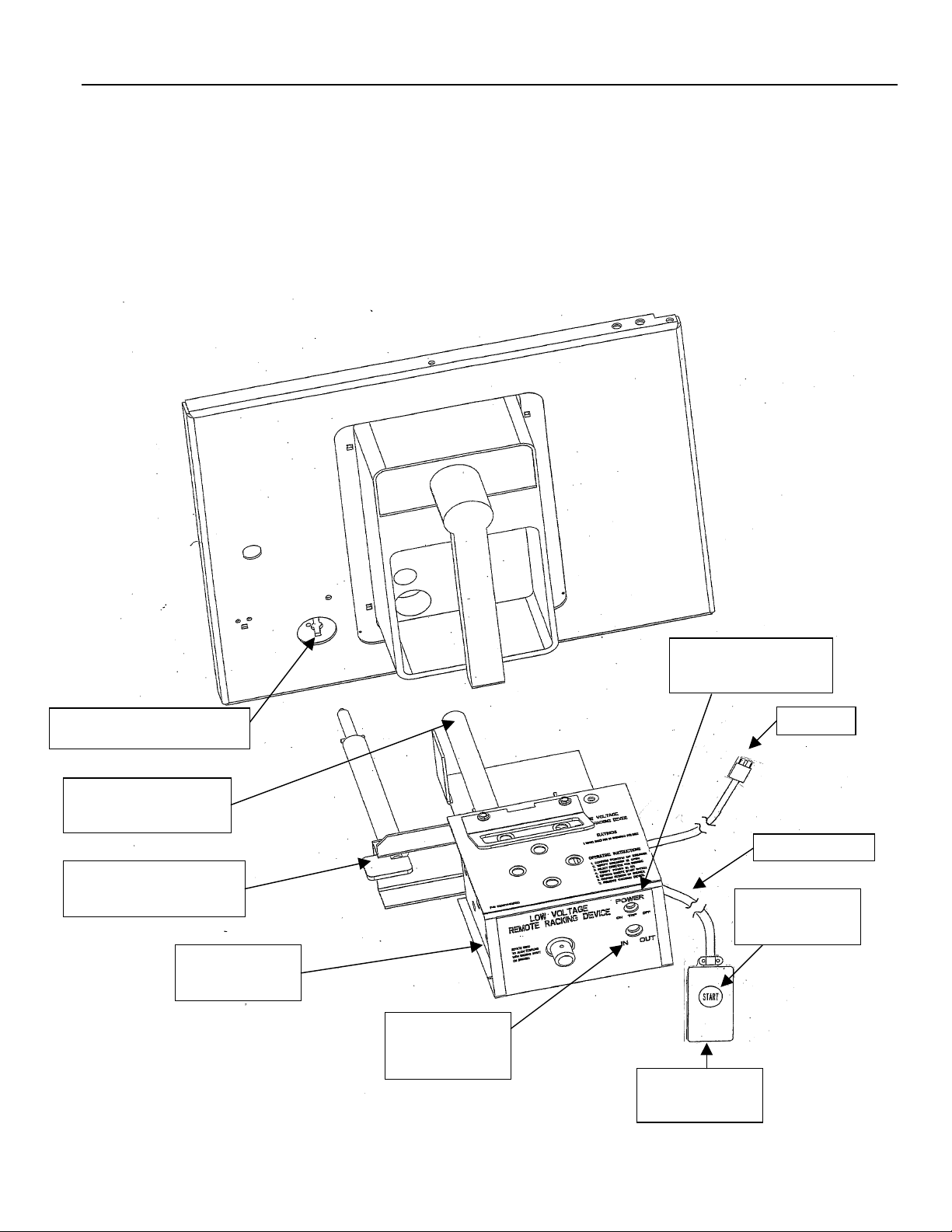

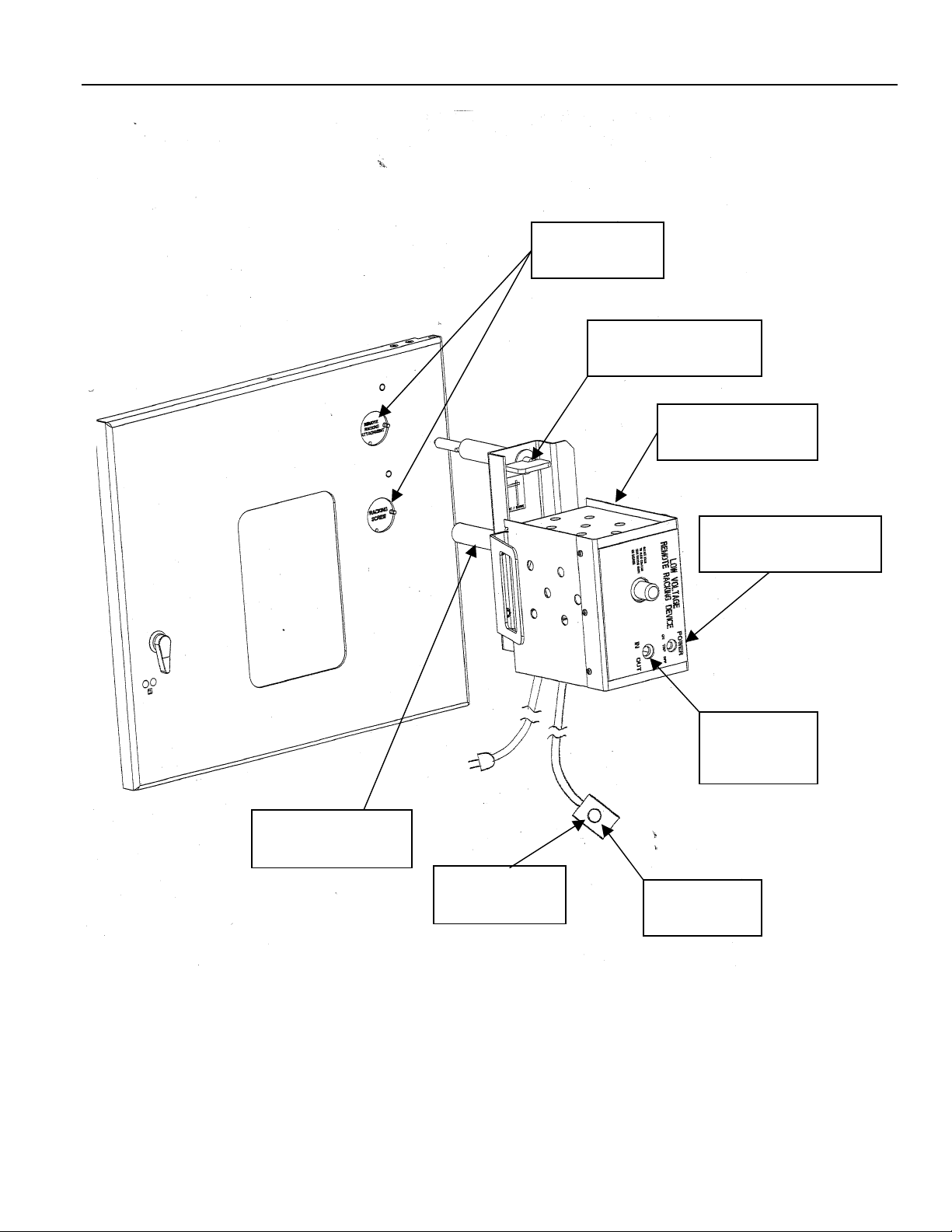

The remote racking operator consists of a drive

train, control switches, and attachment

brackets. The drive train is made of a gear

motor housing (1, Fig. 2), and a square drive

coupler (2, Fig. 2), which couples to the breaker

drawout mechanism.

Two control switches and a circuit breaker are

included with each remote racking operator.

The start switch (3, Fig. 2) housed in the hand-

held box (4, Fig. 2) controls the power to the

motor. Pushing the button closes the switch

and in turn supplies power to the motor. This

control switch is spring loaded; therefore,

continuous pressure on the button is required

to keep the motor running. The motor

directional toggle switch (5, Fig. 2) is mounted

on the motor housing. Two positions are

provided, “IN” and “OUT”. For racking toward

the CONNECT position, the switch should be set

to “IN”. For racking toward the DISCONNECT

position, the switch should be set to “OUT”. The

circuit breaker (6, Fig. 2) senses the motor stall

current when the breaker reaches the end of its

travel, which causes the motor to stall. The

higher motor stall current trips the circuit

breaker to the OFF position and in turn shuts off

the power to the motor. The latch rod (7, Fig. 2)

is designed to provide the means for attaching

the remote racking operator to the front of the

Small Frame Breaker. The latch rod (7, Fig. 2)

hooks into the breaker mounting clip (8, Fig. 2)

for mounting the remote racking operator to

the breaker.

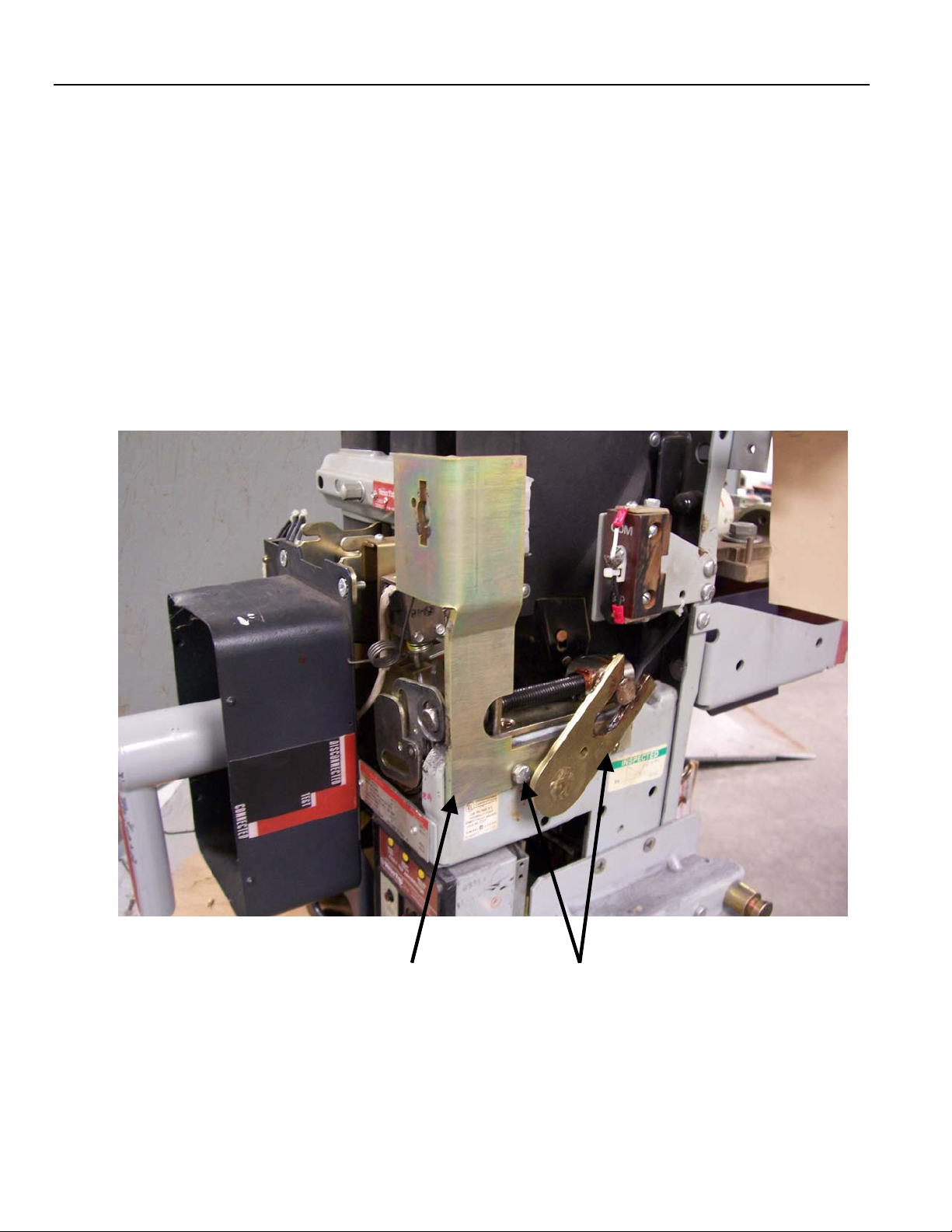

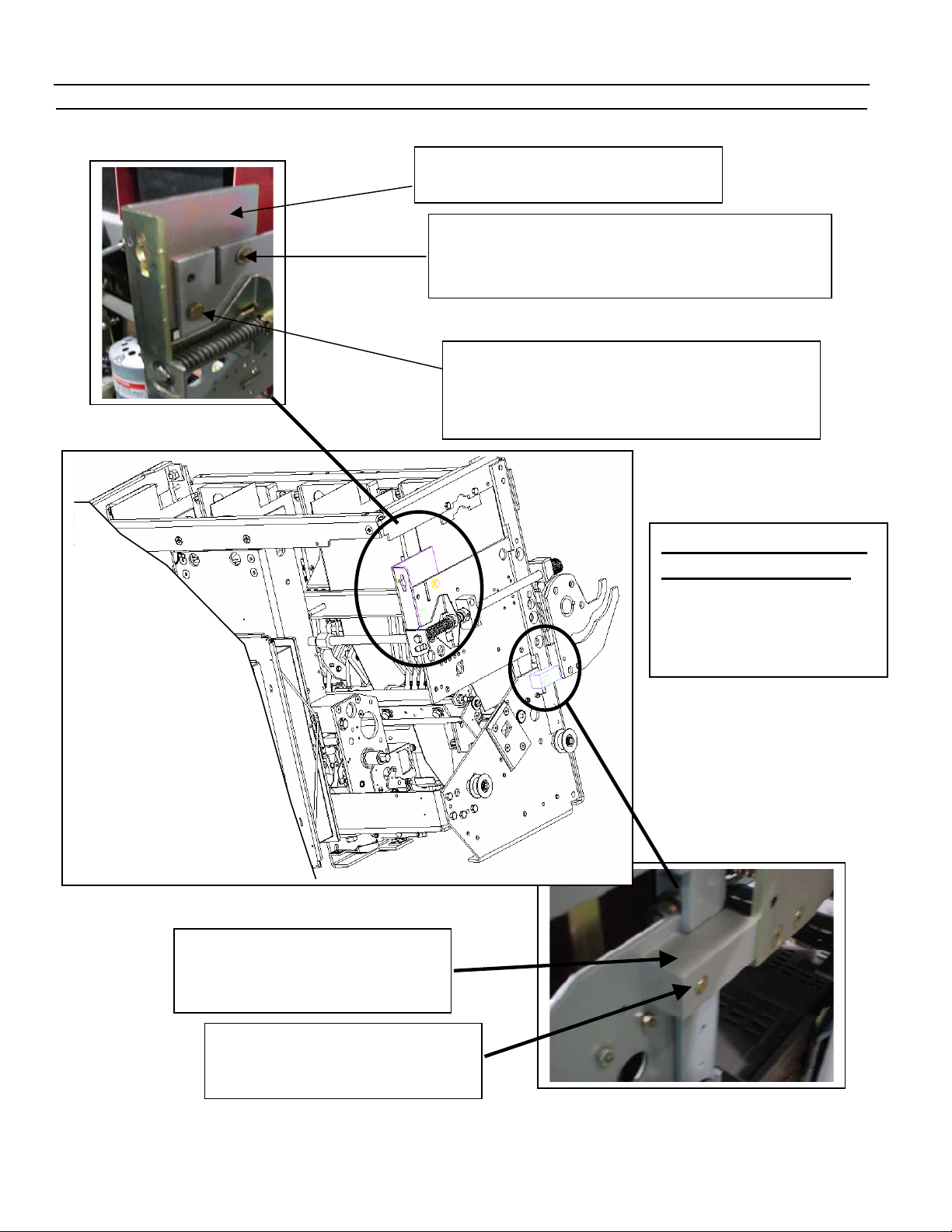

Modification to Existing Small Frame Breakers

Before attaching the remote racking operator

to the existing AKR 30/50 and AKR 30s breakers,

mounting brackets must be added to the

breaker. On the AKR 30S breaker, a mounting

bracket must be mounted on the right side of

the breaker just above the existing racking

screw. Refer to page 6 for the installation

instructions and kit number.

On the AKR 30/50 breaker, a mounting bracket

must be added to the left side of the

escutcheon on the breaker frame. Refer to

page 7 for the installation instructions and kit

number.

Refer to pages 12 and 13 for field modification

to existing breaker doors.

ATTACHING / REMOVING DEVICE

Attaching the Remote Racking Operator to

the Small Frame AKR circuit breaker.

The circuit breaker must be in the OPEN position

before attempting to attach the remote racking

operator to the breaker. On the AKR 30/50

breaker, push the trip button and slide the

racking screw cover in the breaker escutcheon

to the right. Next, slide the remote racking

attachment cover on the cubicle door to the

left. This will expose an opening in the breaker

cubicle door. On the AKR 30S breaker cubicle

door, slide either the upper or lower racking

screw access cover (located on the upper right

corner of the breaker cubicle door) to the left.

This will expose two openings in the cubicle

door. Position the remote racking operator so

that the square drive coupling is aligned with

the square shaft of the drawout (racking)

mechanism and the ¼ -turn latch rod engages

the breaker frame. Push the remote racking

operator toward the breaker to engage the

square drive coupling with the shaft of the

racking mechanism. If the coupling and the

shaft are not in alignment, rotate the motor

shaft extension on the back of the motor

housing in either direction until the square drive

aligns with the square racking shaft. When they

are in alignment, the remote racking operator