Pond-free Features

Pond–free features exchange the open water of the pond for a gravel-topped excavation,

maximizing visual impact while minimizing headaches and maintenance. Typically, a pump

placed in a protective vault inside a lined reservoir continuously recirculates water over a

stream or waterfall. A bed of gravel hides the basin, vault and plumbing from view, leaving

only the stream and waterfall visible.

Table of Contents

Eco-Blox Reservoirs .................................................................................................................................................. 2

Gravel-Filled Reservoirs ...........................................................................................................................................3

Larger Basins ............................................................................................................................................................... 3

Streambed Construction ....................................................................................................................................... 4

Pump Vault

PV1700 Pump Vault Installation .......................................................................................................................... 4

Excavating and setting the PV1700 (Pond-free System) ......................................................................... 5

Plumbing the PV1700 (Pond-free System) ..................................................................................................... 5

Excavating and setting the PV1700 (Eco-Rise System) ............................................................................ 5

Plumbing the PV1700 (Eco-Rise System) ....................................................................................................... 6

PV1800/PV2300 Pump Vault Installation ...................................................................................................... 6

Excavating and setting the PV1800/PV2300 (Pond-free System) ..................................................... 6

For Larger Basin Volumes ...................................................................................................................................... 7

Plumbing the PV1800/PV2300 (Pond-free System) ................................................................................. 7

FastFalls

SP1600/1900/2600/3800 FastFalls Installation ........................................................................................ 7

Setting the FastFalls ................................................................................................................................................ 7

FastFalls Liner and Plumbing Attachment .................................................................................................... 8

Hiding the FastFalls ................................................................................................................................................. 9

Accessories

Triton Check Valve ................................................................................................................................................... 9

Discharge Pipe ‘Perfect Cut’ Reference Chart ............................................................................................ 9

AF1000 Auto Fill ...................................................................................................................................................... 10

Warranty ...................................................................................................................................................................... 11

2

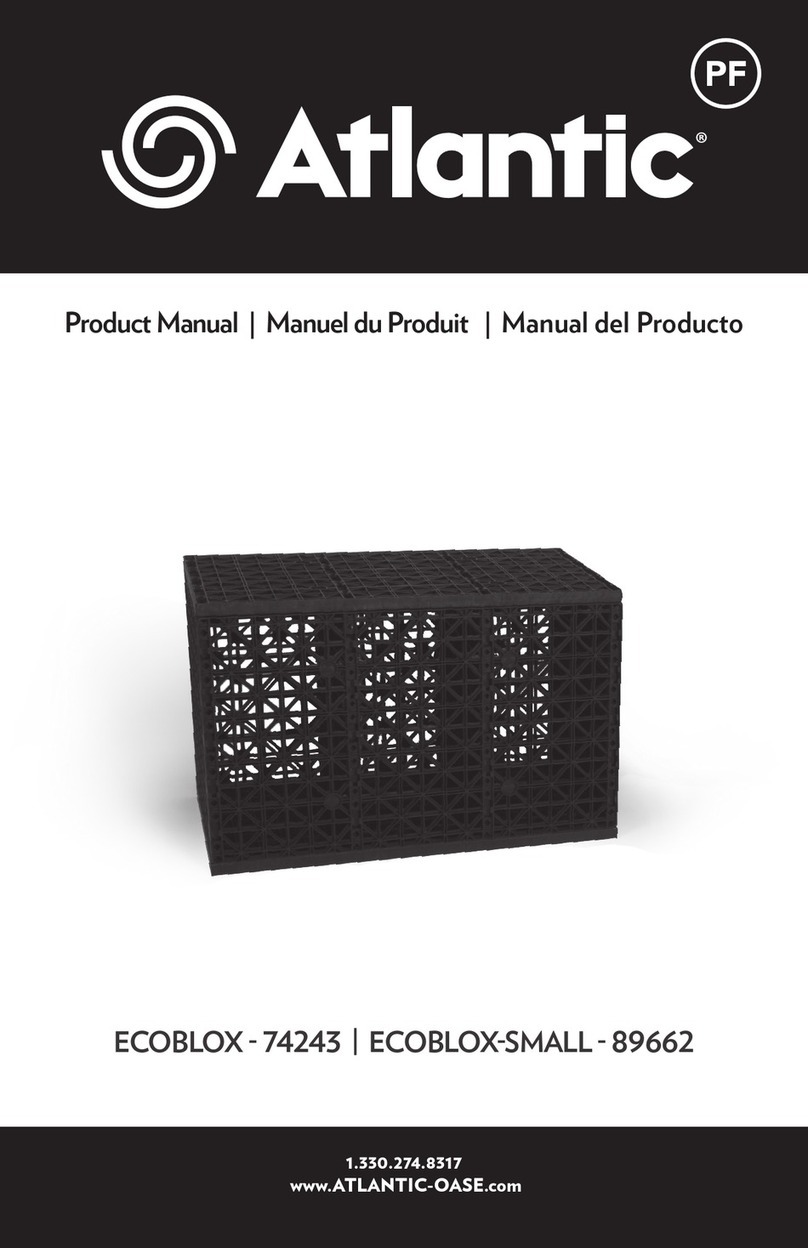

Eco-Blox Reservoirs

Upon start-up, the pump draws water from the reservoir to fill the streambed, from top to

bottom, until the water overflows back into the reservoir to complete the cycle. We call the

amount of water needed to complete this cycle the ‘transitional’ water volume. If the reservoir

is too small, or the streambed built improperly, the water level in the reservoir can drop below

the top of the pump before cycling, leading to pump overheating and damage. We can

calculate the transitional water volume, then design the reservoir to hold at least three times

as much, so the water level in the reservoir never drops by more than one-third when the

pump is turned on, keeping the pump safely submerged at all times. Assuming that it will

take about 3" or 0.25 ft. of water to fill the stream and get the system recirculating, we can

calculate the transitional volume, minimum reservoir volume and Eco-Blox quantity by using

the formulas below:

WATER DEPTH CONVERSIONS

1" deep = 0.08'

2" deep = 0.16'

3" deep = 0.25'

4" deep = 0.33'

5" deep = 0.42'

6" deep = 0.50'

Stream Depth(.25ft) x Avg. Length(ft) x Avg. Width(ft) = Transitional Volume

Transitional Volume x 3 = Minimum Reservoir Volume

Minimum Reservoir Volume ÷ 4.2 = Number of Eco-Blox to fill Reservoir