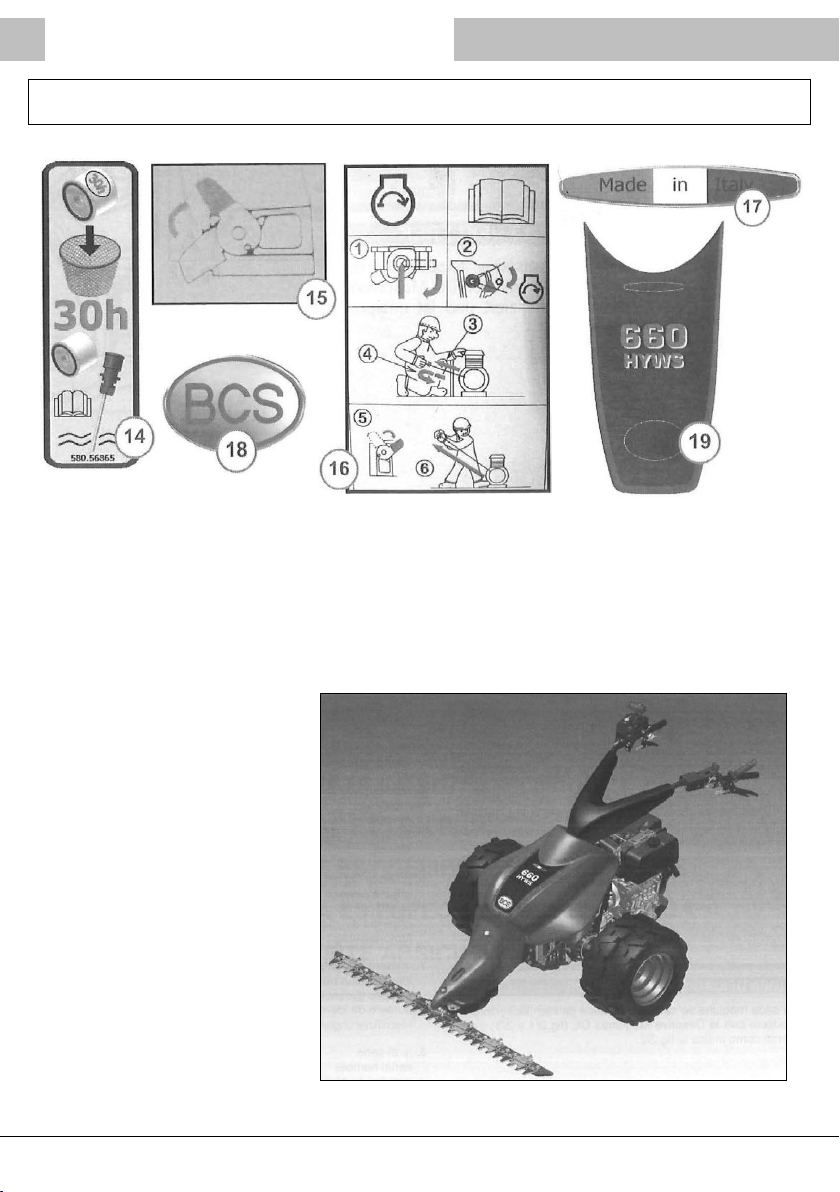

BCS 660HY Hydrostatic Commander

Page 6 BCS660HY/0819

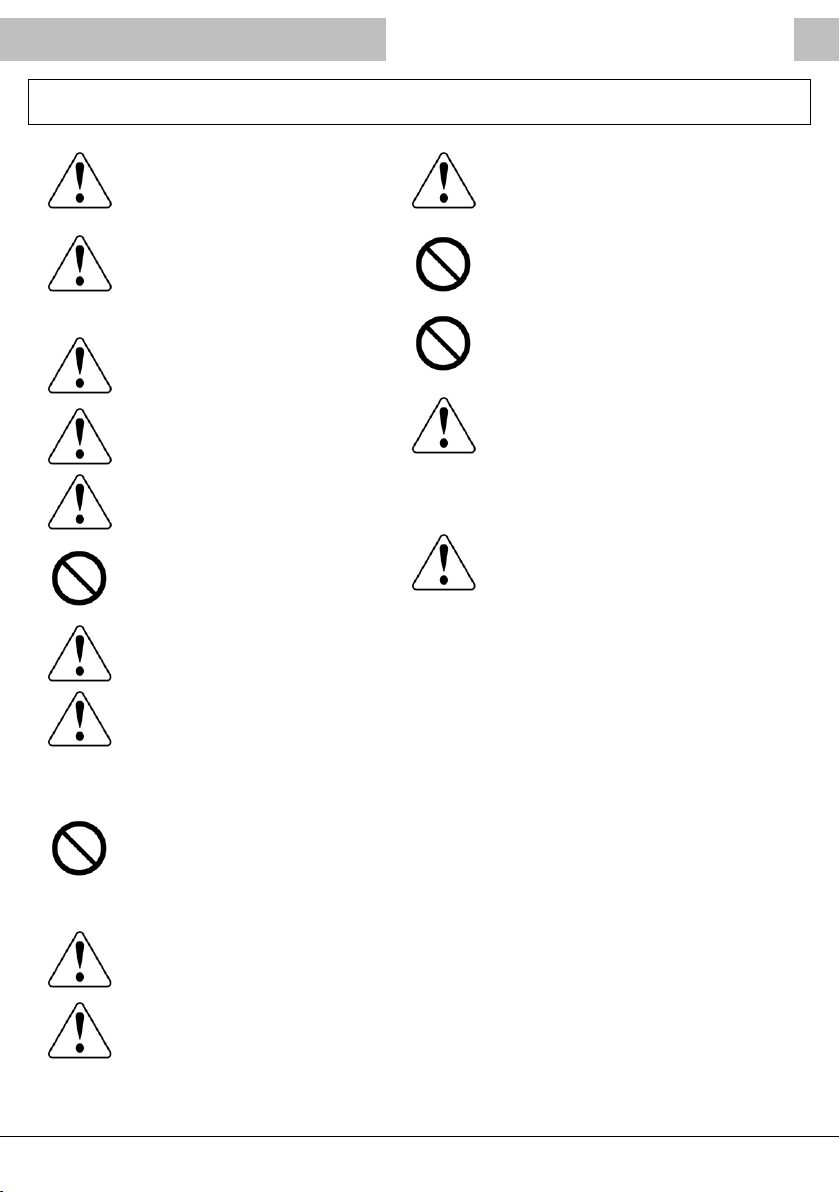

Danger! Do not use the machine

when tired. Do not drink alcohol.

Check the ground before to cut.

Check for stones, sticks or foreign

bodies, which could be catch from

blade or rotating parts and became

very dangerous.

Danger! Do not work on overly

sloping ground where the machine

could slide or tip over.

Before commencing work, wear

appropriate work clothing, gloves,

protective footwear and glasses.

Before getting down from the

machine, turn off the engine,

disable the PTO, remove the

ignition key and lower the

implement to the lowest position.

Travel slowly on bumpy roads.

Slow down on downhill slopes.

Danger! Must not be used by

people under the age of 18 years

and by non-experts.

Danger! Do not reverse with

accelerated engine.

When engine is at full power, it is

dangerous to turn suddenly.

Danger! Do not make sudden

movements with the forwards or

backwards lever.

To avoid the danger of toxic exhausts,

do not use the engine indoors when

turned on.

Fill the fuel tank before starting up the

engine. Only refuel outdoors. Always

turn off the engine. Stay away from

sparks or ames. Do not smoke. Do

not remove the fuel tank cap when the

engine is hot. Safely close the tank cap

and the fuel containers.

Avoid fuel leaks. After having lled

the tank dry all fuel resi-dues on the

machine before starting the engine.

Danger! Do not use the machine

near ditches or piers that may give

way under the weight of the machine,

especially when the surface is friable or

wet.

Always take downhill bends slowly.

Danger! Do not tamper with or disable

the safety devices.

Danger! Do not work with persons near

the machine, foreign objects they may

be launched by the blades or rotating

parts, making it very dangerous.

When the machine is not in use, remove

the keys from the panel and store them

in a place inaccessible to children.

Danger! Do not carry out any type

of adjustments or cleaning when the

engine is in operation.

Danger! Do not have the machine

checked by other people while seated

at the steering wheel with the engine

in operation.

Safety