Any revisions must first be approved by the product designer. Version: 201710 Revision By: TD

12. ADJUSTING

BLOCK

Apply the plastic

grommets into the

holes in the glass

panel HZ-F.

Assemble retainer

plate as shown.

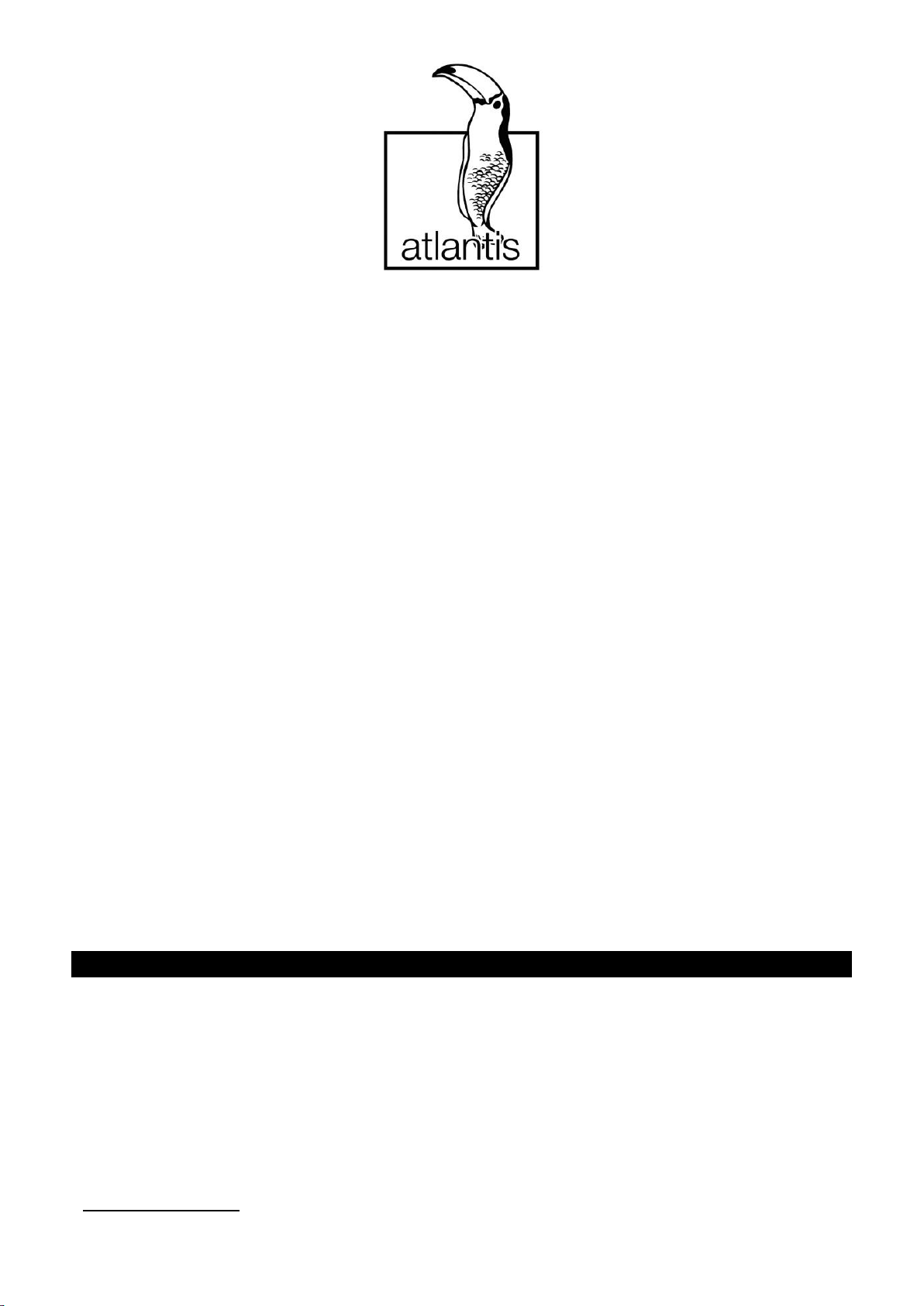

13. ROLLER SET ASSEMBLY TO GLASS DOOR

Ensure the

direction of the

door is correct.

Fit the plastic

grommet

through the

glass first (note

direction of

grommet).

Tighten with

the 4mm hex

key supplied.

14. HANDLE INSTALLATION

Assemble

handles as

shown. Use

3mm Hex

Key

supplied

with handle

set.

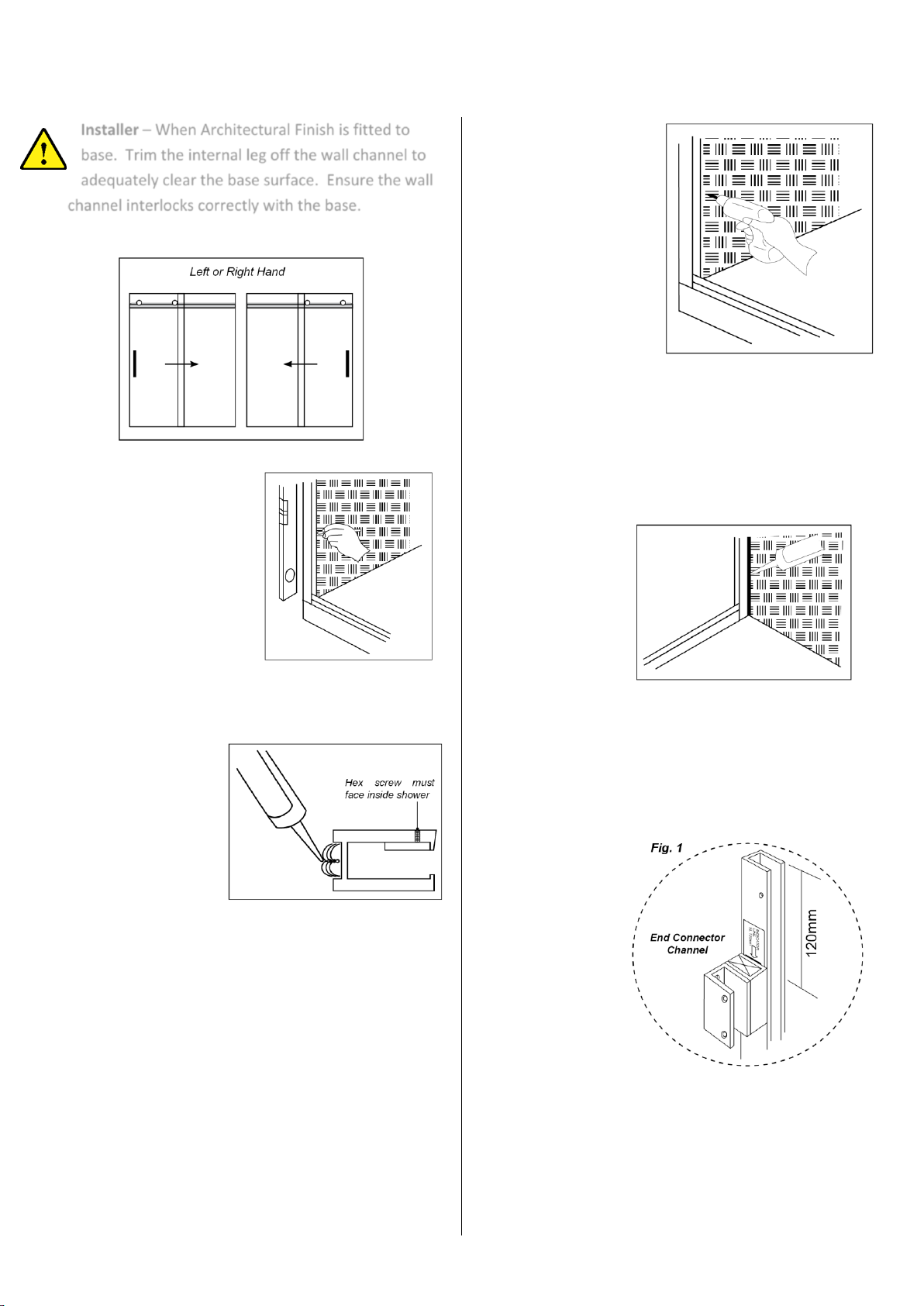

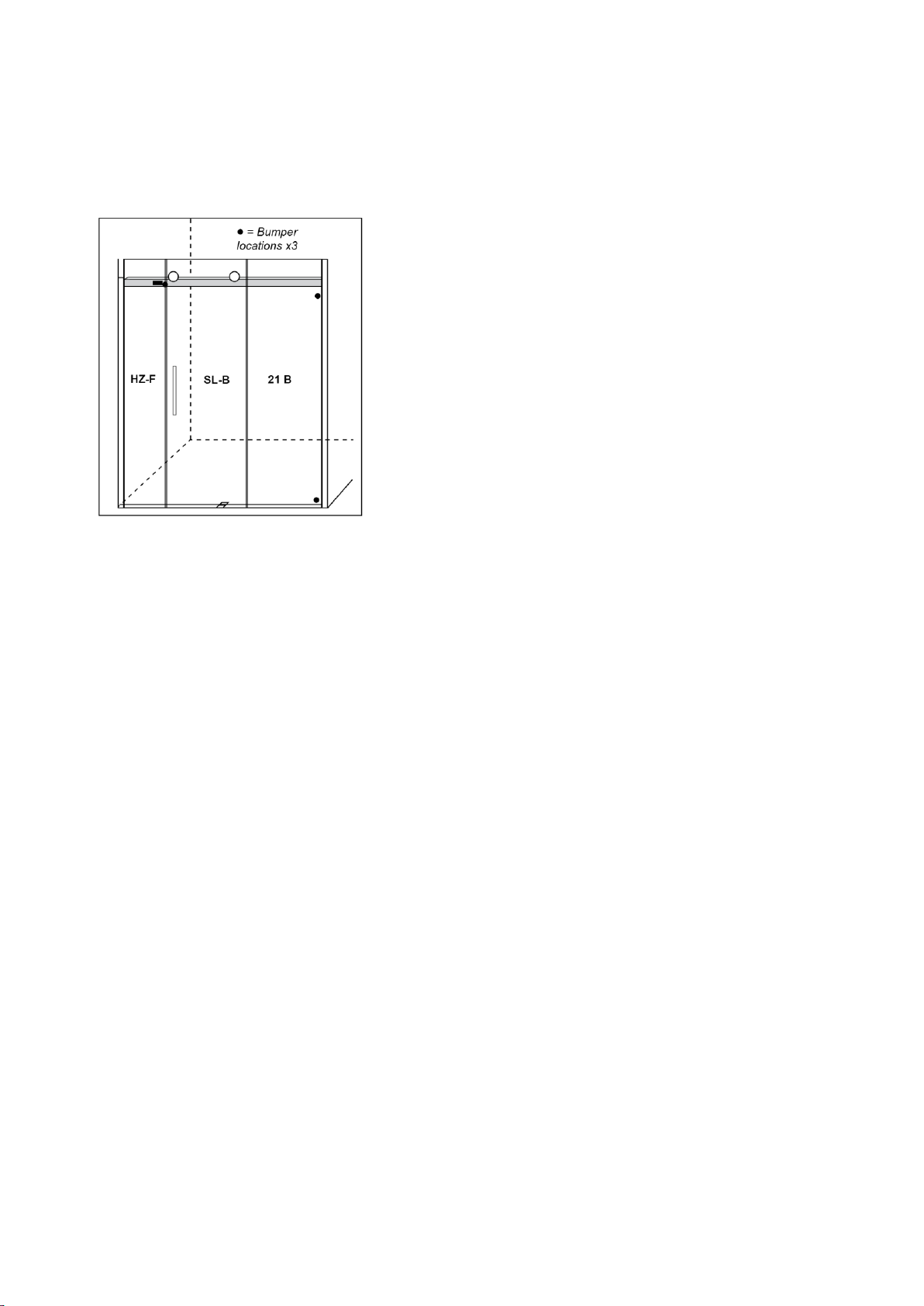

15. DOOR INSTALLATION

Protect the top rail brace outside face with the

blue tape

supplied. Stand

outside the

shower.

Lift the door,

SL-B and place

rollers onto the

top rail brace.

At the same

time locate the

door into the bottom door guide. Adjust the

door height and alignment by loosening the

roller bolt and rotating the outside disc. Ensure

the bottom of the door clears the floor tiles.

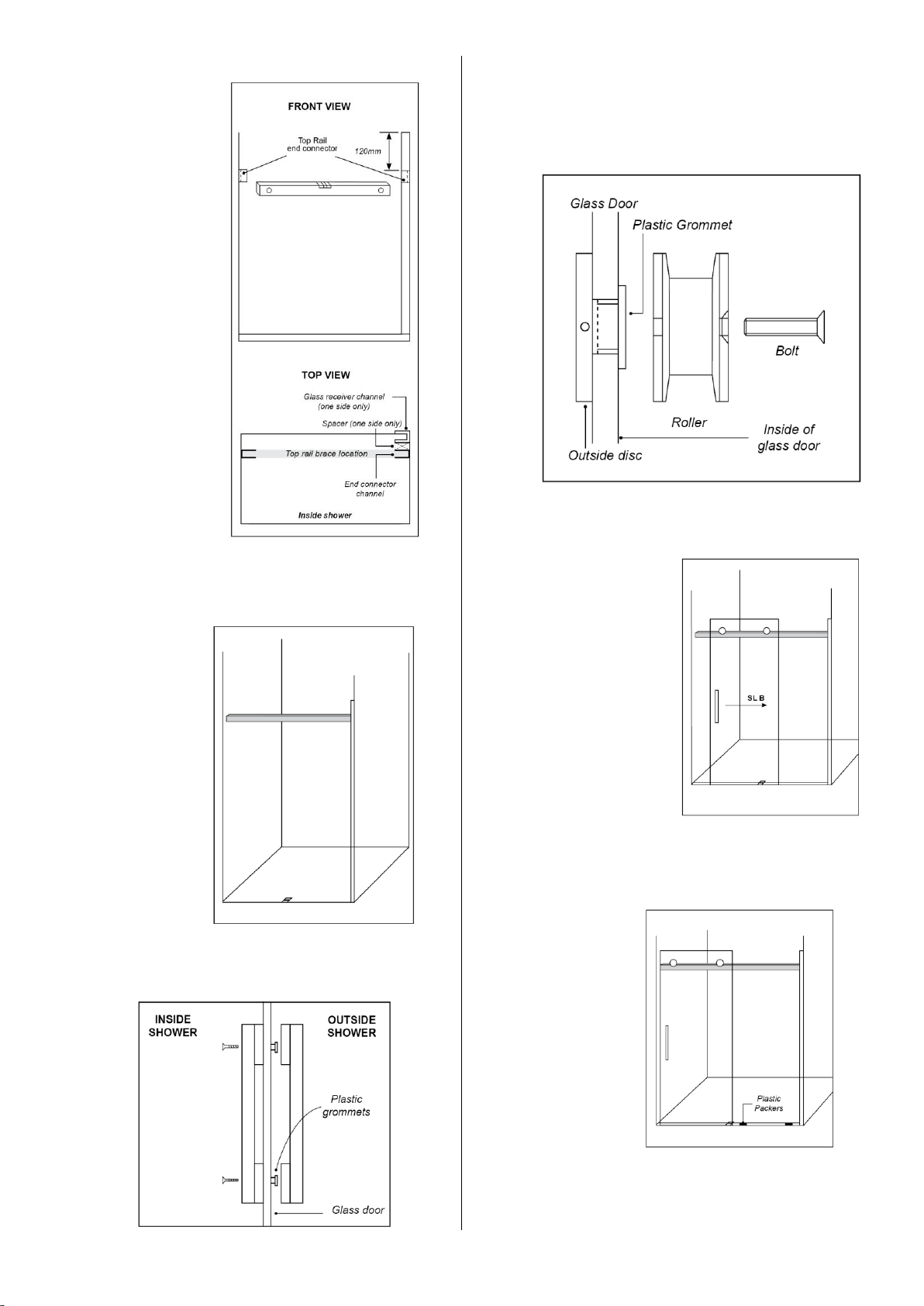

16. INSTALLATION OF FIXED PANEL

Remove dust and dirt first. Seal the connection

between the glass receiver channel and the base

glazing channel with clear silicon, prior to the

installation of panel 21 B.

Locate the glass panel 21 B into the glazing

channel. Add or remove packers in the base

glazing channel as necessary.

17. SILL INFILL

Trim Sill Infill to suit. Apply a continuous dead of

clear silicon to each inside face of the base

channel. Ensure the ends of the Sill Infill are

sealed and place into the base channel in the

location as shown.

18. FASTENING GLASS

Secure the glass panels into the receiver

channels by tightening hex screws firmly with

hex key supplied.

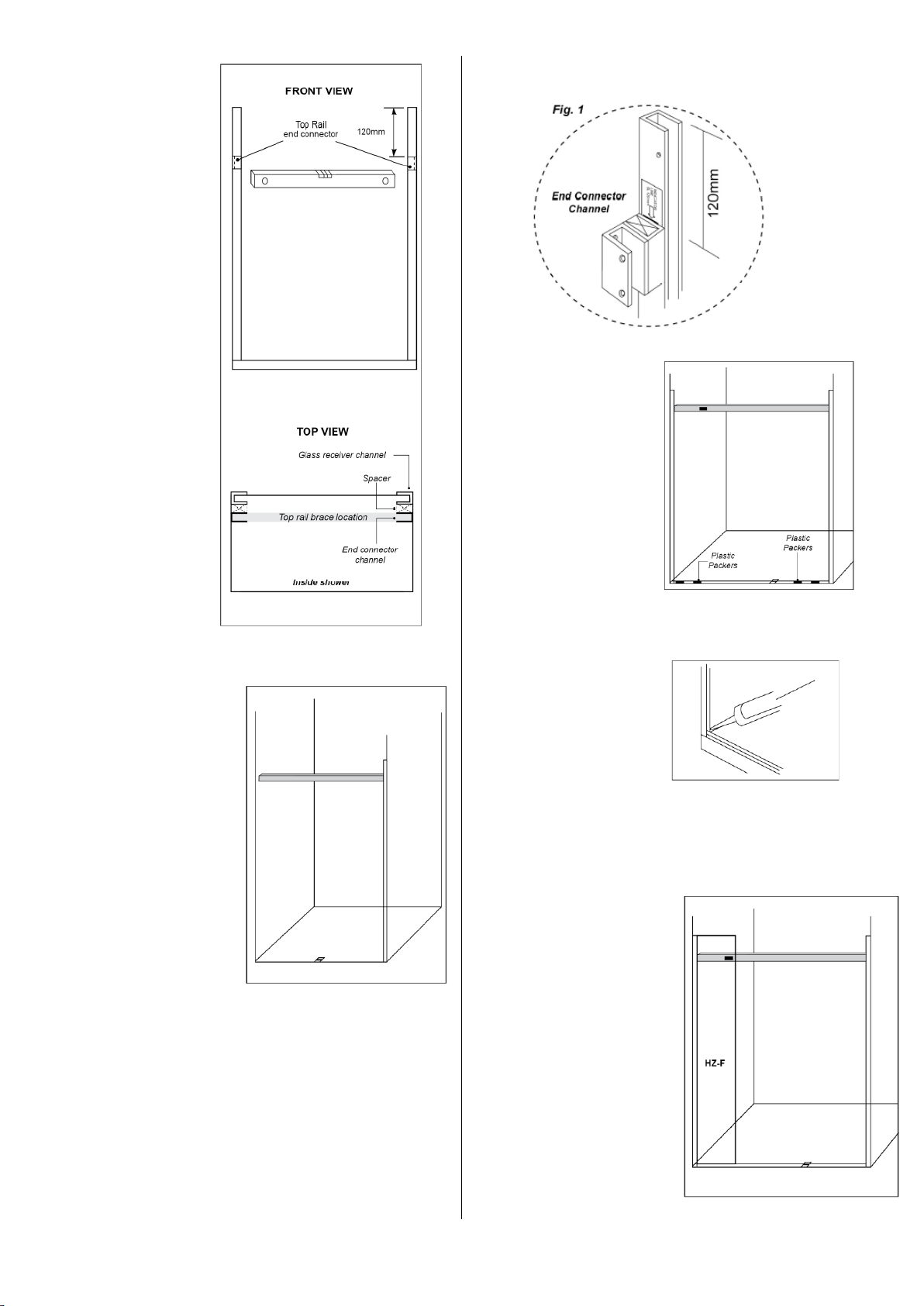

19. ADJUSTING BLOCK COVERS

Add or remove

spacers behind the

adjusting block for

satisfactory door

alignment. Apply

clear silicon to the

heads of the

screws and place

cover plate over end retainer plate. Tape in place

for 24 hours.

20. SILICON APPLICATION

Using the blue tape supplied, mask the glazing

channels and glass at the intersections as

shown. Apply clear silicon to the inside and

outside of the glass panels. Use the spatula

provided to remove the excess silicon. Remove

the masking tape immediately after application.