2920 1390 02

2

Instruction book

T is instruction book describes ow to andle and operate t e subject mac ine(s) to ensure safe operation, optimum working

economy and long service life.

Read this book before putting the machine into operation to ensure correct andling, operation and proper maintenance from

t e beginning. T e maintenance sc edule contains a summary of t e measures for keeping t e dryer in good repair. T e

maintenance procedures are simple but must be carried out regularly.

Keep t e book available for t e operator(s) and make sure t at t e dryer is operated and t at t e maintenance actions are carried

out according to t e instructions. Record all operating data, maintenance work effected, etc. in an operator's logbook available

from Atlas Copco. Follow all applicable safety precautions, amongst ot ers t ose mentioned in t is book.

Repair operations s ould be performed by trained personnel from Atlas Copco w o can also be contacted if any furt er information

is desired.

In all correspondence always mention t e dryer type and t e complete serial number, s own on t e data plate.

For all specific data not mentioned in t e text, consult sections "Maintenance" and "Principal data".

The company reserves the right to make changes ithout prior notice.

Page

3.2 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 During operation . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Problem solving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Principal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.1 Limitations/nominal conditions . . . . . . . . . . . . . . 15

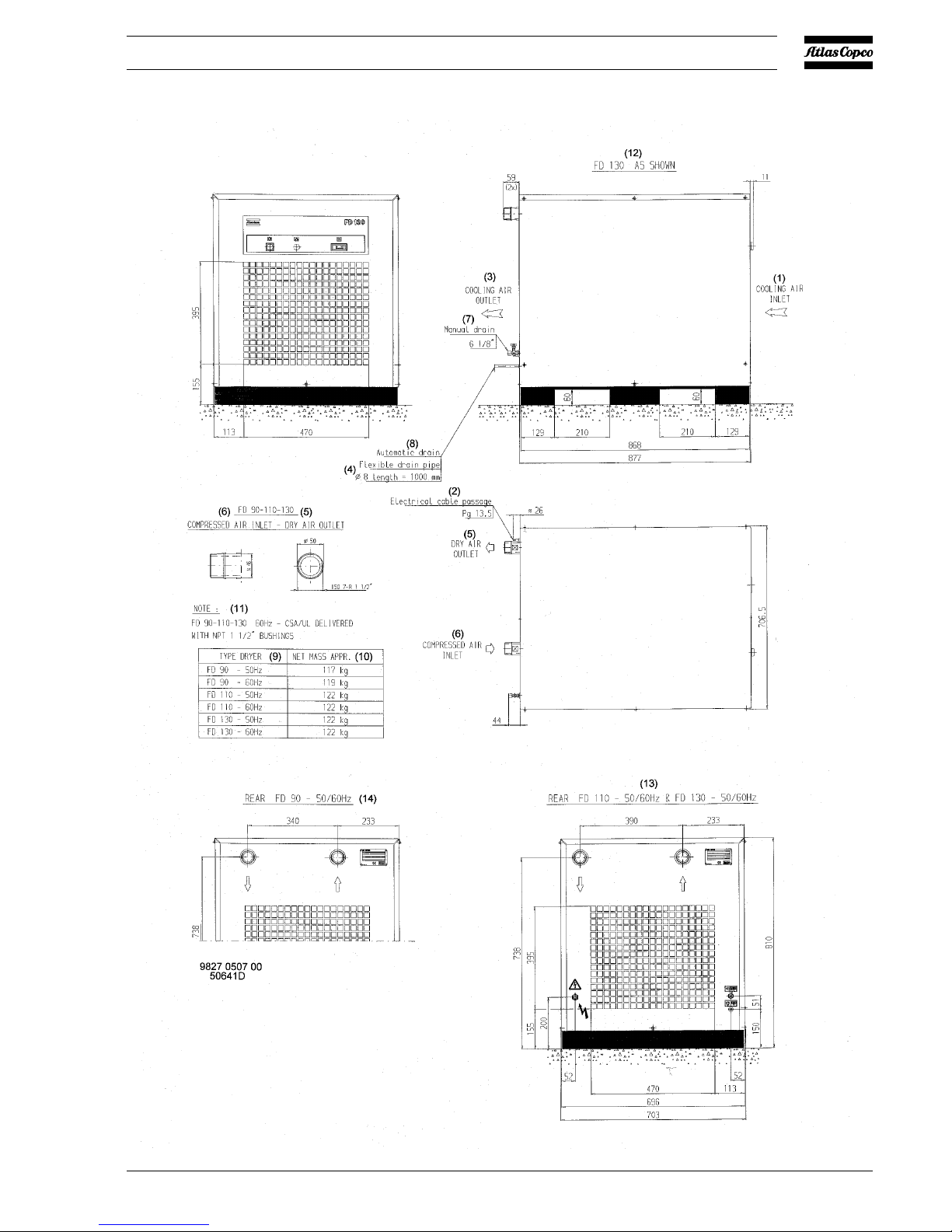

7.2 Specific data of FD90, FD110 and FD130. . . . . . 15

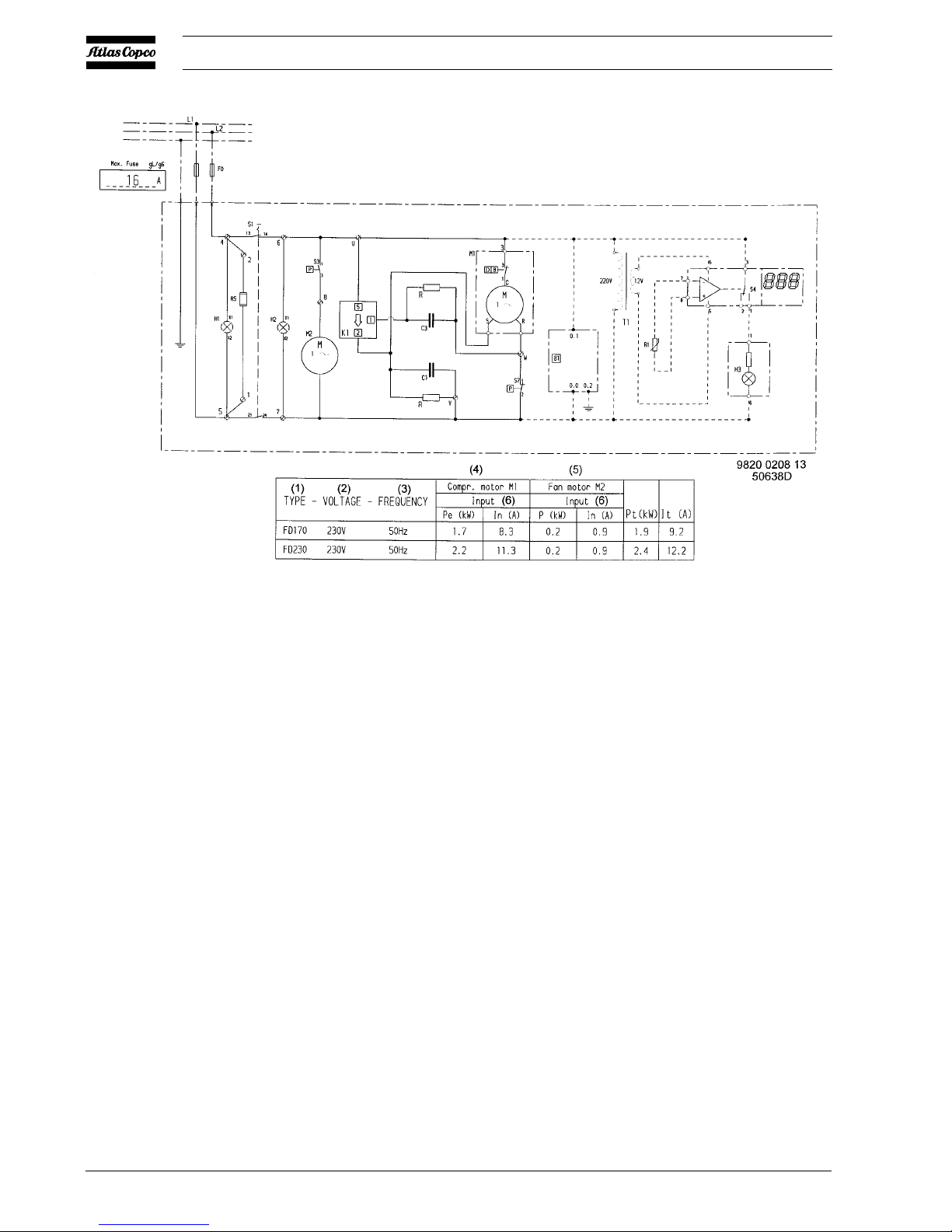

7.3 Specific data of FD170 and FD230 . . . . . . . . . . . 16

8 Conversion list of SI units into British units . . . . . . 16

Contents

Page

1 Leading particulars . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . 3

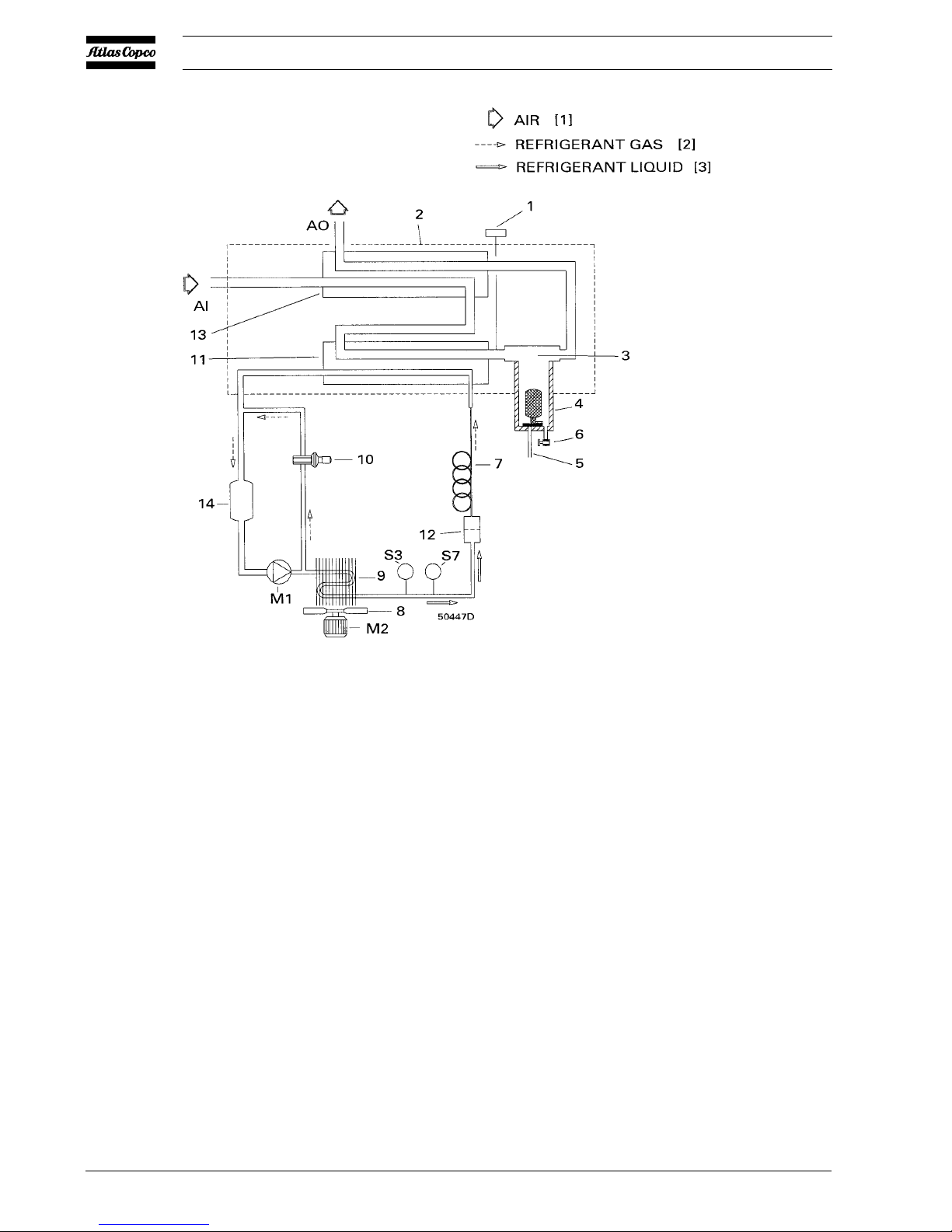

1.2 Air circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Refrigeration circuit . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Automatic regulation system . . . . . . . . . . . . . . . . . 4

1.5 Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Dimension drawings . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Installation proposal . . . . . . . . . . . . . . . . . . . . . . . 11

2.3 Installation instructions . . . . . . . . . . . . . . . . . . . . 12

2.4 Pictograp s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Initial start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13