2© Atlas Copco Industrial Technique AB - 9836 6528 01

Table of Contents

Product Information................................................................................................4

General Information ..........................................................................................4

Safety Signal Words ..............................................................................4

Warranty ................................................................................................4

ServAid ..................................................................................................4

Website..................................................................................................5

Safety Data Sheets MSDS/SDS............................................................5

Country of Origin ...................................................................................5

Dimensional Drawings...........................................................................5

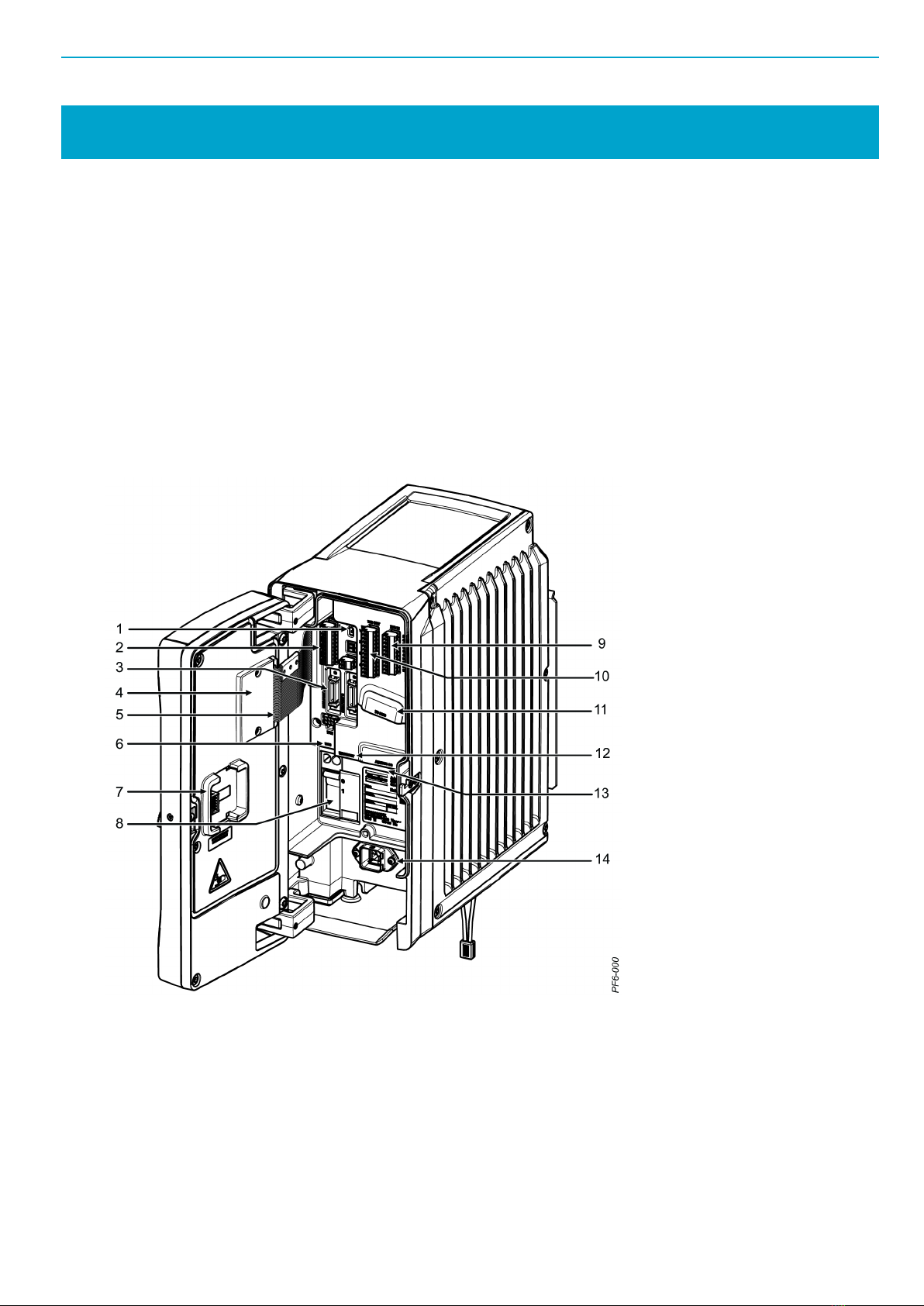

Overview...........................................................................................................5

Normal Environmental Conditions .........................................................5

Technical Product Data .........................................................................5

Line Voltage...........................................................................................5

Mains Fuse ............................................................................................6

Power Consumption ..............................................................................6

Network Connections ............................................................................6

Service Overview..............................................................................................6

Service Recommendations....................................................................6

Installation ...............................................................................................................7

Installation Requirements .................................................................................7

Installation Checklist..............................................................................7

Front Connections .................................................................................7

Installation Instructions .....................................................................................8

Installing the Controller..........................................................................8

Configuring Remote Start for Single or Multiple Controllers..................8

Emergency Stop ....................................................................................8

QST Cable...........................................................................................12

Functional Test of the Residual-Current Circuit Breaker with

Overcurrent Protection (RCBO) Device...............................................13

Operation ...............................................................................................................14

Ergonomic Guidelines.....................................................................................14

Configuration Instructions ...............................................................................14

Programming a Pset............................................................................14

Service ...................................................................................................................15

Preventing ESD Problems ..............................................................................15

Maintenance Instructions................................................................................15

Service Recommendations..................................................................15

Replacing the Backup Battery for the Clock and Calendar Func-

tion.......................................................................................................15

Repair Instructions..........................................................................................15

Wiring ..................................................................................................15

Recycling ...............................................................................................................17

Environmental Regulations.............................................................................17