G2406 Safety Information

© Atlas Copco Industrial Technique AB - 9836 3791 00 7

• Always wear impact-resistant eye and face pro-

tection when involved with or near the opera-

tion, repair or maintenance of the tool or

changing accessories on the tool.

• Be sure all others in the area are wearing im-

pact-resistant eye and face protection.

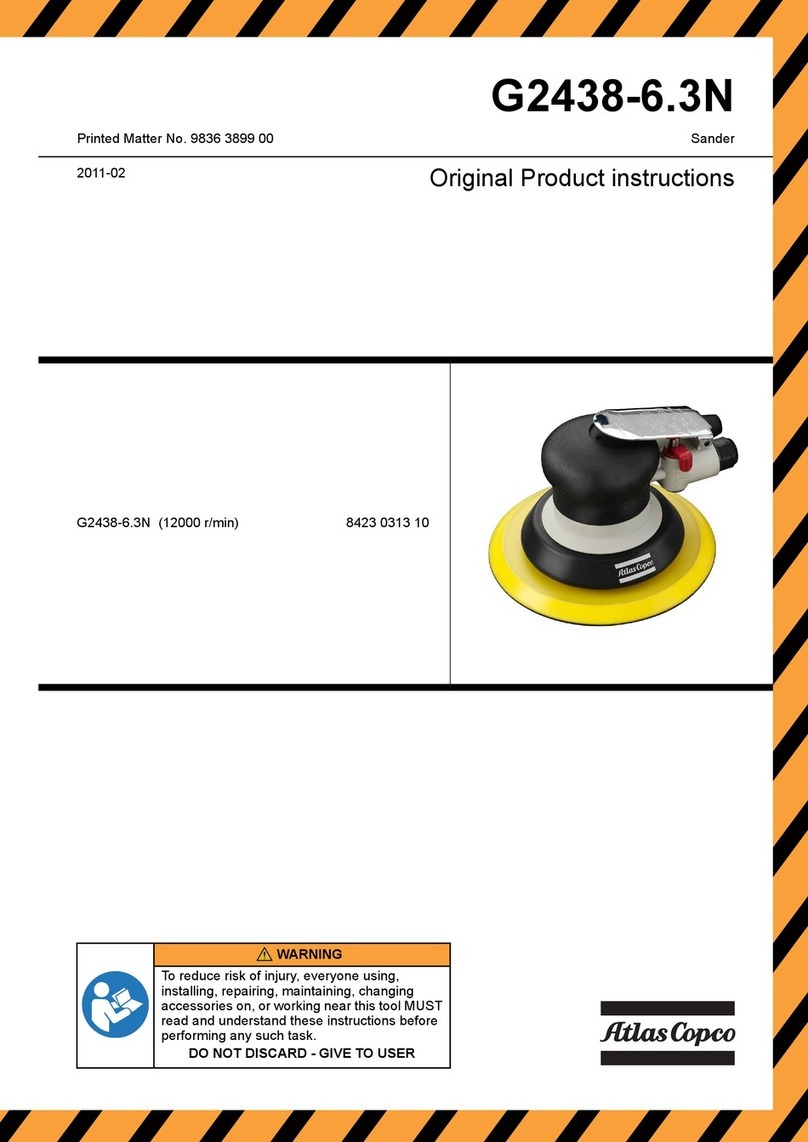

• Daily measure the speed of a rotary sander or

polisher with a tachometer to make sure that it

is not greater than the RPM marked on the

backing pad, drum or abrasive.

• Ensure that the backing pad / abrasive is se-

curely clamped to the sander using the tools

provided.

• Ensure that the workpiece is securely fixed.

Accessory hazards

• Always shut off air supply, relieve hose of air

pressure and disconnect tool from air supply

when changing accessories.

• Use only recommended sizes and types of abra-

sives.

• Never use a backing pad, drum or abrasive with

a permitted speed lower than the air sander

speed.

• Never mount a grinding or cutting-off wheel on

a sander. A grinding wheel that bursts can

cause very serious injury or death when not

properly guarded.

• Use only coated abrasive sanding discs or

sheets properly secured to the backing pad pro-

vided with the air sander. Ensure that self-fix-

ing sanding discs are mounted concentrically.

Operating hazards

• Operators and maintenance personnel must be

physically able to handle the bulk, weight and

power of the tool.

• Hold the tool correctly: be ready to counteract

normal or sudden movements – have both

hands available.

• You can be cut, pinched or burned if you come

into contact with the sanding pad, abrasive or

the work surface. Avoid contact and wear suit-

able gloves to protect hands.

• Inspect backing pad before each use. Do not

use if cracked or broken, or if it has been

dropped.

• Never run the tool unless the abrasive is ap-

plied to the workpiece.

• There is a risk of electrostatic discharge if used

on plastic and other non-conductive materials.

• When using a tool that is designed to have a

guard, the guard should be in place to offer

protection from grinding swarf and other de-

bris.

Repetitive motion hazards

• When using a power tool to perform work-re-

lated activities, the operator might experience

discomfort in the hands, arms, shoulders, neck,

or other parts of the body.

• Adopt a comfortable posture whilst maintain-

ing secure footing and avoiding awkward or

off-balance postures. Changing posture during

extended tasks can help avoid discomfort and

fatigue.

• Do not ignore symptoms such as persistent or

recurring discomfort, pain, throbbing, aching,

tingling, numbness, burning sensation, or stiff-

ness. Stop using the tool, tell your employer

and consult a physician.

Noise and Vibration hazards

• High sound levels can cause permanent hearing

loss and other problems such as tinnitus. Use

hearing protection as recommended by your

employer or occupational health and safety reg-

ulations.

• Exposure to vibration can cause disabling dam-

age to the nerves and blood supply of the hands

and arms. Wear warm clothing and keep your

hands warm and dry. If numbness, tingling,

pain or whitening of the skin occurs, stop using

tool, tell your employer and consult a physi-

cian.

• Hold the tool in a light but safe grip because

the risk from vibration is generally greater

when the grip force is higher. Where possible

support the weight of the tool with a balancer.

• To prevent unnecessary increases in noise and

vibration levels:

• Operate and maintain the tool, and select,

maintain and replace the accessories and

consumables, in accordance with this in-

struction manual;

• Use damping materials to prevent work-

pieces from “ringing.”