Atlas Metal HB Series User manual

HEATED BASE-HB SERIES

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately. See page 2.

HEATED BASE-HB SERIES

ELECTRICALLY HEATED

UNDER-COUNTER

Effective Date: 2019

IMPORTANT INFORMATION

READ BEFORE USE

CONTENTS

RECEIVING AND INSPECTING THE EQUIPMENT

1. VISUALLY INSPECT THE SHIPPING CRATE. DAMAGE SHOULD BE NOTED AND REPORTED TO THE DELIVERING CARRIER.

6. SAVE ALL CRATING MATERIALS UNTIL INSPECTION HAS BEEN MADE OR WAIVED.

5. FREIGHT CARRIERS CAN SUPPLY THE NECESSARY FORMS ON REQUEST.

4. REQUEST AN INSPECTION BY THE SHIPPING COMPANY FOR THE DAMAGED EQUIPMENT WITHIN 10 DAYS FROM RECEIPT OF THE

EQUIPMENT

3. IF CRATE IS NOT DAMAGED AND THERE IS CONCEALED DAMAGE TO THE EQUIPMENT, NOTIFY THE CARRIER. NOTIFICATION MUST BE

MADE VERBALLY AND IN WRITING.

2. IF DAMAGED, OPEN AND INSPECT CONTENTS WITH CARRIER.

SERIAL NUMBER LOCATION

INSTALLATION DATE: _____________________________________________

MODEL #:_______________________________________________________

SERIAL #: _______________________________________________________

THE SERIAL AND MODEL# CAN BE FOUND ON THE OPERATORS CONTROL PANEL. WHEN CALLING ATLAS FOR PARTS AND SERVICE

ALWAYS HAVE THIS INFORMATION AVAILABLE.

RECEIVING & INSPECTING EQUIPMENT....................................................................................................................................................................................1

SERIAL AND MODEL # LOCATION..............................................................................................................................................................................................1

HB - SPECIFICATIONS, FEATURES AND ACCESSORIES.........................................................................................................................................................2

ELECTRICAL CHARACTERISTICS AND CUT-OUT REQUIREMENTS....................................................................................................................................3

OPERATION AND S/S MAINTENANCE........................................................................................................................................................................................4

PARTS LIST...........................................................................................................................................................................................................................................5

TROUBLE SHOOTING GUIDE..........................................................................................................................................................................................................6

ELECTRICAL SCHEMATIC.................................................................................................................................................................................................................7

LIMITED WARRANTY.........................................................................................................................................................................................................................8

WARRANTY INFORMATION............................................................................................................................................................................................................9

Project: ___________

Item No.: ___________

Quantity: ___________

SLIDE-IN SERVING EQUIPMENT

HEATED

BASE

Electrically Heated

Under Counter

HB-3

HB-4

HB-5

BODY: Double wall constructed with 20 gauge, type 304

stainless steel interior liner, with coved corners. Exterior wall

is 22 gauge galvanized steel, with an 18 gauge stainless

steel facia. The body is filled with 1" of high density fiber-

glass insulation on all sides. Interior of the body is provided

with a removable slide assembly to accommodate 12" X 20"

pans.

DOORS: Doors are double wall constructed of 18 gauge,

type 304 stainless steel, fully insulated with high density

fiberglass, and provided with edge mounted, chrome plated

hinges and a slam action latch. Doors are complete with a

moisture-proof gasket.

ELECTRICAL: The unit is provided with an 850 watt ele-

ment, pre-wired to an on/off thermostat switch and pilot light.

The unit is wired for 15 amp., 120 volt, single phase opera-

tion, with a 6’ long, 3-wire cord and plug (NEMA 5-15P).

Specifications subject to change without notice.

SPECIFICATIONS STANDARD FEATURES

gSlides into your counter - puts heated storage where

you need it

gFully insulated for maximum efficiency

gSlide assembly for standard 12” x 20” pans

g Electrically heated - thermostat control

g 1-Year Parts & Labor Warranty

g UL Listed

DI-57

HB-3

Atlas Metal Industries 1135 NW 159th Dr. Miami, FL 33169 (800) 762-7565 Fax: (305) 623-0475 atlasfoodserv.com

DI-58

MODEL “A” STORAGE CAPACITY

12” X 20” PANS

CUT-OUT

REQUIRED

ELECTRICAL

CHARACTERISTICS

SHIP WT.

(LBS.)

HB-3 41-7/8”

(106cm) 815-3/4” X 41-7/8”

(40 X 106cm)

850 W - 7.1 amps.

120V

190

(86.1kg)

HB-4 55-5/8”

(140.9cm) 12 15-3/4” X 55-5/8”

(40 X 140.9cm)

850 W - 7.1 amps.

120V

265

(120.2kg)

HB-5 69-3/8”

(175.8cm) 16 15-3/4” X 69-3/8”

(40 X 175.8cm)

850 W - 7.1 amps.

120V

312

(141.5kg)

“A”

23-5/8”

PLAN VIEW

15-3/4” 14-1/8”

15-1/2” 29-1/8”

FRONT ELEVATION

14-5/8”

END VIEW

2/19-sc

SLIDE- IN HEATED BASE

HB SERIES

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

OPERATION

The unit is ready to operate as soon as it is plugged in and turned on. The thermostat has an off position and

numbers from #1 through #10 (number 10 is the highest setting).

The unit is supplied with a power cord and NEMA plug. Refer to the data plate for the amperage and voltage

information. Use a licensed electrician when installing power source.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------

MAINTENANCE

NEVER CLEAN THE UNIT WITH A CHLORIDE BASED PRODUCT. CHLORIDES OR IMPROPER

CLEANING COULD SCAR, MARK AND/OR CORRODE METAL. DO NOT USE STEEL WOOL OR

ABRASIVE PRODUCTS. TO CLEAN USE SOAPY WARM WATER, RINSE THOROUGHLY TO REMOVE

ALL RESIDUES. FAILURE TO MEET THESE CONDITIONS WILL VOID WARRANTY.

Subsidiary of Mercury Aircraft, Inc.

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail: sales@atlasfoodserv.com

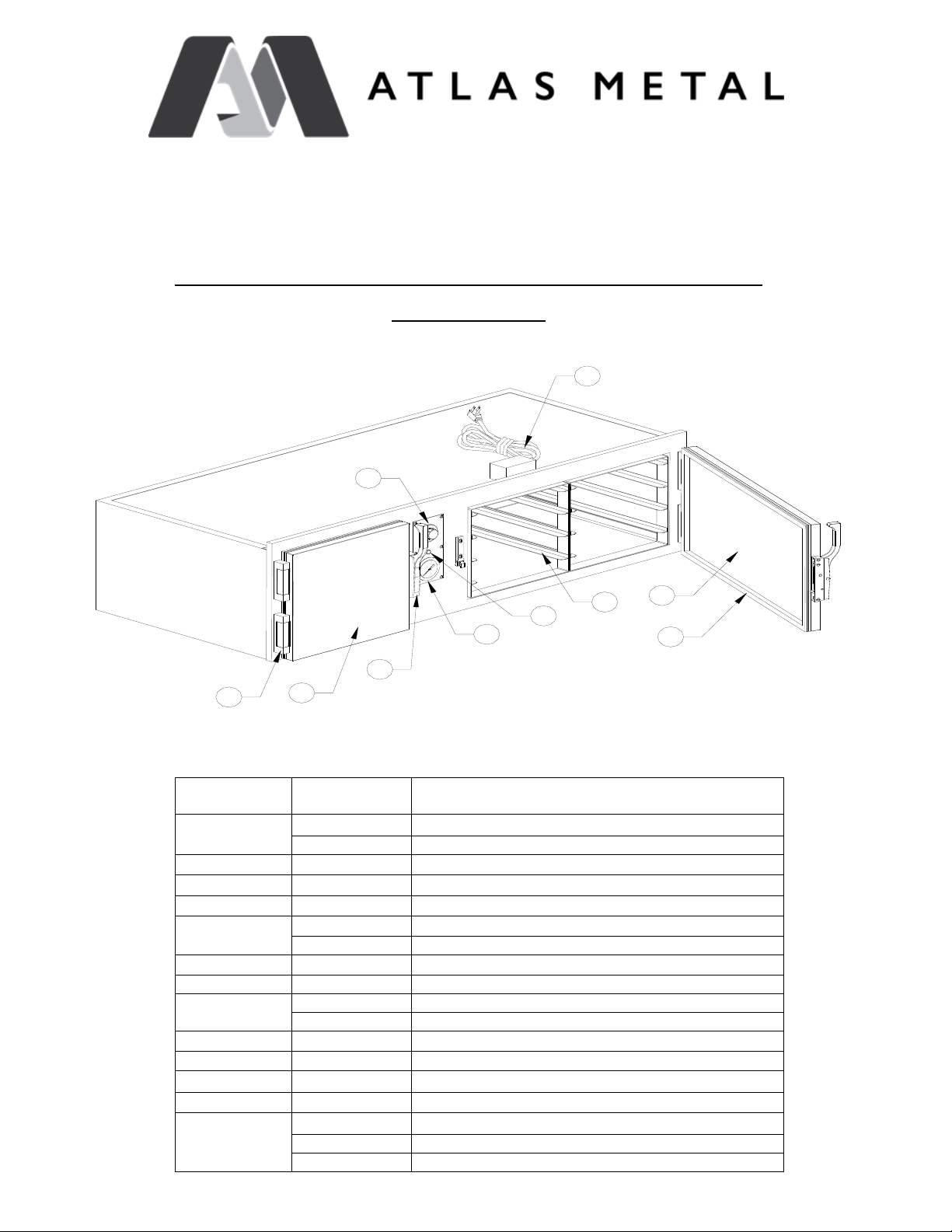

PARTS LIST ELECTRICAL HEATED BASE

HB SERIES

4

2

3

5

1

HB-4 SHOWN

6

7

8

9

10

ITEM

NUMBER

P ART

NUMBER DESCRIPTION

1001-0 Power Cord 14/3-15 Amps 240V

11002-0 Power Cord 14/3-15 Amps 120V

2 22-1407 Thermostat Knob

3 1100-0 Pilot Light

4 1105-0 Thermometer

7010-3 #3 & #4 Door Gasket

57013-3 #4 & #5 Door Gasket

6S83754-4 Door Assembly HB-5

7 S83753-0 Pan Rack

6055-1 Slam Action Latch

86052-1 Slam Action W/ Lock

9 S83754-3 Door Assembly HB-3, HB-4

10 6053-8 Hinge & Cover

11 1087-0 Cord Connector (Not Shown)

12 2500-1 Thermostat (Not Shown)

1053-0 120V / 850W Element (Not Shown)

1054-0 208V / 850W Element (Not Shown)

13

1055-0 240V / 850W Element (Not Shown)

Subsidiary of Mercury Aircraft, Inc.

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail: sales@atlasfoodserv.com

Electric Hot Food Drop-In Trouble Shooting Guide

Symptom Probable Cause

Unit not plugged in.

No power at receptacle.

Thermostat and or switch not in the on position.

Unit will not heat

Call factory for service at 1-800-762-7565

Thermostat’s not turned to the highest setting.

Food products not hot enough when placed in unit.

Food product not being stirred or rotated.

Heat lamp or head strip over the food product is recommended.

Food products not

hot enough.

Call factory for service at 1-800-762-7565.

NOTE:

Before starting any warranty repair work you must first call the factory for authorization.

Failure to do so can make you responsible for repair cost.

LIMITED WARRANTY

Atlas Metal Industries, Inc. warrants to the Purchaser of this product that the

same shall be free from defects in the workmanship and material for a period of

one year from the date of original installation of the equipment, but not to exceed

eighteen (18) months after date of shipment from factory. During this period of

time Atlas Metal Industries, Inc. will replace all defective parts and will pay for

authorized replacement labor. Replacement and installation of such parts and

labor shall be provided only upon prior written authority of Atlas Metal Industries,

Inc.

The Refrigeration warranty is for a twenty (20) month time period and includes

supplying the compressor at a no charge basis provided the damage to the

compressor was not caused by the customer or end user. Authorized

replacement labor will be paid for a period of one year from date of installation.

Freight costs for defective unit to and from Atlas Metal Industries, Inc. are not

included, and all defective parts must be returned to the factory freight prepaid

for evaluation. ALL WARRANTY LABOR MUST BE AUTHORIZED BY ATLAS

METAL INDUSTRIES, INC. PRIOR TO THE ACTUAL WORK BEING DONE.

This warranty does not apply to any equipment or any part thereof, which has

been subjected to shipping damage, improper voltage, alteration, abuse or

misuses, and does not cover loss of food, other products, or damage to property

due to mechanical or electrical malfunction.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION OF THE FACE HEREOF. SELLER DISCLAIMS ANY IMPLIED

WARRANTY OF MERCHANTABILITY OF THE GOODS OR THE FITNESS OF

THE GOODS FOR ANY PURPOSE AND BUYER AGREES THAT THE GOODS

ARE SOLD “AS IS.”

WARRANTY INFORMATION

In order to have your invoice approved for

payment by the factory, please note the following:

_______________________________________________

An authorization number must be obtained from

the factory prior to performing any warranty

service.

_______________________________________________

Atlas Metal will not approve excessive labor due to poor

access to the unit being serviced. If design does not

allow reasonable access, contact the factory.

_______________________________________________

All travel time that exceeds 100 miles round trip

must be authorized by the factory.

_____________________________________________________________________________________

Thank You:

Warranty service Dept.

This manual suits for next models

3

Table of contents

Popular Electric Heater manuals by other brands

CONVECTAIR

CONVECTAIR APERO 7359 BB Installation & operating instructions

Rinnai

Rinnai DEPH-10DTW Operation & installation manual

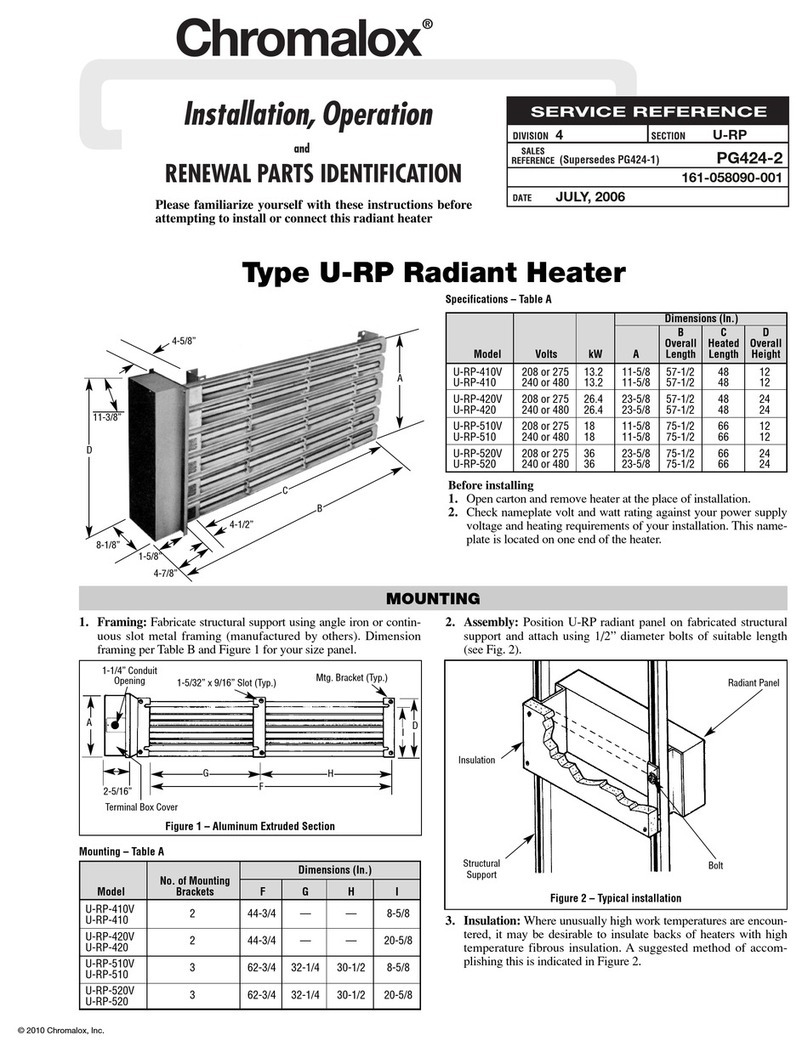

Chromalox

Chromalox PG424-1 Installation, operation and renewal parts identification

EUROM

EUROM 33.297.1 operating instructions

Linea 2000

Linea 2000 Domo DO7340H Instruction booklet

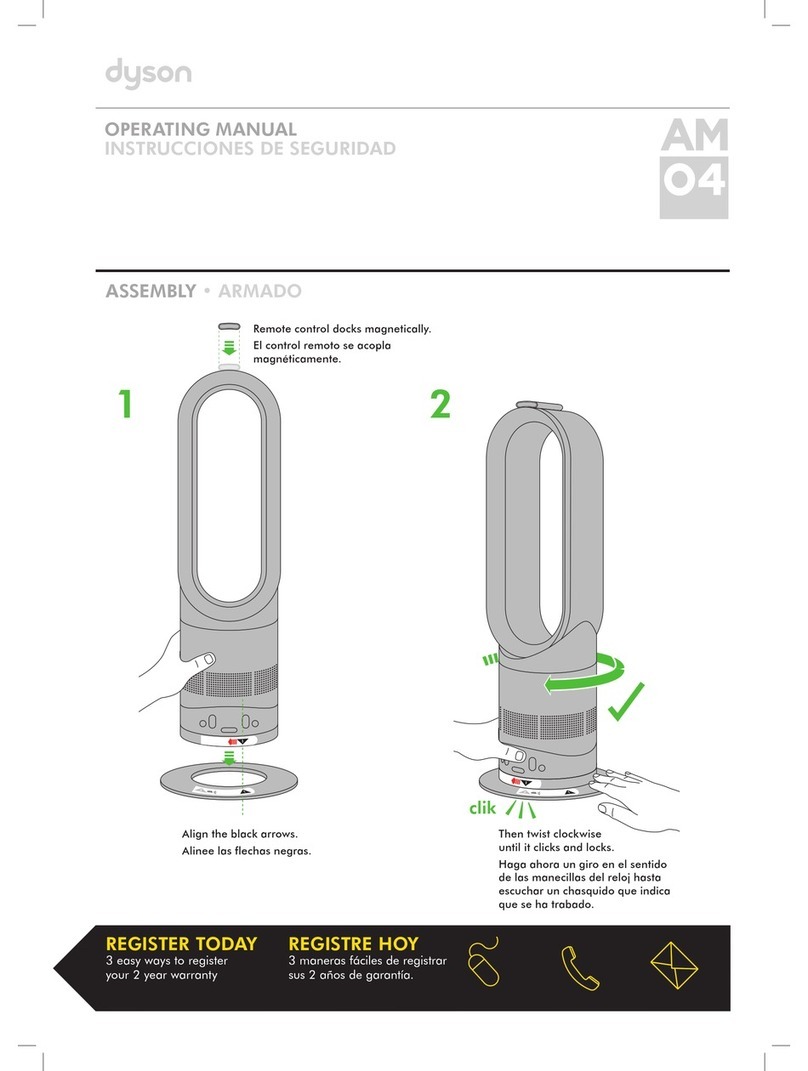

Dyson

Dyson AM04 operating manual