SERVICE MANUALSERVICE MANUAL

MacMachihine: ne: A-EA-Ergorgo

ManManual ual No: No: 000059759755

ATLET SERVICE MANUAL A-ERGOATLET SERVICE MANUAL A-ERGO

Edition 2008BEdition 2008B

1 1 General General information and information and technical datechnical datata

Scope, Scope, service service manual ....................manual ................................................................................................................................................................................ 1.31.3

General General ................................................................................................................................................................................................................................ 1.31.3

Scope Scope of of the the A-Ergo A-Ergo model model .................................................................................................................................................................. 1.31.3

How How to to use use the the manual ...........manual ......................................................................................................................................................................................... 1.41.4

StrucStructure ture ............................................................................................................................................................................................................................ 1.41.4

History History .................................................................................................................................................................................................................................. 1.41.4

Symbol Symbol key key .................................................................................................................................................................................................................... 1.41.4

Safety Safety instructions instructions .................................................................................................................................................................................................................. 1.51.5

General General ................................................................................................................................................................................................................................ 1.51.5

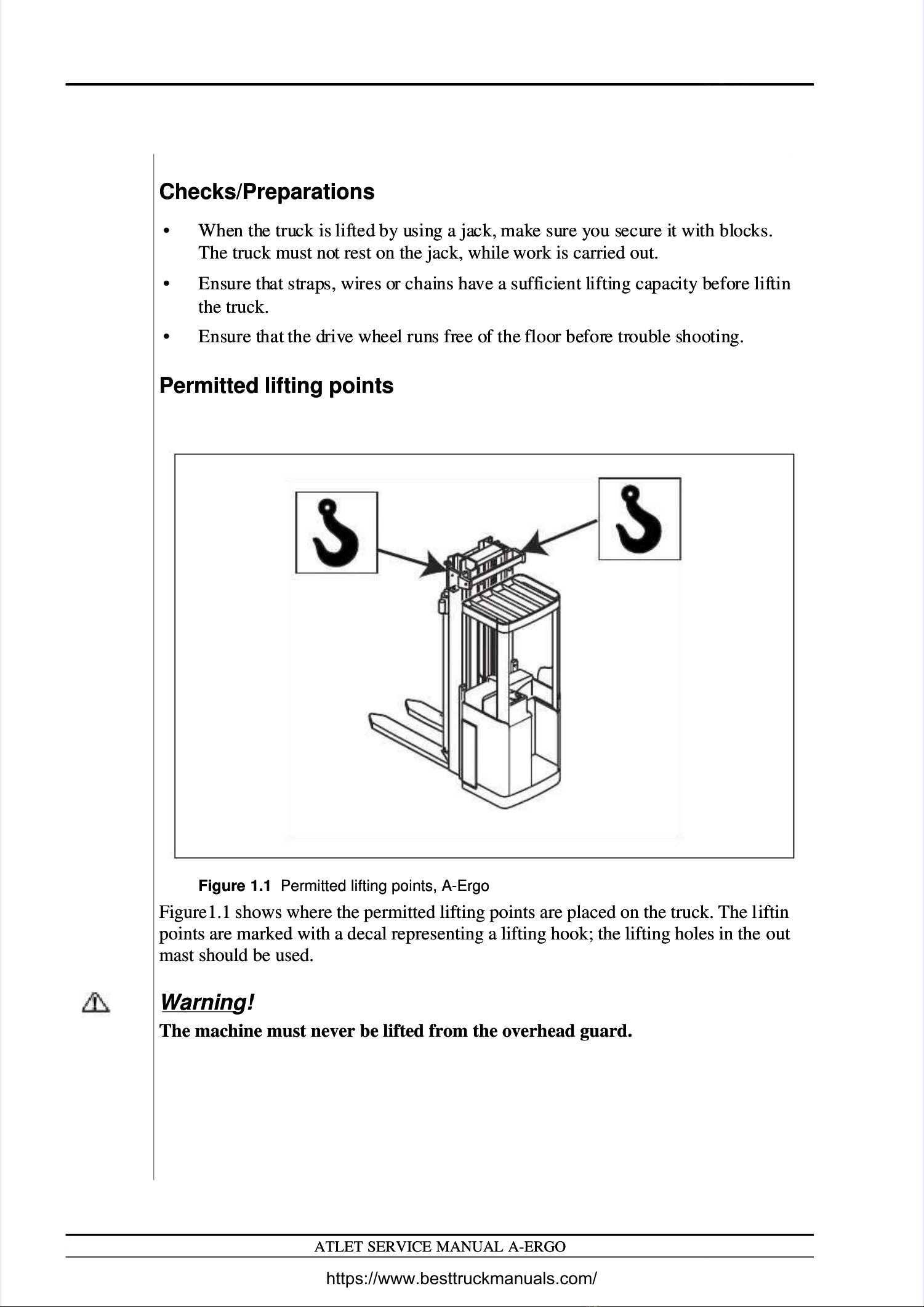

Lifting Lifting the the truck ..................................truck ...................................................................................................................................................................... 1.61.6

Checks/PChecks/Preparations reparations ............................................................................................................................................................................................................ 1.61.6

Permitted Permitted lifting lifting points ............................................................................................points ............................................................................................................ 1.61.6

Welding Welding on on the the truck .................................truck ....................................................................................................................................................... 1.71.7

TTaking aking the the environment environment into into consideration .consideration ................................................................................................................... 1.71.7

Preparations Preparations ...................................................................................................................................................................................................................................... 1.81.8

Service Service .................................................................................................................................................................................................................................. 1.81.8

Trouble Trouble shooting shooting .................................................................................................................................................................................................... 1.81.8

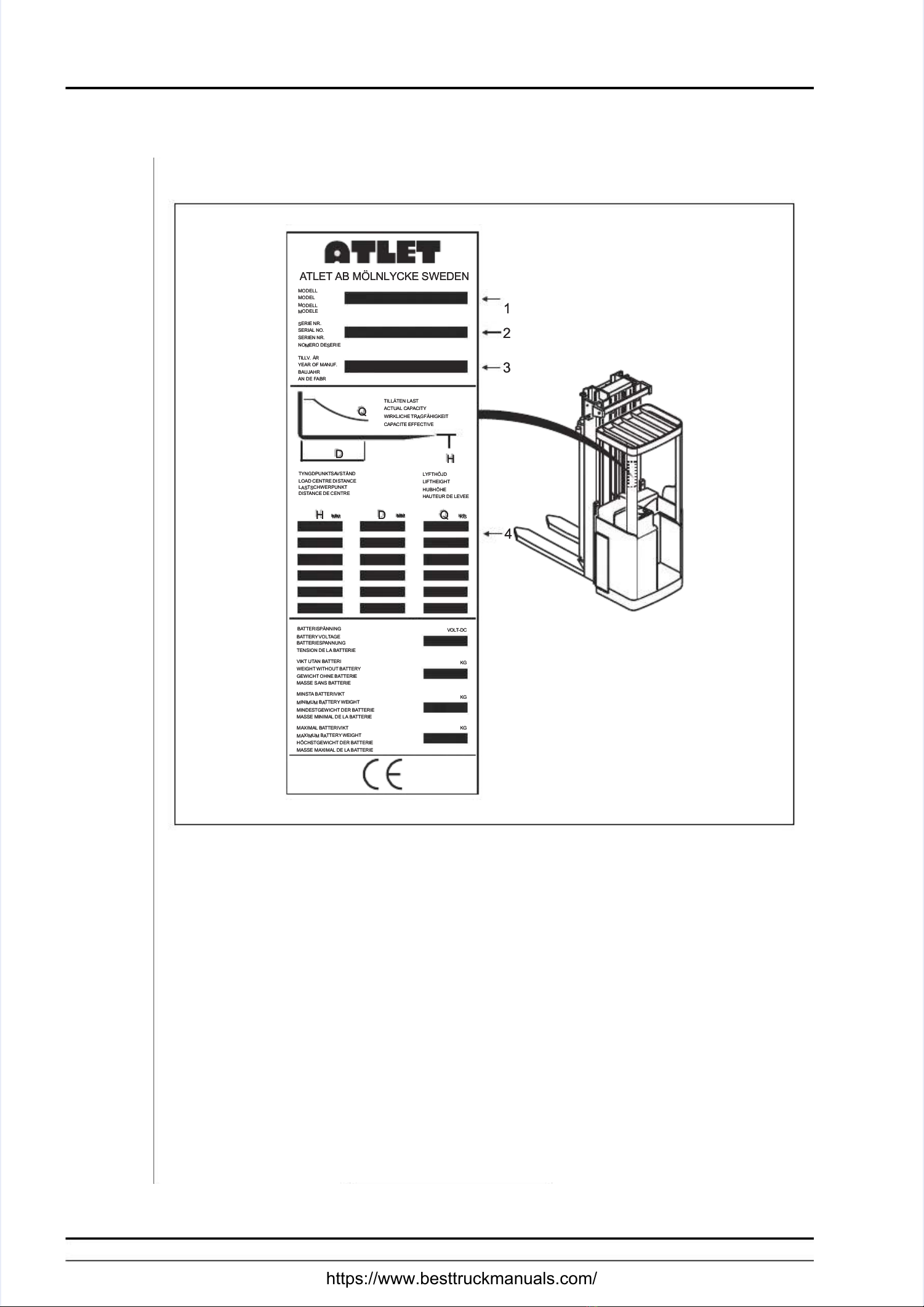

Data Data A-Ergo A-Ergo .......................................................................................................................................................................................................................................... 1.91.9

Designations Designations ................................................................................................................................................................................................................ 1.91.9

Truck Truck designation designation ...................................................................................................................................................................................................................... 1.91.9

Type Type designation designation .................................................................................................................................................................................................................... 1.101.10

Dimensions Dimensions and and weights weights ........................................................................................................................................................................ 1.141.14

Dimensions Dimensions A-Ergo ......................................................................................................A-Ergo ...................................................................................................... 1.141.14

Component Component specification specification ...................................................................................................................................................................... 1.151.15

Recommended Recommended consumable consumable material material .................................................................................................................................................. 1.161.16

Oil Oil and and grease grease ...................................................................................................................................................................................................... 1.161.16

StandaStandards rds and and abbreviations .................................abbreviations ........................................................................................................................................... 1.171.17