Atmos Varioair 3 User manual

Varioair 3

GA1GB.140303.0

2022-10 Index 20

0124

Operating Instructions

English

1.0 Introduction.........................................................3

1.1 Notes on operating instructions ............................3

1.2 Intended use .........................................................4

1.3 Function ................................................................4

1.4 Explanation of symbols.........................................4

2.0 For your safety....................................................5

3.0 Setting up and starting up .................................6

3.1 Scope of supply ....................................................6

3.2 Illustrations............................................................6

3.3 Connections..........................................................8

3.3.1 Electrical connection.............................................8

3.3.2 Connecting a nystagmograph...............................8

3.3.3 Equipotential bonding conductor connection ........8

3.3.4 Connecting the handle..........................................8

3.3.5 Air inlet..................................................................8

3.4 Starting up.............................................................8

4.0 Operation.............................................................9

4.1 Adjusting temperatures.........................................9

4.2 Selecting temperature levels.................................9

4.3 Adjusting stimulation time .....................................9

4.4 Description of operating modes ............................9

4.4.1 Preparation mode .................................................9

4.4.2 Stimulation mode ................................................10

4.4.3 Standby mode.....................................................10

5.0 Cleaning and care.............................................11

5.1 General information on cleaning and disinfection11

5.2 Recommended instrument disinfectants.............11

5.3 Recommended surface disinfectants..................11

6.0 Maintenance and service .................................12

6.1 Sending in the device..........................................12

7.0 Troubleshooting................................................13

8.0 Accessories and spare parts...........................14

8.1 Accessories.........................................................14

8.2 Spare parts .........................................................14

9.0 Technical data ...................................................15

10.0 Disposal.............................................................16

11.0 Notes on EMC....................................................17

2

Table of contents

1.1 Notes on operating instructions

These operating instructions contain important notes on how

to operate the Varioair 3 correctly and eectively. Therefore,

they are intended not only for new operating personnel to be

instructed in its use, but also for use as a reference manu-

al. They help to avoid risks and also to reduce repair costs

and down-times. Furthermore, reliability and service-life of

the equipment will be increased. For these reasons, these

operating instructions must always be kept available

near the device.

Prior to rst use, please peruse the chapter “For your safety”

in order to be prepared for any possible dangerous situa-

tions. To do this during work would be too late.

The basic principles are:

Judicious and careful work provides best protection

against accidents!

Operational safety and readiness for use of the device de-

pend not only on your capabilities, but also on the care and

maintenance given to the Varioair 3. For this reason, regular

cleaning and service work are a must. Major maintenance

and repair work may be carried out only by expert personnel

authorized by ATMOS. In case of repairs, you should insist

that only original spare parts are used. You will then have

the warranty that operational safety, readiness for work, and

the value of your device will be preserved.

• The product Varioair 3 bears CE marking CE 0124 in

accordance with EU Directive 93/42/EEC concerning

medical devices and meets the basic requirements of

Annex I to this directive.

• The product Varioair 3 complies with all applicable

requirements of the Directive 2011/65/EU restricting the

use of certain hazardous substances in electrical and

electronic equipment (“RoHS”).

• The declarations of conformity and our general standard

terms and conditions can be obtained on our website at

www.atmosmed.com.

• The quality management system applied at ATMOS has

been certied according to international standard EN ISO

13485.

• Reprints—also in extracts—only with permission in writ-

ten form by ATMOS.

Abbreviations/symbols contained in these operating

instructions:

• Indicates a list

- Subdivision of a list/activity

The recommended sequence must be followed in each case!

)Indicates particularly important advice!

ªDescribes the eect of an activity

ATMOS

MedizinTechnik GmbH & Co. KG

Ludwig-Kegel-Str. 16

79853 Lenzkirch

Germany

Phone: + 49 7653 689-0

Fax:

+ 49 7653 689-190

+ 49 7653 689-393 (Service Center)

E-mail: [email protected]

Internet: www.atmosmed.com

3

1.0 Introduction

1.2 Intended purpose

Product name: Varioair

Main functions: Stimulation of the vestibular organ

Intended purpose: Stimulation of the vestibular organ

Intended users /

User prole:

Doctors and medical specialists

Intended patient

target group:

Patients of all ages without restric-

tions

Medical conditions

to be diagnosed,

treated or moni-

tored:

Vertigo due to a disorder of the

vestibular organ

Application organ: External auditory canal to eardrum

Application period:

Transient (< 60 min)

Application envi-

ronment:

Outpatient medical facilities, e.g.,

ENT practices, hospital outpatient

departments, medical care centers

Patient selection

criteria:

Patients with intact, physiological

eardrum and external auditory

canal

Indications: Dierential diagnostics for vertigo

Medical contra-

indications:

Pathological eardrum

Other contra-

indications:

Pathological external auditory canal

Warnings: N/A

The product is: active

Sterility/specic

microbial status:

Non-sterile

Single use product

/ reprocessing:

Not a single-use product. Repro-

cessing according to instructions

for use.

1.3 Function

• After activating the main switch, the optical indicators are

tested.

• The device then enters the standby mode in which the

heating and the pump are switched o.

• Possibility to switch to the stimulation mode for stimulat-

ing the vestibular organ. The Varioair 3 is equipped with a

timer for preselecting the stimulation duration.

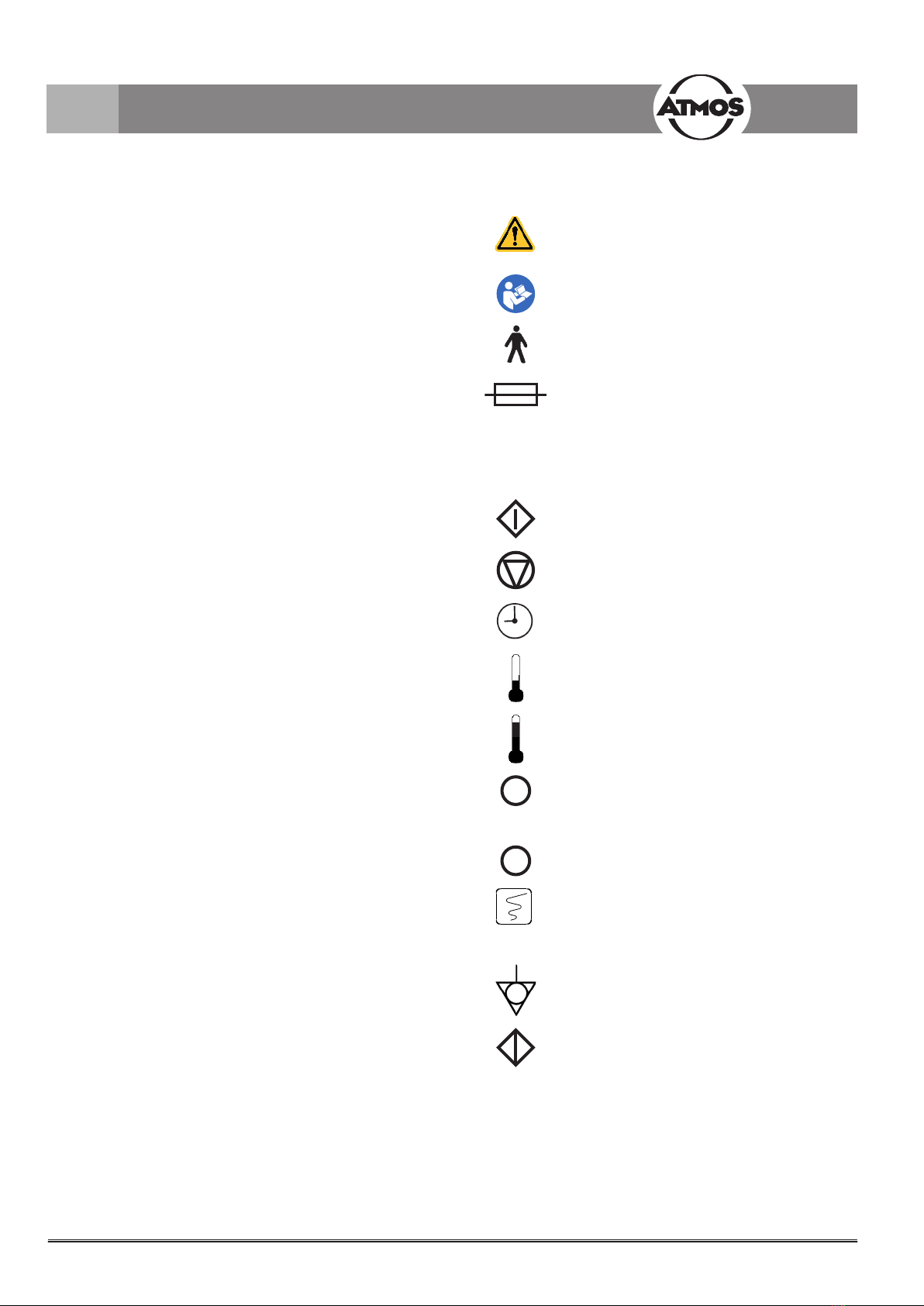

1.4 Explanation of symbols

Observe operating instructions!

According to ISO 7000/0434,

DIN 30600/1008, IEC 348

Follow operating instructions (blue)

Type B equipment as per IEC 417

Fuse

according to IEC 417/5016, DIN 30600/0186

°C Temperature in degree centigrade

sTimer adjustment in seconds

Start

Stop

Timer

Cold stimulation level

Warm stimulation level

•Heating and air ow ON

•Heating and air ow OFF (standby)

Control output for connecting a nystagmo-

graph

(graphical recorder as per DIN 30600,

IEC 417 5192)

Equipotential connection

DIN 30600 495, ISO 417 5021

Air lter

DIN 24300

4

1.0 Introduction

• The Varioair 3 is produced according to IEC 601 / EN

60601 and listed in the following classes:

- VDE Class of protection 1

- Class IIa (93/42/EEC).

• The device may only be connected to a properly installed

grounded safety socket.

• The Varioair 3 may only be used under the supervision

of skilled sta who have been authorized by ATMOS and

trained in its operation (IEC 601-1 / EN 60601-1).

• The mains voltage indicated on the type plate must corre-

spond to the values of the supply network.

• Make sure prior to every application of the equipment that

it is technically safe and in proper condition. Damaged

cables must be replaced immediately!

• Correct conguration in assembly of country-specic

connections:

- green/yellow: protective conductor (PE)

- blue: neutral conductor (N)

- black or brown: phase (L)

• The control panel must be clearly visible and accessible

for the user. Ensure sucient stability of the installation

surface.

• Prior to application, the air temperature must be checked

by the user (display)!

• Switch o the main switch after nishing work in the

practice.

• The Varioair 3 may only be operated in rooms used for

medical purposes, but not in areas subject to explosion

hazards and not in oxygen-rich environments.

• All additional equipment that is connected to the analog

and digital interfaces of the device must meet the require-

ments of relevant EN specications (e.g., EN 60950 for

data processing equipment and EN 60601 for electrical

medical equipment). In addition, congurations must

satisfy system specication EN 60601-1-1. When addi-

tional equipment is connected to the signal input or signal

output section on the device, the person carrying out the

connection is deemed a “system conguration operator”

and as such is responsible for meeting the requirements

of system specication EN 60601-1-1. If you have any

questions, please contact your local specialist supplier or

ATMOS Technical Service.

• ATMOS is not liable for personal injury and damage to

property if

- no original ATMOS parts are being used,

- the advice for use in these operating instructions is

not being observed,

- assembly, new settings, alterations, extensions, and

repairs have been carried out by personnel not au-

thorized by ATMOS.

• The validity for the certicate of conformity expires if the

customer or a third party manipulates the unit, e.g., by

making modications of any kind, using non-authorized

accessories, removing warning or information labels as

well as using the unit for inappropriate applications.

• Please note:

A medical isolation transformer with earth leakage

monitor or any similar safety system acc. to EN 60601-

1 is required if several devices are connected over one

common power supply. The transformer must correspond

to the power consumption of all the devices to be con-

nected.

5

2.0 For your safety

3.1 Scope of supply

• Varioair 3 basic unit

• Power cable

• Handle with tube

• Hose tips (30 pcs.)

• Operating Instructions

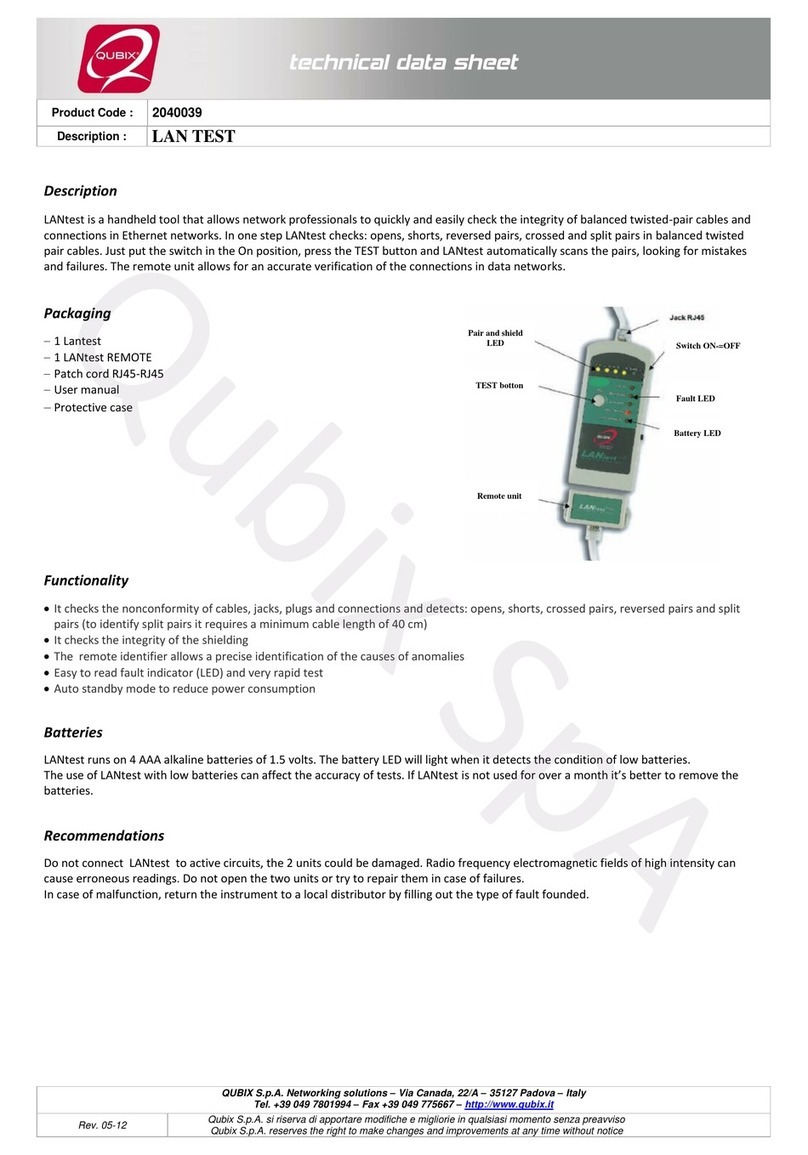

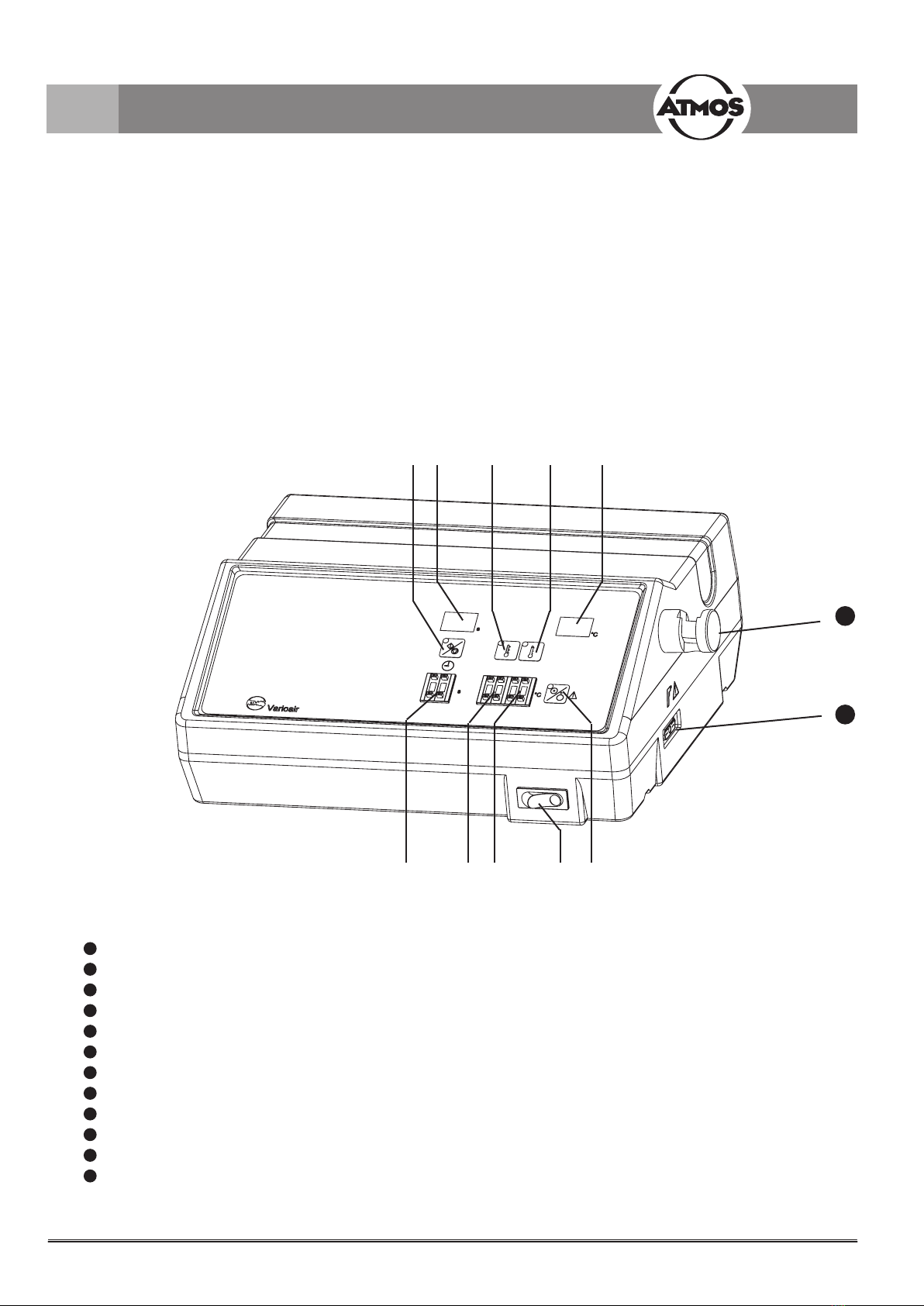

3.2 Illustrations

Fig. 1. Front view

1Main switch

2 Key switch for heating/air ow ON/OFF (standby)

3Coding switch for warm stimulation level

4Coding switch for cold stimulation level

5Coding switch for stimulation time

6 Key switch for selecting the warm stimulation level (e.g., 44 °C)

7 Key switch for selecting the cold stimulation level (e.g., 30 °C)

8 Key switch for start/stop of the stimulation

9 Temperature display (two-gure number, increment of 1 °C), actual value indication

10 Display of stimulation time (two-gure number, increment of 1 s)

11 Support for handle

12 Connection for handle

11

12

6

3.0 Setting up and starting up

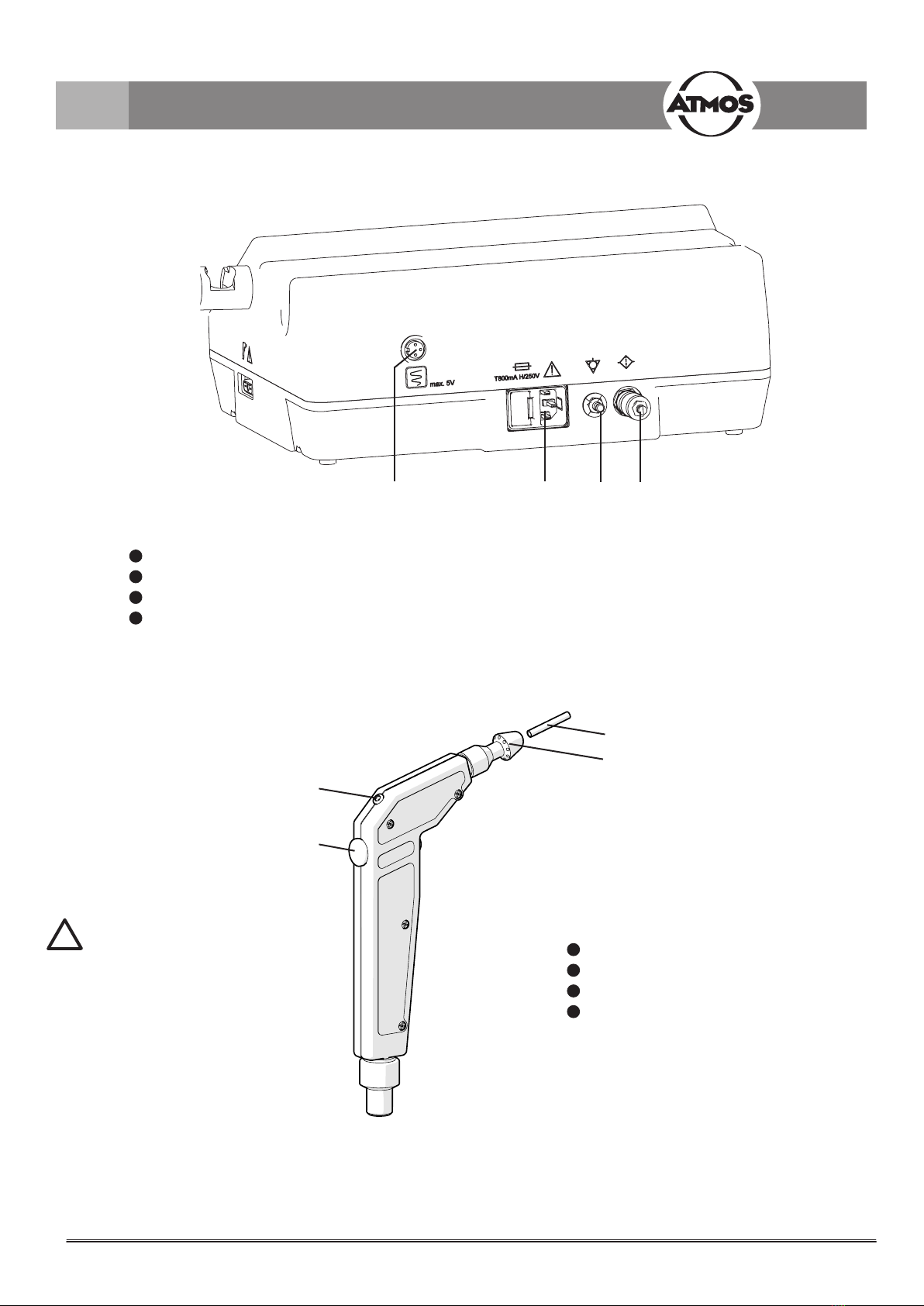

Fig. 2. Rear view

1Control output for controlling a nystagmograph

2Device plug with fuse compartment

3Equipotential bonding connection

4 Air lter (throttle silencer)

Fig. 3. Handle

1LED for indicating the stimulating process

2Timer Start/Stop key

3 Hose tip

4Jet connection

The sprayer nozzle must be

exchanged after each patient.

!

7

3.0 Setting up and starting up

3.3 Connections

3.3.1 Electrical connection

• Connect the power cable to the socket on the unit (,

Fig. 2).

• Insert the power plug in a correctly installed socket with

earthing contact.

3.3.2 Connecting a nystagmograph

• When controlling an ENG (electro-nystagmograph) or a

CNG (computer nystagmograph) at output (, Fig. 2),

please connect only recording equipment approved by

ATMOS. Connecting cable available from ATMOS (see

chapter 8.0).

3.3.3 Equipotential bonding conductor connec-

tion

• Connection for potential equalization (, Fig. 2). Con-

necting cable available from ATMOS (see chapter 8.0).

3.3.4 Connecting the handle

• Only the handle that is intended for this purpose must be

used:

- Press the special connector plug slightly onto the

socket in the unit.

- Fasten it to the housing by turning the holding screws

to the right.

)Do not kink the air tube!

3.3.5 Air inlet

• The ambient air is sucked into the unit through the lter.

• Screw connector for the air lter.

3.4 Starting up

• Insert the handle in its holder; the air outlet must point to

reverse side of the unit.

• Switch on the unit (, Fig. 1).

• Automatic display test with digital numbers “8 8” and

acoustic warning signal.

• Automatic change to standby mode.

8

3.0 Setting up and starting up

• Use the main switch to start the unit.

• Readiness for operation after 1 second.

• Completely press the hose tip onto the handle.

If the hose tip is not completely attached onto the handle,

damage could be caused to the patient’s eardrum.

4.1 Adjusting temperatures

• Two variable temperature levels (20 °C ‒ 47 °C) (48 °C +

49 °C only for testing purposes).

)The lowest achievable stimulation temperature is approx.

2 °C over the ambient temperature.

• Temperature setting by coding switches (, , Fig. 1).

- Left switch: for adjusting the “ten” partition

- Right switch: for adjusting the “one” partition

ªLower keys (+): temperature increase

ªUpper keys (-): temperature decrease

• Standard settings:

- Level for cold stimulation: 30 °C

- Level for warm stimulation: 44 °C

Avoid bending the tip of the hose within the ear / auditory

canal. Otherwise, the error “F1” or “F7” may occur.

4.2 Selecting temperature levels

• For selecting the desired temperature level, use the

respective key (, , Fig. 1).

ªDisplay of the active level via LEDs.

ªDisplay of the air temperature (current value) in °C.

• For switching o the heating system, press the respective

key (, , Fig. 1) of the active temperature level.

ªLED of the temperature level goes out.

ªDisplay of the air temperature (current value) in °C.

4.3 Adjusting stimulation time

• By means of coding switch (, Fig. 1).

!

!

4.4 Description of operating modes

4.4.1 Preparation mode

Purpose:

The temperature set by the user is adjustable.

Properties:

• Temperature: corresponds to the preselected cold or

warm stimulation level.

• Air ow: 5.0 l/min.

Activation:

• By operating one of the key switches for selecting a

temperature level (, , Fig. 1) or by operating the key

switch for heating/air ow ON/OFF (, Fig. 1) in the

standby mode.

• If the active temperature push button is pressed repeat-

edly, the heating is switched o.

ªAir with a temperature that almost corresponds to the

ambient air temperature is available.

Deactivation:

• Operating the key switch heating/air ow ON/OFF (,

Fig. 1) switches the unit to the standby mode.

• Automatic switch to standby mode when the unit is not

used within a 3-minute period.

9

4.0 Operation

4.4.2 Stimulation mode

Purpose:

Stimulation of the vestibular organ.

Properties:

• Temperature: corresponds to the preselected cold or

warm stimulation level.

• Air ow: 5.0 l/min.

• Duration: as pre-set by the timer.

Activation:

• Initially select the type of stimulation by activating either

the warm stimulation or cold stimulation key (, , Fig.

1) (see chapter section 4.1 for presetting of temperature).

• Recommended settings for Germany: 27 °C or

44 °C at 45 s.

• Operate the “timer start key” on the unit or on the handle.

• Preparation for stimulation:

- As long as the push button is pressed, the pump

remains switched o to allow the nozzle to be posi-

tioned in the auditory canal.

• When the push button is released, the thermal stimulation

is performed for the time set by the user (, Fig. 1).

ªLED on handle (, Fig. 3) lights up during thermal

stimulation.

• At the end of the stimulation period, a control signal for a

recording unit is issued at the nystagmograph output.

• After completion of stimulation, the pump is switched o.

• Repeated activation of the “timer start key” during stimu-

lation stops timer operation.

• Second activation of the currently active key deactivates

the corresponding level.

ªHeating is switched o.

ªStimulation with near-ambient air temperature.

Hose tip for the nozzle may not be blocked.

4.4.3 Standby mode

Purpose:

• Reduction of energy consumption.

• Reduction of noise level.

Activation:

• Activation of key “heating/pump on/o” (, Fig. 1).

ªHeating is switched o.

ªPump is switched o after 2 s.

• Automatically after each stimulation process.

• Automatically when the unit is not used within a 3-minute

period.

!

10

4.0 Operation

5.1 General information on cleaning and

disinfection

After use, all parts that come into contact with the patient (jet

connection) must be removed and disinfected! The cleaning

agents and disinfectants listed in section 5.2 are all suitable.

Hose tips must be exchanged after each patient.

The handle is not autoclavable!

The surfaces of the Varioair 3 resist most common surface

disinfectants.

However, do not use

• disinfectants that contain concentrated organic or inor-

ganic acids as they could cause corrosion damage.

• disinfectants containing chloramides, phenol derivatives,

or anionic surfactants, as these may cause stress cracks

in the material used for the housing of the unit.

You may also use disinfectant sprays or disinfectant tissues

for cleaning and disinfection.

)Set main switch of the device to OFF prior to cleaning

and disinfection. Wipe the unit surface with a cloth mois-

tened with a cleaning or disinfecting solution. Take care

that no liquid penetrates the device. The cleaning agents

and disinfectants listed in section 5.3 are all suitable.

)Always observe the instructions for use by the manu-

facturer of the disinfectants, including all concentration

specications.

)The described actions relating to cleaning and disinfec-

tion or sterilization do not substitute the relevant instruc-

tions which must be adhered to prior to operation.

5.2 Recommended instrument disinfectants

Disinfectant Ingredients in 100 g Manufacturer

Sekusept®PLUS

(concentrate)

Glucoprotamin 25 g Henkel, Düsseldorf

Nonionic surfactants, solvents, complexing agents

Gigasept®FF

(concentrate)

Succindialdehyde 11.0 g Schülke & Mayr, Norder-

stedt

Dimethoxytetrahydrofurane 3.0 g

Corrosion protection components, non-ionic surfactants,

and perfumes

Mucocit®-T new

(concentrate)

Bis(3-aminopropyl)laurylamine 8.0 g Merz & Co., Frankfurt/Main

Alkyldimethylbenzylammonium chloride 19.0 g

Cocospropylendiamin-1,5-guanidinium-acetate 7.0 g

5.3 Recommended surface disinfectants

Disinfectant Ingredients in 100 g Manufacturer

TERRALIN

(concentrate)

Benzalkonium chloride 20.0 g Schülke & Mayr, Norder-

stedt

Phenoxypropanols 35.0 g

Hexaquart®forte Benzyl-C12-16 alkyldimethyl, chlorides 20 g BBraun, Melsungen

Didecyldimethylammonium chloride 7.9 g

Non-ionic surfactants 5 – 15%

NTA < 5 %

Incidin Plus

(concentrate)

Glucoprotamin 26.0 g Henkel, Düsseldorf

Non-ionic surfactants

Solvents, complexing agents

Pursept-A

(Disinfectant spray or

disinfectant cloths)

Ethanol 38.9 g Merz & Co., Frankfurt/Main

Glyoxal 0.1 g

Quaternary ammonium compounds 0.05 g

When using disinfectants containing aldehyde and amine on the same object, color changes may occur.

11

5.0 Cleaning and care

Maintenance, repairs, and periodic tests may only be carried out by persons who have the appropriate technical knowledge and

are familiar with the product. To carry out these measures, the person must have the necessary test devices and original spare

parts.

ATMOS recommends: Work should be carried out by an authorized ATMOS service partner. This ensures that repairs and test-

ing are carried out professionally, original spare parts are used, and warranty claims remain unaected.

Carry out an inspection according to the manufacturer’s specications every 12 months.

6.1 Sending in the device

• Remove and properly dispose of consumables.

• Clean and disinfect the product and accessories according to the operating instructions.

• Place any used accessories with the product.

• Fill in the form QD 434 “Delivery complaint / return shipment” and the respective Decontamination certicate.

)This form is enclosed with each delivery and can be found at www.atmosmed.com.

• The device must be well padded and packed in suitable packaging.

• Place form QD 434 “Delivery complaint / return shipment” and the respective Decontamination certicate in an envelope.

• Ax the envelope to the outside of the package.

• Send the product to ATMOS or your dealer.

12

6.0 Maintenance and service

Error in temperature

display

Possible cause Remedy

“F0” Not used

“F1” Maximum allowed temperature

exceeded (>51 °C) (if the tempera-

ture exceeds 51 °C for more than 2

seconds, the pump is switched o

automatically).

• Switch o device, cooling down for approx. 1 minute is

required.

• Check whether temperature setting is too high. If neces-

sary, adjust desired temperature to a value of <51 °C by

means of the coding switches.

• Inform the service sta.

• Bent hose tip within the ear / auditory canal.

“F2” -5 V is missing (supply voltage on

the controller board)

• Inform the service sta.

“F3” Break of the safety NTC • Check proper connection of the handle.

• Replace the handle.

• Inform the service sta.

“F4” Not used

“F5” Break of the regulating NTC • Check proper connection of the handle.

• Replace the handle.

• Inform the service sta.

“F6” Not used

“F7” Temperature too high (>48 °C) • Check whether temperature setting is too high. If neces-

sary, adjust desired temperature to a value of <48 °C by

means of the coding switches.

• Inform the service sta.

• Bent hose tip within the ear / auditory canal.

“F8” Short-circuit of the regulating NTC • Replace the handle.

• Have temperature feeler of the regulating NTC checked by

the service sta.

“F9” Not used

)If errors cannot be corrected with the assistance of the troubleshooting list, please inform the service sta or send in the

device for repair. Do not start any attempts to repair the unit yourself!

13

7.0 Troubleshooting

8.1 Accessories

Description .....................................................................................................................................................REF

Power cable .....................................................................................................................................................507.0859.0

Handle, complete .............................................................................................................................................502.1035.0

Hose tips for jet (30 pcs.) .................................................................................................................................502.0844.0

8.2 Spare parts

Description .....................................................................................................................................................REF

Device base .....................................................................................................................................................000.0796.0

Fuse T 800 mA / H 250V 5x20 mm .................................................................................................................008.0081.0

Power cable .....................................................................................................................................................507.0859.0

Handle, complete .............................................................................................................................................502.1035.0

Jet connection ..................................................................................................................................................502.1045.0

Hose tips for jet (30 pcs.) .................................................................................................................................502.0844.0

14

8.0 Accessories and spare parts

Voltage range 100 - 240 V~ ± 10 %; 50/60 Hz

Current consumption max. 0.75 A

Power consumption max. 85 W

Connections Mains connection via IEC socket;control output for a nystagmograph; equipotential equal-

ization; connection for the handle; air inlet

Fuses 2 x T 1.6 A (f. 250 V~, 50/60 Hz)

Stimulation time Can be preselected by timer from 1 up to 99 sec.

Timer indication Indication accuracy ± 0.5 s ± ½ digit

Air temperature 20°C - 47°C

Lowest temperature Approx. 2°C above room temperature

Temperature indication Indication accuracy ± 0.5 s ± ½ digit

Temperature deviation < ± 1°C

Air ow 5.0 l/min ± 10 %

Operating time Short term operation:

1. Automatic shut-o after completion of stimulation.

2. Automatic shut-o after 3 minutes.

Modes of operation Preparation mode; stimulation mode (at temperature preselected for the cold stimulation

level resp. warm stimulation level); heating o and no air ow (economy mode, standby

mode)

Protective earth conductor

resistance

max. 0.1 Ω

Earth leakage current max. 0.5 mA

Enclosure leakage current max. 0.1 mA

Patient leakage current max. 0.1 mA

Ambient conditions for trans-

port/storage

-20...+50°C; 5...90 % humidity without condensation at air pressure 700...1060 hPa

Ambient conditions operation +10...+35°C; 20...80 % humidity without condensation at air pressure 700...1060 hPa

Maximum operational altitude ≤ 3000 m (NN)

Contamination level Class 2

Overvoltage category II

Dimensions HxWxD 14.5 x 37 x 32 cm

Weight 3.7 kg

Period tests Inspection according to the manufacturers specications every 12 months.

Safety class (EN 60601-1) I

Degree of protection Type B

Protection class IPX0

Further classications accord-

ing to other regulations

VDE protection class 1 (IEC 601/EN 60601)

Classication according to

Appendix IX EC Directive 93/42/

EEC

Class IIa

CE marking CE 0124

Applied standards EN 60601-1: 1990 + A1:1993 + A2:1995

EN 60601-1-2: 1993 (EMV / EMC)

GMDN code 34891

UMDNS code 10-548

ID No. (REF) 502.1100.0

Issue of the technical data: 2016-12-23

15

9.0 Technical data

• Packaging material, cardboard, and/or PE foam can be

fully recycled or returned to your supplier.

• The Varioair 3 does not contain any hazardous materials.

• The housing is fully recyclable.

• The component parts of the Varioair 3 must be disposed

of correctly and the materials are to be separated care-

fully.

• The electronics circuit boards must be fed into the appro-

priate recycling process.

• Used hose tips that no longer can be disinfected must be

discarded into domestic waste immediately.

16

10.0 Disposal

11.1 Guidelines and Manufacturer’s Declaration ‒ Emissions

The Varioair 3 is designed for operation in the environment specied below. The customer or user of the Varioair 3 should ensure

that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment ‒Guidance

RF Emissions acc.to CISPR 11 Group 1 The Varioair 3 uses HF energy for its internal functions. There-

fore, its RF emissions are very low and are not likely to cause any

interference in nearby electronic equipment.

RF Emissions acc. to CISPR 11 Class B

The Varioair 3 is suitable for use in all establishments, including

domestic and those connected directly to a public power supply

network that supplies buildings used for residential purposes.

Harmonic emissions according to

IEC 61000-3-2

Class A

Voltage uctuations/icker according

to IEC 61000-3-3

Corresponds

11.2 Guidelines and Manufacturer’s Declaration ‒ Immunity

The Varioair 3 is designed for operation in the electromagnetic environment specied below. The customer or user of the Varioair 3

should ensure that it is used in such an environment.

Immunity Test IEC 60601 Test

Level Compliance Level Electromagnetic Environment ‒Guidance

Electrostatic dis-

charge (ESD) accord-

ing to IEC 61000-4-2

± 6 kV Contact

± 8 kV Air

Floors should be made of wood or concrete or laid

with ceramic tiles. If oors are synthetic, the relative

humidity should be at least 30 %.

EFT IEC 61000-4-4 ± 2 kV Mains

± 1 kV I/Os

Mains power quality should be that of a typical com-

mercial or hospital environment.

Surges IEC 61000-

4-5

1 kV

Common

2 kV

Dierential

Mains power quality should be that of a typical com-

mercial or hospital environment.

Magnetic eld at pow-

er frequency 50/60 Hz

acc. to IEC 61000-4-8

3 A/m Power frequency magnetic elds should be that of a

typical commercial or hospital environment.

• Medical electrical equipment is subject to special precautions with regard to EMC and must be installed according to the follow-

ing EMC notes.

• Portable and mobile RF communication facilities can inuence medical electrical equipment.

• The use of other accessories, converters, and cables than stated may lead to an increased emission or a reduced interference

immunity of the equipment or system.

The device may not be used directly next to other devices or piled up with other devices. If operation next to or piled with other

devices is necessary, please watch the device to check its intended operation in this arrangement.

17

11.0 Notes on EMC

Immunity Test IEC 60601 Test Level Compliance Level Electromagnetic Environment ‒ Guidance

Voltage Dips / Dropout

IEC 61000-4-11

< 5 % UT

(> 95 % Dip of the UT)

for 0.5 Cycle

40 % UT

(60 % Dip of the UT)

For 5 cycles

70 % UT

(30 % Dip of the UT)

For 25 cycles

< 5 % UT

(> 95 % Dip of the UT)

for 5 s

Mains power quality should be that of a typical

commercial or hospital environment. If the user

of the Varioair 3 requires continued operation

upon the occurrence of disruptions in the energy

supply, the Varioair 3 should make use of an

uninterruptible power supply or a battery.

NOTE UTis the mains alternating current prior to application of the test levels.

11.3 Guidelines and Manufacturer’s Declaration ‒ Immunity

The Varioair 3 is designed for operation in the electromagnetic environment specied below. The customer or user of the Varioair 3

should ensure that it is used in such an environment.

Immunity Test IEC 60601 Test

Level Compliance Level Electromagnetic Environment ‒ Guidance

Conducted RF IEC

61000-4-6

3 Ve

150 kHz to 80 MHz [3 ] V Portable and mobile radio equipment should be used no

closer to the Varioair 3, including cables, than the rec-

ommended distance calculated according to that which

applies to the transmission frequency.

Recommended distances:

d = [ 1,2] √P

d = [ 1,2] √P

d = [ 2,3] √P

where P is the max. power in watts (W) and d is the

recommended separation distance in meters (m).

Field strengths from xed transmitters, as determined by

an electromagnetic site (a) survey, should be less than

the compliance level (b).

Interference may occur in the vicinity of equipment con-

taining following symbol:

Radiated RF IEC

61000-4-3

3 V/m

80 MHz to 2.5 GHz

[3 ] V/m

18

11.0 Notes on EMC

11.4 Recommended separations between portable and mobile RF communications equip-

ment and the Varioair 3

NOTE 1

With 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2

These guidelines may not be applicable in all cases. The emanation of electromagnetic waves is aected by absorption and

reection of buildings, objects, and people.

a

The eld strength of stationary transmitters, such as base stations of cellular phones and mobile terrain radio equipment,

amateur radio transmitters, cbm broadcast and TV stations cannot be predestined exactly. To determine the electromagnetic

environment in regard to stationary transmitters, a study of the location is to be considered. If the eld strength measured at the

site where the Varioair 3 is used exceeds the compliance level above, the Varioair 3 must be observed to demonstrate proper

function. If abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the

Varioair 3.

b

Within the frequency range of 150 kHz to 80 MHz, the eld strength should be below 3 V/m.

The Varioair 3 is intended for use in an electromagnetic environment in which HF disturbances are controlled. The customer or user

of the Varioair 3 can thereby help to prevent electromagnetic interference by maintaining a minimum distance between portable and

mobile RF communication equipment (transmitters) and the Varioair 3 – depending on the output of the communication device as

indicated below.

Safety distance, depending on transmit-frequency m

Nominal output of the

transmitter

W

150 kHz to 80 MHz

d = [ 1,2] √P

80 MHz to 800 MHz

d = [ 1,2] √P

800 MHz to 2.5 GHz

d = [ 2,3] √P

0.01 0.12 0.12 0.23

0.1 0.46 0.46 0.9

1 1.2 1.2 2.3

10 3.8 3.8 7.3

100 12 12 23

For transmitters for which the maximum nominal output is not indicated in the above table, the recommended safe-

ty distance d in meters (m) can be determined using the equation belonging to the respective column whereas P is

the maximum nominal output of the transmitter in watts (W) acc. to manufacturer’s specication.

NOTE 1

With 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2

These guidelines may not be applicable in all cases. The emanation of electromagnetic waves is aected by ab-

sorption and reection of buildings, objects, and people.

19

11.0 Notes on EMC

ATMOS MedizinTechnik GmbH & Co. KG

Ludwig-Kegel-Str. 16

79853 Lenzkirch / Germany

Phone: +49 7653 689-0

www.atmosmed.com

Other manuals for Varioair 3

1

Table of contents

Other Atmos Test Equipment manuals

Popular Test Equipment manuals by other brands

Envitec

Envitec AlcoQuant 6020 operating instructions

TSI Instruments

TSI Instruments 4046 user guide

Keysight Technologies

Keysight Technologies 16380V Operation and service manual

Cal Test Electronics

Cal Test Electronics CT3684 user manual

DMQ

DMQ QH5 U user manual

TRENDnet

TRENDnet TC-TP1 Product information