Use Stage Safety Grade Precautions

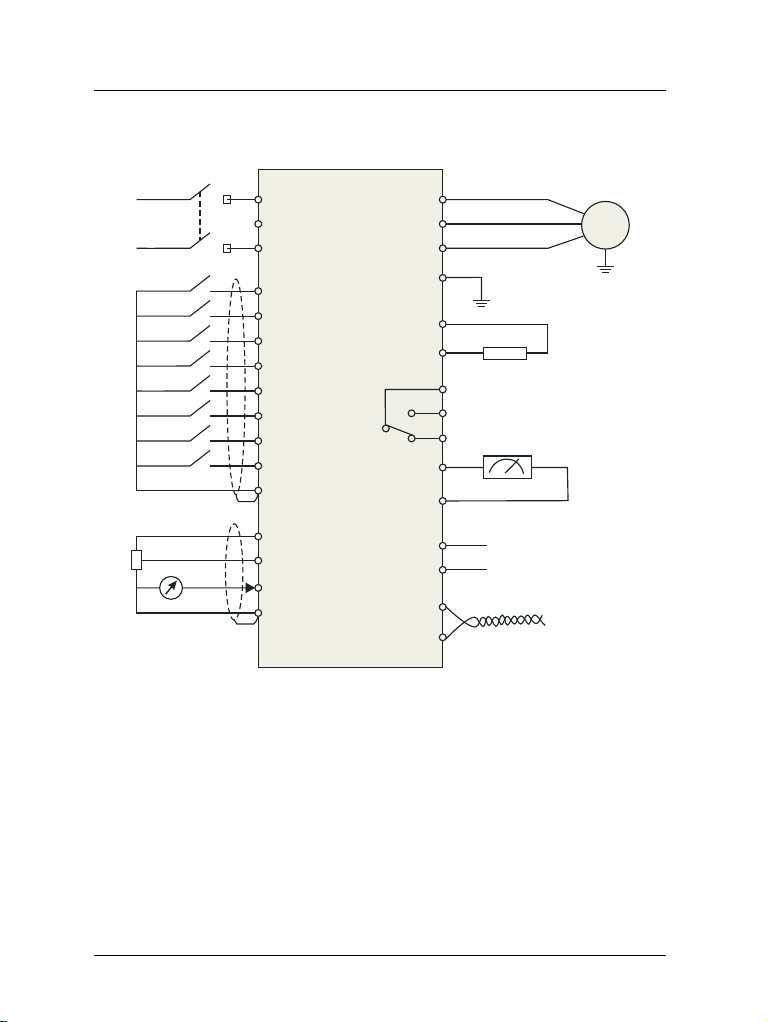

Wiring

²Never connect the power cables to the output terminals

(U,V,W) of the VFD. Pay attention to the marks of the

wiring terminals and ensure correct wiring. Failure to

comply will result in damage to the VFD;

²Install braking resistors at terminals (P+)and (P- or PB)

only. Failure to comply may result in equipment

damage.

²Since all adjustable frequency VFDs from Gozuk have

been subjected to hi-pot test before delivery, users are

prohibited from implementing such a test on this

equipment. Failure to comply may result in equipment

damage.

²Signal wires should to the best of the possibility be

away from main power lines. If this cannot be ensured,

vertical cross-arrangement shall be implemented,

otherwise interference noise to control signal may

occur.

²If motor cables are longer than 100m, it is recommend-

ed output AC reactor be used. Failure to comply may

result in faults.

CAUTION

DANGER

²VFD shall be power-on only after the front cover is

assembled. Risk of electrical hazard.

DANGER

Before

Power-on

²Verify that the input voltage is identical to the rated

voltage of product, correct wiring of input terminals R,S,

T or L1, L2 and output terminals U, V, and W, wiring of

VFD and its peripheral circuits, and all wires should

be in good connection. Risk of VFD damage.

CAUTION

²Do not open the cover after power. Rick of electrical

hazard;

²Do not touches any input/output terminals of VFD with

bare hands. Rick of electrical hazard.

DANGER

After

Power-on ²If auto tuning is required, be careful of personal injury

when motor is running. Risk of accident;

²Do not change the defaults of parameters. Risk of

devices damage.

CAUTION

GK3000 User Manual

-3-