II K 2-2

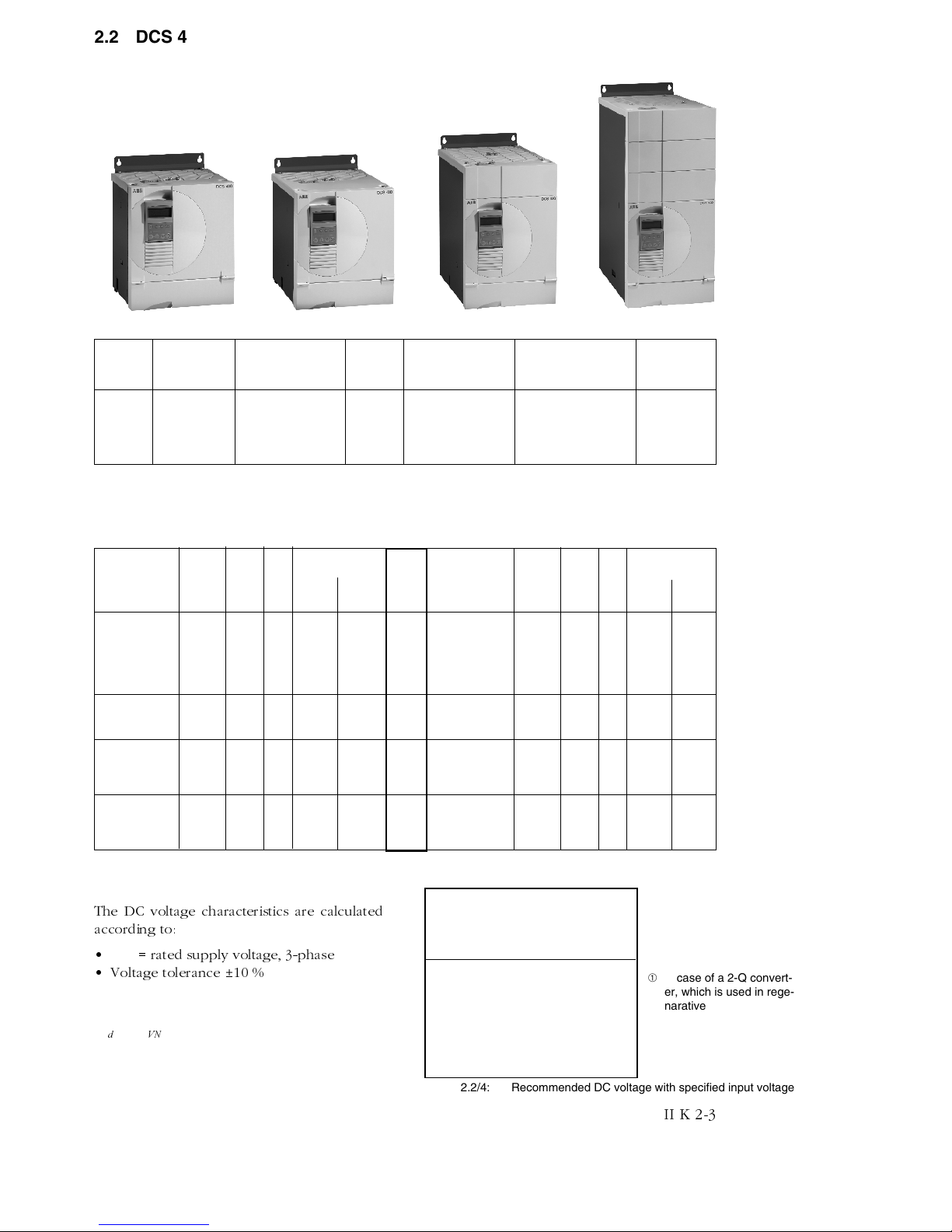

Planned for 2000

under preparation

2.1 Environmental conditions

Mains supply - power part

Voltage, 3-phase: 230 to 500 V in acc. with IEC 38

Voltage deviation: ±10% permanent

Rated frequency: 50 Hz or 60 Hz

Static frequency deviation: 50 Hz ±2 %; 60 Hz ±2 %

Dynamic: frequency range: 50 Hz: ±5 Hz; 60 Hz: ± 5 Hz

df/dt: 17 % / s

Mains supply - Electronics supply

Voltage, 1-phase: 115 to 230 V in acc. with IEC 38

Voltage deviation: -15% / +10%

Frequency range: 45 Hz to 65 Hz

Degree of protection

Power converter module: IP 00

Paint finish

Power converter module, cover: RAL 9002 light-grey

housing: RAL 7012 dark-grey

Fig. 2.1/1: Effect of the site elevation above sea level on the

power converter's load capacity

Current reduction to (%) for armature circuit and field supply

Fig. 2.1/2: Effect of the ambient temperature on the converter

module load capacity.

Current reduction to (%) for armature circuit and field supply

Environmental limit values

Permissible ambient temp. with rated current I DC: +5 to +40°C

Ambient temp., power conv. module:+40°C to 55°C; s. Fig. 2.1/2

Alteration in the ambient temp.: < 0,5°C / minute

Storage temperature: -40 to +55°C

Transport temperature: -40 to +70°C

Relative humidity: 5 to 95%, no condensation

Pollution degree: Grade 2

Site elevation:

<1000 m above M.S.L.: 100%, without current reduction

>1000 m above M.S.L.: with current reduct., s. Fig. 2.1/1

Vibration converter module: 0,5 g; 5 Hz to 55 Hz

Noises: Size as module

(1 m distance)

A1 55 dBA

A2 55 dBA

A3 60 dBA

A4 66...70 dBA, dependent on fan

Compliance with standards

The power converter modules and cubicles are designed for industrial applications.

Within the EU, the components satisfy the requirements European guidelines, shown

in the table below.

Standards in North America

In North America, the system components

satisfy the requirements as listed in the

table below.

70

80

90

100

110

30 35 40 45 50 55°C

Please note:

applies for power converter modules only.

50

60

70

80

90

100

1000 2000 3000 4000 5000m

European Union Directive Manufacturer’s Assurance

Harmonized Standards

Converter module

Machinery Directive

89/392/EEC

93/68/EEC

Declaration of

Incorporation

EN 60204-1

[IEC 204-1]

Low Voltage Directive

73/23/EEC

93/68/EEC

Declaration of Conformity

EN 60146-1-1

[IEC 146-1-1]

EN 50178 [IEC --]

see additional

IEC 664

EMC Directive

89/336/EEC

93/68/EEC

Declaration of Conformity.

Provided that all installation

instructions concerning

cable selection, cabling and

EMC filters or dedicated

transformer are followed.

EN 61800-3

¥

[IEC 1800-3]

where limits are under consideration

EN 50081-2 / EN 50082-2 has been supplied

¥

in accordance with 3ADW 000 032

’Installation in accordance with EMC’

The Technical Construction File to which this

Declaration relates has been assessed by

Report and Certificate from ABB EMC

Certification AB being the Competent Body

according to the EMC Directive.

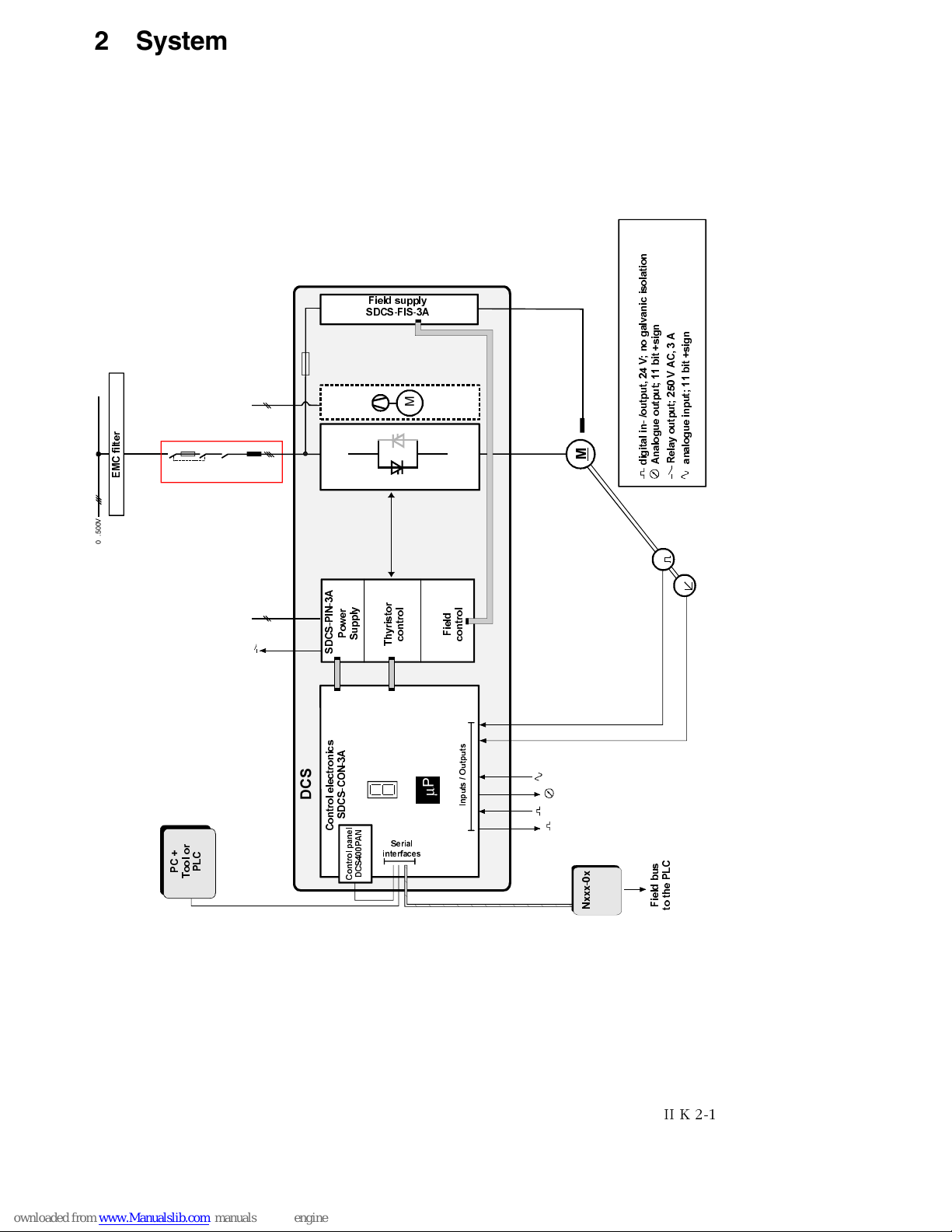

System overview of DCS 400

Safety for Power

conversion Equipment

≤600 V

Standard for module

UL 508 C

Industrial control

Equipment: industrial

products ≤600 V

CSA C 22.2. No.1495