1 / 22

Content

I.

Summary ................................................................................................................................... 2

1. Model ................................................................................................................................ 2

2. Ice production ................................................................................................................... 3

II.

Safety Notices............................................................................................................................ 4

III.

Installation ............................................................................................................................. 5

1. Power supply ..................................................................................................................... 5

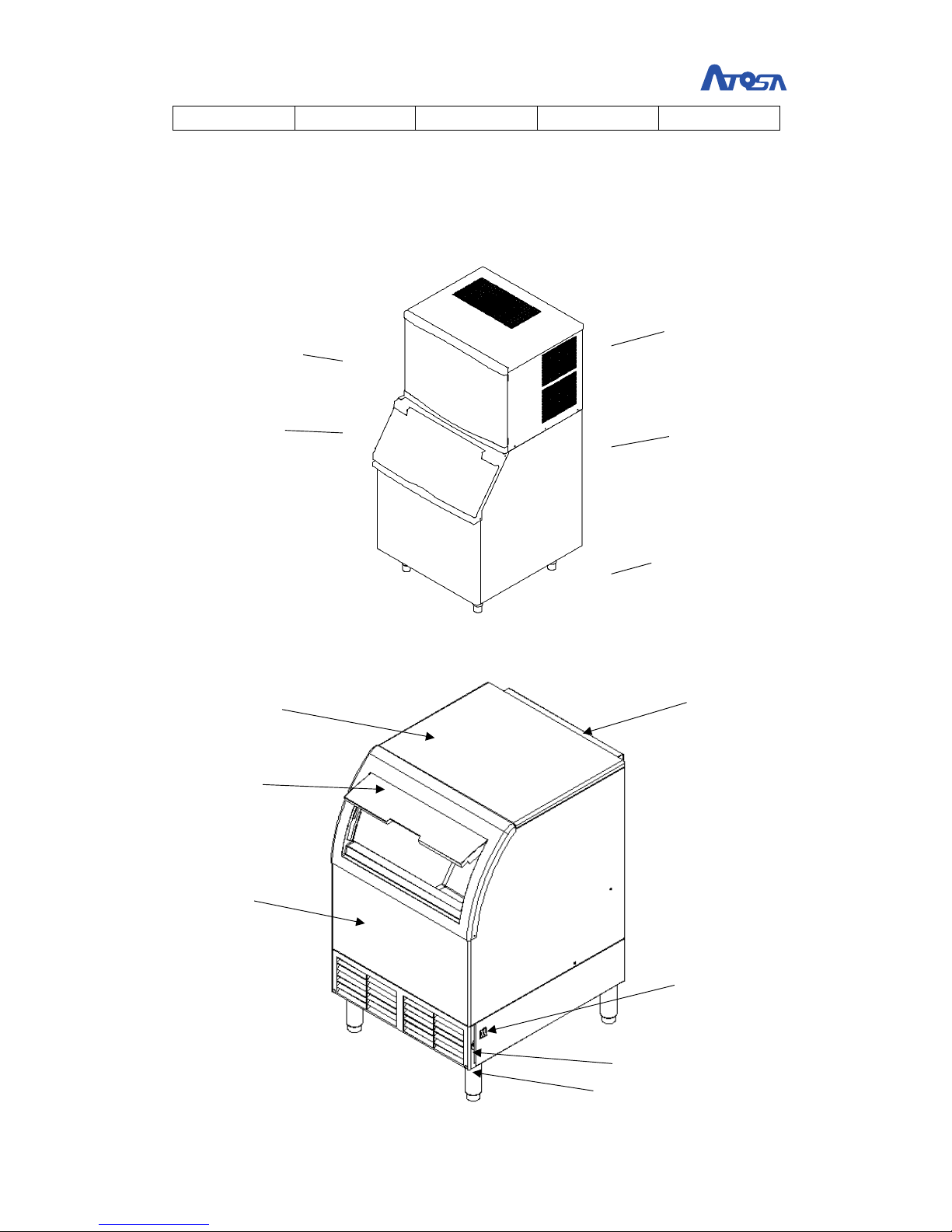

2. Construction ...................................................................................................................... 6

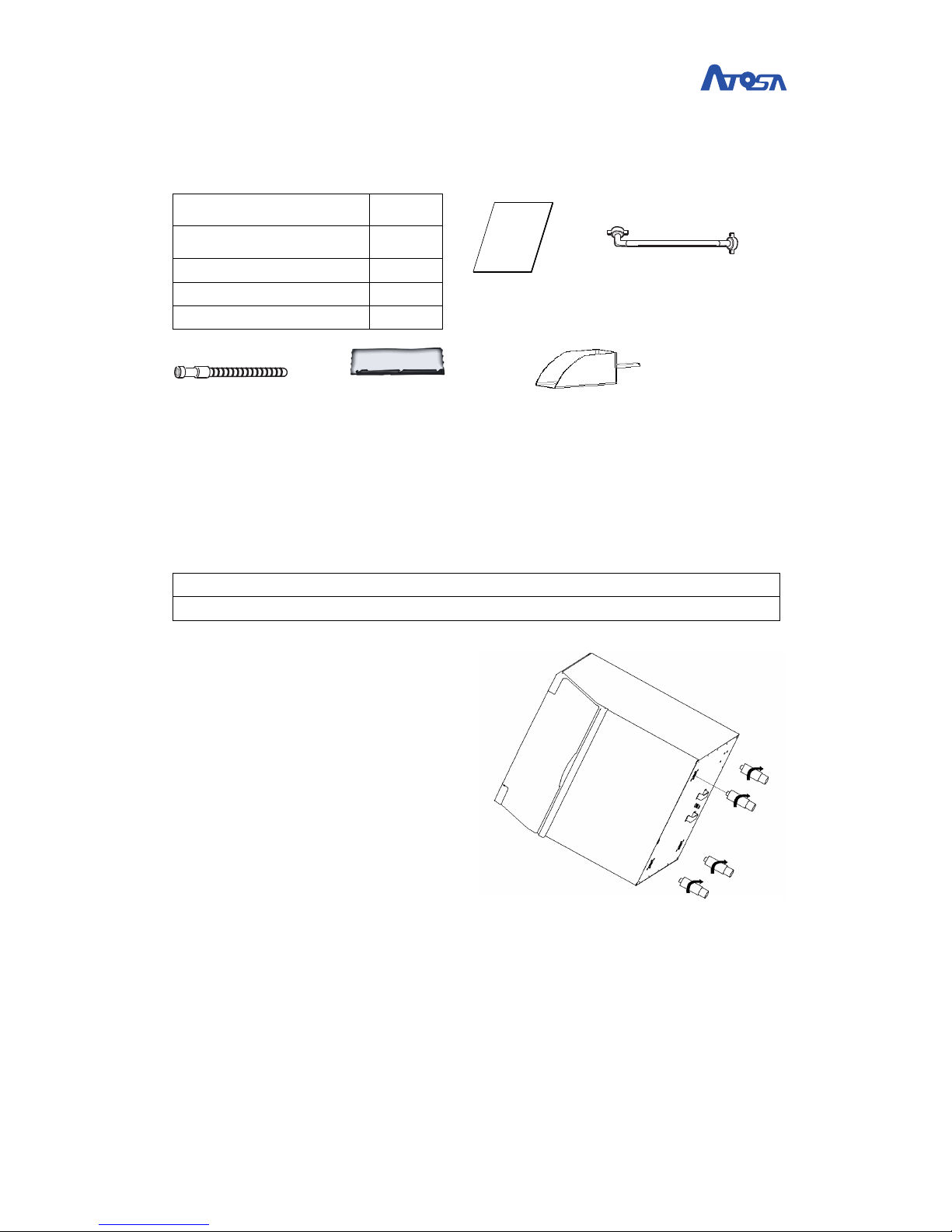

3. Accessories ........................................................................................................................ 7

4. Ice bin installation ............................................................................................................. 7

5. Ice machine head installation ........................................................................................... 7

6. Obstruction panel installation(no in the self-contained machine) ........................... 8

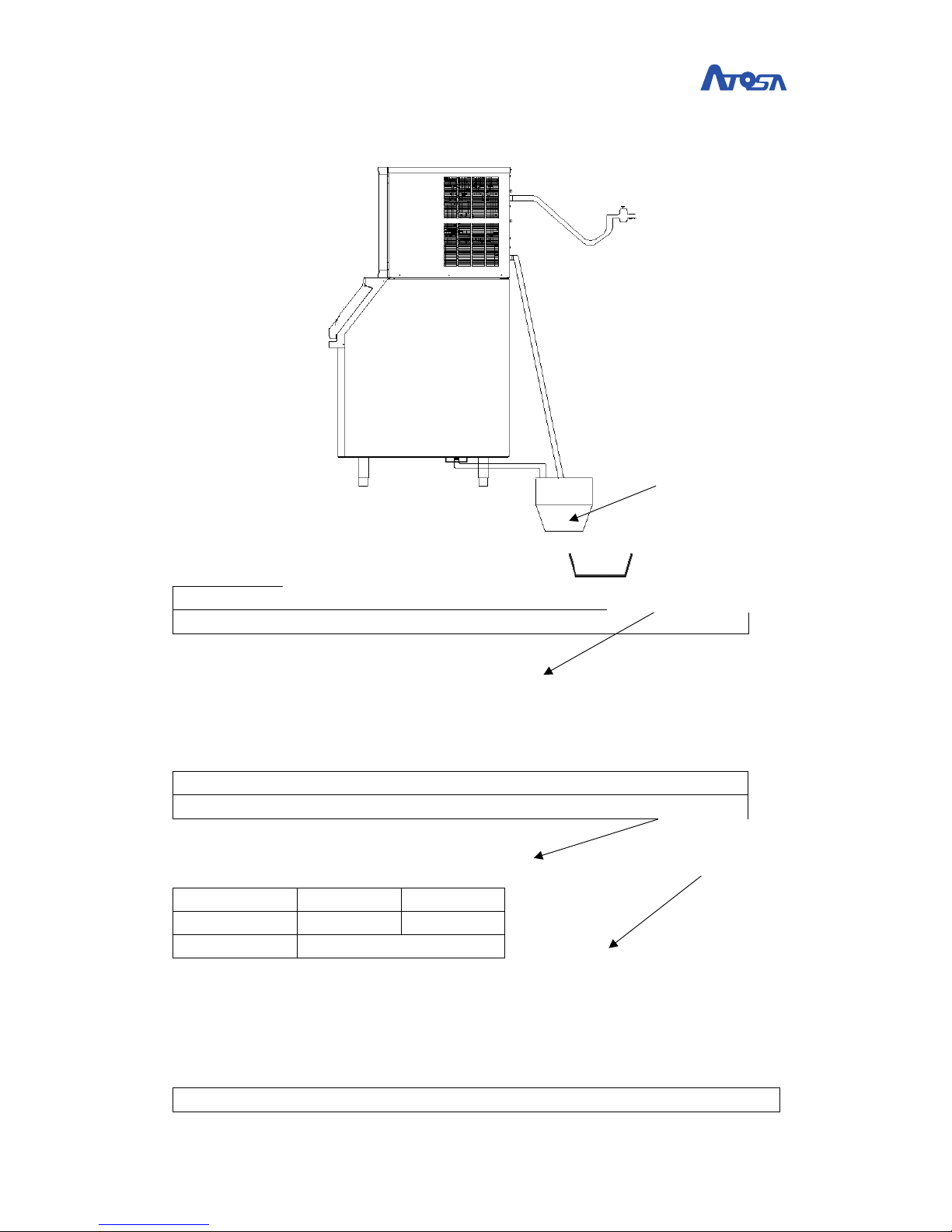

7. Connect the water inlet hose and drain hose ................................................................... 8

8. Installation location ........................................................................................................... 9

IV.

Operation ............................................................................................................................ 10

1. Checklist before operation .............................................................................................. 10

2. operation ......................................................................................................................... 10

3. Ice weight per batch ........................................................................................................ 11

V.

Maintenance ........................................................................................................................... 12

Clean and sanitize ........................................................................................................................... 12

Condenser air-filter wash ........................................................................................................ 15

VI.

Service ................................................................................................................................. 16

1. Diagram ........................................................................................................................... 17

2. Safety protection ............................................................................................................. 17

3. LED indication .................................................................................................................. 17

4. Failures analysis ............................................................................................................... 18

5. Customer Support ........................................................................................................... 19

6. Waste disposal ................................................................................................................ 20

7. Commercial Ice Machine Warranty ................................................................................. 20