Atronix AX Series User manual

INVERTER

atx009de-en0823

Installation and operating instructions

AX series, 1ph

Machine Translated by Google

Operating instructions

a-TroniX inverter AX series, 1ph

Our EU declaration of conformity and warranty conditions can be found on:

Read this instruction manual carefully before installation.

www.a-tronix.de

It contains important regulations and information for the use of this product and

provides technical support for the operator of the device.

All rights reserved.

AKKU SYS Accumulator and Battery Technology Nord GmbH

AKKU SYS Akkumulator- und Batterietechnik Nord GmbH cannot be held responsible for

any inaccuracies or inappropriate information in these operating instructions. The information

in this document can be read without

Connection path 23 D-25469 Halstenbek · GERMANY

may be changed with prior notice, but there is no obligation to continually update it.

Design and equipment changes that improve the production process

Telephone +49 4101 37676-0 · Fax +49 4101 85475-66

or the product are reserved.

Read carefully before use!

5

2.1 Intended use 2.2 PE connection and

leakage current 6

2.3 Surge Protection Devices (SPDs) for PV Installation 3.

Introduction

3.1 Basic Features

8th

3.2 Dimensions

Page

9

3.3 Inverter terminals

4

9

4

10

4

11

4

1. Notes about this manual

5

1.1 Scope 1.2 Target

group 1.3

Symbols used 2. Security

INTRODUCTION

The publication and copyright of this documentation remain with the company:

Table of contents

Page 2 atx009de0823

Machine Translated by Google

Operating instructions

a-TroniX inverter AX series, 1ph

atx009de0823 Page 3

4.2 Battery

6.6 EPS connection

4.3 AC Output/Input 4.4 EPS

Output 4.5 Efficiency

and Protection

6.7 System connection diagrams 6.8

Commission the inverter

4.6 General data 5.

Installation

6.9 Switch off the inverter

4. Technical data

5.1 Check for physical damage 5.2 Packing

list

7. Operation

7.1 Control panel

5.3 Assembly

7.2 Function tree

6. Electrical connection

8.

Maintenance 8.1 Overview of error codes

6.1 PV connection (only for hybrid)

8.2 Troubleshooting and routine maintenance 9.

Decommissioning 9.1 Dismantling the

inverter 9.2

Packaging 9.3 Storage and transportation

6.2 Connecting the battery

4.1 PV input (only for hybrid)

6.3 AC connection 6.4

Ground connection 6.5

Installation of a communication device (Optional)

14

13

20

37

45

17

12

36

45

33

16

44

39

15

26

37

22

14

20

12

36

45

12

45

16

35

16

26

39

23

38

Machine Translated by Google

1.Notes about this manual

CAUTION!

WARNING!

Failure to take preventative protective measures could potentially result in damage

to the product and/or its functions or to something in its surroundings.

This section explains the symbols that appear on the inverter and on the

This symbol indicates a hazardous situation which, if not avoided, could result in

serious injury or death.

A NOTICE

Type plate shown are:

Be careful of hot surfaces. The inverter can become hot during operation. Avoid

touching during operation.

A NOTICE:

Please keep these instructions so that they are accessible at all times.

The inverter complies with the requirements of the applicable CE guidelines.

DANGER!

This symbol indicates texts, hints or tips.

1.1 Scope

1.2 Target group

1.3 Symbols used The

following types of safety warnings and general information

appear in this document as described below:

AX3.0kW-1ph, AX3.7kW-1ph, AX4.6kW-1ph, AX5.0kW-1ph, AX6.0kW-1ph

be performed.

This manual describes the assembly, installation, commissioning, maintenance and

troubleshooting for the following models of the a-TroniX products:

This manual is intended for qualified electricians. All tasks described may only be

carried out by a qualified electrician

atx009de0823

page 4

Machine Translated by Google

and comply with regulations.

Protective conductor connection

• Check the device before installation to ensure there are no

Danger due to high voltages.

Has transport damage that could affect the integrity of the insulation or the safety

distances. Choose the installation location carefully

Danger to life due to high voltages in the inverter!

Danger.

and comply with prescribed cooling requirements. Unauthorized removal of

necessary protective devices, improper use, incorrect

The inverters of the a-TroniX series AX were developed and tested in accordance

with international safety requirements. However, certain safety precautions must be

taken when installing and operating this inverter. The installer must read and follow

all instructions, safety notices and warnings in this installation manual.

Installation and operation may result in serious safety hazards, electric shock

hazards, or equipment damage.

Danger of electric shock!

• All work, including transport, installation, commissioning and maintenance,

• Consult before connecting the inverter to the power grid

Danger to life due to high voltages.

must be carried out by qualified, trained personnel.

the local network operator to obtain the appropriate permits.

There is a residual voltage in the inverter that takes 5 minutes to discharge.

Wait 5 minutes before opening the top lid or the DC lid.

• The electrical installation and maintenance of the inverter must be carried out by a

This connection may only be made by qualified specialist personnel.

be carried out by a qualified electrician and in accordance with local regulations

Read the manual.

The product must not be disposed of as household waste.

page 5

atx009de0823

2. Security

2.1 Intended use

Machine Translated by Google

The capacity that can contribute is the internal capacity of the inverter compared to

PE and external protective elements such as the lighting protection.

• During operation, the DC bus is connected to the AC network via the inverter. As a

result, part of the alternating voltage amplitude reaches the intermediate circuit.

The fluctuating tension is constantly changing

• Do not use the device if abnormalities are detected. Avoid

the state of charge of the parasitic PV capacitor (i.e. capacity to PE). This

• Do not install the device in unfavorable environmental conditions, such as

Make temporary repairs.

is associated with a displacement current that is proportional to the capacity and

• Only approved spare parts may be used for all repairs

e.g. B. in the immediate vicinity of flammable or explosive substances, in a corrosive

or desert-like environment, at extremely high or low temperatures

or in high humidity.

the applied voltage amplitude.

according to their intended use and by a licensed professional

• In every PV system, several elements contribute to the leakage current to protective

earth (PE). These elements can be divided into two main types.

• Do not use the device if the safety devices are not working.

or an authorized AKKU SYS service representative.

• Capacitive leakage current: The leakage current is mainly caused by the parasitic

• Residual current: In the event of an error, e.g. B. a defective insulation, where an under

kidney or are deactivated.

• Liability for commercially available components lies with the respective manufacturer

Capacity of the PV modules compared to PE. The module type, the environmental

conditions (rain, humidity) and even the distance of the modules from the roof

A live cable that comes into contact with a grounded person will flow

an additional current called residual current.

• Use personal protective equipment during installation, including

delegated.

can influence the discharge current. Other factors contributing to parasitic

Gloves and eye protection.

• Inform the manufacturer of any non-standard installation conditions.

The residual current factors of PV systems

• Whenever the inverter has been disconnected from the public grid, leave

Please use extreme caution as some components may retain sufficient charge

to create a risk of electric shock. Before touching any part of the inverter, please

make sure that the surfaces and devices are free of dirt

high temperatures or voltage potentials before proceeding.

2.2 PE connection and leakage current

page 6 atx009de0823

Machine Translated by Google

atx009de0823 Page 7

Installing and selecting an external RCD circuit breaker

Residual current device (RCD)

• Installations where local electrical codes require an RCD circuit breaker with a

lower leakage current rating may result in the external RCD circuit breaker being

accidentally tripped due to the discharge current. The following steps are

recommended to avoid unwanted tripping of the external RCD circuit breaker:

However, the inverter automatically resets when the fault currents

are low, manual reset can be saved.

Speed 300mA per unit.

1. Selecting a suitable RCD circuit breaker is important for the correct operation

of the system. An RCD circuit breaker rated at 30mA

can trigger with a leakage current of 15mA (according to IEC 61008).

• In some countries an external RCD circuit breaker is required. The installer must

check which type of RCD circuit breaker is available in the respective local area

• All a-TroniX inverters are equipped with a certified internal residual current

protective device (RCD) that protects against a possible malfunction in the event

of a malfunction of the PV generator, cables or inverter (DC).

High-quality RCD circuit breakers usually trip at a value that

regulations are required. The installation of an RCD circuit breaker must

is closer to its nominal value.

Protects against electric shock. The residual current protection device in the a-

TroniX inverter can detect leaks on the DC side. There are 2 trigger thresholds for

always be carried out in accordance with local regulations and standards.

2. Configure the trip current of the internal RCD circuit breaker

the FI circuit breaker, as required in the DIN VDE 0126-1-1 standard. A low one

a-TroniX recommends using a type A RCD circuit breaker. a-TroniX

Inverter to a lower value than the tripping current of the external RCD circuit

breaker. The internal RCD circuit breaker trips when the

recommends an RCD circuit breaker with a value between 100mA and 300mA,

Threshold serves to protect against rapid changes in leakage, as in

Current exceeds the permissible value. Because the internal RCD circuit breaker

unless local regulations require a lower value.

occur when people come into direct contact. A higher threshold is used for slowly

increasing leakage currents to reduce the current in grounding conductors

to limit security. The default value for higher speed personal protection is 30mA

and lower for fire protection

Machine Translated by Google

page 8 atx009de0823

2.3 Surge protection devices

(SPDs) for PV installation

WARNING!

Induced surges are the most likely cause of lightning damage in the majority of installations,

particularly in rural areas where power is typically supplied via long overhead power lines.

Surges can affect both the PV generator line and the AC cables leading to the building.

Lightning protection professionals should be consulted for final application. With suitable

external lightning protection, the impact of a direct lightning strike on a building can be

weakened in a controlled manner and the lightning current can be diverted into the ground.

The installation of SPDs to protect the inverter from mechanical damage and excessive

stress includes a surge arrester in the case of a building with an external lightning protection

system (LPS) when a separation distance is maintained. To protect the DC system, a surge

protection device (SPD Type2) should be installed at the end of the DC wiring of the inverter

and on the array between the inverter and the PV generator when the voltage protection

level (VP) of the surge arresters is greater than 1100V, an additional SPD type 3 is required

for overvoltage protection for electrical devices.

The formation of loops in the system must be avoided. This short routing and bundling

requirement includes all associated ground bundling conductors.

To protect the AC system, surge protective devices (SPD Type2) should be installed at the

main input point of the AC supply (at the load cutout), which is located between the inverter

and the meter/distribution system; SPD (test pulse D1) for signal line according to EN

61632-1. All DC lines should be laid as short as possible; plus and minus lines of the string or

the main DC supply should be bundled.

When installing the PV system, surge protection with surge arresters should be

provided. The grid-connected inverter is not equipped with SPDs on either the PV input side

or the grid side.

Spark gap devices are not suitable for use in DC circuits once they are conductive; they only

stop conducting when the voltage across their terminals is typically below 30 volts.

Lightning causes damage either from a direct strike or from surges due to a nearby strike.

Machine Translated by Google

3. Introduction

System advantages:

atx009de0823 Page 9

3.1 Basic properties

The high-quality inverters of the AX series are used to convert solar energy into

alternating current and store energy in the battery. The inverter can be used to

optimize self-consumption, to store in the battery for later use or to feed into the

public grid. The working mode depends on the PV energy and user's preferences.

• Advanced anti-islanding solutions.

• Max. efficiency up to 97.8%. EU efficiency up to 97.0%. THD <3%.

Touch buttons.

• Power factor control. User-friendly HMI.

• PC remote control.

• Safety & Reliability:

• Advanced DSP control technology.

• LED status indicators.

Transformerless design with software and hardware protection.

• Uses the latest high-efficiency power component.

• Protection class IP65.

• Export limitation (CT/Meter/DRM0/ESTOP).

• LCD display technical data, human-machine interaction through four

Machine Translated by Google

Working mode

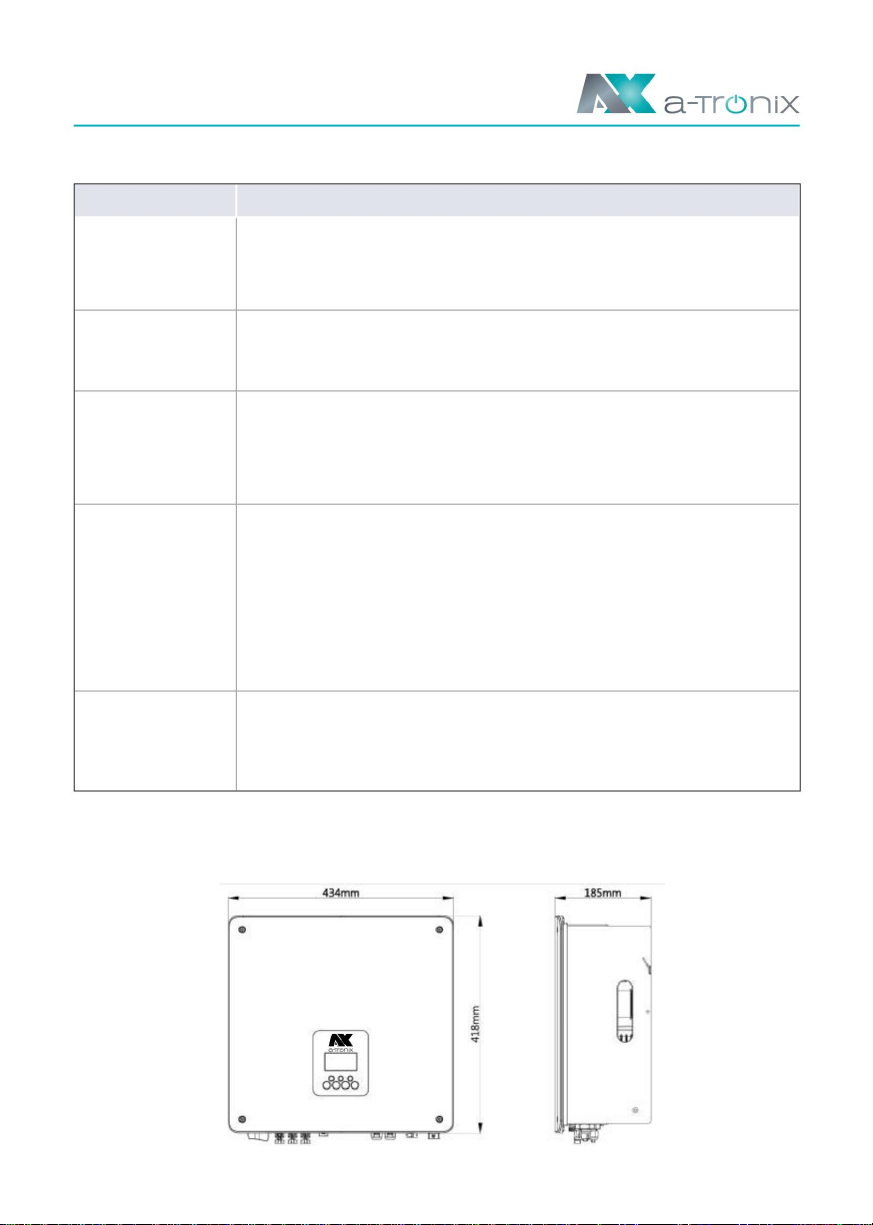

3.2 Dimensions

If there is no PV feed-in, the battery first discharges for local

loads. The battery is charged when an excess of electricity

from other generation sources is detected.

Priority: Load > Battery >

Grid The energy generated by the PV system is used to

optimize self-consumption. The excess energy is used to

charge the batteries and then exported to the grid.

Working mode description

When the grid is off, the system supplies emergency power from

the PV system or battery to power the loads in the house (the

battery is required in EPS mode).

Priority: Load > Grid > Battery

In the case of the external generator, the electricity generated is

first used to supply local consumers and then fed into the public

grid. The battery is charged with the redundant current.

Backup

Priority: Battery > Load > Mains (when charging)

mode

Priority: Load > Battery > Mains (when discharging)

This mode applies to the area in which the electricity price lies

between peak and trough. The user can use off-peak power to

charge the battery.

feed-in

priority

Own consumption

(with

time use

PV power)

force The charging and discharging time can be set flexibly, and you

can also choose whether to charge from the mains or not.

Own consumption

(without

PV power)

atx009de0823

Page 10

Machine Translated by Google

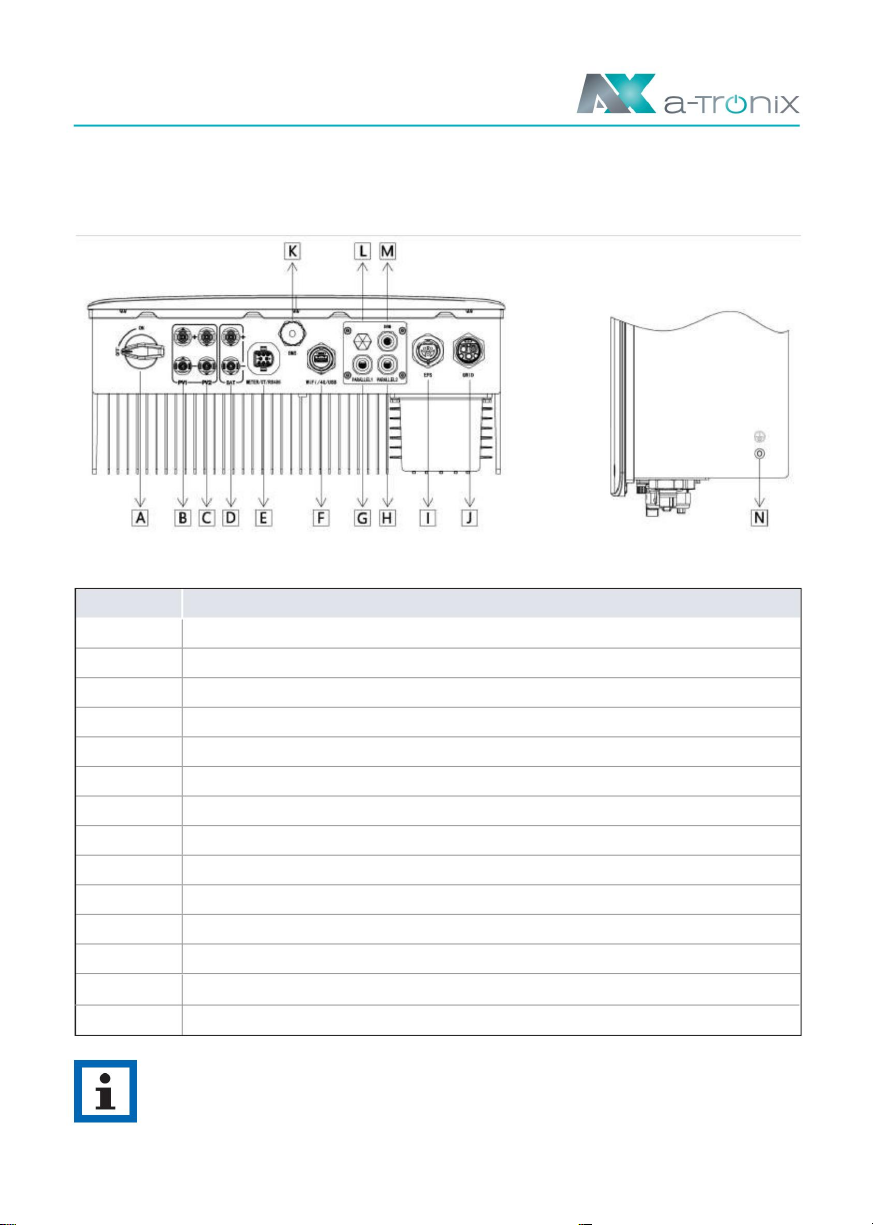

3.3 Inverter terminals

atx009de0823 Page 11

Description

EPS

G

DC switch (only for hybrid)

GRID

PV1 (Only for Hybrid)

H

I

Article

PV2 (Only for Hybrid)

Waterproof lock valve

J

Battery connections

DRM

Measuring device / CT / RS485

Grounding screw

L

M

PARALLEL 1

N

PARALLEL 2

D

A NOTICE:

Only authorized personnel are allowed to establish the connection.

E

A

F

K

b

WiFi/4G/USB

C

BMS

Machine Translated by Google

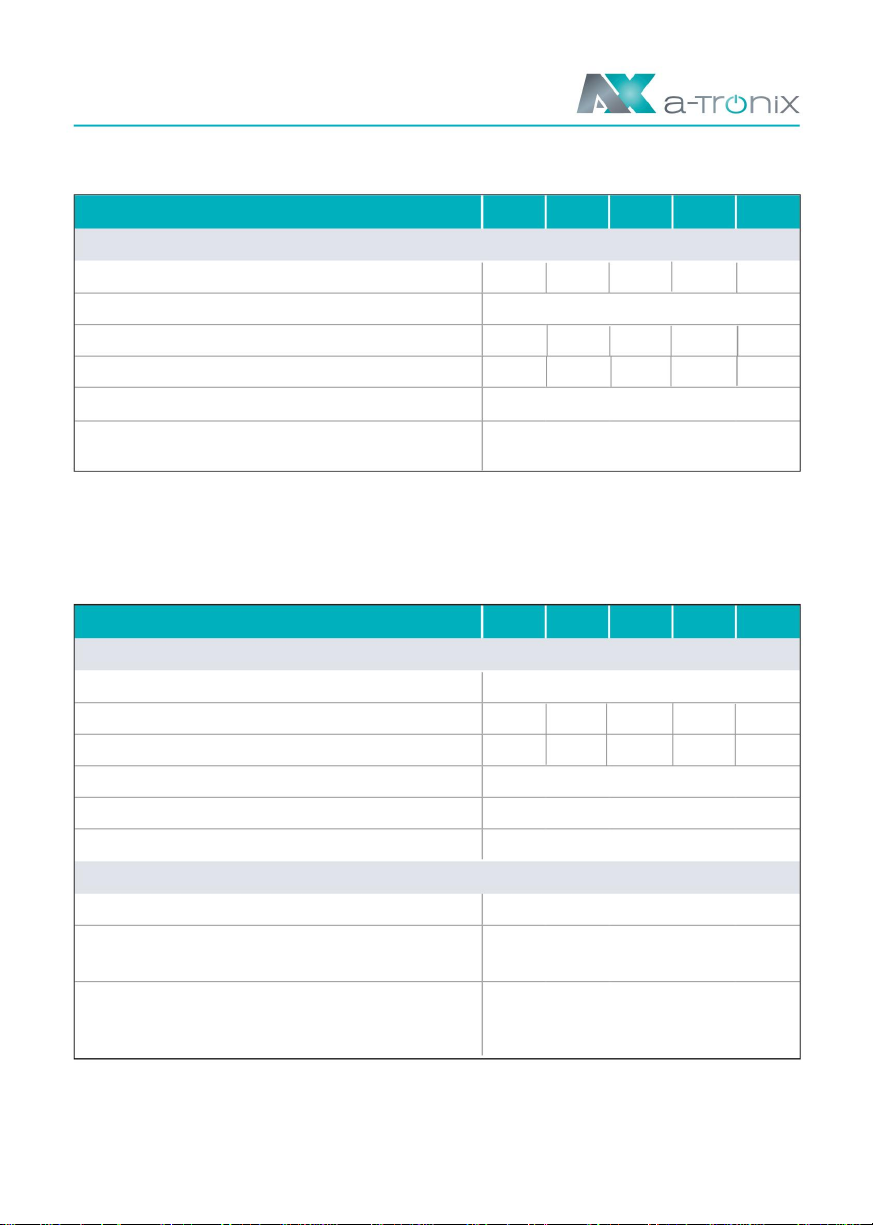

Model AX, 1ph

battery

PV

Model AX, 1ph

Max. DC voltage [V]

20/20

Operating temperature [°C]

360

Max. input current (input A / input B) [A]

80-550

Battery voltage range [V]

Yes

Max. regenerative current of the inverter

2

Battery type

Max. charging current [A]

-20 ~ +50

MPPT voltage range [V]

Optional

LFP

CAN/RS485

Max. recommended DC power [W]

16/16

Strings per MPP tracker

300Vdc

Reverse polarity protection

Nominal DC operating voltage [V]

0

600

40

Storage temperature [°C]

Max. short-circuit current (input A / input B) [A]

100

Recommended battery voltage [V]

-10 ~ +50

to array [mA]

1

Max. discharge current [A]

Switch-on voltage [V]

Number of MPP trackers

80-480

Communication interfaces

DC switch

40

Operating instructions

a-TroniX inverter AX series, 1ph

3kW 3.7kW 4.6kW 5kW 6kW

3kW 3.7kW 4.6kW 5kW 6kW

4. Technical data

4.1 PV input (only for hybrid)

4.2 Battery

A:2250

B:2250

75005500 A:3750A:2750 B:3750B:2750

9000

6900 A:4500

A:3450 B:4500

B:3450

4500

page 12 atx009de0823

Machine Translated by Google

4.3 AC output/input

AC rated power [VA]

Maximum

Max. AC power [VA]

3000

20.9

15.0

47.7

6000

45.5 54.5

3680

Nominal mains frequency [Hz]

9.6A@50us

Output overcurrent protection [A]

7680

4600

Max. AC current [A]

36.7

25.0

Total harmonic distortion

9200

5000

Max. output residual current [A]

0.8 leading to 0.8 lagging

10000

Max. AC apparent power [VA]

6000

50 / 60, ±5

13.6

35

Max. AC current [A]

12000

3300

Nominal mains voltage

(AC voltage range) [V]

23.0

16.7

57.4

27.3

4048

AC rated current [A]

130A@ 10us

22.7

Displacement power factor

34.9

AC inrush current [A]

45.8

27.3

(THDi, nominal power)

41.8

5500

220 / 230 / 240 (180 to 270)

<3%@ rated power

6600

18.4 30

AC INPUT

Model AX, 1ph

AC OUTPUT

6kW

3kW 3.7kW 4.6kW 5kW

4600

Page 13

atx009de0823

Machine Translated by Google

4.4 EPS output

4.5 Efficiency and Protection

3kW 3.7kW 4.6kW 5kW 6kW

3kW 3.7kW 4.6kW 5kW 6kW

Page 14 atx009de0823

Model AX, 1ph

Model AX, 1ph

EPS OUTPUT (WITH BATTERY)

EFFICIENCY

DEFAULT

(THDv, linear load)

<10

G99 / EN50549-1 / CEI 0-21 /

3680 4600

27.3

96.30% 96.33%

EMC

3000

22.7

97.08% 97.08%

EPS nominal voltage [V], frequency [Hz] 220/230/240VAC, 50/60

3600

Euro efficiency

97.04%

EN 62109-1/ EN 62109-2

6000

Max. EPS current [A]

Total harmonic distortion

97.00%

IEC EN 61000-6-3/IEC EN 61000-6-4

16.7

<2%@ rated power

95.26% 95.70%

Max. battery charging power (PV to BAT) (@full load)

VDE-AR-N 4105 and so on

6000

20.9

96.23%

Standby consumption [W]

Certification

Max. EPS power [VA] 5000

<20ms

MPPT efficiency

97.01% 97.08%

Security

EPS peak power (60s) [W] 4400 5500

13.6

MPPT efficiency

98.50%

IEC EN 61000-6-1/ IEC EN 61000-6-2/

7200

99.90%

Switching time [s]

Max. Battery Discharge Power (BAT to AC) (@Full Load)

Machine Translated by Google

4.6 General data

Altitude [m]

Storage temperature [°C]

Naturally

Ingress protection

Noise emission (typical) [dB] Overvoltage

category

Not isolated

Protection class

0% ~ 100 (non-condensing)

Cooling concept Art

LCD, app, website

<2000

Inverter topology

IP65 (for outdoor use)

WLAN / LAN / 4G /GPRS (optional),

I

<35

Dimensions (W x H x D) [mm]

DRM, USB, CT

III (AC), II (DC)

Net weight [kg]

communication

Humidity [%]

LCD display

434*418*185

22

-40 ~ +70

Model AX, 1ph

MEASURES AND WEIGHT

AMBIENT LIMIT

3kW 3.7kW 4.6kW 5kW 6kW

Operating temperature range d. Inverter [°C] -25 ~ +60 (derating at +45°C)

atx009de0823 Page 15

Machine Translated by Google

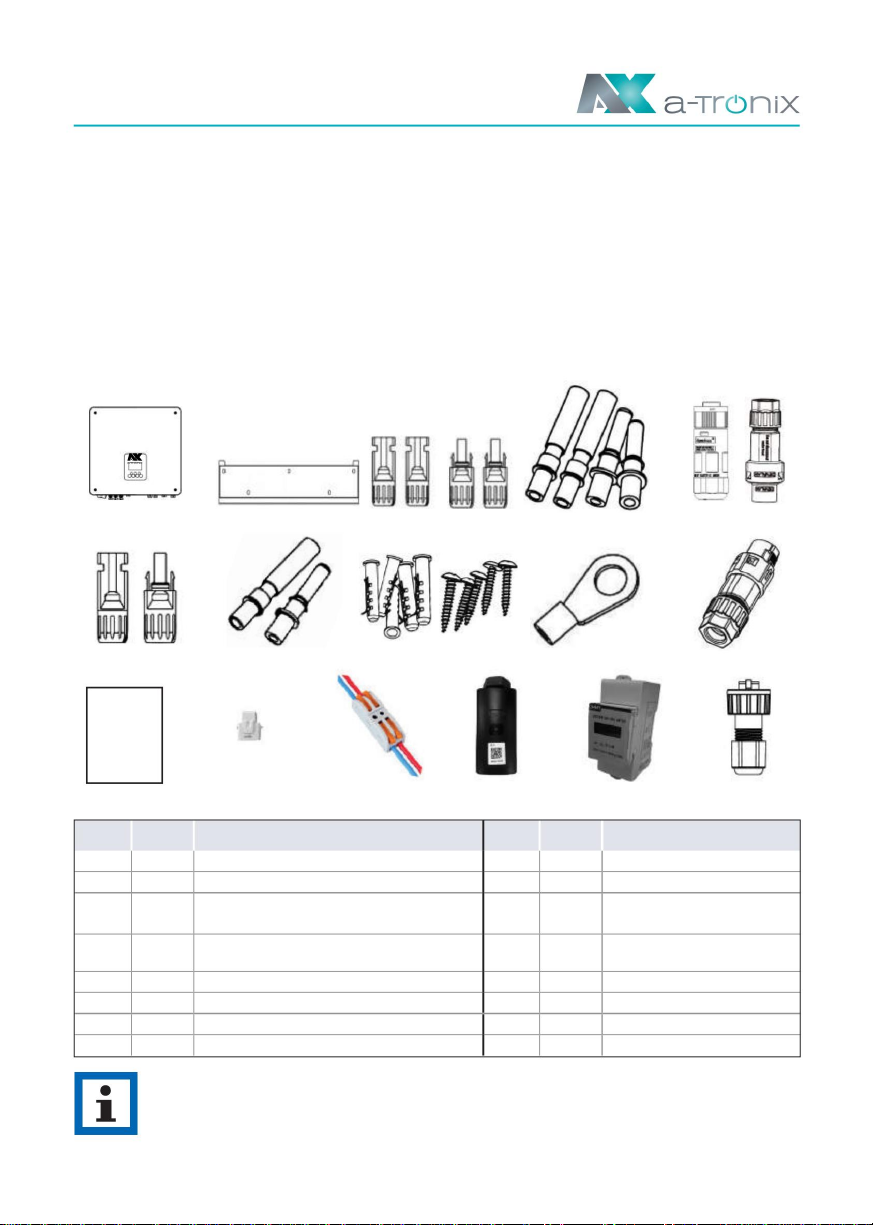

C

K

A NOTICE:

D

L

Only use the components included in the scope of delivery

E

M

Installation.

F

N

If there is visible damage, such as: B. Cracks, please contact your dealer immediately.

G

O

H

P

Open the package and take out the product, please check the accessories first. The packing list is shown below.

IJ

A b

Page 16 atx009de0823

Battery connections (1*positive, 1*negative)

PV pin contacts (only for hybrid)

(2*positive, 2*negative)

Measuring device (optional)

CT extension plug

Installation Guide

5. Installation

Expansion tubes & expansion screws

Quick installation guide

Object quantity description

CT (with 10m cable)

Ground connection

Object quantity description

Communication port

Brackets

AC connections

Inverter

PV connections (only for hybrid)

(2*positive, 2*negative)

RJ45

5.2 Packing list

5.1 Check for physical damage

Make sure that the inverter was undamaged during transport.

1

1

A

2

1

E

L

Battery pin contacts (1*positive, 1*negative) O

I

G

1

N

K4

4

P

1

21 WLAN / LAN / 4G (Optional)

b

D

5

1

F

M

J

C

H

1

1

1

2

Machine Translated by Google

• The wall on which the inverter hangs should meet the following conditions:

300300

mmmm

is not enough (e.g. wooden wall, wall covered with a thick decorative layer).

B. The inverter needs to be supported or reinforced if the strength of the wall

5.3 Assembly

atx009de0823 Page 17

No SunlightImpact of rain No Impact of rain

Not a direct one snow formation

snow formationSunlight Direct

Space requirements

Installation precautions

• Not directly in cool air

• Not higher than approx. 2000m above sea level

• Not in direct sunlight

• The slope of the wall should be within +5*

A. Solid brick/concrete or equivalent mounting surface;

• Not in an environment with precipitation or high humidity (>95%)

• Not in areas where highly flammable materials are stored

Please avoid direct sunlight, rain and snow during installation and operation.

• Under good ventilation conditions

• Not in potentially explosive areas

• Away from the TV antenna or antenna cable

• The ambient temperature ranges from -25°C to +60°C.

Make sure the installation location meets the following conditions:

position Minimum distance

Left

Below 300mm

front

Right

300mm

300 300 300mm

300mm

Above

mm 300mm

mm

Machine Translated by Google

Step 1. Attach the bracket to the wall • Select the

location where you want to install the inverter. Attach the bracket

to the wall and mark the position of the 5 holes in the bracket.

Page 18 atx009de0823

Assembly steps

Tools required for installation: • Hand

screwdriver; • Electric

drill (8mm drill set); • Crimping pliers; wire

stripper; Screwdriver.

be provided.

Installation angle requirements: • Do not tilt

the energy storage unit forward, horizontally, upside

down, backwards or sideways.

Installation space requirements: • When

installing the energy storage device, ensure that there are no other devices,

flammable and explosive materials nearby, and reserve enough space to meet

the heat dissipation and safety insulation requirements of the installation fulfill. •

When mounting on the wall, no objects may be

placed under the energy storage unit.

• Drill the holes with an electric drill, make sure the holes are at least 50mm deep,

and then tighten the expansion tubes.

Machine Translated by Google

atx009de0823 Page 19

• Insert the dowels into the holes and tighten them.

2. Adjusting the inverter to the wall mount • Hang the inverter over

the mount, lower the inverter slightly and make sure that the 2 mounting rods on

the back are properly secured in the 2 grooves of the mount.

Assemble the bracket with the screws.

Machine Translated by Google

6. Electrical connection

A NOTICE

WARNING

NOTE PV

modules:

Please ensure that they are of the same type, have the same performance and

specifications, are oriented identically and are tilted at the same angle. To save cables

and reduce DC losses, we recommend installing the inverter as close to the PV

modules as possible.

Please choose a suitable external DC switch if the inverter does not have a built-in

DC switch.

• The voltage of the PV modules is very high and is in a dangerous voltage range.

Please observe the electrical safety rules when connecting.

• Please do not connect PV positive or negative to ground!

6.1 PV connection (only for hybrid)

Step 1: PV string connection

The AX 1ph series inverters can be connected to 2 strings of PV

modules. Please choose suitable PV modules with high reliability

and quality. The open circuit voltage of the connected module array

should be less than 600V, and the operating voltage should be

within the MPPT voltage range.

atx009de0823

Page 20

Machine Translated by Google

This manual suits for next models

5

Table of contents

Other Atronix Inverter manuals

Popular Inverter manuals by other brands

Victron energy

Victron energy BlueSolar Series manual

Nibe

Nibe UKVS 230 Installation and maintenance instructions

MAER IDROPULITRICI

MAER IDROPULITRICI BYTURBO instruction manual

Victron energy

Victron energy MultiPlus 12/1600/70 manual

NXP Semiconductors

NXP Semiconductors UM11603 user manual

Haier

Haier SUPER MATCH AS35S2SF1FA-WH Service manual