Serviceanleitung_US2000V5_EN_V0.0.docx

BEDIENUNGSANLEITUNG Table of contents US-2000 (DCP 2000 V5)

1. Maintenance ................................................................................................... 4

1.1. Monthly maintenance ............................................................................................. 4

1.2. Cleaning of the band channel ................................................................................ 5

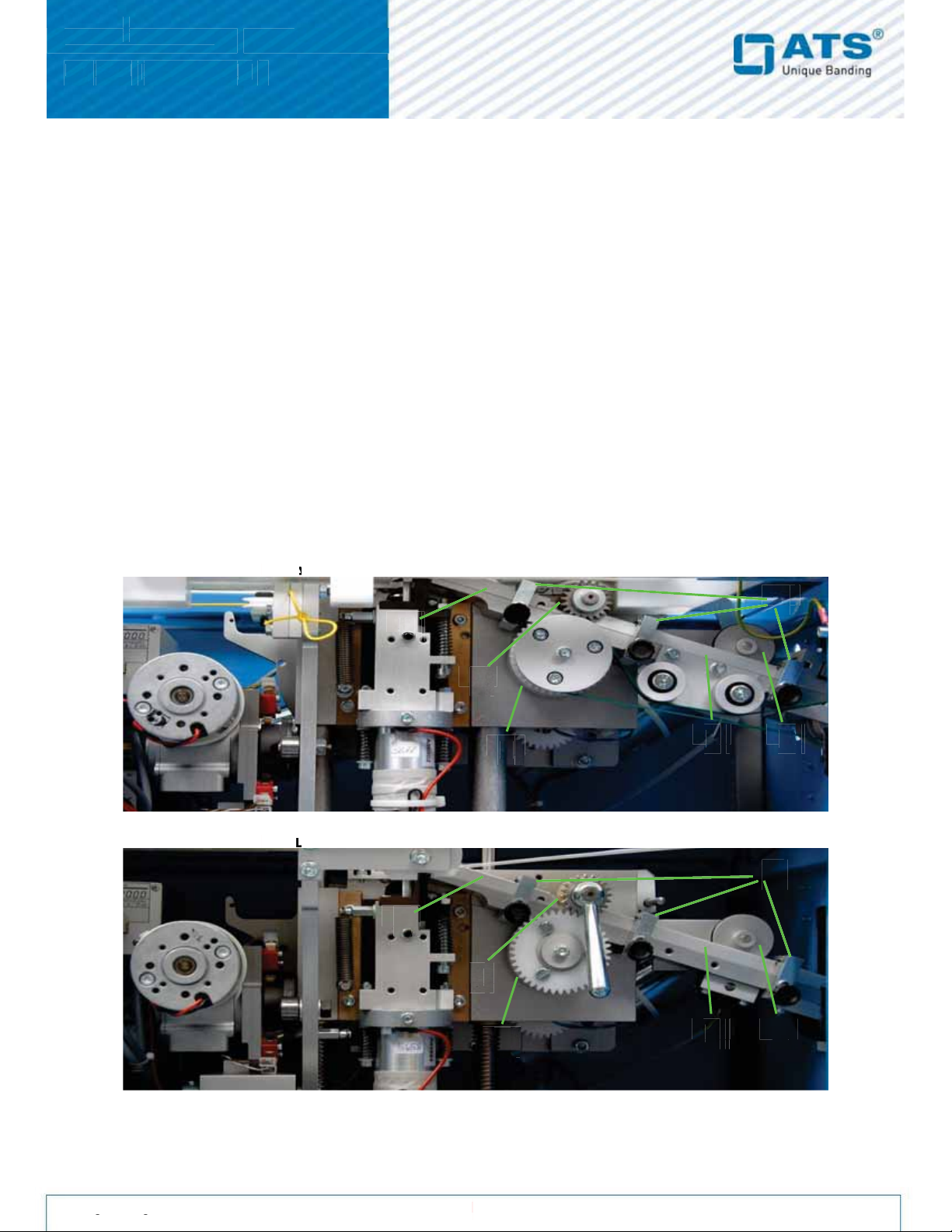

2. Mechanical settings ....................................................................................... 6

2.1. Rubber roller ............................................................................................................... 6

2.1.1. Adjusting the rubber roller pressure .....................................................................6

2.1.2. Replacing the rubber roller .................................................................................. 6

2.2. Encoder ................................................................................................................... 7

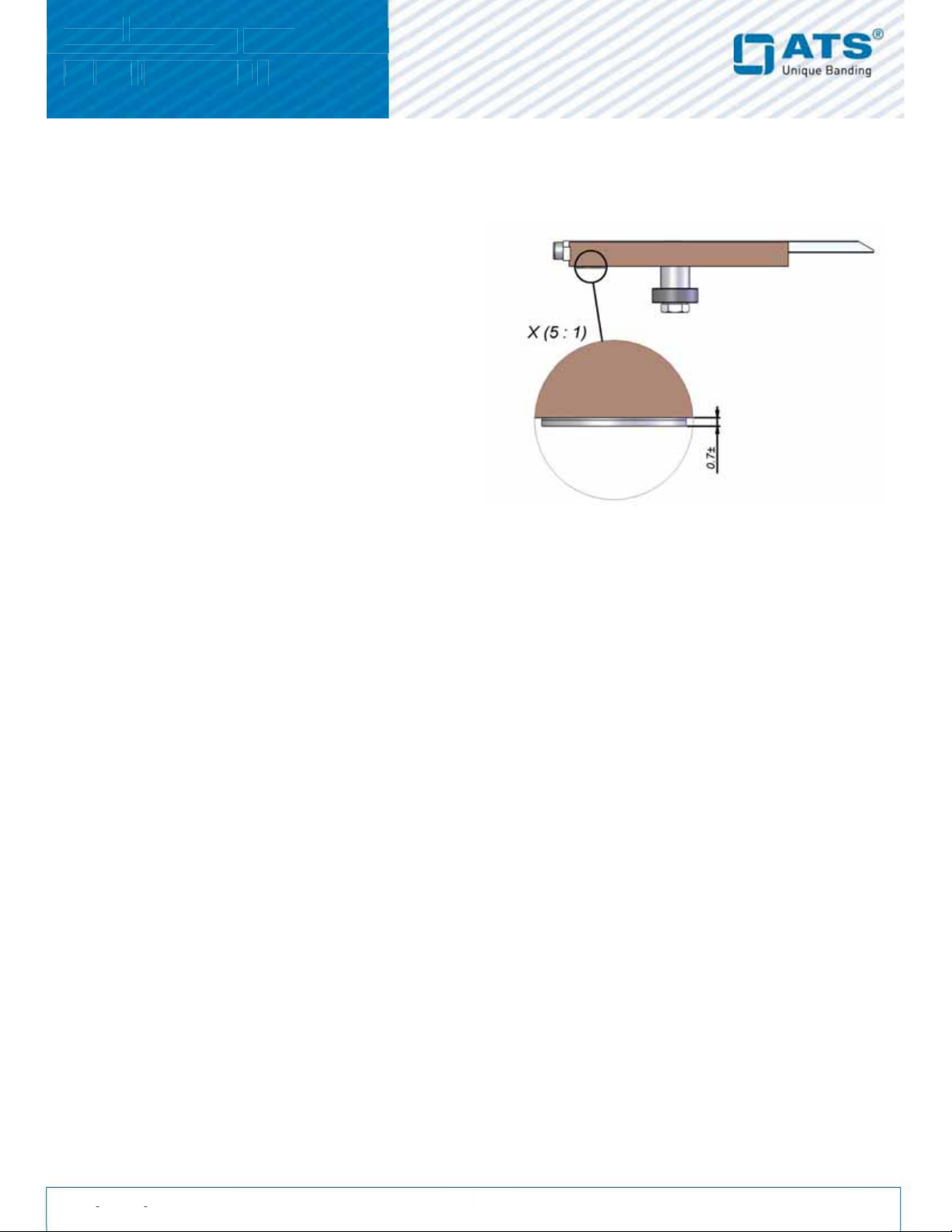

2.3. Anvil ........................................................................................................................ 7

2.3.1. Adjusting play of the Anvil .................................................................................. 7

2.3.2. Adjustment for a parallel weld ............................................................................ 8

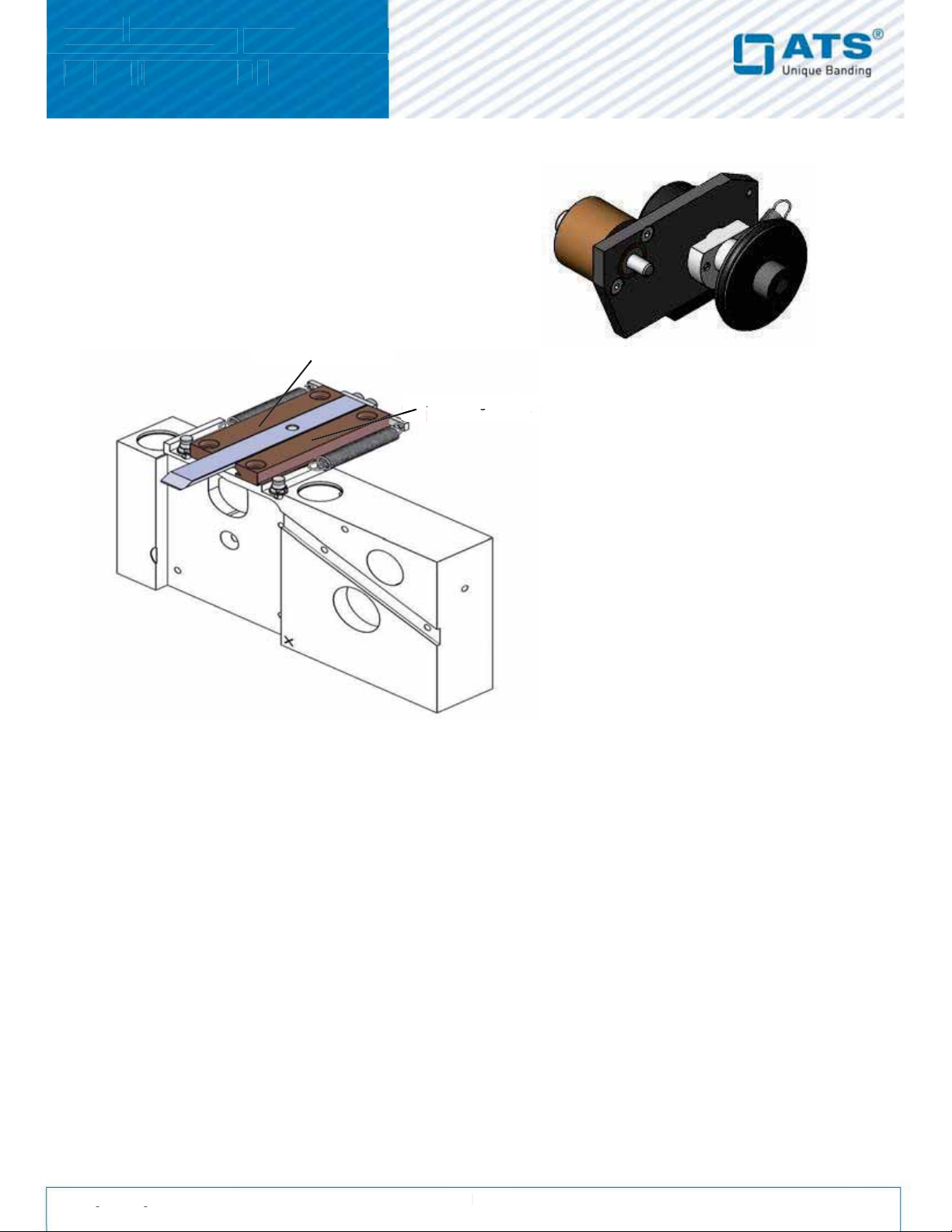

2.4. Sonotrode slide .................................................................................................... 8

2.4.1. Removing the sonotrode slide ............................................................................ 9

2.4.2. Mounting the sonotrode slide ............................................................................. 9

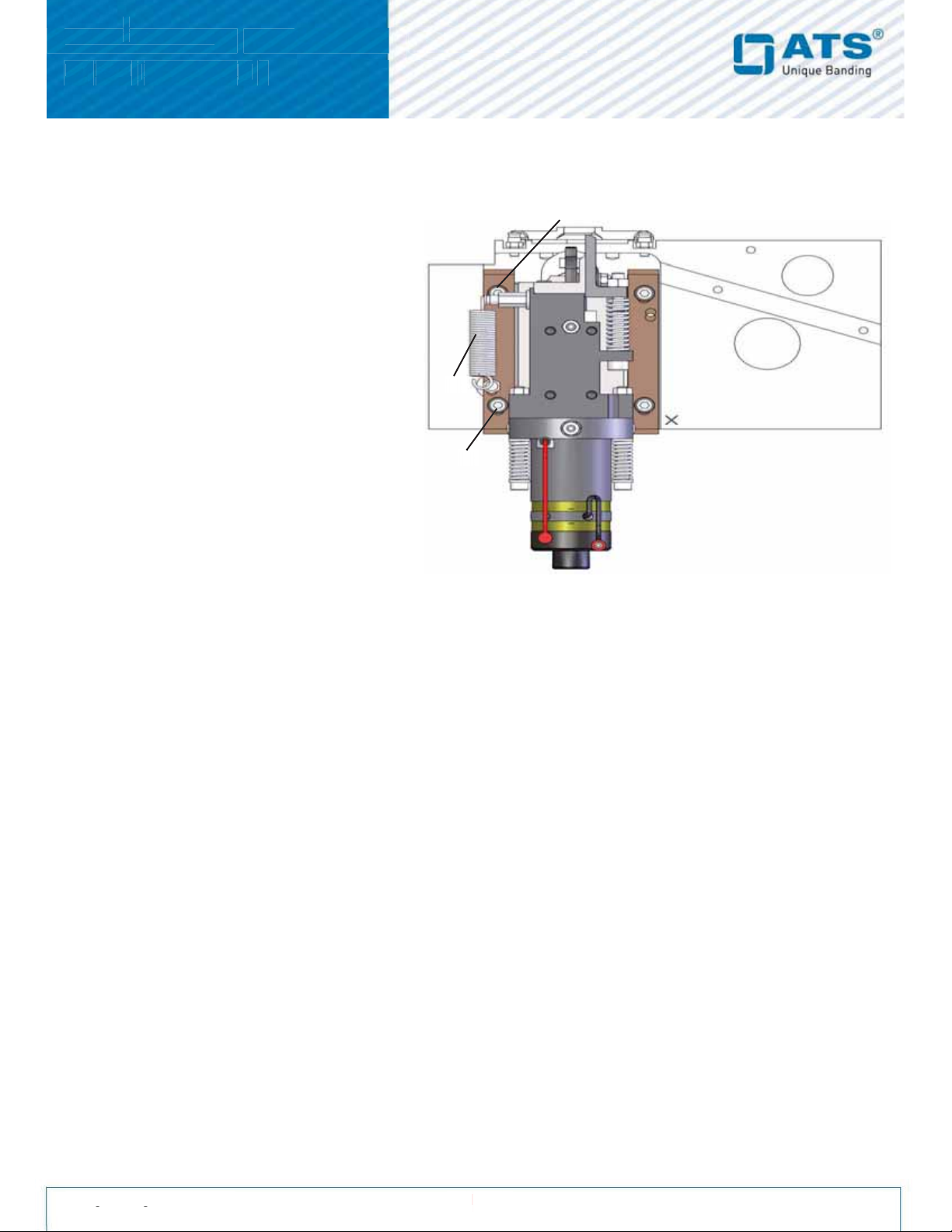

2.5. Sonotrode and generator ....................................................................................9

2.5.1. Removing the sonotrode ................................................................................... 10

2.5.2. Mounting the new sonotrode ..............................................................................10

2.5.3. Adjusting the generator ..................................................................................... 11

2.6. Cutter ...................................................................................................................12

2.6.1. Replacing the cutter ..........................................................................................12

2.6.2. Maintenance of the cutter ..................................................................................12

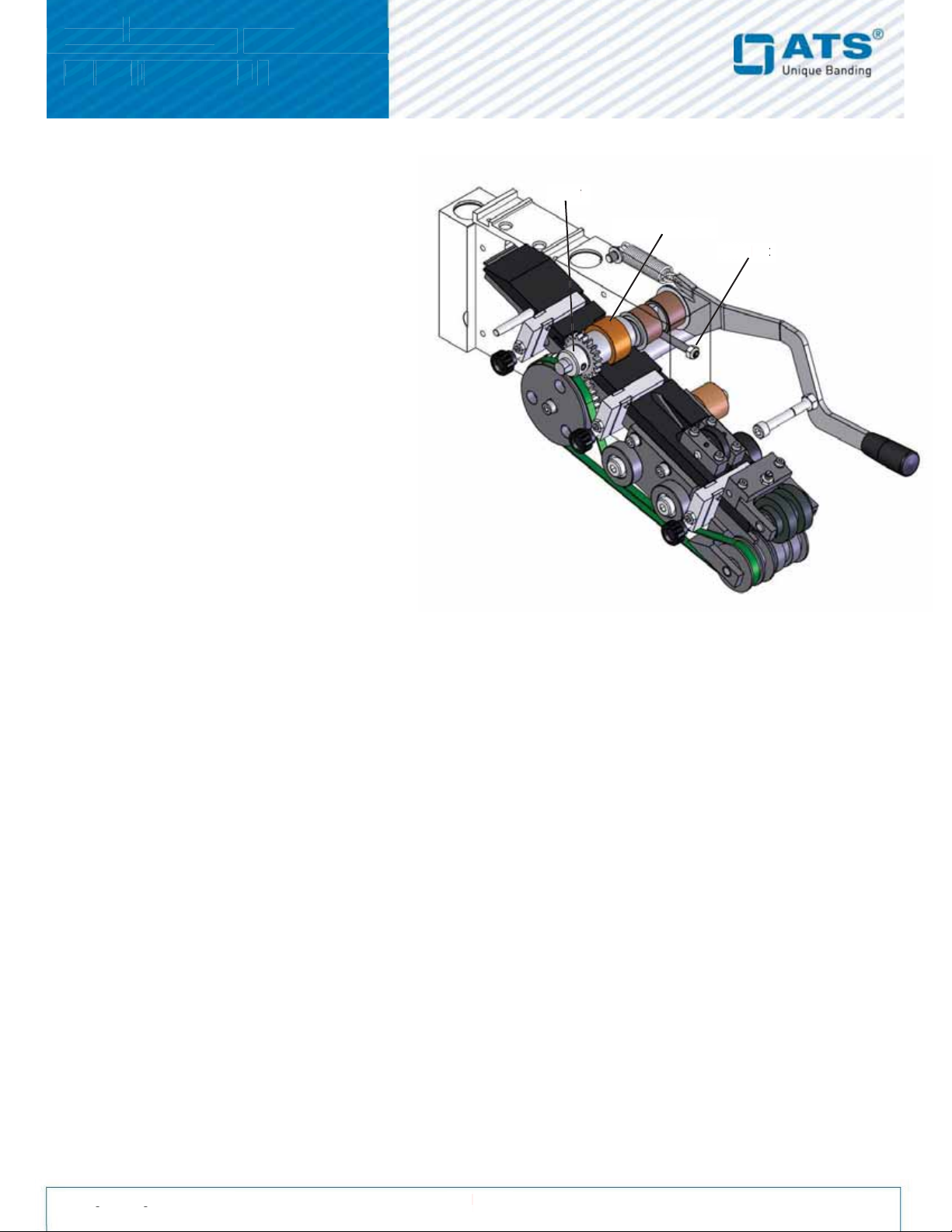

2.7. Aggregat Motor M1 ..............................................................................................13

2.7.1. Replacing the aggregatmotor ............................................................................13

2.7.2. M1 gear ratio .....................................................................................................13

2.8. Band Motor M2 .....................................................................................................14

2.8.1. Replacing the bandmotor ..................................................................................14

2.8.2. M2 gear ratio .....................................................................................................14

2.9. Arch Motor M3 .....................................................................................................15

2.9.1. Removing the arch-motor .................................................................................15

2.9.2. Mounting the new arch-motor ...........................................................................15

2.9.3. M3 gear ratio .......................................................................................................15

2.10. Driving shaft .......................................................................................................16

2.10.1. Removing the driving shaft ................................................................................16

2.10.2. Adjusting the driving shaft (clutch/ brake) ..........................................................17

2.11. Arch-string (yellow cord) ...................................................................................18

2.11.1. Adjusting the arch-string....................................................................................18

2.11.2. Loop Cup Adjustment.............................................................................................................18

2.11.3. Ejection Pin Adjustment.....................................................................................19