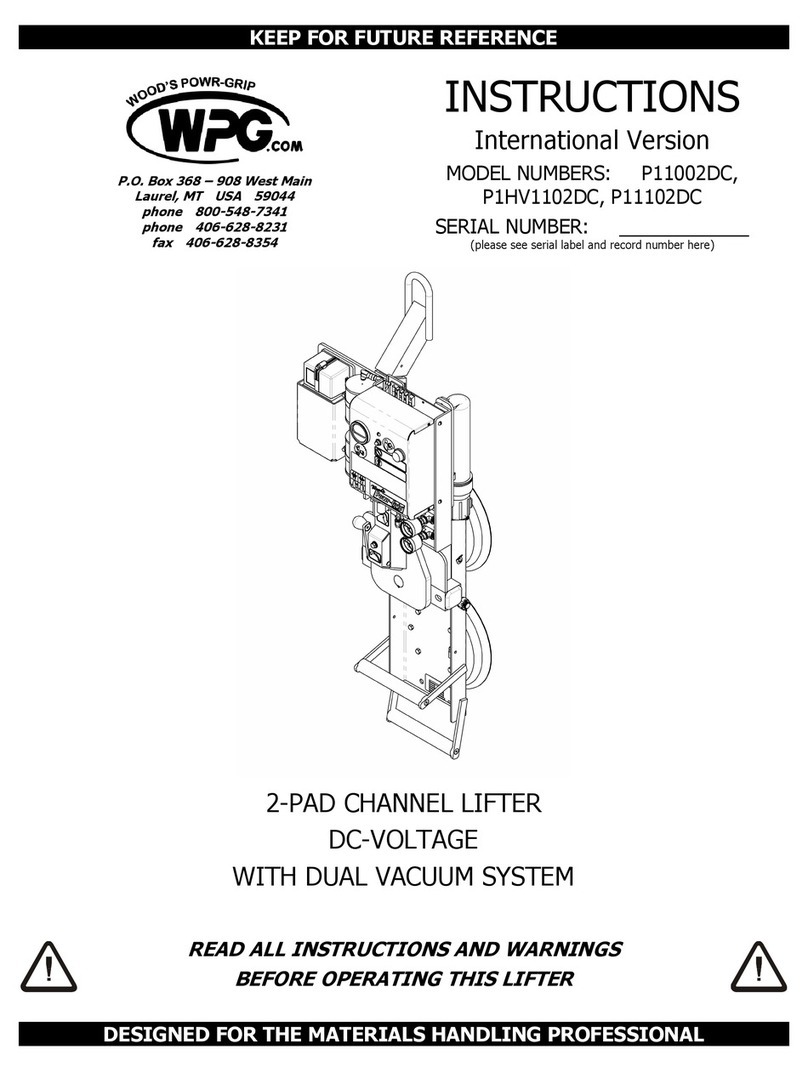

ATT NUSSBAUM SPRINTER MOBIL 2500 Installation instructions

SPRINTER MOBIL 2500

SPRINTER MOBIL 3000

Serial No.:

Serien Nr.:

HYMAX PRO 2500

HYMAX PRO 3000

Made

in

Germany

Operating manual | Inspection book

Betriebsanleitung | Prüfbuch

012

2SPRINTER MOBIL - HYMAX PRO 05.11.2015 20110005 OPI

is a brand of Otto Nußbaum GmbH & Co. KG

20110005 OPI 05.11.2015 SPRINTER MOBIL - HYMAX PRO 3

Contents Page

ENGLISH

1 Introduction______________________________ 5

2 General information ______________________ 6

2.1 Set up and test the system. _____________________6

2.2 Hazard information ____________________________6

3 Safety regulations ________________________ 6

3.1 Safety inspection ______________________________7

4 Assembly and commissioning_____________ 7

4.1 Set up guidelines ______________________________7

4.2 Commissioning ________________________________7

4.3 Changing the assembly location _______________8

4.4 Selecting the anchors __________________________9

4.5 Assembly ______________________________________9

5 Operating manual_______________________ 10

5.1 Lifting the vehicle ____________________________ 11

5.2 Lowering the vehicle_________________________ 11

6 Maintenance and care of the

system__________________________________ 12

6.1 System maintenance plan ___________________ 12

6.1.1 As required or visible damage ________________ 12

6.1.2 Maintenance 1 x per year____________________ 12

6.1.3 Maintenance every 2 years __________________ 13

6.1.4 Maintenance every 6 years __________________ 14

6.2 Cleaning and care of the system _____________ 14

6.3 Cleaning and care of stainless steel___________ 14

7 Behavior in cases of error ________________ 16

7.1 Moving onto an obstacle ____________________ 17

7.2 Emergency discharge during blackout________ 17

8 Technical information____________________ 18

8.1 Technical data ______________________________ 18

8.1.1

SPRINTER MOBIL 2500 - HYMAX PRO 2500 ________18

8.1.2

SPRINTER MOBIL 3000 - HYMAX PRO 3000 ________18

8.2 Safety devices_______________________________ 18

9 System master sheet_____________________ 19

9.1 Manufacturer________________________________ 19

9.2 Purpose _____________________________________ 19

9.3 Changes to the design / construction_________ 19

9.4 Changing the assembly location _____________ 19

10 Data sheet ______________________________ 20

11 Hydraulic plan __________________________ 21

12 Spare parts lists__________________________ 22

12.1

SPRINTER MOBIL 2500 - HYMAX PRO 2500 ________22

12.2 SPRINTER MOBIL 3000 - HYMAX PRO 3000 ______ 29

13 Set up protocol__________________________ 36

13.1 Transfer protocol_____________________________ 37

14 Safety inspection ________________________ 38

14.1 Single safety inspection before commissioning 38

14.2 Regular safety inspection and maintenance __ 39

14.3 Exceptional safety inspection ________________ 40

15 Electrical circuit diagram ________________ 77

15.1 230 V 1~/PE__________________________________ 79

15.2 230 V 3~/PE__________________________________ 83

15.3 230 V 3~/PE | 400 V 3~/PE ____________________ 87

15.4 400 V 3~/PE__________________________________ 91

15.5 400 V 3~/PE CE-STOP _________________________ 95

15.6 400 V 4-pole main switch ____________________ 101

16 Declaration of conformity _______________ 105

16.1 SPRINTER MOBIL_____________________________ 105

16.2 HYMAX PRO ________________________________ 106

4SPRINTER MOBIL - HYMAX PRO 05.11.2015 20110005 OPI

Inhalt Seite

DEUTSCH

1 Einleitung _______________________________ 41

2 Allgemeine Information__________________ 42

2.1 Aufstellung und Prüfung der Anlage __________ 42

2.2 Gefährdungshinweise________________________ 42

3 Sicherheitsbestimmungen________________ 42

3.1 Sicherheitsüberprüfung_______________________ 43

4 Montage und Inbetriebnahme ___________ 43

4.1 Aufstellungsrichtlinien ________________________ 43

4.2 Inbetriebnahme _____________________________ 44

4.3 Wechsel des Aufstellungsortes ________________ 44

4.4 Auswahl der Dübel___________________________ 45

4.5 Montage____________________________________ 46

5 Bedienungsanleitung ____________________ 46

5.1 Anheben des Fahrzeuges ____________________ 47

5.2 Senken des Fahrzeuges ______________________ 47

__________ 48

6.1 Wartungsplan der Anlage ____________________ 48

6.1.1 Bei Bedarf oder sichtbarer Beschädigung _____ 48

6.1.2 Wartung 1 x jährlich __________________________ 48

6.1.3 Wartung alle 2 Jahre _________________________ 50

6.1.4 Wartung alle 6 Jahre _________________________ 50

_____________ 50

___________ 51

7 Verhalten im Störungsfall_________________ 52

7.1 Auffahren auf ein Hindernis___________________ 52

7.2 Notablass bei Stromausfall____________________ 53

8 Technische Information __________________ 54

8.1 Technische Daten ___________________________ 54

8.1.1

SPRINTER MOBIL 2500 - HYMAX PRO 2500 ________54

8.1.2

SPRINTER MOBIL 3000 - HYMAX PRO 3000 ________54

8.2 Sicherheitseinrichtungen _____________________ 54

9 Stammblatt der Anlage __________________ 55

9.1 Hersteller ____________________________________ 55

9.2 Verwendungszweck _________________________ 55

9.3 Änderungen an der Konstruktion _____________ 55

9.4 Wechsel des Aufstellungsortes ________________ 55

10 Datenblatt ______________________________ 56

11 Hydraulikplan ___________________________ 57

12 Ersatzteillisten ___________________________ 58

12.1

SPRINTER MOBIL 2500 - HYMAX PRO 2500 ________58

12.2 SPRINTER MOBIL 3000 - HYMAX PRO 3000 ______ 65

13 AufstelIungsprotokolI ____________________ 72

13.1 Übergabeprotokoll___________________________ 73

14 Sicherheitsprüfungen ____________________ 74

14.1 Einmalige Sicherheitsprüfung vor Inbetriebnahme

_____________________________________________ 74

14.2 Regelmäßige Sicherheitsprüfung und Wartung 75

14.3 Außerordentliche Sicherheitsprüfung _________ 76

15 Elektroschaltplan ________________________ 78

15.1 230 V 1~/PE__________________________________ 79

15.2 230 V 3~/PE__________________________________ 83

15.3 230 V 3~/PE | 400 V 3~/PE ____________________ 87

15.4 400 V 3~/PE__________________________________ 91

15.5 400 V 3~/PE CE-STOP _________________________ 95

15.6 400 V 4-pol. Hauptschalter __________________ 101

16 Konformitätserklärungen________________ 105

16.1 SPRINTER MOBIL_____________________________ 105

16.2 HYMAX PRO ________________________________ 106

ENGLISH Translation

1 Introduction

Nußbaum products are a result of many years

of experience. A high quality standard and su-

perior concept guarantees you reliability, long

lifetimes and economical operation. To prevent

unnecessary damage and hazards, read this ope-

rating manual carefully and always comply with its

contents.

!Any other use, or use beyond purpose is

considered improper.

!Otto Nußbaum GmbH & Co.KG is not liable for

any resulting damage. The operating compa-

ny alone carries the risk.

Proper use also includes:

Adherence to all instructions in this operating

manual.

Compliance with inspection and maintenance

work and the inspections stipulated.

The operating manual is to be followed by all

personnel working on the system. This is notably

with regards to Section 3 „Safety conditions.“

In addition to safety information from the

operating manual, comply with rules and regula-

tions at the location of use.

Proper system handling.

Operating company obligations:

The operating company is obliged to only permit

personnel to work on the system who

Understand the principle regulations about work

safety and accident prevention and who have

been trained in working with the system.

Have read the safety section and warning infor-

mation in this operating manual, have under-

Hazards in working with the system:

Nußbaum products have been designed and

built to state-of-the-art and to recognized safety

standards. However, improper use may lead to

hazards to life and limb of the user or result in

property damage.

The system may only be operated

For proper intended use

If it is technically in perfect condition

Organizational measures

The operating manual is always to be kept ready

at the location of use of the system.

Supplemental to the operating manual, refer to

and comply with generally valid legal and other

binding regulations for accident prevention and

for environmental protection.

Check occasionally that personnel have an

awareness of hazards and safe work in compli-

ance with the operating manual!

Use personal protective equipment as needed

or required by regulations.

All safety and hazard information on the system

is to be kept in a legible condition!

-

cations of the manufacturer. This is only guaran-

teed for original parts.

Deadlines pre-set or given in the operating

manual for repeating tests / inspections must be

followed.

Maintenance work, error removal

Comply with pre-determined setting, main-

tenance and inspection work and intervals

in the operating manual, including details for

may only be done by specialists who have parti-

cipated in a special factory training.

Guarantee and liability

In principle, our „General sales and supply con-

ditions“ apply.

Guarantee and liability claims for personal and

property damage are excluded if due to one or

more of the following causes:

Improper use of the system.

Improper assembly, commissioning, operation

and maintenance of the system.

Operating the system with defective safety de-

vices or improperly attached or non-functional

safety and protection devices.

Non-compliance with information in the

operating manual in terms of transport, storage,

assembly, commissioning, operation, mainte-

Independent construction changes to the sys-

tem.

Independent changes to the system (e.g. drive

ratios: power, rotation speed, etc.)

6SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

Improperly done repairs.

force majeure.

2 General information

Technical documentation contains important in-

formation for safe operation and for retaining

functional safety of the system.

To verify system set up, the set up protocol form is

to be signed and sent to the manufacturer.

Forms are available in this inspection book for

use in verifying single, regular and extraordina-

ry safety checks. Use the forms to document in-

spections and leave the completed forms in the

inspection book.

The system master forms must record changes to

the construction and changes to set up location.

2.1 Set up and test the system.

Safety relevant work on the system and safety

inspections may only be done by personnel speci-

in general and in this documentation as technical

experts and specialists.

Technical experts are people (freelance expert

engineers, TÜV specialists) that may inspect and

assess due to their education and experience

with lift systems. They are knowledgeable in the

appropriate work safety and accident preventi-

on regulations.

Specialists (competent people) are people who

lift systems and have participated in a special

factory training by the system manufacturer.

2.2 Hazard information

To become aware of the hazardous points and

important information, the following three symbols

are used with the descriptive meaning. Pay parti-

cular attention to text positions that are labeled by

these symbols.

iNote! Labels information about a key function

or points to an important remark!

!

damage or other operating company property

damage if the highlighted process is not done

properly!

Danger !

and limb, if the highlighted process

is not done properly there is a mortal

danger!

3 Safety regulations

When working with systems comply with legal

accident prevention regulations according to

BGG 945, inspection of lifts; BGR 500 and operation

of systems; VBG 14.

Particular attention is drawn to compliance with the

following regulations:

When operating the system, follow safety regula-

tions and operating instructions in the operating

manual.

The total weight of the accepted load may not

exceed

- 2,500 kg for SPRINTER MOBIL 2500 - HYMAX PRO

2500 and

- 3,000 kg for SPRINTER MOBIL 3000 - HYMAX PRO

3000,

where a maximum load distribution of 3:2 or 2:3

in or against the drive-in direction is permitted.

Only personnel aged 18 or over may operate

systems independently, they must be trained in

the company. They must be explicitly tasked with

operating the system (excerpt from BGR 500),

see transfer protocol.

Operation of the system is only permitted on a

smooth, solid surface.

During lifting or lowering, the work area of the

system should be clear or people.

It is prohibited from moving people with the lift.

It is prohibited to climb onto the system.

After design and maintenance on load bearing

parts the system must be inspected by a techni-

cal expert.

Initial access into the system may only be done

after the main switch (2) is off and locked.

equipment, check in advance whether it could

be damaged.

Consider any possible centre of mass shifts when

disassembling heavy vehicle components.

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 7

3.1 Safety inspection

The safety inspection is required to guarantee

operational safety of the lift system. It is to be done:

lift system use the „single safety inspection“

form

least once per year.

Use the „regular safety inspection“ form

3. After changes to the lift system construction

Use the „extraordinary safety inspection“ form

!Single and regular safety inspections must be

done by a specialist. It is recommended to do

maintenance at the same time.

iAfter a change in construction (for examp-

le changing the load carrying capacity or

changing the lifting height) and after signi-

(e.g. welding work), inspection by a technical

expert is required (extraordinary safety inspec-

tion)

This inspection book contains forms with a detailed

inspection plan for safety inspections. Please use

the appropriate form, record the condition of the

inspected system and leave the completed form

in this inspection book.

4 Assembly and commissioning

4.1 Set up guidelines

There is the option to anchor the lift on an exi-

concrete thickness min. 160 mm (normal rein-

forcement).

To protect the electrical cable all cable condu-

plastic pipes.

commissioning, the operating company must

have the lift grounding conductors inspected

on-site according to IEC regulation (60364-6-61).

An insulation resistance test is also recommen-

ded.

The anchoring of the lift must be carried out

by trained manufacturer personnel or a contract

partner. If the operating company has appropri-

ately trained assemblers, the system can also be

set up by them. Set up is to be done according

to the assembly instructions.

A standard system may not be set up in explosi-

on endangered spaces or wash halls.

Provide an on-site electrical connection of 3 ~/N

+ PE, 400 V, 50 Hz, fuses with 16 A, slow.

iThe foot bumper (15) must always be mounted

with the orange sticker (16) on the side where

the cylinder (17) is located.

15 Foot bumper 022

16 Orange sticker

17 Cylinder

18 Load capacity Sticker

4.2 Commissioning

iThe SPRINTER MOBIL - HYMAX PRO has been

inspected and accepted by Nußbaum. The

test need no longer be carried out by a speci-

alist before initial commissioning.

18 16

15 17

2

1

3

4

1 Cover hood

2 Main switch

3 "LIFT" button

4 "LOWER" button

8SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

- Remove the front cover hood (1)

- Loosen and remove the sealing screw (5) of the

oil tank

Fill new hydraulic oil (e.g. HLP 32). About 8 litres

are needed.

Provide an on-site electrical connection of 3 ~/N

+ PE, 400 V, 50 Hz, fuses with 16 A, slow.

Connect the electric cable to the customer-pro-

vided mains breaker (e.g. a Cekon plug).

003

Turn on main switch (2) and press the „LIFT“

button (3).

!If the lift does not move upwards after a few

seconds, the direction of rotation of the motor

is incorrect. Swap 2 phases on the plug.

Then press the „LIFT“ button (3) again and rai-

se and lower the lift to its limit positions several

times without load. This will largely ventilate the

hydraulic system.

4.3 Changing the assembly location

To operate the lift, it must be raised about

500 mm so that the back wheel axes (9) and

guide roller (6) can be engaged.

6 Guide roller 004

7 Torsion shaft

8 Towing bar

9 Wheel axles

Place the guide rollers (6) over the torsion shafts

(7). Then push them until the tappet (10) is

located in the notch (11) of the guide

roller.

6 Guide roller 005

10 Tappet 11 Notch

19 Guide roller holder

The wheel axles (9) are in the lower plate of the

lift (12).

9 Wheel axle 019

12 Wheel axle storage

iTo simplify mounting, it may be necessary to

raise or lower the lift a little.

Then lower the lift completely. Hang the tow

bar (8) into the guide roller (6) and the lift can then

be moved.

5

8

9

6

7

19

6

11

10

12

9

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 9

To remove the roller, follow the instructions in the

reverse order.

The mobile hand unit quickly makes the SPRINTER

MOBIL - HYMAX PRO ready to use again.

To change the setup location of an anchored lift,

the conditions according to the setup guidelines in

Section 4.1 must be ensured.

!Use new anchors. The old anchors are no lon-

4.4 Selecting the anchors

Safety anchor with threaded bolts and nuts

BM 10-15/70/40

Safety anchor with threaded bolts and nuts

High quality anchor FH II-B (bolts and nuts)

FH II 15/50 B

Heavy duty anchor

HSL-3-G M10/40

Heavy duty anchor

Hilti HIT-V-5.8/M10/130

iSimilar value anchors and other known brands

of anchor manufacturers can be used when

considering the conditions.

4.5 Assembly

iFollow the instructions enclosed in the anchor packaging.

011

10 SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

5 Operating manual

When handling the system, it must ab-

solutely comply with safety regula-

tions. Carefully read the safety regula-

To prevent operation by unauthorized

-

ter working height has been reached.

Operating element 007

2 Main switch

3 „LIFT“ button

4 „LOWER“ button

For SPRINTER MOBIL - HYMAX PRO lifts,

the motor of the vehicle supported

side, otherwise the vehicle could fall.

The total centre of mass of the

vehicle and its load must be between

bearing towards the middle of the lift,

otherwise the vehicle could fall.

Slowly drive the vehicle to the middle in both the

lengthwise and crosswise directions over the drive-

in rails.

Vehicle with front-wheel drive:

008

Vehicle with rear-wheel drive:

009

3

2

4

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 11

010

5.1 Lifting the vehicle

!Warning! The hydraulic lines may not be driven

over. This can lead to damage and, if leaks re-

sult, even to the lift sinking.

!The total centre of mass must be considered.

iIf required, use the ramps for safe acceptance

of the vehicle.

Secure the vehicle against rolling; pull the hand

brake, engage the gears.

Inspect the hazardous area.

No person or object may stand in the working

area of the lift, or on the lift.

Switch on controls. Turn the main switch (2) to

Position polymer overlays below the points spe-

overlays may not be placed on edge, otherwise

the vehicle could fall.

Lift the vehicle. Push the „LIFT“ (3) button.

If the wheels are not blocked, interrupt the lifting

process and check for proper seating of the po-

lymer overlays.

Raise the vehicle to the desired working height.

Then position the operating unit in such a way

hydraulic hose) cannot be damaged by external

5.2 Lowering the vehicle

!Warning! The hydraulic lines may not be driven

over. This can lead to damage and, if leaks re-

sult, even to the lift sinking.

Inspect the hazardous area. No person or object

may stand in the working area of the lift, or on the

lift.

!The vehicles cannot be lowered into the lowest

position without wheels. Otherwise the lift can-

not raise the load using its own force. The vehi-

cle could be damaged.

015

Lower the vehicle to the desired working height.

The system is equipped with an optional CE-STOP

During „LOWER“ (4) to the lowest position, the

system stops at a height of 300 mm.

To allow the system to lower further, it is necessa-

ry to release the „LOWER“ button (4) and press it

again.

A signal tone sounds until the system has rea-

ched the lowest position.

The entire lowering process must be observed.

If the lift is in the detectable lowest position, re-

move the polymer overlays and drive the vehicle

from the lift.

12 SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

6 Maintenance and care of the

system

Before maintenance, do all prepara-

tion work so there is no danger to life or

limb or object damage during mainte-

nance and repair work.

Value is placed on long lifetimes and safety in

the development and production of Nußbaum

products. To guarantee the safety of the opera-

tor, product reliability, low running costs, keep the

warranty and also the long-lifetime of the product,

proper set up and operation is just as important as

of the countries we supply to. For example, Eu-

experts every 12 months of work of the platform.

To guarantee the largest possible availability and

functional capacity of the lift system, ensure the

list of any cleaning, care and maintenance work

is done.

The lift system is to be serviced at regular inter-

vals according to the following plan. For intensive

operation and higher degree of contamination

shorten the service interval.

The complete function of the lift system is to be

observed during daily use. Customer service must

be informed of any malfunctions or leaks.

To simplify maintenance work, follow instructions

on the maintenance sticker that is found some-

where on the unit, depending on the lift design.

6.1 System maintenance plan

Before beginning service, disconnect

from power. The system is to be se-

cured against unintentional lowering

and unauthorized access.

6.1.1 As required or visible damage

6.1.2 Maintenance 1 x per year

Check condition of the model plate, load

capacity and sticker. Exchange them if

damaged or illegible.

Check condition of the Model plate, load capa-

city and sticker. Exchange them If damaged or

illegible.

Free the piston rod of the lifting cylinder of sand

and dirt.

Check the wiper for damage.

Moving parts such as joint bolts and DU bearings,

sliding pieces, sliding surfaces and rollers are to

be cleaned and checked for wear, exchange

if required.

Moving parts such as joint bolts, sliding pieces

and sliding surfaces are to be cleaned and che-

cked for wear and lightly greased. Do not over-

lubricate.

Check the polymer overlays and replace if re-

quired.

Check all available safety devices for function.

Check the state and function of the mobile set.

Check ease of motion of the tow bar (8), guide

roller (6) and wheel axles (9).

According to manufacturer instructions, the hy-

draulic oil should be changed every two years in

-

ences e.g. location, temperature swings, inten-

the quality of the hydraulic oil. For this reason,

the oil must be checked during annual safety in-

spections and maintenance.

The oil is used if it has a milky colour or if the hy-

draulic oil smells unpleasantly.

To change oil, lower the lift is to its lowest position

then suction the oil out of the oil container and

replace the contents.

The manufacturer recommends a high-quality

clean hydraulic oil. The required oil volume and

type is to be taken from the technical data. Af-

upper and lower marking on the oil dipstick, or

Dispose of the old oil according to regulations

-

-

disposal points).

All weld seams must have a visual inspection.

Stop the system and contact the manufacturer if

there are cracks or breaks in weld seams.

Check the powder coating and improve if re-

quired.

immediately after detection. If these points are

cause wide-ranging and permanent damage.

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 13

These points are to be lightly sanded (120 grit),

cleaned and degreased. Afterwards, rework

with a suitable touch up paint (note the RAL No.).

Check galvanized surfaces and touch up as

needed. White rust is fostered by permanent hu-

midity, poor ventilation.

Rust is brought out by mechanical damage, wear,

aggressive deposits (de-icing salt, leaking opera-

The affected areas can be treated by using a

sanding cloth (A 280 grit). If required, the parts

are to be treated with a suitable, resistant mate-

rial (paint etc.).

Check the protective hose and hydraulic hoses:

Check the condition of the protective hose

around the hydraulic lines. These should be ex-

changed if there is damage. During this, check

hydraulic lines for any crushing points (from third

Any affected lines must be exchanged. Other-

wise pressurized hoses must be exchange as re-

quired, however at latest after 6 years.

Hose lines are to be replaced:

for damage to the outer coating up to the in-

sert (chafe marks, cuts, cracks)

for brittleness of the outer coating (crack for-

mation), deformation of the natural shape in

the depressurized and in pressurized states.

if leaking

for damage or deformation of the mounting

if the lifetime has been exceeded

Repair of the hose line using the implemented

Extending the replacement intervals given in the

guideline is possible if the inspection for safe-

work condition is done in adjusted, shortened

time frames, if required and by competent per-

sonnel.

If ther is an extension of the replacement inter-

val, no situation may occur which could result in

injury of employees or other personnel.

For systems with aluminium panelling, these must

be removed to clean the drive in rails of dirt.

Check the torque of the fastening anchor.

The condition and function of the load suspensi-

on means are to be checked.

Check the torque of the fastening screws.

Also see the assembly protocol.

Torque (Nm) for shaft screws

Fastening class 8.8

0,08* 0,12** 0,14***

M8 17,9 23,1 25,3

M10 36 46 51

M12 61 80 87

M16 147 194 214

M20 297 391 430

M24 512 675 743

Fastening class 10.9

0,08* 0,12** 0,14***

M8 26,2 34 37,2

M10 53 68 75

M12 90 117 128

M16 216 285 314

M20 423 557 615

M24 730 960 1060

* Lubricated slide friction number 0.8 MoS2

** Lightly oiled slide friction number 0.12

*** Ensured slide friction number 0.14 screw with micro-

encapsulated plastic

sliding bearings. Despite this, due to environmen-

dirt) bearing zones may become noisy.

In this case, spray the affected areas with an

acid and resin free oil spray (no adhesive oil or

biologically degradable oil). Noises normally

occur after the system has been raised and lo-

wered several times.

Check the function of the CE STOP with warning

signal.

6.1.3 Maintenance every 2 years

Change the hydraulic oil according to manuf-

acturers instructions.

14 SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

6.1.4 Maintenance every 6 years

Exchange the protective and hydraulic hoses.

Excerpt from BGR 237

6 years including 2 years storage time.

Increased demands e.g. due to increased

usage times, e.g. multi-shift operation, short cy-

cle times and pressure impulses and large ex-

hose lines:

2 year operation duration

6.2 Cleaning and care of the system

A regular and expert clean helps retain the value

of the system.

Additionally, it can also be a pre-requisiste for the

preservation of guarantee claims for any eventual

corrosion damage.

The best protection for the system is regular

removal of contaminants of any kind.

This includes above all:

De-icing salt

Sand, pebbles, earth

Industrial dust of all types

Water, also in connection with other environ-

Aggressive deposits of all types

-

on

The frequency of system cleaning depends,

among other things on the frequency of use, of

system handling, of workshop cleanliness, and the

location of the system.

Furthermore, the degree of contamination de-

pends on the time of year, the weather conditions

and workshop ventilation.

Under adverse circumstances, weekly system

cleaning might be required, however a monthly

Do not use and aggressive and abrasive materi-

als for cleaning, rather use mild cleaners, e.g. a

commercially available detergent and luke warm

water.

For cleaning, do not use high pressure washers

(e.g. steam cleaners).

Carefully remove all contamination with a

sponge, or if required with a brush.

Make sure that there is no residue of the cleaner

on the system.

Dry the system with a cloth and spray it with a

spray wax or oil.

6.3 Cleaning and care of stainless steel

be done with our stainless steel cleaner. We re-

commend our stainless steel cleaning spray (1) for

this.

Immediately remove iron particles, grinding dust,

swarf, and weld spatter. These foreign bodies can

accelerate rust if they are deposited on the stain-

less steel surface. The passive layer of the non-

corroding steel is broken and this leads to pinhole

corrosion.

To guarantee a perfect stainless steel, in princi-

ple we recommend regular cleaning and care

of stainless steel in exterior areas (at best every 6

months).

Contamination and deposits that have already

occurred or severe corrosive etching can be re-

moved with our special „Pelox“ cleaner (2).

For stainless steel products that are placed close

to seawater, seawater resistant products can be

implemented in V4A quality.

Detailed information can be found under

www.edelstahl-rostfrei.de.

All stainless steel parts from the Feldmann product

range are made from V2A or V4A with material

numbers 1.4301 or 1.4401104. The surface is ground

(mostly 240 grit).

parts can rust!

Stainless steel stands for a guarantee for long life-

time and elegance. To permanently retain the

high value of the surface, it is indispensable to take

care of and protect the material regularly.

-

ences or improper treatment.

How does rust bloom occur?

Environment related:

For higher humidity with salt content close to salt

water.

In industrial areas with particularly aggressive air

contamination (acid rain).

By surfaces in contact with de-icing salt spray

water close to streets.

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 15

By contact with chlorine water (V2A is not suita-

ble for swimming pools).

Assembly related:

During processing with tools that are in contact

with normal iron.

of the surface.

When the surface comes into contact with

building-chemical related foreign materials (cal-

cium, cement dust, etc.) that deposit on the sur-

face.

Aggressive cleaning materials.

1. Cleaner spray 7064-PF cleans, cares for and

protects stainless steel parts.

2. Pelox 7065-PE special cleaner for the strongest

3. Cleaner and preservative 50-ESP cleans and

protects (long term protection).

16 SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

7 Behavior in cases of error

Defective operational readiness of the system may be due to a simple error. Check the system for the

listed sources of error.

If the error cannot be removed after an inspection to the named causes, then inform customer service

or your dealer.

Problem: Motor does not start

Possible causes: Remedy:

No power supply Check the power supply

The main switch (2) is not switched on, or is

defective Check the main switch (2).

Defective fuse Have fuses checked

"LIFT" (3) button defective Inform customer service

Motor defective Inform customer service

Problem: Motor starts, load is not lifted

Possible causes: Remedy:

Load is too heavy Unload the lift

Pressure line leaking Inform customer service

The connector for the left is designed for a

clockwise phase order.

Your power socket may not match. One of the

phases must be swapped.

Problem: The lift cannot be lowered

Possible causes: Remedy:

Lifting table is sitting on an obstacle See 7.1 Moving onto an obstacle

Hydraulic valve defective Inform customer service

"LOWER" (4) button defective Inform customer service

Incorrect push button actuated Push the correct push button

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 17

7.1 Moving onto an obstacle

If the system moves onto an obstacle during

lowering, then it remains in position due to the me-

chanical resistance. In this case the lift must be mo-

ved upwards by pushing the “LIFT” (3) button on the

operating panel until the obstacle can be remo-

ved. Afterwards the lift is in a normal work conditi-

on and can continue to be operated as described

in the operating manual.

7.2 Emergency discharge during blackout

An emergency discharge is an access

into the system controls and may only

be done by experienced specialists.

The emergency discharge must be

done in the following described se-

quence, otherwise it can lead to

damage and hazard to life and limb.

Any kind of external leakage is not

permitted and must immediately

taken care of. This is absolutely neces-

sary especially before an emergency

discharge.

Reason which make an emergency discharge

necessary are for example, electrical blackout, for

errors in the lowering valves, etc.

1. Switch off the main switch (2)

2. Loosen and remove the front unit covers (1).

3. Valve pins V1 and V2 must be pushed

from above simultaneously using a suitable

(e.g. screwdriver).

13 Valve V1

14 Valve V2

4. The lowering process starts immediately.

5. The entire lowering process must continuously

be observed. Observe the reaction of the

vehicle.

6. Let the valve down in case of danger.

7. Lower the vehicle to the lowest position.

13 14 5

18 SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

8 Technical information

8.1 Technical data

8.1.1

SPRINTER MOBIL 2500 - HYMAX PRO 2500

System load capacity 2,500 kg

Load distribution Max. 3:2 or 2:3 in or

against the drive- in direction

(Consider the centre

of mass of the vehicle)

Effective lifting range

of the system Approx. 990 mm

System lift time Approx. 15.8 s

with 2,500 kg load

System lowering time Approx. 10.8 s

with 2,500 kg load

Operating pressure Approx. 220 bars

Pressure relief valve Approx. 260 bars

Filling volume oil container Approx. 8 litres

on-site connection 3~/N+PE, 400 V, 50 Hz

with 16 A fuses, slow,

according to VDE regulations

8.1.2

SPRINTER MOBIL 3000 - HYMAX PRO 3000

System load capacity 3,000 kg

Load distribution Max. 3:2 or 2:3 in or

against the drive- in direction

(Consider the centre

of mass of the vehicle)

Effective lifting range

of the system Approx. 990 mm

System lift time Approx. 16.9 s

with 3,000 kg load

System lowering time Approx. 10.9 s

with 3,000 kg load

Operating pressure Approx. 240 bars

Pressure relief valve Approx. 260 bars

Filling volume oil container Approx. 8 litres

on-site connection 3~/N+PE, 400 V, 50 Hz

with 16 A fuses, slow,

according to VDE regulations

8.2 Safety devices

Hydraulic system fuse against over-pressure.

Secure against lifting and lowering the system

too fast.

Fuse to prevent unauthorized use.

The corresponding movement stops when the

operating button ("LIFT" (3) or "LOWER" (4)) is re-

leased.

Protection against crushing.

Secure against shear and crushing points in the

foot area.

20110005 OPI 08.12.2015 SPRINTER MOBIL - HYMAX PRO 19

9 System master sheet

9.1 Manufacturer

Otto Nußbaum GmbH & Co.KG

Korker Straße 24

D-77694 Kehl-Bodersweier

9.2 Purpose

The SPRINTER MOBIL - HYMAX PRO lift is a lifting accessory for the lifting of vehicles up to a total weight

of 2,500 kg or 3,000 kg, in normal workshop operation at a maximum load distribution of 3:2 in or against

the drive-in direction.

Additionally, there is a distinction between cars operated with front or rear drive.

The lift is not set up for standing on the receiving plate or for personnel conveyance.

The set up of the standard lift is not permitted in explosion endangered work shops.

inspected afterwards by a specialist who approves the changes.

Operation of the lift is done by an operating unit that is located immediately next to the lift.

9.3 Changes to the design / construction

Inspections by a technical expert are required before recommissioning (date, type of change, technical

expert signature).

.................................................................................................................................................................................

......

.................................................................................................................................................................................

......

Name, address of technical expert

......................................................................................... ..................................................................................

......

Location, date Technical expert signature

9.4 Changing the assembly location

Inspections by a technical expert are required before recommissioning (date, type of change, specialist

signature).

.................................................................................................................................................................................

......

.................................................................................................................................................................................

......

Name, address of technical expert

......................................................................................... ..................................................................................

......

Location, date Technical expert signature

20 SPRINTER MOBIL - HYMAX PRO 08.12.2015 20110005 OPI

10 Data sheet

SPRINTER MOBIL 2500 - HYMAX PRO 2500

SPRINTER MOBIL 3000 - HYMAX PRO 3000

7686_NB 05.11.2014 018

This manual suits for next models

3

Table of contents

Languages:

Other ATT NUSSBAUM Lifting System manuals