Operating Manual and Inspection Book

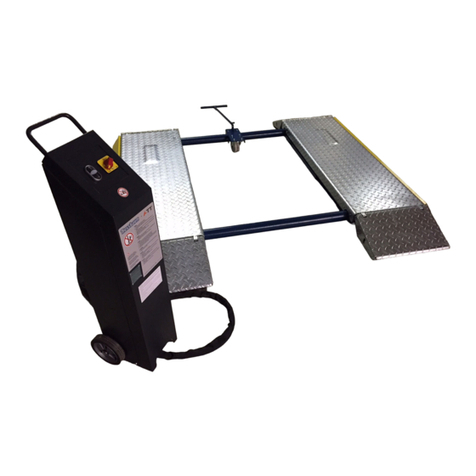

SMARTLIFT2.30 SL, 2.35 SL, 2.40 SL/ HYMAX S3000, 3500, 4000

20110015 OPI 4 Version 1.0

Contents

Introduction............................................................................................................................5

Assembly protocol.................................................................................................................7

Transfer protocol...................................................................................................................8

1General information.........................................................................................................9

1.1 Set up and test the lift..................................................................................................9

1.2 Hazard information......................................................................................................9

2Lift master forms............................................................................................................10

2.1 Manufacturer.............................................................................................................10

2.2 Purpose.....................................................................................................................10

2.3 Changes to the design / construction.........................................................................11

2.4 Changing the assembly location................................................................................11

2.5 Declarations of conformity.........................................................................................12

3Technical information....................................................................................................15

3.1 Technical data...........................................................................................................15

3.2 Safety devices...........................................................................................................16

3.3 Data sheets...............................................................................................................17

3.3.1 Data sheets 2.30 SL...............................................................................................17

3.3.2 Data sheets 2.35 SL...............................................................................................20

3.3.3 Data sheets 2.40 SL...............................................................................................23

3.4 Electrical plans..........................................................................................................25

4Safety regulations..........................................................................................................30

5Operating manual ..........................................................................................................31

5.1 Positioning the vehicle...............................................................................................31

5.2 Lifting the vehicle.......................................................................................................32

5.3 Lift synchronization....................................................................................................33

5.4 Lowering the vehicle..................................................................................................33

5.5 LED display on the operating unit..............................................................................34

6Behavior in cases of error.............................................................................................36

6.1 Emergency discharge................................................................................................37

6.2 Moving onto an obstacle............................................................................................37

6.3 Triggering the safety mechanism...............................................................................38

6.4 Manual equalization of the lifting rails........................................................................38

6.5 Readjustment of the "Up and Down Off"....................................................................38

7Maintenance and care of the lift....................................................................................40

7.1 Maintenance plan......................................................................................................41

7.2 Cleaning the lift..........................................................................................................46

7.3 Readjustment of the polyflex belt...............................................................................47

7.4 Check / exchange the lift nut system .........................................................................48

7.5 Checking the stability of the lift ..................................................................................49

8Assembly and commissioning......................................................................................49

8.1 Set up guidelines.......................................................................................................49

8.1.1 Set up and anchoring the lift...................................................................................49

8.1.2 Electrical assembly and power connection.............................................................51

8.2 Lifting arm assembly..................................................................................................54

8.3 Commissioning..........................................................................................................54

8.4 Changing the assembly location................................................................................54

9Safety inspection...........................................................................................................61

9.1 Assembly instructions capture bar fixation.................................................................61

Single safety inspection before commissioning ...................................................................67

Regular safety inspection and maintenance........................................................................68

Exceptional safety inspection..............................................................................................78

10 Spare parts list | Ersatzteilliste | Liste des pièces des rechange………………………75