AU Tool EM315 User manual

深圳市偶然科技有限公司

深圳市偶然科技有限公司

深圳市光明新区长春南路中鹏程工业园

www.autooltech.com

User Manual

AUTOOL EM315/EM325

Smart Inverter Jump Starter

Shenhua Innovation Park, Baoan, Shenzhen, China

www.autooltech.com

+86-400 032 0988 / +86-755-27807580

Trademark

AUTOOL Technology Co, Ltd. has registered its trademarks in

several countries including China, the trademark is . With

regard to the other trademark, service logo, domain name, icon

and company name mentioned in this manual, they shall all

belong to AUTOOL and its other affiliated company, in other

countries without the registration yet of these trademark, service

logo, domain name, icon and company name of AUTOOL, here

we announce they are owned by AUTOOL. Any company or

person shall not use the trademark, service logo, domain name,

icon and company name of AUTOOL before getting approved by

AUTOOL with written certificates. Please visit our website

contact us.

1

Caution and Precautions

All maintenance and repair work must be carried out with the

power supply completely cut off. Please confirm that the power

plug has been disconnected before opening the case.

During the warranty period, if the user erroneously overhauls

the products without the proper guide by the AUTOOL, the

AUTOOL company will not be responsible for the caused

breakdown and free maintenance.

All connection operations shall be performed after the user

confirms that the power has been turned off. The correct order

is to connect the welding gun wire and the ground wire to the

welding machine first, confirm that the ground wire connection

is firm, finally plug the power plug into the power supply.

•

•

•

3

Product Overview

2

Connect the positive (+) of the output cable to the positive (+)

of battery and the negative (-) of the output cable to the

negative (-) of the battery.

Never use a charging connection to start the engine, which will

easily burn the meter and generator.

When the starter cannot start the engine, please check if the

input power cord meets the relevant specifications, or check if

the power cord is connected.

If the work piece is too far away from the welder (50-100 m),

when the user chooses the extension wire for welding gun and

ground wire, please use a wire with a larger cross section to

avoid the cable voltage decrease.

Please do not experiment blindly or do careless overhaul,

which may result into more breakdown, making it more difficult

to perform normal repair& maintenance.

The exposed part of the machine is powered with a voltage

that can cause danger, any direct or indirect contact to that

may cause an electric shock accident, and a serious electric

shock will cause death.

Welding operations should be carried out in a relatively dry

environment, and the air humidity should generally not exceed

90%.

The ambient temperature should be between 10℃ and 40℃.

Avoid welding in daylight or rain, and do not allow water or rain

to seep into the welder.

Avoid welding work in dusty areas or in corrosive

atmospheres.

Avoid gas-shielded welding operations in environments with

strong air flow.

•

•

•

•

•

•

•

•

•

This device only supports 12v battery charging. Before charging

12V batteries, the function switch should be set to Battery

Charger button.

This device only supports 12v vehicle jump start. Before starting

vehicle, press the function button to be set to Engine Starter

button. The positive(+) and negative(-) power pole share both

charging and starting function.

Electric welding function: high efficiency, energy saving, light.

Stable ARC, easy to control the melt pool. High no-load voltage

and better energy thrust, can be used for a wide range of

material: stainless steel, alloy steel, carbon steel, copper and

other non-ferrous metals. The welder uses a variety of welding

rods of different specifications and materials, including acid,

alkaline and cellulose type welding rods, which can be used for

aerial work, indoor and outdoor decoration, etc. Compared with

domestic and foreign similar products, it has small size, light

weight and easy installation.

•

•

•

•

•

5

4

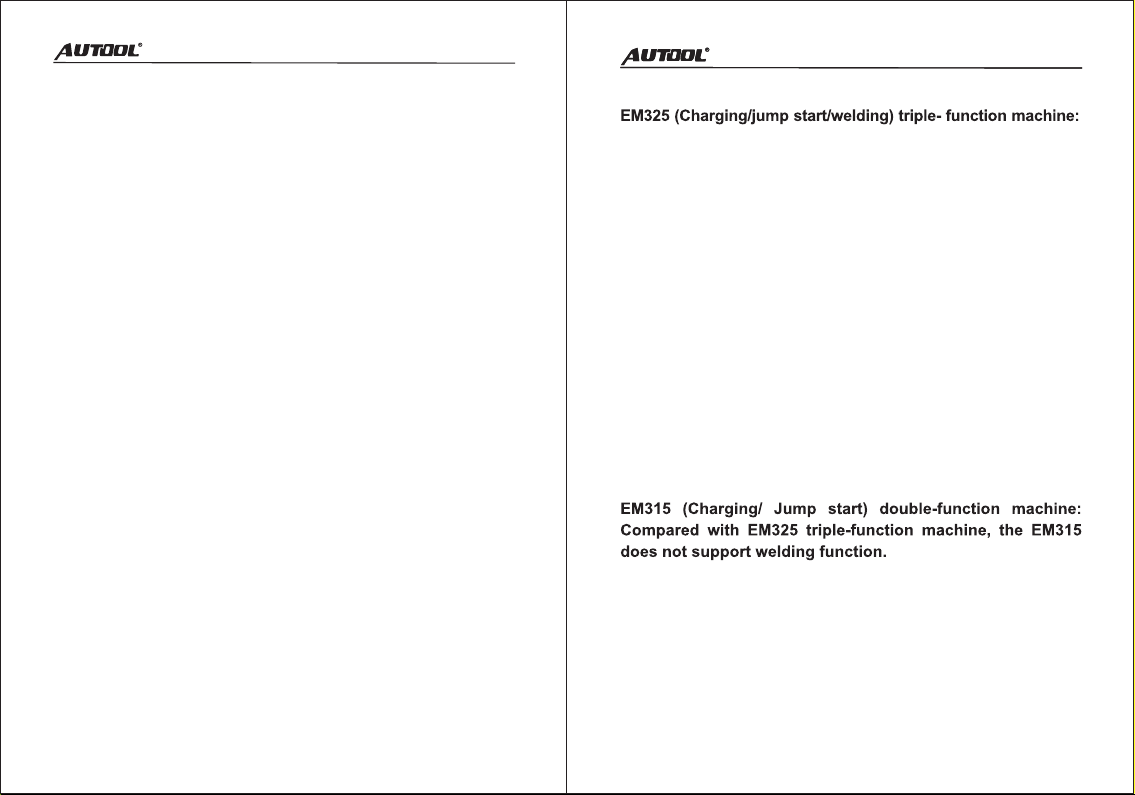

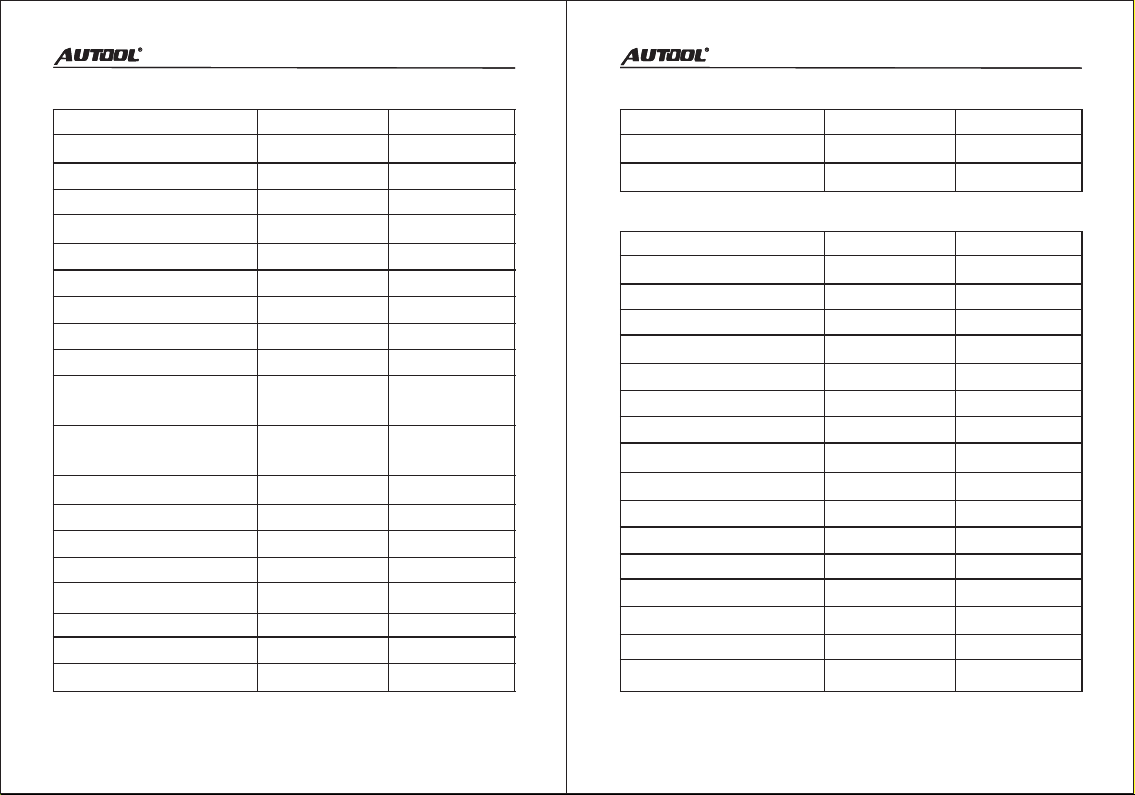

Type

Input rated voltage

Input frequency

EM315(EU)

220 V±15%

50 Hz - 60Hz

EM315(USA)

110 V±15%

50 Hz - 60Hz

5.6KVA

30A

12V

400A

12V

2.9

30A

12V

400A

12V

KVA

Rated input power

Charging current

Charging voltage

Starting current

Starting voltage

Charging no-load voltage

Starting no-load voltage

No-load loss

Effectiveness (%)

Power factor

Insulation grade

Enclosure protection rating

Net weight (kg)

Dimensions (cm)

15A

15A

30W

85%

0.73

F

IP21

8.4kg

46.5*33*26.5cm

15A

15A

30W

85%

0.73

F

IP21

8.4kg

46.5*33*26.5cm

Technical Parameters

Input rated voltage

Input frequency

Rated input power

Welding current

Welding voltage

Charging current

Charging voltage

Starting current

Starting voltage

Type

40℃ 35% Load

continuation rate output

40℃ 100% Load

continuation rate output

Charging no-load voltage

Starting no-load voltage

Welding no-load voltage

No-load loss

Effectiveness (%)

Power factor

Insulation grade

Enclosure protection rating

EM325(EU)

220V±15%

50Hz-60Hz

6.8KVA

20A-140A

21V-25.6V

30A

12V

400A

12V

140A

23.3V

83A

23. 2V

15A

15A

56V

30W

85%

0.73

F

IP21

EM325(USA)

110V±15%

50Hz-60Hz

2.9KVA

20A-80A

21V-23.2V

30A

12V

400A

12V

48A

22V

48A

22V

15A

15A

56V

30W

85%

0.73

F

IP21

Type

Net weight (kg)

Dimensions (cm)

EM325(EU)

9kg

46.5*33*26.5cm

EM325(USA)

46.5*33*26.5cm

9kg

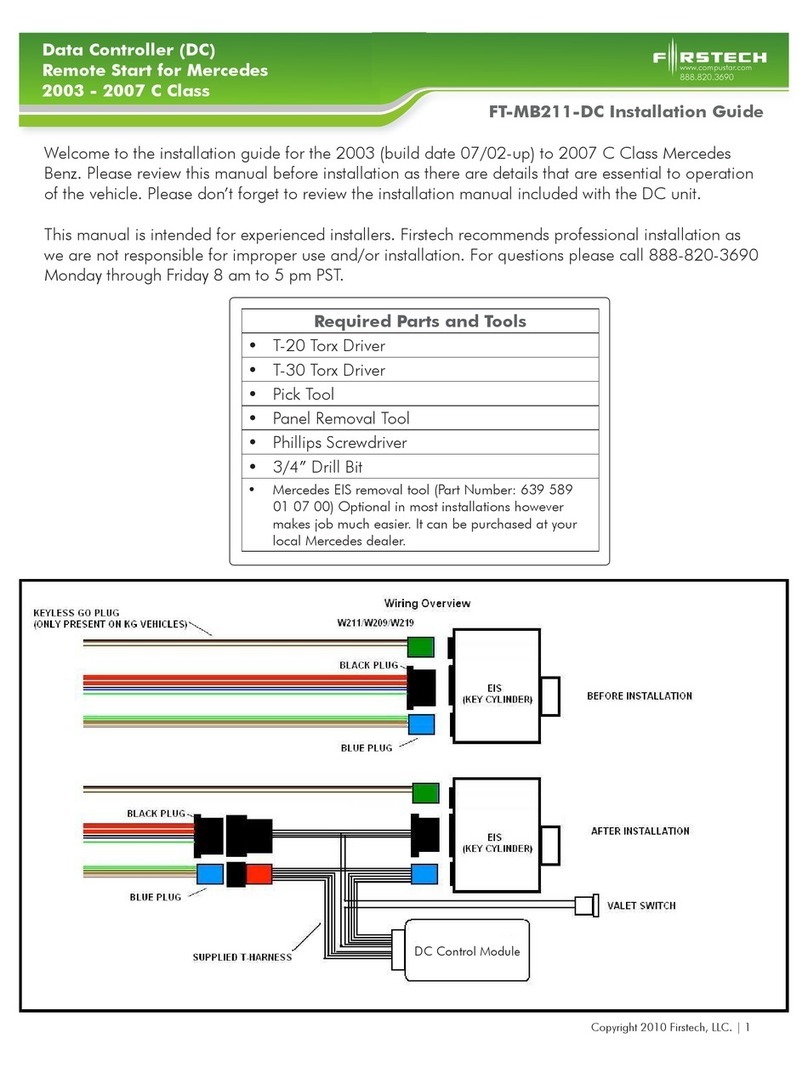

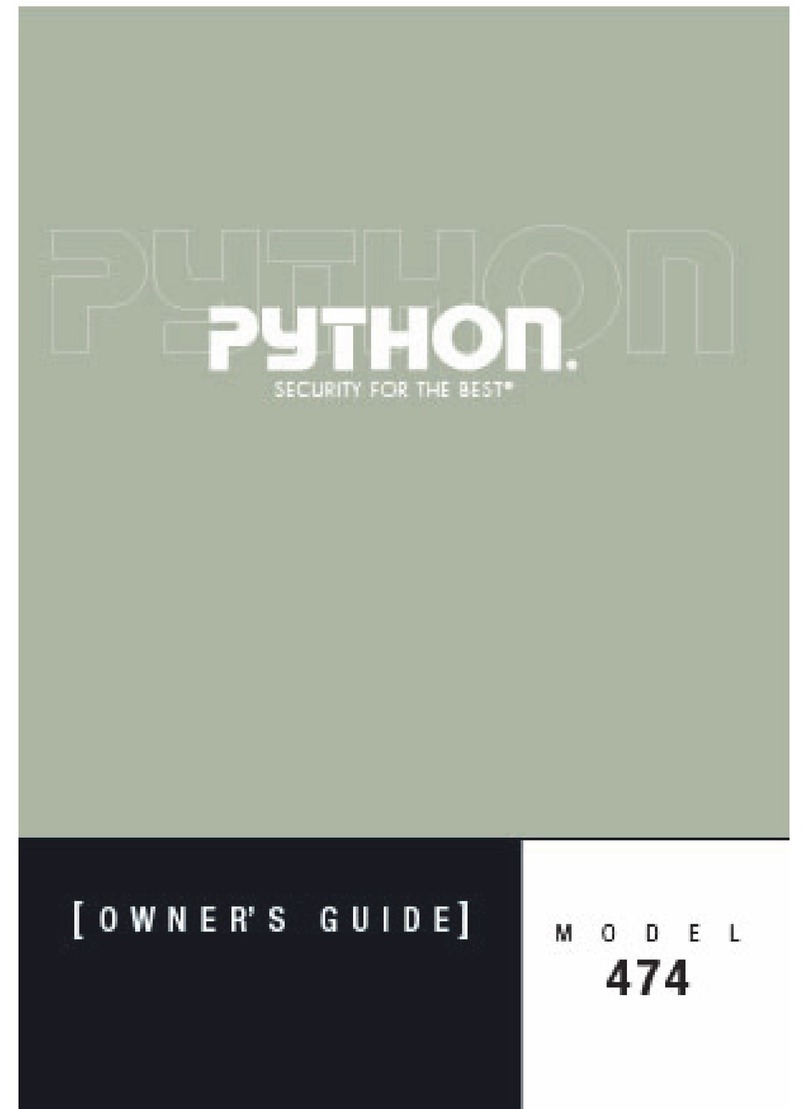

Product FeaturesUnit Appearance

7

6

Compared with ordinary charger, the charger is smaller, lighter

and the power is larger;

Charging time and power are twice as fast as traditional

machines, and it is the most advanced electronic charger in

China;

The charging current can be adjusted within the range of 6-

60A and is not affected by changes in the input AC voltage;

The machine adopts smart temperature control, fan cooling

and automatic shutdown protection in over-heat.

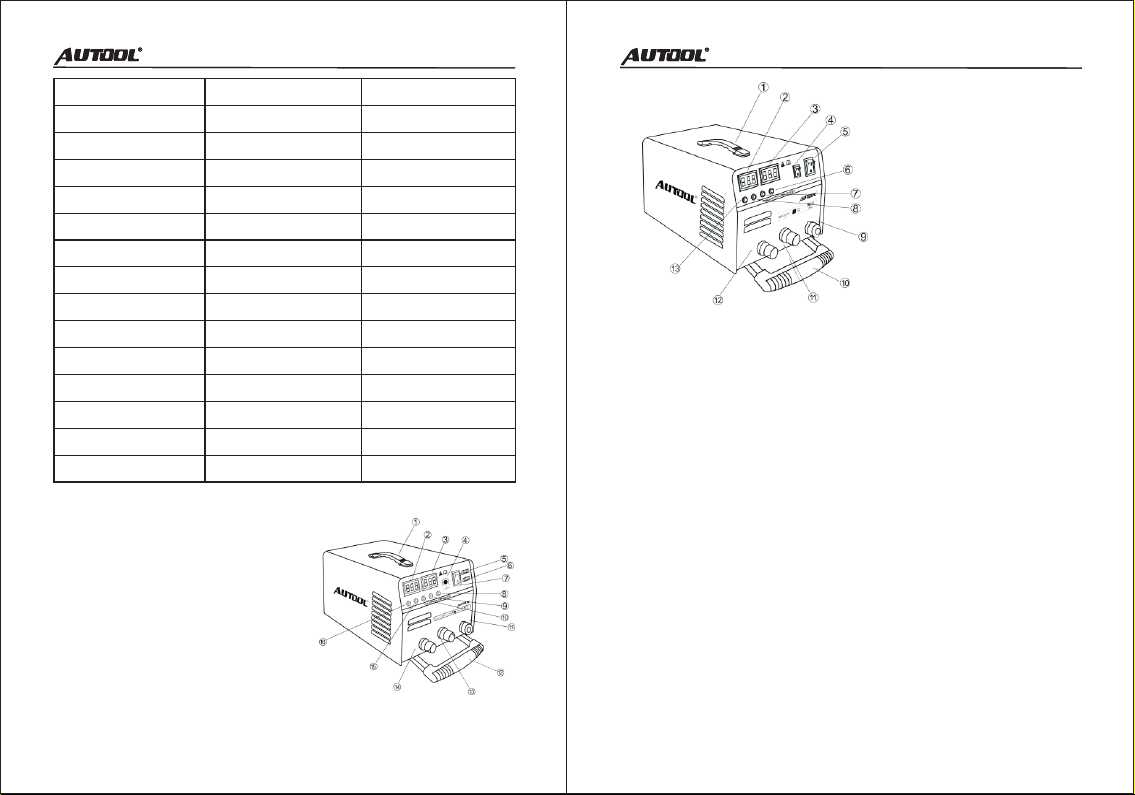

EM325

② Ammeter;

③ Voltmeter;

④ Current adjustment knob;

⑤ Charging/ starting switch;

⑥ Welding switch;

⑦ Power switch;

⑧ Error indicator;

⑨ Welding indicator;

⑩ Starting indicator;

:

① Handles;

⑪ Power cord; ⑫ Pull bar; ⑬ Negative pole(-);

⑭ Positive pole(+); ⑮ Fully charged; ⑯ Charging indicator.

EM315

② Ammeter;

③ Voltmeter;

④ Charging / starting switch;

⑤ Power switch;

⑥ Error indicator;

⑦ Starting indicator;

⑧ Fully charged

⑨ Power cord;

⑩ Pull bar;

:

① Handles;

⑪ Negative pole(-);

⑫ Positive pole(+);

⑬ Charging indicator.

EM325 Charging:

•

•

•

•

EM325 Starting:

It is mainly used to solve the breakdowns after the failure of

starting a car, due to loss of power, aging and ultra-low

temperature environment;

The design of the car jump start power supply is safe;

Convenient, reliable, no need to charge, ultra-low temperature

start.

Long service life and maintenance-free, to solve the problem

that the car engine can not start normally.

•

•

•

•

EM325 Welding:

Efficient, energy-saving and light, with good dynamics;

Easy to do ARC welding: small splash, stable current and

good forming;

Suitable for all kinds of acid and alkaline welding rods;

Wide range of uses: auto repair industry, aerial work, field

operations, indoor and outdoor decoration.

•

•

•

•

Compared with ordinary charger, the charger is smaller, lighter

and the power is larger;

Charging time and power are twice as fast as traditional

machines, and it is the most advanced electronic charger in

China;

The charging current can be adjusted within the range of 6-

60A and is not affected by changes in the input AC voltage;

The machine adopts smart temperature control, fan cooling

and automatic shutdown protection in over-heat.

•

•

•

8

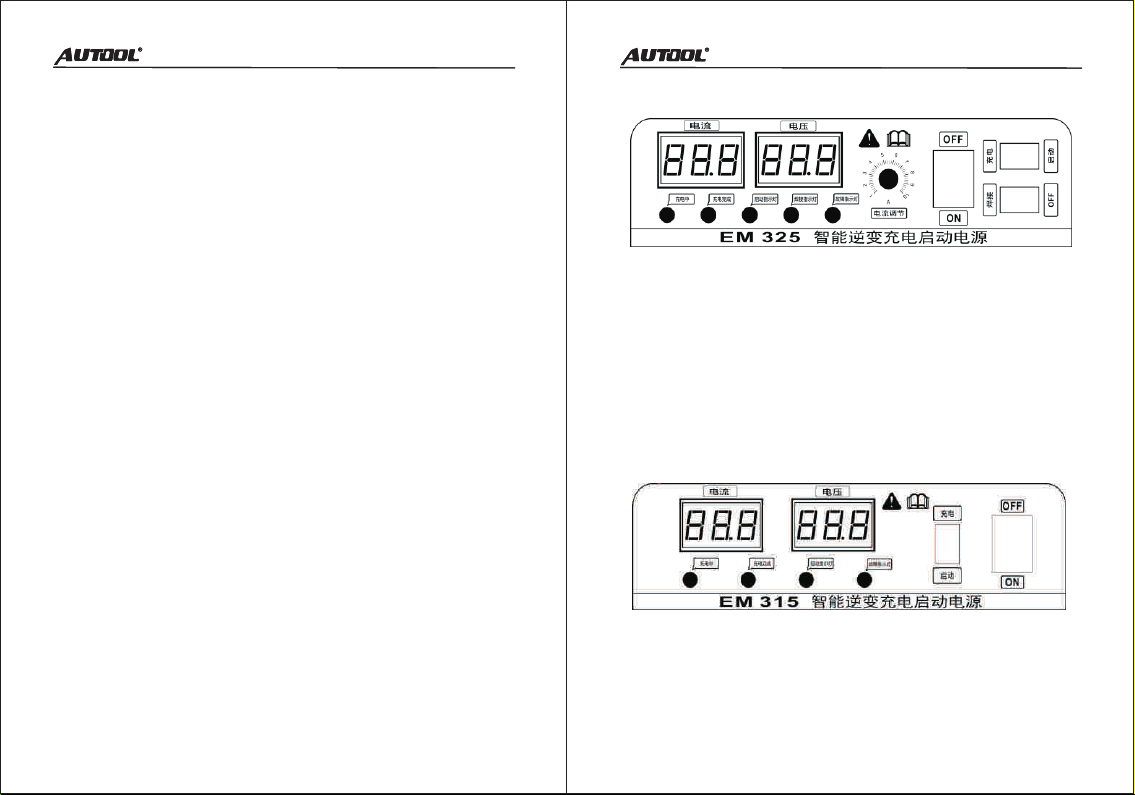

EM325 (Charging / Starting /

Welding) Panel Functions:

EM315 Charging:

•

It is mainly used to solve the breakdowns after the failure of

starting a car, due to loss of power, aging and ultra-low

temperature environment;

The design of the car jump start power supply is safe;

Convenient, reliable, no need to charge, ultra-low temperature

start.

Long service life and maintenance-free, to solve the problem

that the car engine can not start normally.

•

•

•

EM315 Starting:

•

9

For battery charging: Press the button “Charge/ Start” to

“Charge”, after that the charging starts.

For starting the vehicle, press the button “Charge / Start” to

“Start” to function.

In charging and starting function situation, the “Weld” button

must be off.

For welding function, press the button “Weld” to start working.

•

•

•

Note: Please pay attention for different purpose of use.

•

EM315 (Charging / Starting) Panel

Functions:

For battery charging: Press the button “Charge/ Start” to

“Charge”, after that the charging starts.

For starting the vehicle, press the button “Charge/ Start” to

“Start” to function.

•

•

Note: Please pay attention for different purpose of use.

Operation

Charging mode:

For battery charging, press the button “Charge/ Start” to

“Charge”, after that the charging starts.

•

Connect the positive clamp (+) to the battery positive (+) pole,

connect the negative clamp (-) to the battery negative (-) pole.

The charging value of charging depends on the type of

rechargeable battery, generally it’s about 10% of its maximum

current.

The charging time depends on the type of battery; in addition,

as the charging time grow more, the charging current will

decline to some extent.

This unit can be charged with one or more batteries at the

same time. When you charge the vehicle, the original battery

clamps should be removed.

•

•

•

10

•

11

When you start a high-powered engine, it is best to charge the

car battery for about 15 minutes and then start.

When start the diesel engine, the spark plug should be

preheated before starting.

When connect the clamps, connect the negative pole first and

then the positive pole.

•

•

•

Safety Note for Welding Machine Use

Please always keep good ventilation. This is good for the

longer service life and working condition of the welder.The

EM325 welder is a small welder. While in operating, a large

working current is through. Natural ventilation cannot meet the

cooling requirements of the welder. A fan is installed to

effectively cool down the welder temperature to make it work

smoothly. The user should confirm that the ventilation is not

covered or blocked, and the surrounding objects should be

farther than 0.3 meters.

Overload prohibited. The user should remember to observe

the maximum allowable load current (relatively selectable load

duration), keep the welding current not exceeding the

maximum allowed load current. The current overload will badly

shorten the life of the welder and may even burn the welding

machine.

•

•

EM325 welder has installed over-voltage, over-current and over-

heat protection circuits. When the grid voltage, output current

and internal temperature exceed the set standard, the welder will

stop working; furthermore, excessive use (such as excessive

voltage) will still cause damage to the welder, so you should still

pay attention to the following:

Note:

Turn off the power before removing the battery clamp.

Fireworks or flame are strictly prohibited at the operation site

as flammable gas will be generated during

charging.

Be careful to avoid rain, snow or moisture, as it will erode.

The positive(+) and negative(-) poles must be distinguished

while using.

The machine should be protected from vibration or collision

while using.

Do not charge the battery that has ice on it.

Clean the rechargeable battery before charging to prevent

short circuits and detect the initial voltage.

•

•

•

•

•

•

•

Starting mode:

When you start the vehicle, there are some notes to be kept in

mind:

For starting the vehicle, press the button “Charge/ Start”to

“Start” to function.

•

•

Prohibit too high voltage. The power supply voltage is in the

“Technical Parameters” table. Under normal circumstances, the

voltage automatic compensating circuit in the welding machine

will ensure that the welding current is kept within the allowed

range. If the power supply voltage exceeds the allowed value,

the welding machine will be damaged. The user should fully

understand this situation and take appropriate preventive

measures.

Situation when standard load continuation rate is

exceeded: If the welder exceeds the standard load

continuation rate during operation, the welder may suddenly

enter the protection state and stop the work. The excessive

heat triggers the temperature control switch, causing the

welder to stop working, and the red indicator light on the front

panel lights up. In this case, you do not have to unplug the

power supply, so that the cooling fan can continue to work to

cool down the welder temperature. When the temperature

drops to the standard range, the red indicator light is off, and

you can restart the welder.

Regularly blow off the dust with dry and clean compressed

air. If the welder is used in an environment with heavy smoke

and air pollution, the welder should be cleaned and dry daily.

Regular check to the internal circuit connection of the

welder. Confirm that the line is connected correctly, the joint is

firm (especially when the joint or component is inserted). If it is

found to be rusted and loose, please use sandpaper to polish

the rust layer or oxide film, reconnect and tighten it.

Avoid water or vapor entering the welder inside. If this

happens, the inside of the welder should be dried. You should

•

•

•

12

•

13

check the welder's insulation with a megohmmeter (including

the parts between the connection nodes,between the

connection point and the unit cover). The welding work can

only be continued if there is no abnormal phenomenon.

Store the machine. Please put the machine back into package

when the welder is not used for a long time, put it in a dry

environment.

•

•

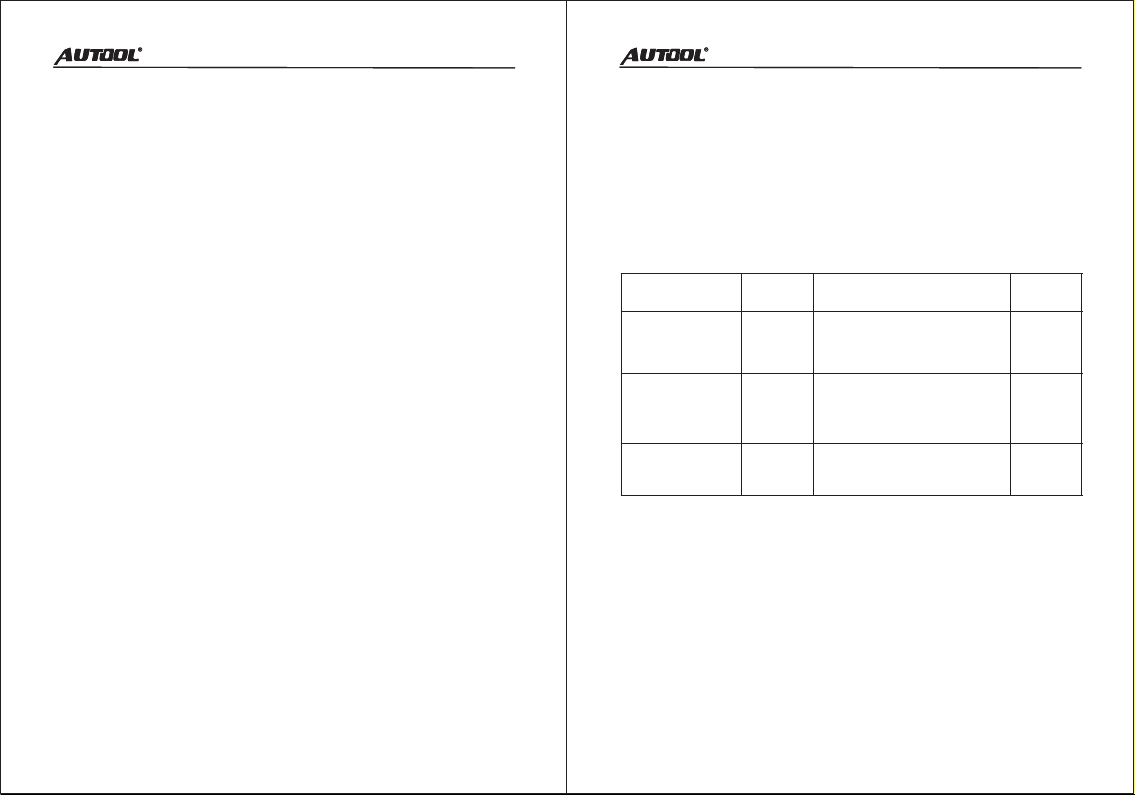

Package List

Name

Number

Name

Number

The main unit

1

Power cord with clamp for

welding (only used for EM325)

1

Power cord with

(+)clamp for

charging/starting

1

Power cord with (-)clamp for

charging/starting

1

Manual

1

Qualification certificate

1

Warranty

There are 3 years' warranty for AUTOOL product main unit and

1 year warranty for the accessories since the day the customers

have received the product parcel.

Repair or replace the equipment will be done according to the

specific fault conditions;

We guarantee that all replacement parts, accessories or

equipment are brand new;

When there is a product breakdown that can not be solved

within 90 days, customer should provide video and pictures as

proof, we will bear the freight cost and provide customer the

accessories in need to replace. After receiving the product for

more than 90 days, the customer shall bear the freight cost, we

will provide the accessory for free to replace.

•

•

14

•

15

Warranty Access

Warranty not Covered in

Conditions Listed Below

Product is bought through non-official AUTOOL purchase

channel.

Product failure is caused by incorrect use of the product, use

for other wrong purpose or human factors.

•

•

Disclaimer: The AUTOOL Technology Co, Ltd. reserves the right

to change product designs and specifications without prior notice.

The physical appearance and color may differ from those shown

in the instruction manual. Please refer to the actual product. If

you have any question, please contact the dealer or the Autool

service center. The company have the final explanation right of

product and shall not bear any consequences due to

misunderstanding.

注册商标

偶然公司已在中国及海外若干国家进行了商标注册,其标志为

。本手册所提及之偶然公司其它商标、服务标志、域

名、图标、公司名称均属偶然及其下属公司之产权。在偶然公司之

商标、服务标志、域名、图标、公司名称还未注册之国家,偶然公

司声明其对未注册商标、服务标志、域名、图标、公司名称之所有

权。本手册所提及之其它产品及公司名称的商标仍属于原注册公司

所有。在未得到拥有人的书面同意之前,任何人不得使用偶然公司

或所提及的其它公司之商标,服务标志,域名,图标,公司名称。

您如有任何疑问,可以访问偶然网址:www.autooltech.com,或

发送邮件至:aftersale@autooltech.com,与偶然公司联系。

注意事项及预防措施 (环境):

所有的维护,检修工作都必需在完全切断电源的情况下进行,请

在打开机壳前确认已拨下电源插头。

在保修期间,如果未经深圳市偶然科技有限公司允许,用户对其

使用的 AUTOOL产品的任何故障擅自进行错误的检修,提供的

免费维修保证将失效。

所有的连接操作在确认电源已切断的情况进行,正确的顺序是

先将焊线及地线连接到焊机上,确认地线连接可靠,无松动

后,最后再将电源插头插到电源上。

请将输出电缆线正极(+)与电瓶正极(+)相连,负极(-)与电瓶负极

(- )相连。

绝不能用充电连接方式来起动发动机,这样容易烧坏电表和电

机。

•

•

•

•

•

16

启动机不能起动发动机,检查输入电源线是否符合相关规格,或检

查线路是否接好。

如果工件与焊机距离太远(50-100米),用户选用延接线(焊枪接

线和地线)时,请选用横截面适当增大的,以免电缆电压下降。

盲目实验和不谨慎的检修可能会导致故障面积的扩大,给正式

的检修造成困难。

本设备在通电状态下,设备内裸露部分带有可导致危险的电

压,任何直接或间接的接触都可能导致电击的事故发生,严重

的电击将导致死亡!

焊接操作应在一个相对干燥的环境下进行,空气湿度一般不应超

过 90%。

周围温度应在 10℃至 40℃之间。

避免在日光下或雨中进行焊接,不要让水或雨水渗进焊机内。

避免在灰尘区或含有腐蚀性气体环境下进行焊接工作。

•

产品概述

EM325 (充电/启动/电焊)三用机:

17

EM315 (充电/启动)二用机,相对于EM325,二用机不支持电焊

功能。

•

•

•

•

•

•

•

设备仅支持12V铅酸电池充电,选择12V充电时,功能开关应该

拨至“充电”,正负极柱是“充电”和“启动”共用。

设备仅支持12V铅酸电池启动,选择启动时,功能开关应该拨至

“启动”,正负极柱是“充电”和“启动”共用。

电焊功能:高效,节能,轻便,且具有良好的推动性,电弧稳

定,溶池容易控制;较高的空载电压和较好的能量推力补偿,

用途广泛,可焊接不锈钢,合金钢,碳钢,铜和其他有色金

属;该焊机使用各种不同规格和材质的焊条,包括酸性,碱性

及纤维素型的焊条,可用于高空作业,室内外装修等,与国内

国外同类产品相比具有体积小,重量轻,安装简便,容易等特

点。

•

•

•

技术参数

输入额定电压

输入频率

额定输入功率

电焊电流电压调节范围

充电电流电压

启动电流电压

40℃35%暂载率输出

启动空载电压

电焊空载电压

空载损耗

效率

功率因数

绝缘等级

外壳防护等级

包装重量(kg)

包装尺寸(cm)

40℃100%暂载率输出

充电空载电压

220V +15%

50Hz/60Hz

5.6KVA

20A/140A ~ 21V/25.6V

30A ~ 12V

400A ~ 12V

140A/25.6V

83A/23.3V

15V

15V

56V

30W

85%

0.73.

F

IP21

9

46.5*33*26.5

110V+15%

50Hz/60Hz

2.9KVA

20A/80A ~ 21V/23.2V

30A ~ 12V

400A~ 12V

80A/23.2V

48A/22V

15V

15V

56V

30W

85%

0.73 ,

F

IP21

9

46.5*33*26.5

产品型号 EM325(欧规) EM325(美规)

18 19

输入额定电压

输入频率

额定输入功率

充电电流电压

启动电流电压

充电空载电压

启动空载电压

空载损耗

效率

功率因数

绝缘等级

外壳防护等级

包装重量(kg)

包装尺寸(cm)

220V+ 15%

50Hz/60Hz

2.5KVA

30A ~ 12V

400A ~ 12V

15V

15V

30W

85%

0.73

F

IP21

8.4

46.5*33*26.5

110V+15%

50Hz/60Hz

2.5KVA

30A ~ 12V

400A~ 12V

15V

15V

30W

85%

0.73

F

IP21

8.4

46.5*33*26.5

产品型号 EM315(欧规) EM315(美规)

整机机构示意图

① 提手

② 电流表

③ 电压表

④ 电流调节旋钮

⑤ 充电/启动开关

⑥ 焊接开关

⑦ 电源开关

⑧ 故障指示灯

⑨ 焊接指示灯

⑩ 启动指示灯

⑪ 电源线

⑫ 拉杆

⑬ 负极(-)

⑭ 正极(+)

⑮ 充电完成指示灯

⑯ 充电中指示灯 EM325 结构示意图

① 提手

② 电流表

③ 电压表

④ 充电/启动开关

⑤ 电源开关

⑥ 故障指示灯

⑦ 启动指示灯

⑧ 充电完成指示灯

⑨ 电源线

⑩ 拉杆

⑪ 负极(-)

⑫ 正极(+)

⑬ 充电完成指示灯

EM315 结构示意图

功能特点

EM325 充电特点:

和普通充电机相比,优势明显,体积小,重量轻,功率大;

充电时间和功率比传统充电机快两倍,是目前国内最先进的电

子型充电机;

充电电流可在6-60A范围内调节选定,且不受输入交流电压变化

的影响;

机内采用智能温控,风扇散热和过热自动关机保护。

•

•

•

•

EM325 启动特点:

主要用于解决因汽车启动电池亏电,老化和超低温环境等原因所

引起的汽车无法启动的故障;

汽车应急启动电源设计理念为安全;

方便,可靠,无需充电,超低温启动;

•

•

•

20 21

超长寿命和终身免维护安全,解决汽车用户遇到的汽车引擎无

法正常启动问题。

•

EM315 充电特点:

和普通充电机相比,优势明显,体积小,重量轻,功率大;

充电时间比传统机型快两倍,功率是传统机型的两倍,是国内

目前最先进的电子型充电机;

充电电流可在(6-80)A范围内调节选定,且不受输入交流电压变

化的影响;

机内采用智能温控,风扇散热和过热自动关机保护。

•

•

•

•

EM315 启动特点:

主要用于解决因汽车启动电池亏电,老化和超低温环境等原因

所引起的汽车无法启动的故障;

汽车应急启动电源设计理念为安全;

方便,可靠,无需充电,超低温启动;

超长寿命和终身免维护安全, 解决汽车用户遇到的汽车引擎无

法正常启动问题。

•

•

•

•

在蓄电池充电时:需将“充电/启动”开关键拨到充电位置,此

时为充电工作模式;

在启动汽车时:需将“充电/启动”开关键拨到启动位置,此时

为启动车辆工作模式;

在充电、启动工作状态时,“焊接”开关键必需拨到 OFF 位置;

选择电焊功能时:就只要把“焊接”开关键拨到焊接位置就可

以了。

•

•

•

•

EM315(充电/启动)机型面板功能说明

EM325 电焊特点:

和普通充电机相比,优势明显,体积小,重量轻,功率大;

充电时间比传统机型快两倍,功率是传统机型的两倍,是国内

目前最先进的电子型充电机;

充电电流可在(6-80)A范围内调节选定,且不受输入交流电压变

化的影响;

机内采用智能温控,风扇散热和过热自动关机保护。

•

•

•

•

EM325(充电/启动/电焊)机型面板功能说明

在蓄电池充电时:需将“充电/启动”开关键拨到充电位置,此

时为充电工作模式;

在启动汽车时:需将“充电/启动”开关键拨到启动位置,此时

为启动车辆工作模式;

•

•

操作方法

充电模式

在蓄电池充电时:需将“充电/启动”开关键拨到充电位置,此

时为充电工作模式,请将电瓶夹线的正极“+”对接蓄电池正极

“+”,负极“-”对接蓄电池负极“-”;

在取下电池夹之前应先关闭电源;充电时会产生可燃气体,因

此操作现场严禁烟火;

应注意雨水,下雪或潮湿会侵蚀,在使用时一定要分清“+”

“-”极;

充电机在使用时应避免受到振动和撞击,不要给结冰凝固的电

池充电;

在充电前先清洁被充电池,预防有杂物形成短路,检测其初始

电压;

充电规律:充电时其充电值大小取决于被充电池的种类,一般

为其最大电流的 10% 左右;

充电时间: 随电池的种类而定;另外随着充电时间延续,充电

电流也会有所下降。

•

22 23

启动模式

在启动车辆时,应注意几点:

在启动汽车时:需将“充电/启动”开关键拨到启动位置,此时

为启动车辆工作模式,请将电瓶夹线的正极“+”对接蓄电池正

极“+”,负极“-”对接蓄电池负极“-”;

起动大功率发动机时,最好给蓄电池快充电15分钟左右,再启

动;

•

•

•

•

•

•

•

•

本机可同时充一个或多个电池,给车辆充电时,应摘下原电池夹头。

焊机使用的安全要点

EM325焊机已安装过压、过流及过热保护电路,当电网电压,输出

电流及机内温度超过设定的标准后,焊机将停止工作;但过度的

使用(如电压过高)仍会导致焊机的损坏,所以您仍需注意以下

事项:

确保通风良好!EM325焊机是小型焊机,在操作时,有较大的

工作电流通过,自然通风不能满足焊机冷却要求,内装一个风

扇来有效的冷却焊机以使其工作平稳。使用人员应确认通风处

未被覆盖或堵塞,焊机和周围物体的距离应不小于0.3米,用户

应一直注意保持良好的通风,这时对于焊机更好的工作和保证

更长的使用寿命是非常重要的。

禁止过载!使用人员应记得随时观察最大的允许负载电流(相

对可选定的负载持续率),保持焊接电流不超过最大的允许负

载电流,电流过载将会明显的缩短焊机的使用寿命,甚至可能

烧毁焊机。

禁止电压过高!电源电压在“主要技术参数”表中,在一般情

况下,焊机内的电压自动补偿电路将保证焊接电流保持在允许

范围内,如果电源电压超过允许值,将会损坏焊机,使用人员

应充分了解此种情况,并采取相应的预防措施。

如果焊机工作时超过标准负载持续率,焊机可能会突然进入保

护状态而中止工作,这表示焊机超出标准负载持续率,过度热

能触发了温控开关,使焊机停止工作,同时在前部面板上的红

•

•

•

•

起动柴油机时,应先将其火花塞进行预热后再起动;

连接夹头时,先接负极再接正极

•

•

24 25

色指示灯亮起。在这种情况下,您不必拨下电源插头,以便冷

却风扇可持续工作对焊机进行冷却。当红色指示灯熄灭后,温

度降至标准范围,可以重新开始焊接。

定期用干燥清洁的压缩空气吹去灰尘,如果焊机在浓烟和空气

污染严重的环境下使用,应每天给焊机除尘。

定期检查焊机内部电路连接情况,确认线路连接正确,连接头

牢固(特别是插入接头或元件),如果发现有生锈和松脱,应

用沙纸打磨掉生锈层或氧化膜,重新连接,并加以紧固。

避免水或水汽进入焊机内部,如果出现此种情况,应对焊机内

部进行干燥处理。随后,用兆欧表测量焊机的绝缘情况(包括

连接节点之间及连接点与机壳之间)。只有证实没有异常情

况,才可继续焊接工作。

如果长时间不用焊机,应将焊机放回原包装箱并存放在干燥的

环境中。

•

•

•

•

包装清单

名称

充电/启动电源线夹钳正极“+”

充电/启动电源线夹钳负极“-”

数量

1

1

单位

条

条

名称

主机

用户手册

数量

1

1

单位

台

本

电焊焊接夹钳连接线(仅用

于 EM325 三用机)

合格证 1张1条

售后服务

售后保修:

AUTOOL 整机自客户签收日起享有3年保修期,附件1年保修期。

保修方式:

根据具体的故障情况对设备进行修理或更换;

我方保证所有更换的部件、附件或设备都是全新;

在客户收到产品90天内出现故障同时提供视频和图片,我方承

担运费并免费提供相应配件给客户更换。收到产品超过90天,

客户承担相应的费用,我方免费提供配件给客户更换;

•

•

•

以下情况不再免费保修范围:

非正规渠道购买AUTOOL的产品;

未按产品说明书要求使用和维护造成的损坏;

•

•

声明:偶然公司保留更改产品设计与规格的权利,届时恕不另行

通知。实物外观与颜色可能与说明书中显示的有差别,请以实物

为准。我们已尽最大努力力求使书中所有描述准确,但仍难免有

不妥之处,如有疑问,请联系经销商或偶然售后服务中心,本公

司对产品拥有最终解释权,不承担任何因误解而产生的后果。

This manual suits for next models

1

Table of contents