AuCom EMX3-0053B User manual

USER MANUAL

MODBUS TCP INTERFACE

RIGHT FROM

THE START

Modbus TCP Interface | Rev D 3/2019

Contents

1. Warnings.............................................................................................. 2

2. Important User Information................................................................ 2

3. Installation........................................................................................... 3

4. Device Configuration ........................................................................... 6

5. PLC Configuration ............................................................................... 8

6. Feedback LEDs.................................................................................... 8

7. Operation ............................................................................................. 9

8. Modbus Registers.............................................................................. 10

9. Network Design................................................................................. 21

10. Specifications .................................................................................... 23

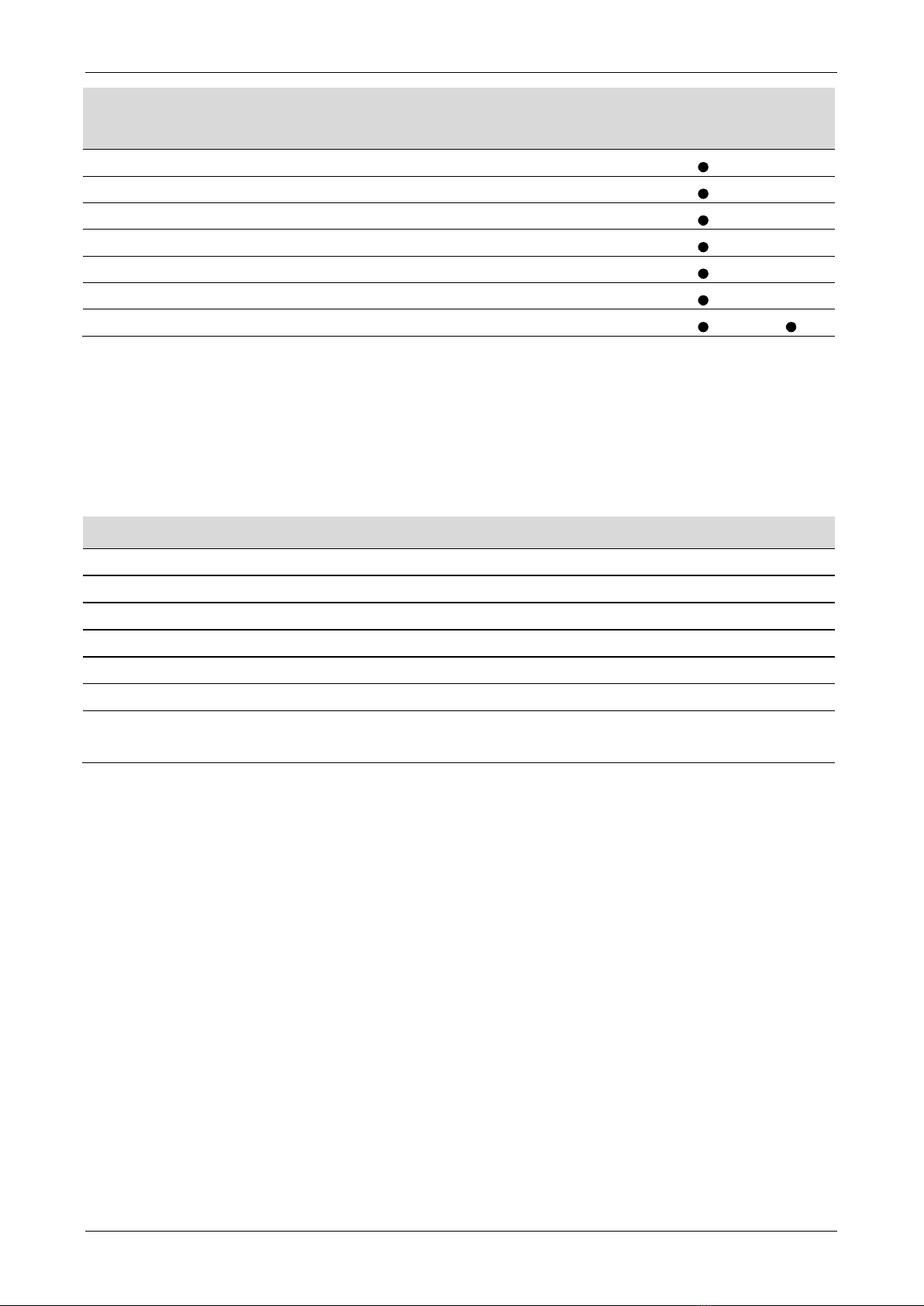

Product Compatibility

The Modbus TCP Interface is compatible with the following AuCom soft starters:

•CSX – 24 VAC/VDC and 110/240 VAC control voltage.

The Modbus TCP Interface is not suitable for use with CSX starters using 380/440

VAC control voltage.

•EMX3 – all models.

•MV – all models.

Disclaimer

The examples and diagrams in this manual are included solely for illustrative

purposes. The information contained in this manual is subject to change at any time

and without prior notice. In no event will responsibility or liability be accepted for

direct, indirect or consequential damages resulting from the use or application of this

equipment.

© 2019 AuCom Electronics Ltd. All Rights Reserved.

USER MANUAL

2Modbus TCP Interface (710-14812-00D)

1. Warnings

WARNING

For your safety, isolate the soft starter completely from mains voltage before

attaching or removing accessories.

WARNING

Observe all necessary safety precautions when controlling the soft starter

remotely. Alert personnel that machinery may start without warning.

2. Important User Information

2.1 Safety

It is the installer's responsibility to follow all instructions in this manual and to follow

correct electrical practice.

Close attention is required to the electrical installation and the system design to avoid

hazards either in normal operation or in the event of equipment malfunction. System

design, installation, commissioning and maintenance must be carried out by personnel

who have the necessary training and experience. They must read this safety

information and this guide carefully.

2.2 Product Design

The Modbus TCP Interface allows the soft starter to connect to an Ethernet network

and be controlled or monitored using an Ethernet communication model.

Familiarity with Ethernet protocols and networks is required to operate the device

successfully. For difficulties using this device with third party products, including

PLCs, scanners and commissioning tools, contact the relevant supplier.

USER MANUAL

Modbus TCP Interface (710-14812-00D) 3

3. Installation

CAUTION

Remove mains and control voltage from the soft starter before attaching or

removing accessories. Failure to do so may damage the equipment.

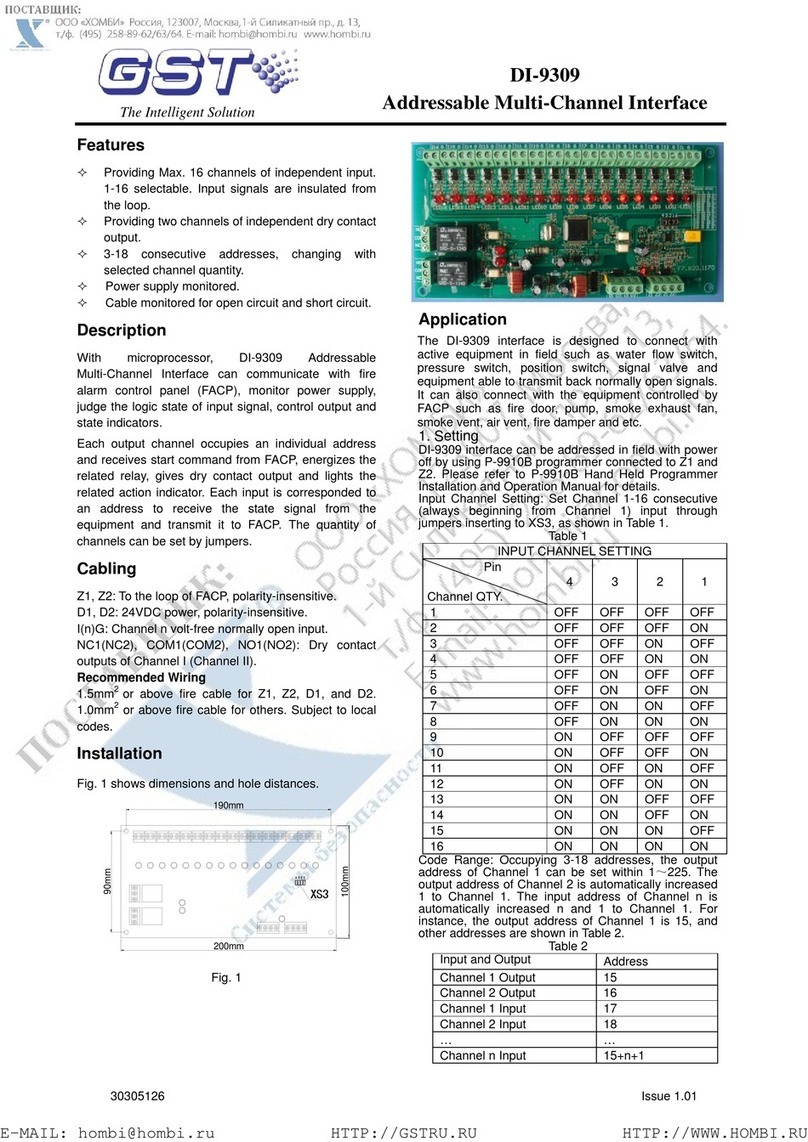

3.1 Installation Procedure

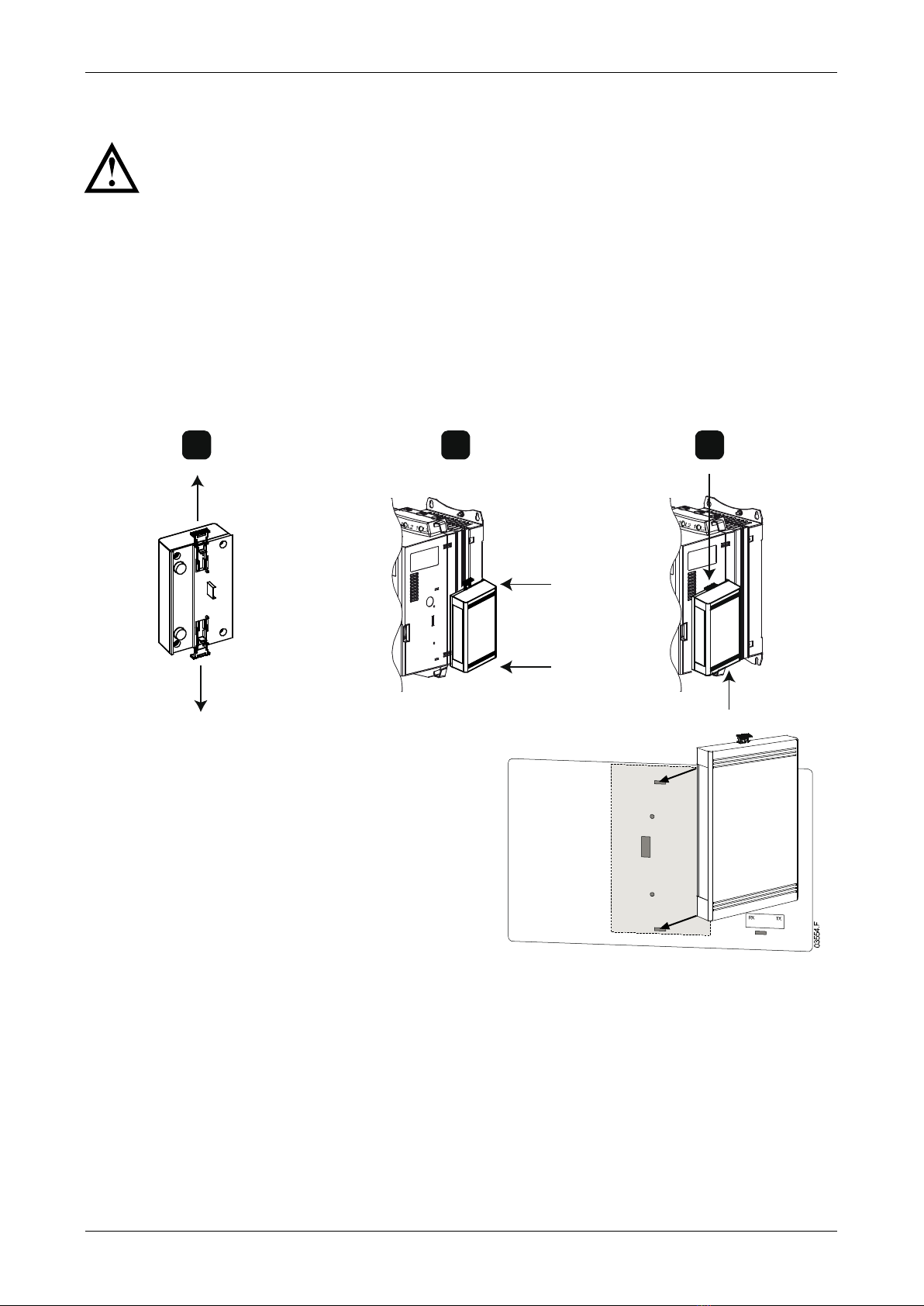

1. Remove control power and mains supply from the soft starter.

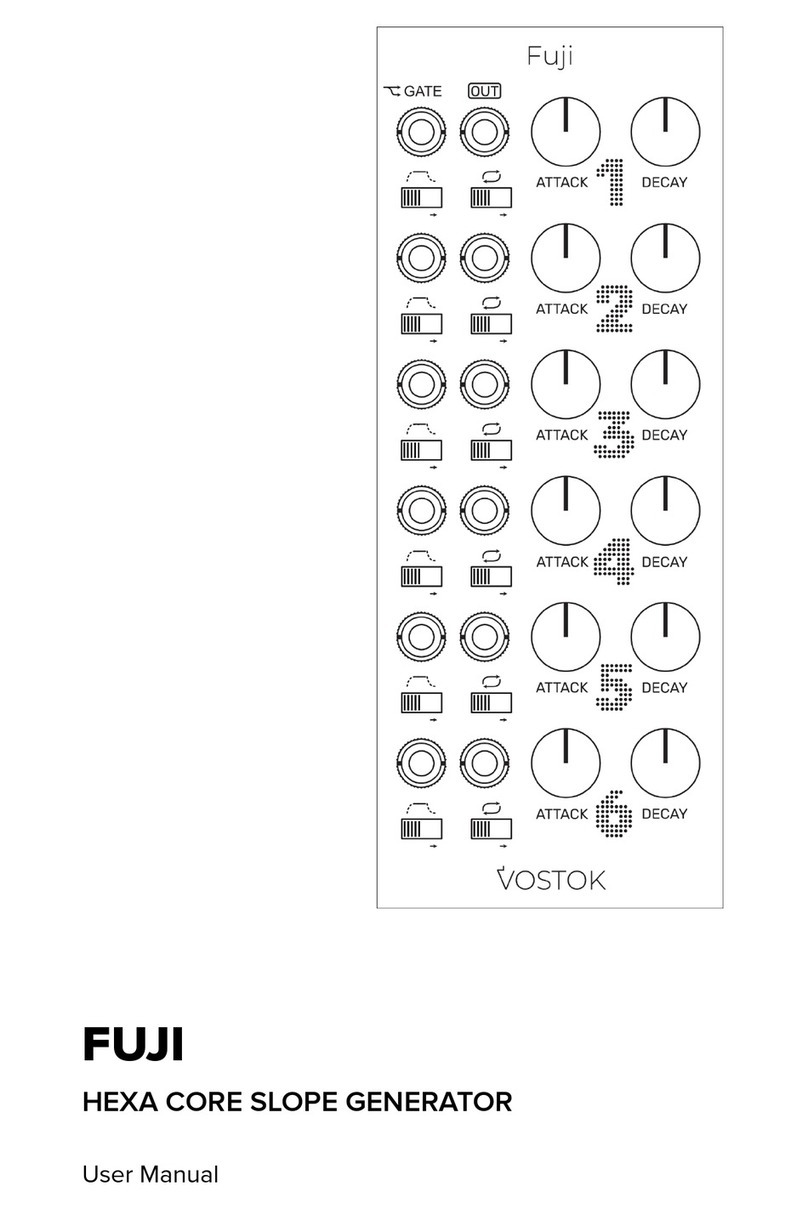

2. Fully pull out the top and bottom retaining clips on the interface. [A]

3. Line up the interface with the comms port slot. [B]

4. Push in the top and bottom retaining clips to secure the interface to the starter. [C]

5. Connect Ethernet Port 1 or Port 2 on the Modbus TCP Interface to the network.

6. Apply control power to the soft starter.

ABC

10178.C

MV:

Plug the interface onto the back of the

controller.

USER MANUAL

4Modbus TCP Interface (710-14812-00D)

To remove the interface:

1. Remove control power and mains supply from the soft

starter.

2. Disconnect all external wiring from the interface.

3. Fully pull out the top and bottom retaining clips on the

interface. [A]

4. Pull the interface away from the soft starter.

03550.C

A

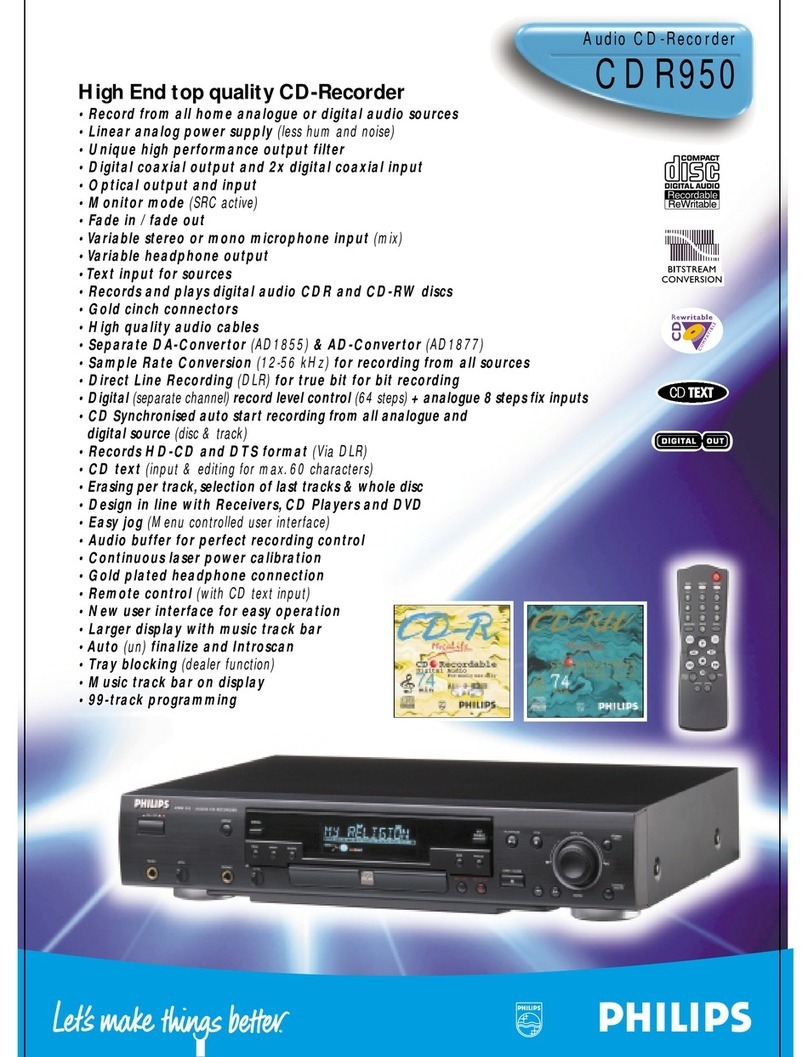

3.2 Soft Starter Connection

The device is powered from the soft starter.

CSX: For the Modbus TCP Interface to accept fieldbus commands, a link must be fitted

across terminals A1-02 on the soft starter.

The Modbus TCP Interface is not suitable for use with CSX starters using

380/440 VAC control voltage.

EMX3 and MV: Input links are required across the stop and reset inputs if the soft

starter is being operated in Remote mode. In Local mode, links are not required.

NOTE

EMX3 and MV: Control via the fieldbus communication network is always

enabled in local control mode, and can be enabled or disabled in remote

control mode (parameter 6R

Comms in Remote

). Refer to the soft starter user

manual for parameter details.

CSX

EMX3 or MV

14698.A

1

3

2

1

Soft starter

1

Soft starter (remote mode)

A1, 02: Stop input

C31, C32: Stop input

C41, C42: Reset input

2

Modbus TCP Interface

2

Modbus TCP Interface

3

RJ45 Ethernet ports

3

RJ45 Ethernet ports

14699.A

1

3

2

USER MANUAL

Modbus TCP Interface (710-14812-00D) 5

3.3 Network Connection

Ethernet Ports

The device has two Ethernet ports. If only one connection is required, either port can

be used.

Cables

Use Category 5, 5e, 6 or 6e cable to connect to the device.

EMC Precautions

To minimise electromagnetic interference, Ethernet cables should be separated from

motor and mains cables by 200 mm.

If the Ethernet cable must cross motor or mains cables, the crossing should be at an

angle of 90°.

3.4 Network Establishment

The controller must establish communications directly with each device before the

device can participate in the network.

3.5 Addressing

Each device in a network is addressed using a MAC address and an IP address.

•The device can be assigned a static IP address during configuration, or can be

configured to accept a dynamic IP address (via DHCP).

•The MAC address is fixed within the device and is printed on a label on the front of

the device.

USER MANUAL

6Modbus TCP Interface (710-14812-00D)

4. Device Configuration

NOTE

The Error LED flashes whenever the device is receiving power but is not

connected to a network. The Error LED will flash occasionally during the

configuration process.

4.1 Overview

The Modbus TCP Interface is configured with a static IP address as default. To avoid IP

address conflicts and to ensure successful deployment, we recommend that the device

is connected directly to a PC or laptop to configure the IP address, before connecting

to the network.

4.2 Configuration Methods

•Ethernet attributes can be configured directly in the device using the on-board web

server. The default address for a new Modbus TCP Interface is 192.168.0.1. The

default subnet mask is 255.255.255.0. The web server will only accept connections

from within the same subnet domain.

Changes made via the on-board web server are stored permanently in the device.

•If the subnet domain of the device is different from the controller, or if the IP

address has been changed and is no longer known, use the Ethernet Device

Configuration Tool to scan the network and identify the device. Changes made via

the Ethernet Device Configuration Tool cannot be stored permanently in the device

and will be lost when control power is cycled.

4.3 On-board Web Server

To configure settings using the on-board web server, the module must be installed on

a soft starter, control power must be available, and the device and computer must be

connected to each other or to the same Ethernet network.

To configure the device using the on-board web server:

1. Start a browser on the PC and enter the device address, followed by /ipconfig.

The default address for a new Modbus TCP Interface is 192.168.0.1.

USER MANUAL

Modbus TCP Interface (710-14812-00D) 7

2. Edit the settings as required. Click "Submit" to save the new settings. To store the

settings permanently in the device, tick "Static".

3. If prompted to enter a username and password:

username: admin

password: admin

NOTE

If you change the IP address and lose your record of it, use the Ethernet Device

Configuration Tool to scan the network and identify the interface.

NOTE

If you change the subnet mask, the web server will not be able to communicate

with the device after the new settings are saved.

4.4 Ethernet Device Configuration Tool

Use the Ethernet Device Configuration Tool to connect to the device if you do not know

the IP address, or if the subnet mask of the web server does not match.

To configure settings using the Ethernet Device Configuration Tool, the device must be

installed in a soft starter, control power must be available, and the device and PC must

both be connected to the Ethernet network.

The Ethernet Device Configuration Tool can be downloaded from www.aucom.com.

NOTE

If your PC has a firewall enabled, you must add the tool to the list of authorised

programs.

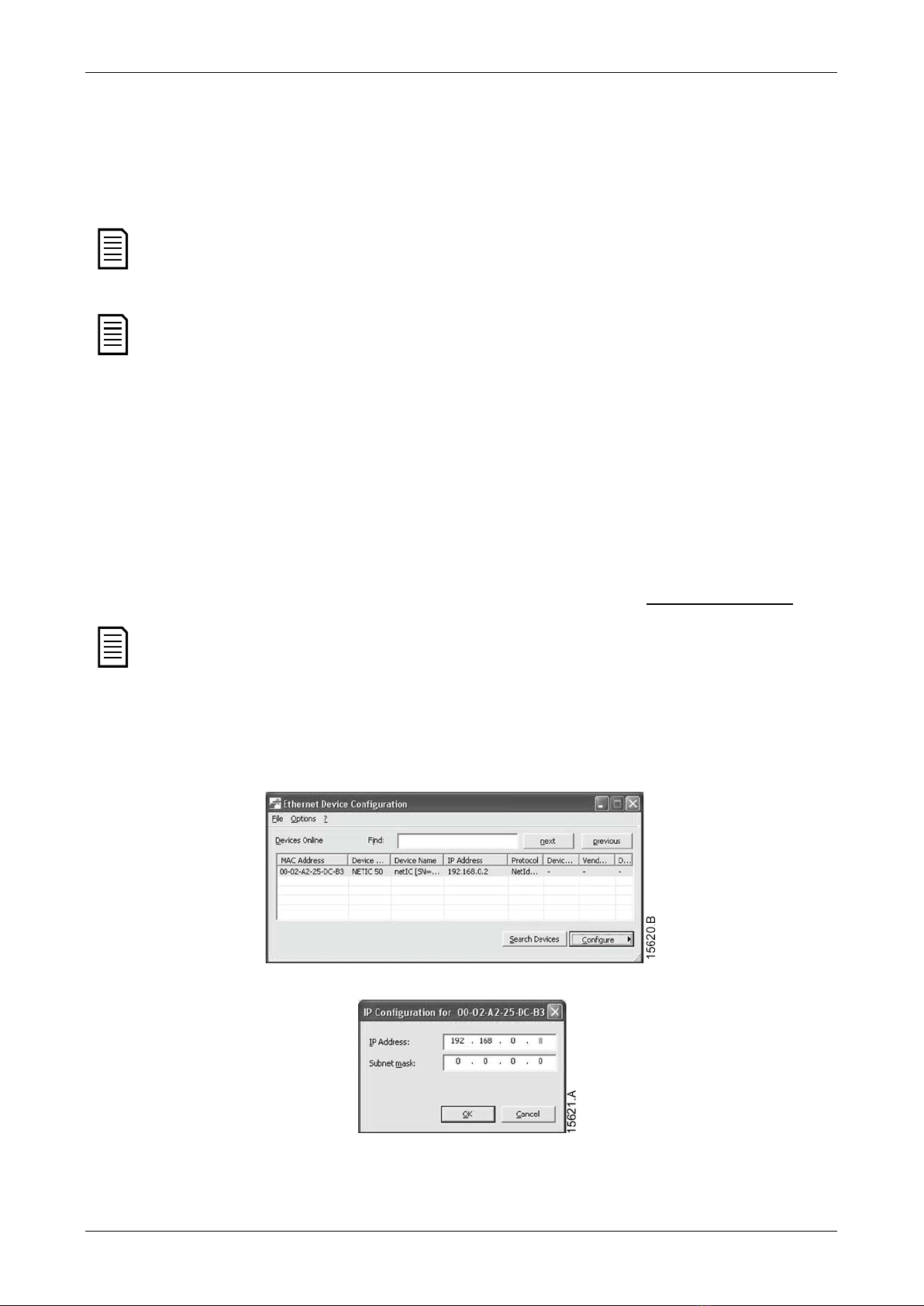

To configure the device using the Ethernet Device Configuration Tool:

1. Start the Ethernet Device Configuration Tool.

2. Click on Search Devices. The software will search for connected devices.

3. To set a static IP address, click Configure then select Set IP address.

USER MANUAL

8Modbus TCP Interface (710-14812-00D)

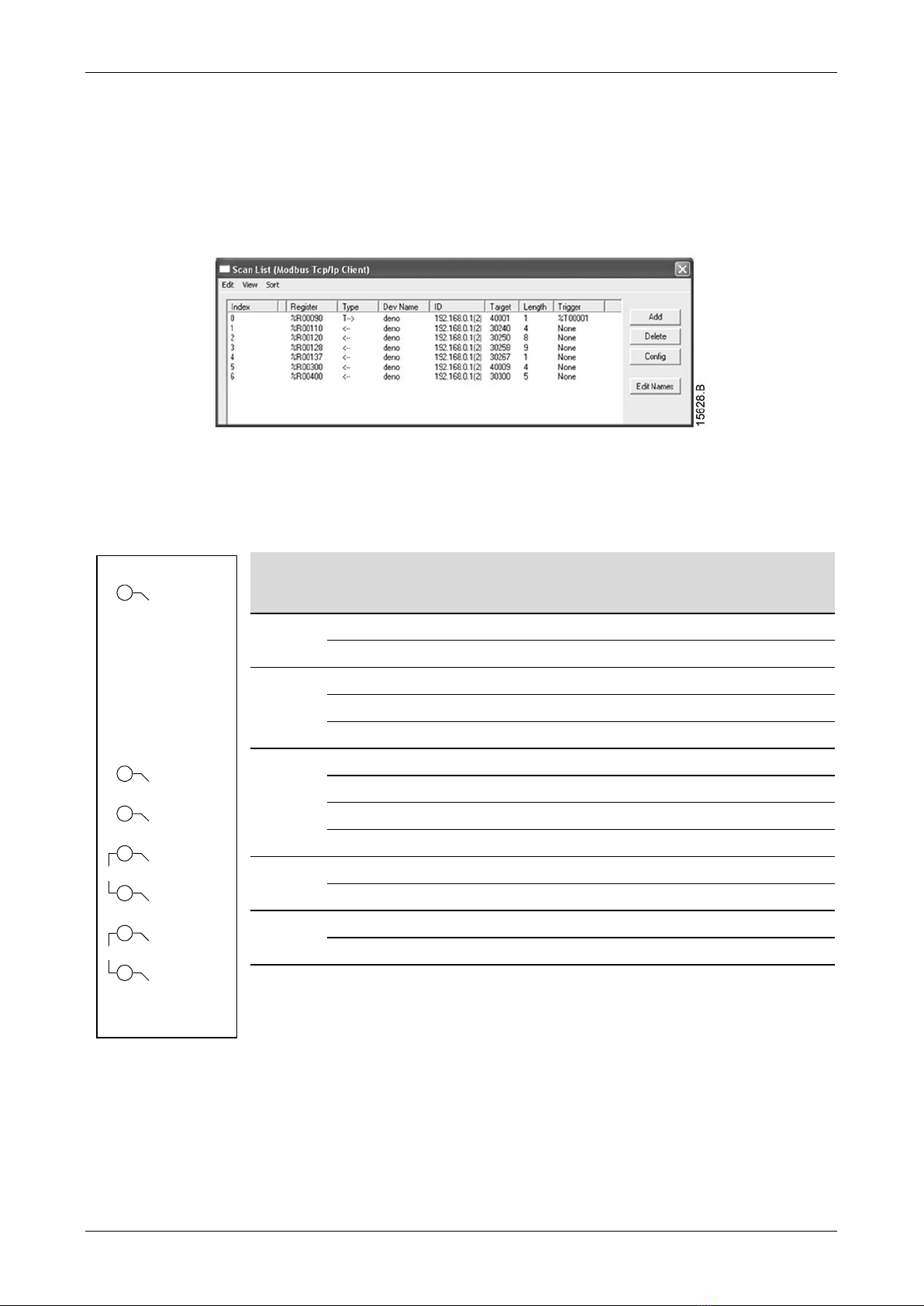

5. PLC Configuration

The PLC must be configured to map registers within the interface to addresses within

the PLC.

Example mapping of PLC registers to registers within the Modbus TCP Interface

(Target):

The device must be configured directly in the PLC. No additional files are required.

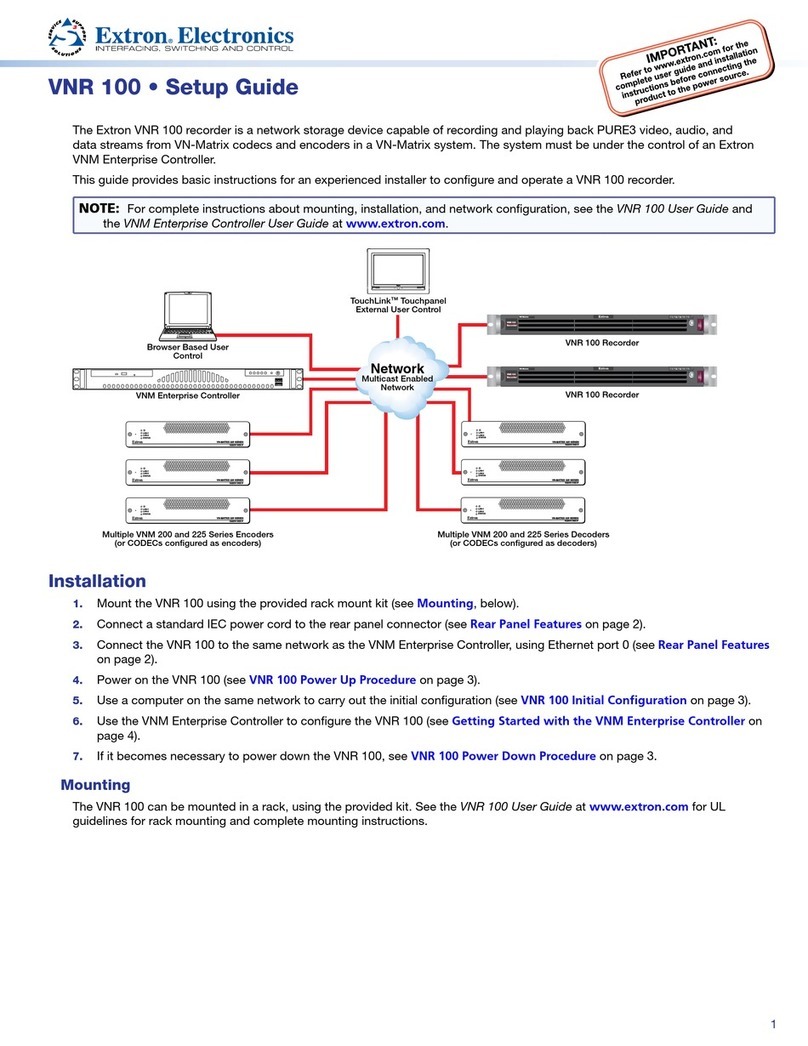

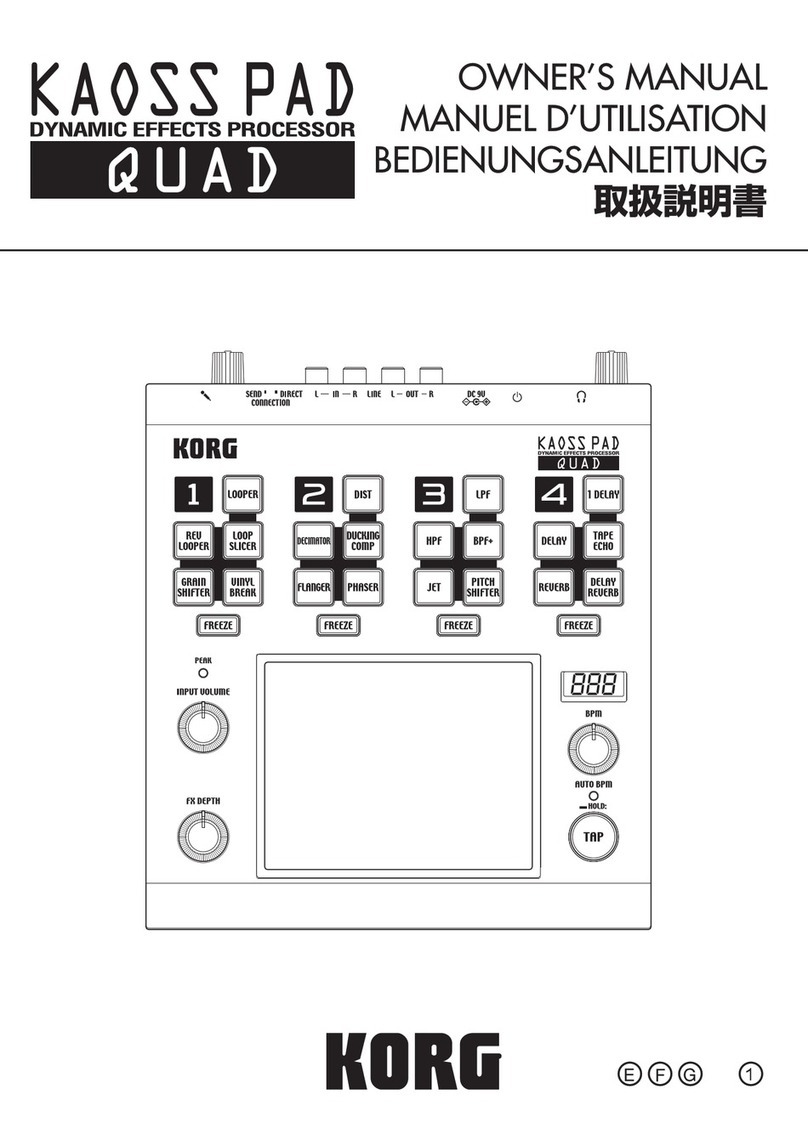

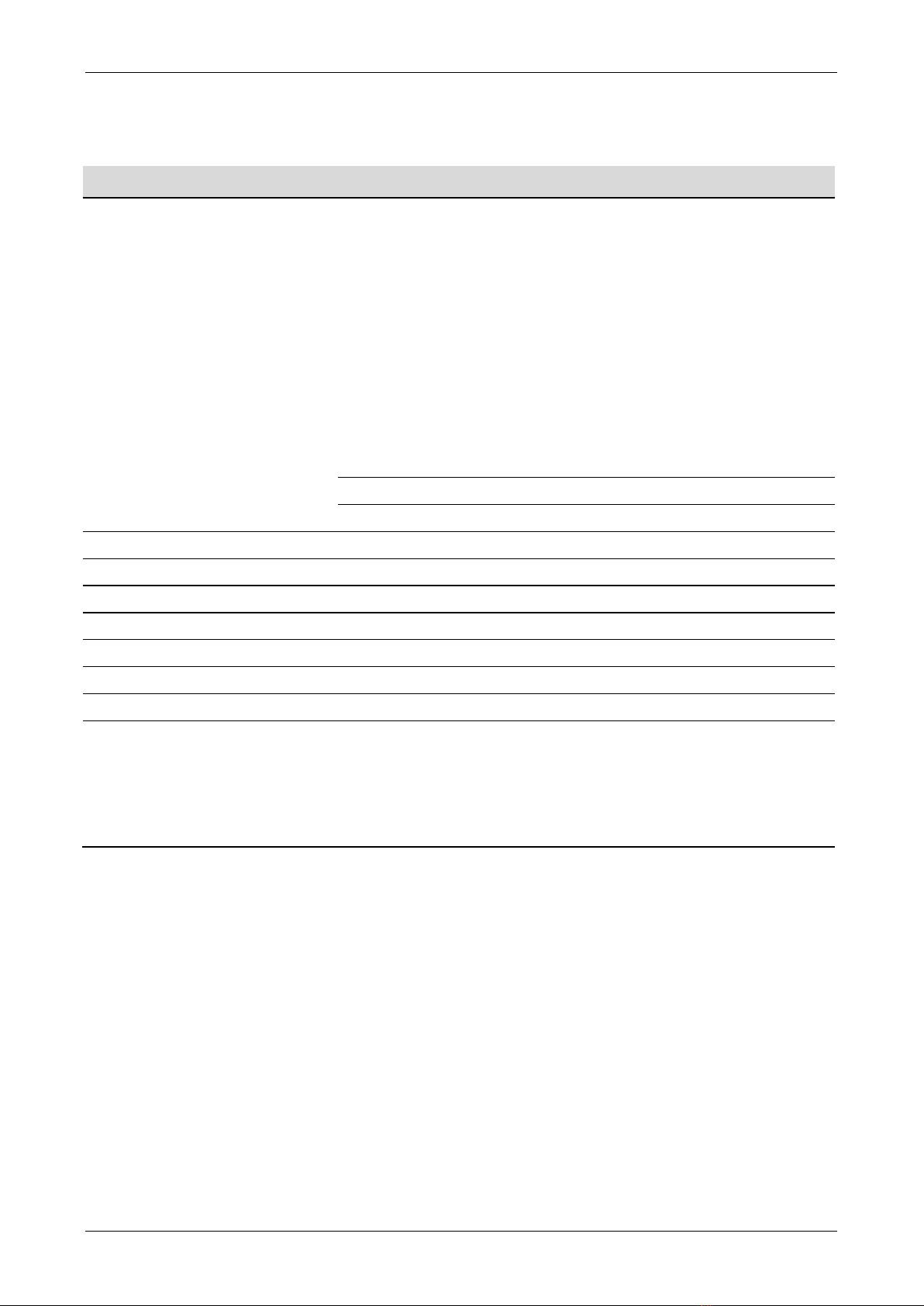

6. Feedback LEDs

1 2

TX/RX 2

TX/RX 1

Link 2

Link 1

Error

Status

Power

14702.B

LED

name

LED

Status

Description

Power

Off

Device is not powered up.

On Device is receiving power.

Error

Off

No error.

Flashing

System error.

On

Communication error.

Status

Off

Not ready.

Slow flash Ready but not configured.

Fast flash

Configured and waiting for communication.

On Communication has been established.

Link x

Off

No network connection.

On

Connected to a network.

TX/RX x

Flashing

Establishing connection.

On

Operating normally.

USER MANUAL

Modbus TCP Interface (710-14812-00D) 9

7. Operation

The Modbus TCP Interface must be controlled by a Modbus client (such as a PLC)

which complies with the Modbus Protocol Specification. For successful operation, the

client must also support all functions and interfaces described in this document.

7.1 Device Classification

The Modbus TCP Interface is a Modbus server and must be managed by a Modbus

client over Ethernet.

7.2 Ensuring Safe and Successful Control

Data written to the device will remain in its registers until the data is overwritten or

the device is reinitialised. The device will not transfer successive duplicate commands

to the soft starter.

•If the soft starter is started via fieldbus communications but stopped via the keypad

or a remote input, an identical start command cannot be used to restart the starter.

•If the soft starter may also be controlled via the keypad or the remote inputs (as

well as via fieldbus communications), a control command should be immediately

followed by a status query to confirm the command has been actioned.

USER MANUAL

10 Modbus TCP Interface (710-14812-00D)

8. Modbus Registers

NOTE

The available features and parameter details may vary according to the model

and software version of the starter. Refer to the soft starter user manual for

details of parameters and supported features.

NOTE

All references to registers mean the registers within the interface unless

otherwise stated.

8.1 Compatibility

The Modbus TCP Interface supports two modes of operation.

•In Standard Mode, the interface uses registers defined in the Modbus Protocol

Specification.

•In Legacy Mode, the interface uses the same registers as AuCom's Modbus

Interface. Some registers differ from those specified in the Modbus Protocol

Specification.

The mode of operation is determined by the values of bit 15 in register 40001.

•Standard Mode: set Bit 15 = 1. Bits 0~7 of register 40001 are used for command.

•Legacy Mode: set Bit 15 = 0. The remaining bits of register 40001 are reserved.

Examples

10000000 00000001 = start the motor (Standard Mode).

10000000 00000000 = stop the motor (Standard Mode).

00000000 xxxxxxxx = switch to Legacy Mode. The interface will ignore the remaining

bits in register 40001 and will check the value in register 40002.

8.2 Parameter Management

Parameters can be read from and written to the starter. When writing parameters to

the soft starter, every parameter will be updated to match the values in the PLC.

CAUTION

Do not change the default values of the Factory parameters (parameter group

20). Changing these values may cause unpredictable behaviour in the soft

starter.

USER MANUAL

Modbus TCP Interface (710-14812-00D) 11

8.3 Standard Mode

Command and Configuration Registers (Read/Write)

Register

Description

Bits

Details

40001

Command

(single write)

0 to 7

To send a command to the starter, write the

required value:

00000000 = Stop

00000001 = Start

00000010 = Reset

00000100 = Quick stop (coast to stop)

00001000 = Forced communication trip

00010000 = Start using Parameter Set 11

00100000 = Start using Parameter Set 21

01000000 = Local control

10000000 = Remote control

8 to 14

Reserved

15

Must = 1

40002

Reserved

40003

Reserved

40004

Reserved

40005

Reserved

40006

Reserved

40007

Reserved

40008

Reserved

40009

2

Parameter

management

(single/multiple

read or multiple

write)

0 to 15

Manage soft starter programmable parameters

1Ensure that the programmable input is not set to Motor Set Select before using this

function.

2Refer to the relevant soft starter literature for a complete parameter list. The first

product parameter is always allocated to register 40009. The last product parameter is

allocated to register 40XXX, where XXX = 008 plus total number of available

parameters in the product. The Modbus TCP protocol limits read/write operations to a

maximum of 123 registers at one time. The registers must be consecutive. These

registers support multiple write (Modbus function code 16). Attempting to write to a

single register will return an error code 01 (Illegal function code).

USER MANUAL

12 Modbus TCP Interface (710-14812-00D)

Status Reporting Registers (Read Only)

NOTE

For models EMX3-0053B and smaller, current reported via communications is

10 times greater than the actual value (displayed on the keypad).

Register

Description

Bits

Details

30240 Starter state 0 to 3 1 = Ready

2 = Starting

3 = Running

4 = Stopping (including braking)

5 = Restart delay (including temperature

check)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

4

1 = Positive phase sequence

(only valid if bit 6 = 1)

5

1 = Current exceeds FLC

6

0 = Uninitialised

1 = Initialised

7 to 15

Reserved

30241

Trip code

0 to 7

Refer to

Trip Codes

on page 19.

8 to 15

Reserved

30242

Motor current

0 to 7

Average 3-phase motor current (A)

8 to 15

Reserved

30243 Motor

temperature

0 to 7 Motor 1 thermal model (%)

8 to 15

Reserved

30244 ~

30249

Reserved

30250

Version

0 to 5

Reserved

6 to 8

Product parameter list version

9 to 15 Product type code:

4 = CSX

6 = EMX3

11 = MV

30251 Model number 0 to 7

Reserved

8 to 15

Soft starter model ID

30252

Reserved

30253

Reserved

USER MANUAL

Modbus TCP Interface (710-14812-00D) 13

Register

Description

Bits

Details

30254

Starter state

0 to 4

0 =

Reserved

1 = Ready

2 = Starting

3 = Running

4 = Stopping

5 = Not ready (restart delay, restart

temperature check, run simulation)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

5 1 = Warning

6 0 = Uninitialised

1 = Initialised

7 0 = Local control

1 = Remote control

8

Reserved

9 0 = Negative phase sequence

1 = Positive phase sequence

10 to 15 Refer to

Trip Codes

on page 19.

30255

Current

0 to 13

Average rms current across all three phases

14 to 15

Reserved

30256

Current

0 to 9

Current (% motor FLC)

10 to 15

Reserved

30257 Motor

temperature

0 to 7 Motor 1 thermal model (%)

8 to 15

Motor 2 thermal model (%)

30258 Power 0 to 11 Power

12 to 13

Power scale

0 = Multiply power by 10 to get W

1 = Multiply power by 100 to get W

2 = Power (kW)

3 = Multiply power by 10 to get kW

14 to 15

Reserved

30259

% Power factor

0 to 7

100% = power factor of 1

8 to 15

Reserved

30260 Voltage 0 to 13 Average rms voltage across all three phases

(medium voltage products only)

14 to 15

Reserved

30261 Current 0 to 13 Phase 1 current (rms)

14 to 15

Reserved

USER MANUAL

14 Modbus TCP Interface (710-14812-00D)

Register

Description

Bits

Details

30262 Current 0 to 13 Phase 2 current (rms)

14 to 15

Reserved

30263 Current

0 to 13

Phase 3 current (rms)

14 to 15

Reserved

30264

Voltage

0 to 013

Phase 1 voltage, rms

(medium voltage products only)

14 to 15

Reserved

30265 Voltage 0 to 13

Phase 2 voltage, rms

(medium voltage products only)

14 to 15

Reserved

30266 Voltage 0 to 13

Phase 3 voltage, rms

(medium voltage products only)

14 to 15

Reserved

30267

Parameter list

version number

0 to 7

Parameter list minor revision

8 to 15

Parameter list major version

30268 Digital input

state

0 to 15 For all inputs, 0 = open, 1 = closed (shorted)

0 = Start

1 = Stop

2 = Reset

3 = Input A

4 = Input B

5 = Input C, if fitted

6 = Input D, if fitted

7 to 15 =

Reserved

30269~

30281

Reserved

USER MANUAL

Modbus TCP Interface (710-14812-00D) 15

8.4 Legacy Mode

Registers

NOTE

For models EMX3-0053B and smaller, current reported via communications is

10 times greater than the actual value (displayed on the keypad).

NOTE

Legacy Mode reports read-only status information in registers 40003 onwards,

to match the register definitions of the clip-on Modbus Module for use with

older soft starters. Identical data is also available via registers 30003 onwards.

Register

Description

Bits

Details

40001

Reserved

0 to 14

Reserved

15

Must be zero

40002

Command

(single write)

0 to 2

To send a command to the starter, write the

required value:

1 = Start

2 = Stop

3 = Reset

4 = Quick stop (coast to stop)

5 = Forced communication trip

6 = Start using Parameter Set 1

7 = Start using Parameter Set 2

3 to 15

Reserved

40003

Starter state

0 to 3

1 = Ready

2 = Starting

3 = Running

4=Stopping (including braking)

5 = Restart delay (including temperature

check)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

4

1 = Positive phase sequence

(only valid if bit 6 = 1)

5 1 = Current exceeds FLC

6

0 = Uninitialised

1 = Initialised

7 to 15

Reserved

40004

Trip code

0 to 7

Refer to

Trip Codes

on page 19.

8 to 15

Reserved

USER MANUAL

16 Modbus TCP Interface (710-14812-00D)

Register

Description

Bits

Details

40005

Motor current

0 to 7

Average 3-phase motor current (A)

8 to 15

Reserved

40006 Motor temperature 0 to 7 Motor 1 thermal model (%)

8 to 15

Reserved

40007

Reserved

40008

Reserved

40009

1

~

40200

Parameter

management

(single/multiple

read or multiple

write)

0 to 7

Manage soft starter programmable

parameters

8 to 15

Reserved

40600

Version

0 to 5

Binary protocol version

6 to 8 Parameter list version number

9 to 15

Product type code:

4 = CSX

6 = EMX3

11 = MV

40601

Reserved

40602

Reserved

40603

Reserved

40604 Starter state 0 to 4 0 =

Reserved

1 = Ready

2 = Starting

3 = Running

4 = Stopping

5 = Not ready (restart delay, restart

temperature check, run simulation)

6 = Tripped

7 = Programming mode

8 = Jog forward

9 = Jog reverse

5

1 = Warning

6

0 = Uninitialised

1 = Initialised

7

Local/Remote

0 = Local control

1 = Remote control

8

Reserved

9 0 = Negative phase sequence

1 = Positive phase sequence

10 to 15

Reserved

USER MANUAL

Modbus TCP Interface (710-14812-00D) 17

Register

Description

Bits

Details

40605

Current

0 to 13

Average rms current across all three phases

14 to 15

Reserved

40606 Current 0 to 9 Current (% motor FLC)

10 to 15

Reserved

40607 Motor temperature 0 to 7 Motor 1 thermal model (%)

8 to 15

Reserved

40608

Power

0 to 11

Power

12 to 13 Power scale

0 = Multiply power by 10 to get W

1 = Multiply power by 100 to get W

2 = Power (kW)

3 = Multiply power by 10 to get kW

14 to 15

Reserved

40609

% Power factor

0 to 7

100% = power factor of 1

8 to 15

Reserved

40610 Voltage 0 to 13 Average rms voltage across all three phases

(medium voltage products only)

14 to 15

Reserved

40611

Current

0 to 13

Phase 1 current (rms)

14 to 15

Reserved

40612

Current

0 to 13

Phase 2 current (rms)

14 to 15

Reserved

40613

Current

0 to 13

Phase 3 current (rms)

14 to 15

Reserved

40614

Voltage

0 to 13

Phase 1 voltage, rms

(medium voltage products only)

14 to 15

Reserved

40615 Voltage 0 to 13 Phase 2 voltage, rms

(medium voltage products only)

14 to 15

Reserved

40616 Voltage 0 to 13 Phase 3 voltage, rms

(medium voltage products only)

14 to 15

Reserved

40617 Parameter list

version number

0 to 7 Parameter list minor revision

8 to 15

Parameter list major version

USER MANUAL

18 Modbus TCP Interface (710-14812-00D)

Register

Description

Bits

Details

40618 Digital input state 0 to 15 For all inputs, 0 = open, 1 = closed (shorted)

0 = Start

1 = Stop

2 = Reset

3 = Input A

4 = Input B

5 = Input C, if fitted

6 = Input D, if fitted

7 to 15 =

Reserved

40619~

40631

Reserved

1Refer to the relevant soft starter literature for a complete parameter list. The first

product parameter is always allocated to register 40009. The last product parameter is

allocated to register 40XXX, where XXX = 008 plus total number of available

parameters in the product. The Modbus TCP protocol limits read/write operations to a

maximum of 123 registers at one time. The registers must be consecutive. These

registers support multiple write (Modbus function code 16). Attempting to write to a

single register will return an error code 01 (Illegal function code).

USER MANUAL

Modbus TCP Interface (710-14812-00D) 19

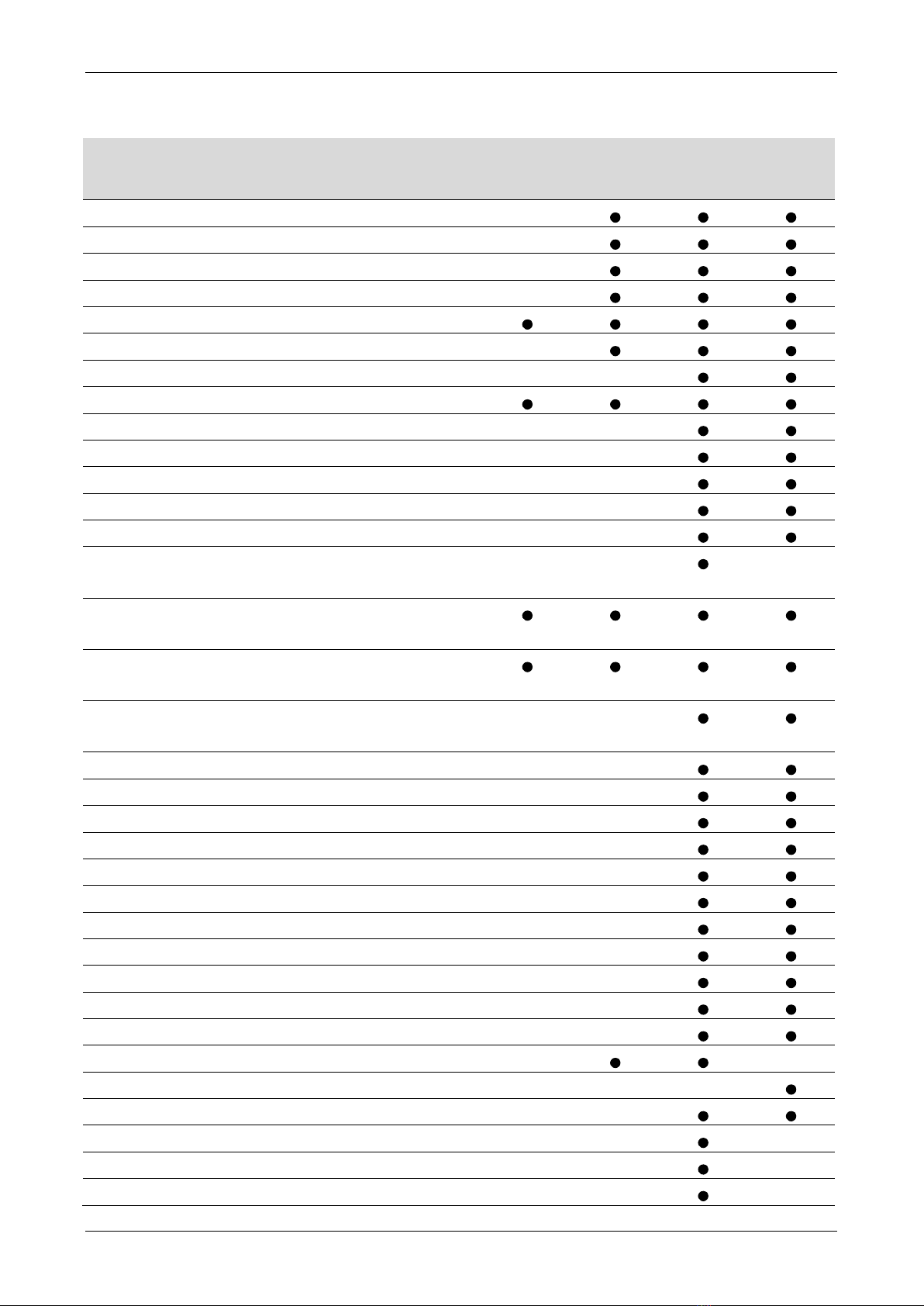

8.5 Trip Codes

Trip

Code

Description

CSX

CSX

i

EMX3

MV

1 Excess start time

2

Motor overload

3

Motor thermistor

4

Current imbalance

5

Frequency

6 Phase sequence

7

Instantaneous overcurrent

8

Power loss

9

Undercurrent

10

Heatsink (starter) overtemperature

11 Motor connection

12 Input A trip

13

FLC too high

14

Unsupported option (function not

available in inside delta)

15

Starter communication (between

device and soft starter)

16

Network communication (between

device and network)

17

Internal fault x (where x is the fault

code detailed in the table below)

201Ground fault

23

Parameter out of range

24

Input B trip

25

Bypass fail (bypass contactor)

26

L1 phase loss

27 L2 phase loss

28 L3 phase loss

29

L1-T1 shorted

30

L2-T2 shorted

31

L3-T3 shorted

32

Motor 2 overload

332Time-overcurrent (Bypass overload)

34 SCR overtemperature

35

Battery/clock

36

Thermistor circuit

37

RTD/PT100 A

38

1

RTD/PT100 B

USER MANUAL

20 Modbus TCP Interface (710-14812-00D)

Trip

Code

Description

CSX

CSX

i

EMX3

MV

39

1

RTD/PT100 C

40

1

RTD/PT100 D

41

1

RTD/PT100 E

421RTD/PT100 F

431RTD/PT100 G

45

RTD circuit fail

46

Analog input trip

1Available with EMX3 only if the appropriate option card is fitted.

2For EMX3, time-overcurrent protection is only available on internally bypassed

models.

Internal Fault X

The table below details the internal fault code associated with trip code 17.

Internal fault

Message displayed on the keypad

70 ~ 72 Current Read Err Lx

73

ATTENTION! Remove Mains Volts

74 ~ 76

Motor Connection Tx

77 ~ 79 Firing Fail Px

80 ~ 82

VZC Fail Px

83 Low Control Volts

84 ~ 98

Internal fault X

Contact your local supplier with the fault code (X).

Table of contents