3

Introduction

Vehicle distinguishing features ____________________________________________________________________________________________________________________________ 4

Dimensions __________________________________________________________________________________________________________________________________________________ 6

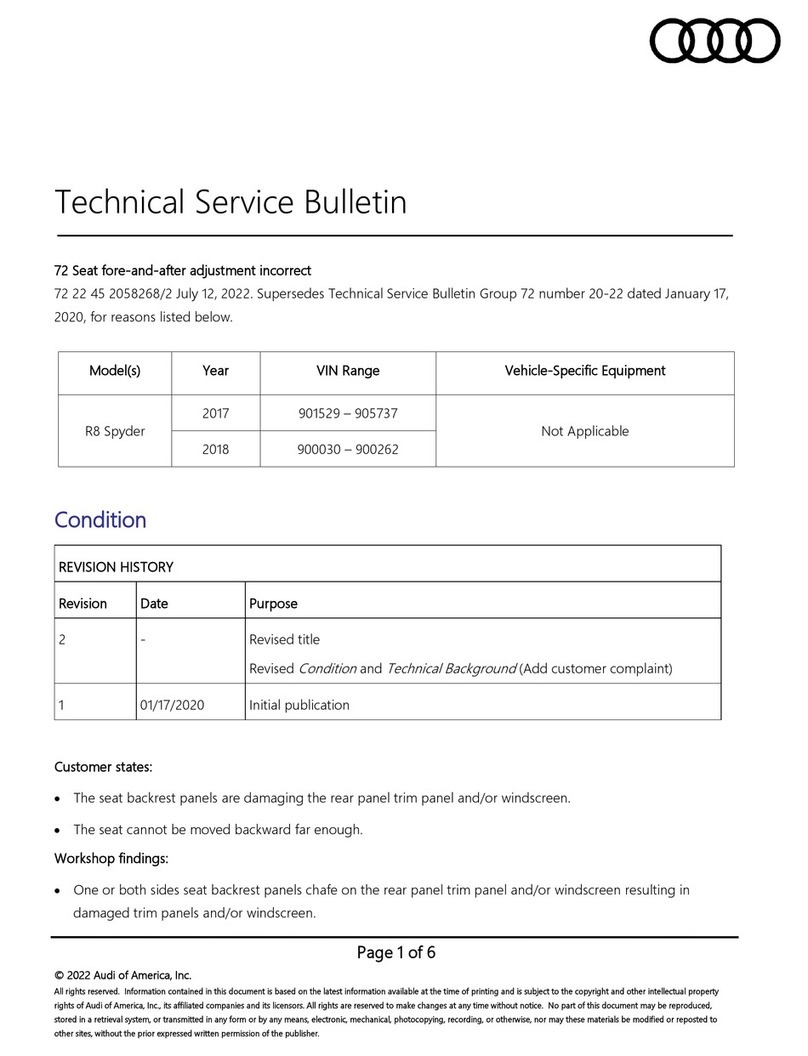

Passive safety

Overview _____________________________________________________________________________________________________________________________________________________ 8

Components _________________________________________________________________________________________________________________________________________________ 8

System overview ___________________________________________________________________________________________________________________________________________10

Airbag control unit J234 ___________________________________________________________________________________________________________________________________12

Internal combustion engines

3.0l V6 TDI engine Gen.2 evo (EA897) ___________________________________________________________________________________________________________________14

Third-generation 2.0l R4 TFSI engine (EA888) _________________________________________________________________________________________________________16

Technical features __________________________________________________________________________________________________________________________________________18

Power transmission

Overview ____________________________________________________________________________________________________________________________________________________24

Selector mechanism _______________________________________________________________________________________________________________________________________26

Emergency release, parking lock _________________________________________________________________________________________________________________________27

Plug-in hybrid drive ________________________________________________________________________________________________________________________________________ 28

Hybrid module (separation clutch actuator, sensors) __________________________________________________________________________________________________30

8-speed automatic gearbox 0D7 (cutaway view, ATF and MTF systems, ATF supply) _______________________________________________________________36

Gearbox schematic, gear set, shift elements ____________________________________________________________________________________________________________44

Shift matrix, operating modes, mechatronic module __________________________________________________________________________________________________46

ATF cooling _________________________________________________________________________________________________________________________________________________58

Function diagram, information and data exchange ____________________________________________________________________________________________________ 60

Functions influencing gearbox control (Audidriveselect, e-tronmodes) ____________________________________________________________________________61

Combinations of selector positions and e-tron modes within the Audi drive select modes ________________________________________________________63

Service _______________________________________________________________________________________________________________________________________________________64

Chassis

Overall concept _____________________________________________________________________________________________________________________________________________66

Brake system _______________________________________________________________________________________________________________________________________________68

Electro-mechanical brake servo __________________________________________________________________________________________________________________________69

Brake system pressure accumulator VX70 _______________________________________________________________________________________________________________71

Wheels and tyres ___________________________________________________________________________________________________________________________________________73

Air conditioning and cooling

Thermal management and heat pump __________________________________________________________________________________________________________________74

Coolant circuits _____________________________________________________________________________________________________________________________________________ 82

Operating states of the heat pump ______________________________________________________________________________________________________________________ 90

Air conditioning the vehicle interior ______________________________________________________________________________________________________________________ 93

System overview ___________________________________________________________________________________________________________________________________________94

Infotainment

Overview ____________________________________________________________________________________________________________________________________________________96

Service

Inspection and maintenance ______________________________________________________________________________________________________________________________ 97

Appendix

Self study programmes ____________________________________________________________________________________________________________________________________99

Reference

NoteThe self study programme teaches a basic understanding of the design and mode of operation of new models,

new automotive components or new technologies.

It is not a repair manual! Figures are given for explanatory purposes only and refer to the data valid at the

time of preparation of the SSP.

This content is not updated.

For further information about maintenance and repair work, always refer to the current technical literature.

Contents

ProCarManuals.com