AUMA AC(V) 01.2 User manual

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2

Profibus DP

Device integrationManual

Read operation instructions first.

●Observe safety instructions.

Purpose of the document:

This document contains information for the commissioning staff of the distributed control system and DCS software

engineers.This document is intended to support the actuator integration into the DCS via fieldbus interface.

Reference documents:

●Operation instructions (Assembly and commissioning) for the actuator

●Manual (Operation and setting) AC 01.2 actuator controls Profibus DP

Reference documents can be downloaded from the Internet (www.auma.com) or ordered directly from AUMA

(refer to <Addresses>).

Table of contents Page

41. Safety instructions................................................................................................................. 41.1. Prerequisites for the safe handling of the product 51.2. Range of application 51.3. Warnings and notes 51.4. References and symbols

72. General information about Profibus DP............................................................................... 72.1. Basic characteristics 72.2. Basic functions of Profibus DP 72.3. Transfer mode 72.4. Bus access 72.5. Functionality 82.6. Protective functions 82.7. Device types

93. Commissioning...................................................................................................................... 93.1. Introduction 103.2. Parameter setting 113.3. Bus address (slave address) 113.4. Configuring the Profibus DP interface 123.5. Communication start-up 123.6. AUMA user parameters (AUMA specific parameters) 123.6.1. Process representation input arrangement (user parameters) 133.6.2. Settable (user definable) signals 183.6.3. Additional (user-definable) parameters (option) 183.6.4. Further adaptation options 193.7. Communication monitoring 193.7.1. Connection monitoring of the Profibus DP communication 193.7.2. Fail Safe and Global Control Clear telegrams 193.8. I & M functions

214. Description of the data interface ......................................................................................... 214.1. Input data (process representation input) –signals 214.1.1. Process representation input (default process representation) 234.1.2. Description of the bytes in the process representation input 354.2. Output data (process representation output) 354.2.1. Process representation output arrangement

2

Actuator controls

Table of contents AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

364.2.2. Description of the output data 414.3. Profibus DP V1 services 424.4. Redundancy 424.4.1. Redundant behaviour according to AUMA redundancy 444.4.2. Redundant behaviour according to Profibus DP-V2 redundancy (PNO guideline 2.212)

454.5. Profibus DP-V2 functions 464.5.1. Profibus DP-V2 redundancy 484.5.2. Profibus DP-V2 time-synchronisation with time stamp

535. Description of the Profibus DP board.................................................................................. 535.1. Indications (indication and diagnostic LEDs)

556. Corrective action.................................................................................................................... 556.1. Troubleshooting 566.2. Diagnostics

587. Technical data......................................................................................................................... 587.1. Profibus DP interface

608. Appendix................................................................................................................................. 608.1. Proposed wiring diagram for external sensors, 2-wire technology 618.2. Proposed wiring diagram for external sensors, 3-wire technology 628.3. Proposed wiring diagram for external sensors, 4-wire technology 638.4. Parameters

91Index........................................................................................................................................

3

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Table of contents

1. Safety instructions

1.1. Prerequisites for the safe handling of the product

Standards/directives The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

They include among others:

●Standards and directives such as IEC 60079 “Explosive atmospheres":

- Part 14: Electrical installations design, selection and erection.

- Part 17: Electrical installations inspection and maintenance.

●Applicable configuration guidelines for fieldbus applications.

Safety instructions/

warnings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out by suitably qualified personnel authorised by the end user or contractor

of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Work performed in potentially explosive atmospheres is subject to special regulations

which have to be observed.The end user or contractor of the plant is responsible

for respect and control of these regulations, standards, and laws.

Electrostatic charging Highly efficient charge generating processes (processes more efficient than manual

friction) on the device surface must be excluded at any time, since they will lead to

propagating brush discharges and therefore to ignition of a potentially explosive

atmosphere.

This also applies to fireproof coatings or covers available as an option.

Ignition dangers Gearboxes were subjected to an ignition hazard assessment in compliance with the

currently applicable standard according to ISO 80079-36/ -37.Hot surfaces,

mechanically generated sparks as well as static electricity and stray electric currents

were identified and assessed as major potential ignition sources.Protective measures

to prevent the likelihood that ignition sources arise were applied to the gearboxes.

This includes in particular lubrication of the gearbox, the IP protection codes and the

warnings and notes contained in these operation instructions.

Commissioning Prior to commissioning, imperatively check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage. Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe national regulations.

●During operation,thehousingwarmsup and surface temperatures> 60°C may

occur.To prevent possible burns, we recommend checking the surface temper-

ature prior to working on the device using an appropriate thermometer and

wearing protective gloves.

4

Actuator controls

Safety instructions AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior written consent of the manufacturer.

1.2. Range of application

AUMA actuator controls are exclusively designed for the operation of AUMA actuators.

Other applications require explicit (written) confirmation by the manufacturer.The

following applications are not permitted, e.g.:

●motor control

●pump control

No liability can be assumed for inappropriate or unintended use.

Observance of these operation instructions is considered as part of the device's

designated use.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in these

operation instructions, each marked by the appropriate signal word (DANGER,

WARNING, CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level of risk. Failure

to observe this warning results in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning could result in minor or moderate injury. May also be

used with property damage.

Potentially hazardous situation. Failure to observe this warning could result

in property damage. Is not used for personal injury.

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in these instructions:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Via the menu to parameter

Describes the menu path to the parameter.When using the push buttons of local

controls, the required parameter can be quickly found on the display.Display texts

are shaded in grey: .

5

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Safety instructions

➥Result of a process step

Describes the result of a preceding process step.

Warning signs at the device

The following warning signs can be attached to the device.

General warning sign

General warning of a danger zone.

Hot surface

Warning of hot surfaces, e.g.possibly caused by high ambient temperatures or strong

direct sunlight.

Electrical voltage

Hazardous voltage! Warning of electric shock.At some devices, the warning sign

additionally includes a time interval, e.g. 30 s.Once power supply is switched off,

you will have to wait for the indicated period. Only then may the device be opened.

6

Actuator controls

Safety instructions AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

2. General information about Profibus DP

For exchange of information among automation systems and between automation

systems and the connected distributed field devices, the use of serial fieldbus systems

for communication is state-of-the-art.Thousands of applications have proved

impressively that, in comparison with conventional technology, cost savings of up to

40 % in wiring, commissioning, and maintenance are achieved by using fieldbus

technology.While in the past the fieldbus systems used were often manufacturer

specific and incompatible with other bus systems, the systems employed today are

almost exclusively open and standardized.This means that the user does not depend

on individual suppliers and can choose within a large product range the most suitable

product at the most competitive price.

Profibus DP is the leading open fieldbus system in Europe and is also used

successfully throughout the world.The application range includes automation in the

areas of manufacturing, processing, and building. Profibus DP is an international,

open fieldbus protocol which has been standardized in the fieldbus standards IEC

61158 and IEC 61784.This standardization ensures that the investments by

manufacturers and users are protected to the best possible degree and the

independence of the manufacturer is guaranteed.

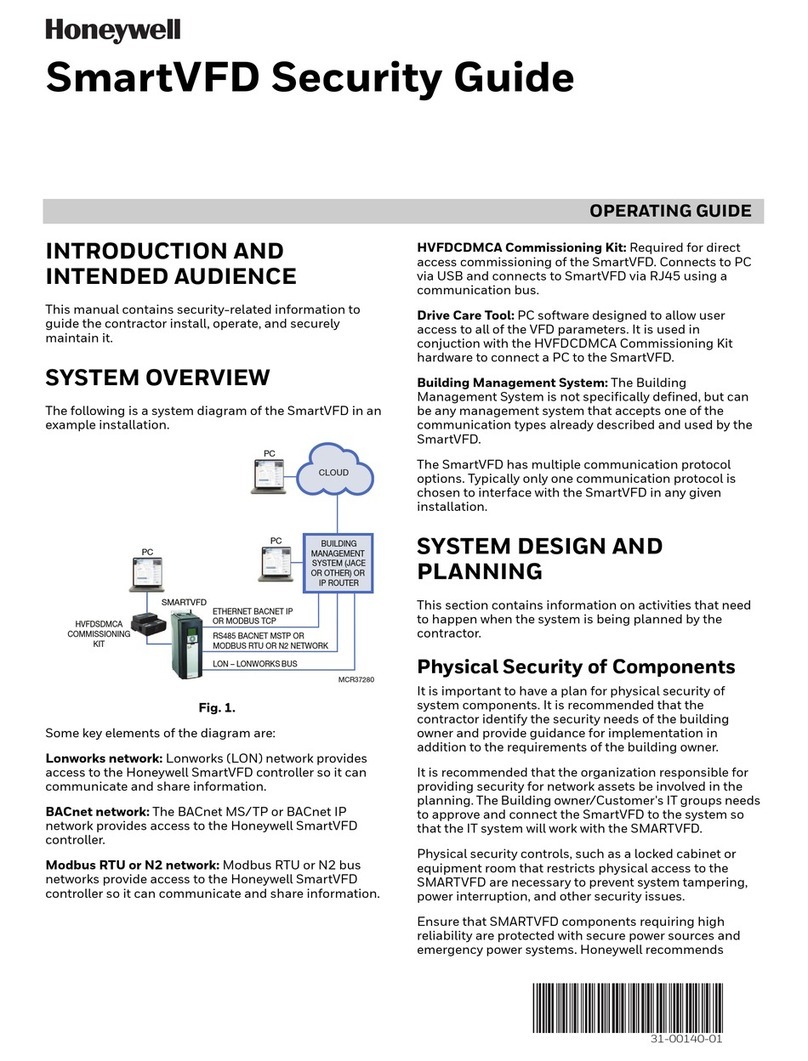

2.1. Basic characteristics

Profibus DP defines the technical and functional features of a serial fieldbus system

allowing interconnection of distributed, digital automation devices.Profibus DP

distinguishes between master and slave devices.

Profibus DP is designed for fast data transmission on the field level.Here, central

control devices, such as a PLC or PC, communicate via a fast serial connection with

peripheral field devices such as input/output devices, valves, and actuators.

Data exchange among these field devices is based on cyclic communication.The

respectively necessary communication functions are defined by the Profibus DP

basic functions according to IEC 61158 and IEC 61784.

Master devices Master devices control data traffic on the bus.A master is allowed to send messages

without an external request.Within the Profibus protocol, masters are also called

‘active devices’.

Slave device Slave devices such as AUMA Profibus DP actuators are peripheral devices.Typical

slave devices are input/output devices, valves, actuators, and measuring transducers.

They do not have bus access rights, i.e.they may only acknowledge received

messages or, at the request of a master, transmit messages to that master. Slaves

are also called ‘passive devices’.

2.2. Basic functions of Profibus DP

On a cyclic basis, the master reads the input information from the slaves and writes

the output information to the slaves. In addition to this cyclic data transfer of the

processrepresentation, ProfibusDP alsoprovides powerful functions for diagnostics

and commissioning. Data traffic is monitored through the monitoring functions on

the master and slave side.

2.3. Transfer mode

●RS-485 twisted pair cable or fibre optic cable

●AUMA actuators support baud rates up to 1.5 Mbits/s.

2.4. Bus access

●Token-passing between the masters and polling between master and slave

●Mono-master or multi-master systems are possible.

●Master and slave devices: max. 126 devices at a bus

2.5. Functionality

●Peer-to-peer (process data exchange [DATA EX]) or Multicast (control com-

mands to all slaves)

7

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP General information about Profibus DP

●Cyclic process data exchange between DP master and DP slaves.

●Additional acyclic data exchange between DP master and DP slaves for

Profibus DP withV1 services.

●DP-V2 redundancy according to PNO guideline 2.212

●DP-V2 time stamp according to PNO guideline 2.192 or IEC 61158 / 64784

●Checking the configuration of the DP slaves

●Synchronisation of inputs and/or outputs

2.6. Protective functions

●All messages are transmitted with Hamming Distance HD=4.

●Watchdog timer at DP slaves

●Access protection for the inputs/outputs of DP slaves (Sync and Freeze)

●Process data exchange monitoring with configurable timer interval at the master

●Adjustable failure behaviour

2.7. Device types

●DP master class 2 (DPM2), e.g.programming/configuration tools

●DP master class 1 (DPM1), e.g.central controllers such as PLC, PC

●DP slave, e.g. AUMA Profibus DP devices.Devices with binary or analogue

inputs/outputs, actuators, plug valves

8

Actuator controls

General information about Profibus DP AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

3. Commissioning

3.1. Introduction

When commissioning a Profibus DP network, the devices on the Profibus DP must

be parameterized and configured using the programming software at the controls

(Profibus configurator).

The programming software first reads the GSD file (GeneralStationData) of the

individual actuators.The GSD file contains information about the device properties

needed by the master.

Afterwards, the user can configure and parameterize the device at the Profibus DP

for the programming software of the process control system.

This information is then stored in the controls (DP master) and sent to the actuators

(DP slaves) each time cyclic communication is started.

The process representation input and output bytes are used to control the actuator

and to supply the feedback signals.If a configuration with consistent data is selected,

certain PLCs require special functional elements for the control of the Profibus DP

slaves.

Certification AUMA actuators with Profibus DP are certified by the Profibus user organisation

(PNO).

ID number Each DP slave and each DP master have individual ID numbers.The ID number is

required for the DP master to identify the type of device connected without signification

protocol overhead.The master compares the ID numbers of the connected DP

devices to the ID number in the specified configuration data.The process data transfer

will only be started if the correct device types with the correct station addresses were

connected to the bus.This ensures a high security against configuration errors.

The PNO manages the ID numbers together with the device master data (GSD).

AUMA actuators with actuator controls AC 01.2 are listed under the following ID

numbers at the PNO:

●ID number of the standard version: 0x0C4F with functions for:

- Single channel Profibus DP interface (not redundant)

-Redundant Profibus DP interface according to AUMA redundancy (I or II)

- Optional Profibus DPV1 services

●ID number of the extended version:0x0CBD with functions for:

-Redundant Profibus DP interface according to Profibus DP-V2 redundancy

- Time stamp and alarms according to Profibus DP-V2

- Optional Profibus DPV1 services

Device Master Data

(GSD) For Profibus DP, the performance features of the devices are documented by the

manufacturer and made available to the users as device data sheet and device

master data. Structure, contents and coding of the device master data (GSD) are

standardised.They enable comfortable configuration of any DP slaves with

configuration devices by different manufacturers.

For AUMA actuators with AC 01.2 controls, the following GSD files are available:

●Standard version: AUMA0C4F.GSD with functions for:

- Single channel Profibus DP interface (not redundant)

- Redundant Profibus DP interface according to AUMA redundancy

- Optional Profibus DPV1 services

●Optional version: AUMA0CBD.GSD with functions for:

-Redundant Profibus DP interface according to Profibus DP-V2 redundancy

- Time stamp and alarms according to Profibus DP-V2

- Optional Profibus DPV1 services

9

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Commissioning

Information GSD files can be downloaded from our website: www.auma.com.

3.2. Parameter setting

The parameter setting is partly defined in the Profibus standard, e.g. one bit for

switching bus monitoring on and off (watchdog).

In addition, the Profibus DP interface can receive further user parameters thus

enabling complete configuration of the process representation input.These

parameters can be modified via the programming software of the controls.New

programming software supports the parameter setting via text and a menu selection.

For older versions, the parameters must be entered as hexadecimal numbers.

Table 1:Structure of the parameter telegram RemarkBitByte

01234567

000WD_ONFreezeSyncUnlockLock1

WD factor 12

WD factor 23

MinTSDR4

ID no. high5

ID no. low6

Group ID7

DP-V1 status 100WD_Base0000DPV1 Enable8

DP-V1 status 2000000Enable Process AlarmPrmCmd9

DP-V1 status 3Alarm ModePrmStruct000010

Settings for basic functions of the Profibus:

WD_Base WD_Base = 0 (time base 10 ms)

WD_Base = 1 (time base 1 ms)

Connection monitoring time of the Profibus DP communication:

TWD = (1 or 10 ms, depending on WD_Base) x (WD factor 1) x (WD factor 2)

MinTSDR Minimum response time of the actuator (in TBit)

ID no. ID number of the actuator

Group ID Group assignment by the master

Settings for Profibus DP-V1 services (option):

DPV1 Enable Activates the DP-V1 services available as an option; must be set to 1 when using

DP-V1 services.

Settings for Profibus DP-V2 functions (option):

Enable Process Alarm Enables the process alarm (required for time synchronisation with time stamp), must

be set to 1.

Alarm Mode Number of supported alarms, must be set to 0 (i.e. one alarm of each type is

supported).

PrmStruct Structured parameter setting possible, must be set to 1.

PrmCmd Parameter command activated, must be set to 1 for Profibus DP-V2 redundancy.

In the bytes following byte 10 of the parameter telegram the user parameters for

adaptation of the process representation input to the DCS can among others be

found (AUMA specific parameters).

The GSD file available on the website does not contain any user parameters for

adapting the process representation input to DCS requirements.The actuator will

10

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

use the default process representation with this GSD file. For further information

please refer to <Process representation input (default process representation)>.

3.3. Bus address (slave address)

Each participant at the bus is addressed via its specific bus address (slave address).

The bus address may be assigned only once per fieldbus network.

The bus address is stored in a non-volatile memory.

On delivery, address 126 (default value) is set for all devices.

The bus address (slave address) can be set in the following ways:

●Locally via push buttons (indication in the display).

For details on setting refer to the operation instructions to the actuator or

Manual (Operation and Setting) AUMATIC AC 01.1 Profibus DP.

●Using the AUMA CDT service software (via PC or laptop with Bluetooth).

The latest version of the AUMA CDT can be downloaded from our website:

www.auma.com.

●Via fieldbus. Please note that only one device with the address 126 (default

value) may be connected to Profibus DP.A new bus address may be assigned

to the actuator using the SAP 55 (Service-Access-Point Set Slave Address).

For redundant version according to Profibus DP-V2 redundancy, only the address

of the primary channel can be set;the address of the backup channel is derived from

the primary.

For redundant version according to AUMA redundancy, the addresses of both

channels can be set individually.

3.4. Configuring the Profibus DP interface

During configuration, the number of input and output bytes reserved for each device

in the controls’memory is selected. Additionally, the method of data processing is

defined: consistent or non-consistent.

Information Only the number of bytes determined in the configuration is transferred between DP

master and DP slave.

The following configurations are possible with AUMA Profibus DP actuators:

Number of output bytesNumber of input bytes

11

41

81

12

42

82

162

14

44

84

164

86

166

48

88

128

412

812

1212

11

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Commissioning

Number of output bytesNumber of input bytes

1612

420

820

1220

432

832

1232

1632

2640

All these configurations (except 1 In, 1 Out) can be selected as consistent or

non-consistent.

The number of input bytes indicates how many of the maximum 40 bytes are sent

to the DP master by the DP slave.

The number of output bytes indicates how many of the maximum 26 bytes are sent

to the DP slave by the DP master.

If, for example, a configuration with 8 input bytes is selected, only the first 8 bytes

are sent by the DP slave to the DP master during data exchange. In this case, the

master does not have access to bytes 9 to 40.This way, the DP master saves memory

space since only 8 input bytes are reserved for the actuator.

Data issued by AUMA actuators shall be consistently processed by the DP master.

This ensures that the value of a 2-byte variable (position transmitter, analogue

customer input) does not change after reading out the first byte and, thus, does not

distort the value. If a master does not offer the option of consistent configuration

because of the DCS, configuration without consistency can be selected.

3.5. Communication start-up

Whenswitchingonthe DP master, itfirst sendsone parameterand oneconfiguration

telegram to each DP slave.If parameters and configuration are correct, the DP slave

enters the ‘Data Exchange’mode to exchange process data between controls and

slave.Then, the DP master can control the DP slave and read its current state via

the process representation.

If communication is interrupted (e.g.when switching the slave off or in the event of

Profibuscablerupture), it isautomatically resumed bythe DPmaster once thecause

of the fault is eliminated.

3.6. AUMA user parameters (AUMA specific parameters)

The process representation input can be updated by means of the user parameters.

Default values and selection options are defined in a specific GSD file available on

request.

Two GSD files are available for AUMATIC AC 01.2/ACExC 01.2.A standard version

(AUMA04CF for ident-no. 0x0C4F) and an optional version with additional user

parameters for setting time stamp and alarms according to Profibus DP-V2

(AUMA0CBD for ident no. 0x0CBD).

3.6.1. Process representation input arrangement (user parameters)

The process representation input data can be arranged in any order. Arrangement

is defined by means of the user parameters in the GSD file, available on request.

Users may assign a specific indication to each Profibus DP signal.The data volume

of the transmitted data depends on the type of signals selected (u8, u16, i, individual

signals).

12

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

3.6.2. Settable (user definable) signals

Table 2:Description of the parameter settings DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

–(0) = "Bit: Reserved"

For limit seating:Limit switch operated in direction CLOSE

For torque seating:Torque switch and limit switch operated in dir-

ection CLOSE

(1) = "Bit: End p. CLOSED"

For limit seating:Limit switch operated in direction OPEN

For torque seating:Torque switch and limit switch operated in dir-

ection OPEN

(2) = "Bit: End p. OPEN"

End position CLOSED reached or intermediate position reached

(die Zwischenstellungsanzeige erfolgt nur, wenn Parameter

= )

Signal blinking:Actuator runs in direction CLOSE.

(3) = "Bit: End p. CLOSED, blink"

End position OPEN reached or intermediate position reached.

(die Zwischenstellungsanzeige erfolgt nur, wenn Parameter

= )

Signal blinking:Actuator runs in direction OPEN.

(4) = "Bit: End p. OPEN, blink"

The position setpoint is is within max. error variable (outer dead

band). Is only signalled if Profibus DP master has set the

bit (process representation output).

(5) = "Bit: Setpoint reached"

Es wird ein Fahrbefehl über die Drucktaster der Ortssteuerstelle

oder den Feldbus in Richtung ZU durchgeführt:

oder (Prozessabbild Ausgang). Dieses Bit

bleibt auch bei Fahrpausen gesetzt (z.B.aufgrund der Totzeit oder

der Reversiersperrzeit).

(6) = "Bit: Running CLOSE"

Es wird ein Fahrbefehl über die Drucktaster der Ortssteuerstelle

oder den Feldbus in Richtung AUF durchgeführt:

oder (Prozessabbild Ausgang). Dieses Bit

bleibt auch bei Fahrpausen gesetzt (z.B.aufgrund der Totzeit oder

der Reversiersperrzeit).

(7) = "Bit: Running OPEN"

Selector switch is in position LOCAL.

(8) = "Bit: Selector sw. LOCAL"

Selector switch is in position REMOTE.

(9) = "Bit: Sel. sw. REMOTE"

Selector switch is in position OFF.

(10) = "Bit: Sel. sw. OFF"

Limit switch operated in end position CLOSED

(11) = "Bit: Limit sw. CLOSED"

Limit switch operated in end position OPEN

(12) = "Bit: Limit sw. OPEN"

Torque switch operated in direction CLOSE

(13) = "Bit:Torque sw. CLOSE"

Torque switch operated in direction OPEN

(14) = "Bit:Torque sw. OPEN"

Collective signal 05:

The device is ready for remote control.

No AUMA warnings, AUMA faults or signals according to NAMUR

are present.

(15) = "Bit: Device ok"

Collective signal 10:

Indication according to NAMUR recommendation NE 107

Actuator function failure, output signals are invalid.

(16) = "Bit: Failure"

Collective signal 08:

Indication according to NAMUR recommendation NE 107

The actuator is being worked on;output signals are temporarily in-

valid.

(17) = "Bit: Function check"

Collective signal 07:

Indication according to NAMUR recommendation NE 107

Actuator is operated outside the normal operation conditions.

(18) = "Bit: Out of spec."

Collective signal 09:

Indication according to NAMUR recommendation NE 107

Recommendation to perform maintenance.

(19) = "Bit: Maintenance requ."

13

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Commissioning

DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

Collective signal 03:

Contains the result of a disjunction (OR operation) of all faults.

The actuator cannot be operated.

(20) = "Bit: Fault"

Collective signal 02:

Contains the result of an OR disjunction of all warnings.

(21) = "Bit:Warnings"

Collective signal 04:

Contains the result of a disjunction (OR-operation) of the signals,

forming the "Not ready REMOTE" group.

The actuator cannot be operated from REMOTE.

(22) = "Bit: Not ready REMOTE"

The actuator is in off-time (e.g.stepping mode or reversing preven-

tion time).

(23) = "Bit: Op. pause active"

The actuator is within the set stepping range.

(24) = "Bit: Start step mode"

Actuator is running (output drive is moving)

Hard wired collective signal consisting of signals:

●(26)

●(27)

●(28)

(25) = "Bit: Actuator running"

Output drive rotates due to operation command from LOCAL.

(26) = "Bit: Running LOCAL"

Output drive rotates due to operation command from REMOTE.

(27) = "Bit: Running REMOTE"

Output drive rotates without electric operation command (manual

operation).

(28) = "Bit: Running via handw."

The actuator is in an intermediate position e.g. neither in end posi-

tion OPEN nor in end position CLOSED.

(29) = "Bit: In interm. position"

The failure behaviour is active.

(30) = "Bit: Failure behav. active"

Intermediate position 1 reached

(31) = "Bit: Intermediate pos. 1"

Intermediate position 2 reached

(32) = "Bit: Intermediate pos. 2"

Intermediate position 3 reached

(33) = "Bit: Intermediate pos. 3"

Intermediate position 4 reached

(34) = "Bit: Intermediate pos. 4"

Intermediate position 5 reached

(35) = "Bit: Intermediate pos. 5"

Intermediate position 6 reached

(36) = "Bit: Intermediate pos. 6"

Intermediate position 7 reached

(37) = "Bit: Intermediate pos. 7"

Intermediate position 8 reached

(38) = "Bit: Intermediate pos. 8"

A high signal (+24 V DC) is present at digital input 1.

(39) = "Bit: Input DIN 1"

A high signal (+24 V DC) is present at digital input 2.

(40) = "Bit: Input DIN 2"

A high signal (+24 V DC) is present at digital input 3.

(41) = "Bit: Input DIN 3"

A high signal (+24 V DC) is present at digital input 4.

(42) = "Bit: Input DIN 4"

A high signal (+24 V DC) is present at digital input 5.

(43) = "Bit: Input DIN 5"

A high signal (+24 V DC) is present at digital input 6.

(44) = "Bit: Input DIN 6"

Parameter not available

(45) = "Bit: Input DIN 7"

Parameter not available

(46) = "Bit: Input DIN 8"

No valid communication via fieldbus (despite available connection)

(47) = "Bit: FailState fieldbus"

The actuator is controlled via the I/O interface (parallel).

(48) = "Bit: I/O interface"

Operationmode EMERGENCY isactive(EMERGENCY signal was

sent).

(49) = "Bit: EMCY behav.act."

Operation mode EMERGENCY stop is active (EMERGENCY stop

button pressed).

(50) = "Bit: EMCY stop active"

Operation mode Service (via Bluetooth) is active.

(51) = "Bit: Service active"

Actuator is interlocked.

(52) = "Bit: Interlock active"

Selector switch is in position Local control (LOCAL) or 0(OFF).

(53) = "Bit: Sel. sw. not REMOTE"

Manual operation is active (handwheel is engaged);optional signal

(54) = "Bit: Handwheel active"

14

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

Received setpoint cannot be performed as the positioner is not

available.

(55) = "Bit:Wrong command"

Motor protection tripped.

(56) = "Bit:Thermal fault"

●When connecting to a 3-ph AC system and with internal 24 V

DC supply of the electronics: Phase 2 is missing.

●When connecting to a 3-ph or 1-ph AC system and with external

24V DC supply of the electronics: One of the phases L1, L2 or

L3 is missing.

(57) = "Bit: Phase fault"

The phase conductors L1, L2 and L3 are connected in the wrong

sequence.

(58) = "Bit:Wrong phase sequence"

Due to insufficient mains quality, the controls cannot detect the

phase sequence (sequence of phase conductors L1, L2 and L3)

within the pre-set time frame provided for monitoring.

(59) = "Bit: Mains quality"

Torque fault in direction CLOSE

(60) = "Bit:Torque fault CLOSE"

Torque fault in direction OPEN

(61) = "Bit:Torque fault OPEN"

Torque fault in directions CLOSE or OPEN

(62) = "Bit:Torque fault"

Warning:Max.permissible operating time for an operation (OPEN-

CLOSE) exceeded

(63) = "Bit: Operat.time warning"

Warning:Max.number of motor starts (starts) or max.running time/h

exceeded

(64) = "Bit: On time warning"

The internal 24 V AC voltage supply of the controls has exceeded

the power supply limits.

The 24V AC voltage supply is used to control the reversing contact-

ors, to assess the thermoswitches, to supply the internal actuator

heater and, as an option, to generate the 115 V AC supply for the

customer.

(65) = "Bit: 24 V AC, internal"

The24VDC auxiliary voltage (e.g.forsupplyof the control outputs)

is outside the supply voltage limits.

(66) = "Bit: 24 V DC control volt."

The internal 24 V DC supply voltage of the controls for supply of

the electronic components is outside the supply voltage limits.

(67) = "Bit: 24 V DC, internal"

The external 24V DC voltage supply of the controls has exceeded

the power supply limits.

(68) = "Bit: 24 V DC, external"

Collective signal 14:Internal error

(69) = "Bit: Internal error"

Collective signal 15:Internal warning

(70) = "Bit: Internal warning"

No actuator reaction to operation commands within the set reaction

time.

(71) = "Bit: No reaction"

Incorrect configuration, i.e.the current setting is invalid.

(72) = "Bit: Configuration error"

Parameter not available

(73) = "Bit:Temp. fault controls"

Parameter not available

(74) = "Bit:Temp. fault motor"

Parameter not available

(75) = "Bit:Temp.fault gearbox"

Heater failure at actuator (control unit)

(76) = "Bit:Wrn heater"

Real time clock has not yet been set.

(77) = "Bit: RTC not set"

Parameter not available

(78) = "Bit:Wrn humidity"

Warning:

Position feedback of actuator was not yet referenced for limit end

positions.

(79) = "Bit:WrnRefActPos"

Warning:

Current position feedback signal range is outside the permissible

range.

(80) = "Bit:WrnSigRgeActPos"

Warning:

A signal loss has occurred for actuator position feedback.

(81) = "Bit:WrnSigLossActPos"

15

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Commissioning

DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

Warning: Actual position of actuator

Collective signal consisting of:

●(79)

●(80)

●(81)

(82) = "Bit:WrnActPosition"

Warning:

Optical receiving signal (channel 1) incorrect (no or insufficient Rx

receive level) or RS-485 format error (incorrect bit(s))

(83) = "Bit:Wrn FO ring"

Warning on time max. running time/h exceeded

(84) = "Bit:WrnOnTiRunning"

Warning on time max. number of motor starts (starts) exceeded

(85) = "Bit:WrnOnTiStarts"

Parameter not available

(86) = "Bit:Wrn vibration"

Parameter not available

(87) = "Bit:Wrn dew point"

Warning:Temperature within controls housing too high

(88) = "Bit:WrnControlsTemp"

Parameter not available

(89) = "Bit:Wrn motor temp."

Parameter not available

(90) = "Bit:Wrn gearbox temp."

Warning: Loss of signal analogue input 1

(91) = "Bit:Wrn input AIN 1"

Warning: Loss of signal analogue input 2

(92) = "Bit:Wrn input AIN 2"

Warning: Loss of signal actual process value

(93) = "Bit:WrnActProcVal"

Warning: Loss of signal process setpoint

(94) = "Bit:WrnProcSetpoint"

Warning: Loss of signal of actuator setpoint position

(95) = "Bit:WrnSetpointPos"

Fieldbus failure

(96) = "Bit: Fieldbus failure"

A local STOP is active.

Push button STOP of local controls is operated.

(97) = "Bit: Local Stop"

Wrong operation command

Indicates that several operation commands were received simultan-

eously via Profibus DP (e.g. Remote OPEN and Remote CLOSE

simultaneously or Remote CLOSE/Remote OPEN and Remote

SETPOINT simultaneously) or that the max.value for a setpoint

position has been exceeded (setpoint position > 1,000).

(98) = "Bit:Wrong operation cmd"

Channel 1 is the active operation command channel.

(99) = "Bit: Channel 1 active"

Channel 2 is the active operation command channel.

(100) = "Bit: Channel 2 active"

Motor runs in direction CLOSE.

(101) = "Bit: Motor running Close"

Motor runs in direction OPEN.

(102) = "Bit: Motor running Open"

Time synchronisation is active.

(103) = "Bit:Time Sync active"

The Interlock function prevents an operation in operation mode

REMOTE.

(104) = "Bit: Interlock Remote"

The Interlock function prevents an operation in operation mode

LOCAL.

(105) = "Bit: Interlock Local"

The Interlock function prevents an operation in operation mode

REMOTE or in operation mode LOCAL.

(106) = "Bit: Interlock"

Operation mode disabled.

(107) = "Bit: Disabled"

Warning: Configuration setting is incorrect.

The device can still be operated with restrictions.

(108) = "Bit: Config.Warning"

Channel 1 is in the data exchange state (DataEx).

(109) = "Bit: Pb DataEx Ch1"

Channel 2 is in the data exchange state (DataEx).

(110) = "Bit: Pb DataEx Ch2"

Warning: FO cable system reserve reached (critical or permissible

Rx receive level)

(111) = "Bit:Wrn FOC budget"

No valid fieldbus communication via channel 1 (application does

not communicate with the DCS).

(112) = "Bit: FieldbusFailsafeAct.1"

No valid fieldbus communication via channel 2 (application does

not communicate with the DCS).

(113) = "Bit: FieldbusFailsafeAct.2"

Bus communication available on channel 1.

(114) = "Bit: Chan1 BusComm"

16

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

Bus communication available on channel 2.

(115) = "Bit: Chan2 BusComm"

Partial Valve StrokeTest (PVST) is active.

(116) = "Bit: PVST active"

Partial Valve StrokeTest (PVST) could not be successfully com-

pleted.

(117) = "Bit: PVST fault"

Partial Valve StrokeTest (PVST) was aborted or could not be

started. Remedy: Perform RESET or restart PVST.

(118) = "Bit: PVST abort"

Release signal OPEN not active:Operation commands in direction

OPEN are disabled.

(119) = "Bit: Interlock OPEN"

Release signal CLOSE not active:Operation commands in direction

CLOSE are disabled.

(120) = "Bit: Interlock CLOSE"

Bypass of interlock function is active.

(121) = "Bit: Bypass Interlock"

No reaction detected at actuator output drive.

(122) = "Bit: Fault no reaction"

Config. error of REMOTE interface active.

(123) = "Bit: Config error remote"

Warning:Limitvalue fortorquewarning in direction OPENexceeded.

(124) = "Bit:Torque wrn OPEN"

Warning: Limit value for torque warning in direction CLOSE ex-

ceeded.

(125) = "Bit:Torque wrn CLOSE"

Warning:Voltage of RTC button cell too low.

(126) = "Bit: RTC button cell"

Warning: FO cable connection is not available.

(127) = "Bit:Wrn FOC connection"

Actual actuator position (0 –1,000 per mil)

(128) = "u16: Actual position"

Analogue input 1

(129) = "u16: Input AIN 1"

Analogue input 2

(130) = "u16: Input AIN 2"

Torque in direction CLOSE, unit in %

(131) = "u16:Torque CLOSE %"

Torque in direction OPEN, unit in %

(132) = "u16:Torque OPEN %"

Torque in direction CLOSE, unit in Nm

(133) = "u16:Torque CLOSE Nm"

Torque in direction OPEN, unit in Nm

(134) = "u16:Torque OPEN Nm"

Torque in direction CLOSE, unit in ft-lb

(135) = "u16: torque CLOSE ft-lb"

Torque in direction OPEN, unit in ft-lb

(136) = "u16:Torque OPEN ft-lb"

Actual torque value

(137) = "u16:Torque"

Actual actuator position (0 –100 percent)

(139) = "u16: Actual Position 0-100%"

Parameter not available(160) = "i16: Actual position"

Parameter not available(161) = "i16: Input AIN 1"

Parameter not available(162) = "i16: Input AIN 2"

Parameter not available(163) = "i16:Torque CLOSE %"

Parameter not available(164) = "i16:Torque OPEN %"

Parameter not available(192) = "float: Actual position"

Parameter not available(193) = "float: Input AIN 1"

Parameter not available(194) = "float: Input AIN 2"

Parameter not available(195) = "float:T CLOSE %"

Parameter not available(196) = "float:T OPEN %"

Parameter not available(197) = "float:T CLOSE Nm"

Parameter not available(198) = "float:T OPEN Nm"

Parameter not available(199) = "float:T CLOSE lbs/ft."

Parameter not available(200) = "float:T OPEN lbs/ft."

Parameter not available

(201) = "Cylinder printing max."

Parameter not available

(202) = "Hydraulics fault"

Parameter not available

(203) = "Hydraulics warning"

Safe ESD function (Emergency Shut Down) is active.

1)

(204) = "Safe ESD"

17

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Commissioning

DescriptionDesignation

(process representation)

Prm-Text-Def GSD file

Safe STOP function is active.

1)

(205) = "Safe Stop"

A SIL fault has occurred (collective signal).

1)

(206) = "SIL fault"

A SIL function is active.

1)

(207) = "SIL function active"

(PVST) Partial Valve StrokeTest should be executed

(208) = "PVST required"

Mechanic maintenance requirement

(209) = "Mechanic lifetime"

Seal maintenance requirement

(210) = "Seal lifetime"

Lubricant maintenance requirement

(211) = "Seal lifetime"

Contactor maintenance requirement

(212) = "Contactor lifetime"

The set maintenance interval has expired.

(213) = "Maintenance interval"

Maintenance required

(214) = "Maintenance required"

The safety function indications via fieldbus are for information only and must not be used as part of a safety function.The I/O signals of

the SIL module must be used for this purpose.

1)

3.6.3. Additional (user-definable) parameters (option)

Parameter description of additional user parameters for setting the time stamp and

alarms according to Profibus DP-V2, available with the optional version

AUMA0CBD.gsd.

Table 3:Description of additional settings DescriptionSettingPrm-Text GSD Datei

ExtUserPrmData =

No function–1 "Setpoint valid bit"

DP-V2 time stamp deactivated.Text(0) = "disable"2 "Timestamp (TS)"

DP-V2 time stamp activated.Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"3 "TS -> End Position Close"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"4 "TS -> End Position Open"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"5 "TS -> Torque Limit Switch Close"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"6 "TS -> Torque Limit Switch Open"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"7 "TS -> Ready and Remote"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"8 "TS -> Fault"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

DP-V2 time stamp of signal deactivated.

Text(0) = "disable"9 "TS -> Power Supply Fault"

DP-V2 time stamp of signal activated.

Text(1) = "enable"

Without function (reserved)–10 "TS -> reserved"

Without function (reserved)–11 "reserved Byte"

3.6.4. Further adaptation options

From firmware 04.05.xx, the actuator controls provide the option to adapt to the

existing DCS configurations of the actuator type range AC 01.1/ACExC 01.1.Actuator

controls of type range AC 01.2/ACExC 01.2 can be adapted as to support the default

arrangement of the Profibus DP-V0 process representation input of

AC 01.1/ACExC 01.1 without changing the Profibus configuration of the DCS.

Setting is performed using the following parameter:

>> =

18

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

Information ●Only the Profibus DP-V0 standard arrangement of the process representation

input of AC 01.1/ACExC 01.1 is supported, deviating arrangements of the

Profibus DP-V0 process data input require use/installation of AUMA04CF.gsd

or AUMA0CBD.gsd file in the DCS.

●With = the AC 01.2/ACExC 01.2 does not provide

any diagnostic NAMUR NE 107 information within the cyclic process data rep-

resentation.

●EDD or DTM of the AC 01.2/ACExC 01.2 must imperatively be used for acyclic

communication via Profibus DP-V1 with AC 01.2/ACExC 01.2!

●Factory setting: =

3.7. Communication monitoring

3.7.1. Connection monitoring of the Profibus DP communication

The connection monitoring within the master has to be activated to monitor both

master and cable connection between master and actuator (parameter telegram

byte 1, bit 3, WD_ON = 1).

Only if the connection monitoring is active can the actuator react in the even of loss

of communication once the monitoring time also set in the master has elapsed.

The reaction of the actuator also depends on the settings for failure behaviour or

EMERGENCY BEHAVIOUR.

3.7.2. Fail Safe and Global Control Clear telegrams

Another possibility to set the slave to a safe state in the event of a fault are the fail

safe telegrams (telegrams with data length = 0). If fails safe telegrams are received,

the actuator remains in the DataExchange state;depending on the respective setting,

the actuator may initiate the failure behaviour or the EMERGENCY behaviour.The

actuator quits the Fail Safe state as soon as valid telegrams with the data length

0 are received.

Furthermore, the Global Control Clear (GC Clear) master telegrams can also be

used to initiate the failure behaviour or the EMERGENCY behaviour.This state can

be disabled using a Global Control Operate telegram (GC Operate).

For activated EMERGENCY behaviour:

The actuator can start its operation due to an EMERGENCY signal or a loss

of communication.

Risk of personal injuries or damage to the valve.

→For commissioning and maintenance work: Set selector switch to position 0

(OFF).The motor operation can only be interrupted in this selector switch posi-

tion.

→If the actuator starts its operation by accident:Set selector switch to position 0

(OFF).

3.8. I & M functions

The actuator controls support the I & M functions according to PNO guideline 3.502.

With the term Identification & Maintenance (I & M) functions, the Profibus user

organisation e.V. (PNO) introduced a new functionality for all Profibus devices with

acyclic communication channel that may prove very useful for plant operators.The

I & M functions define how certain device-describing data (according to name plate)

is to be uniformly stored in the Profibus devices.Engineering tools may then read

and inteprete the data according to a code which can be accessed on the PNO

server.This providesuniformand powerfulaccessto all important andcurrent device

data, one of the major requirements for asset management.

Part of the device-specific I & M information is the unambiguous asset identification

using a manufacturer ID (MANUFACTURER_ID, for AUMA actuators = 319), the

19

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 Profibus DP Commissioning

order number (ORDER_ID) of the actuator as well as the individual serial number

(SERIAL_NUMBER). Further data supplements the asset information.

SizeContent

Header

10 OctetsManufacturer specific

I & M Block

2 OctetsMANUFACTURER_ID

20 OctetsORDER_ID

16 OctetsSERIAL_NUMBER

2 OctetsHARDWARE_REVISION

4 OctetsSOFTWARE_REVISION

2 OctetsREVISION_COUNTER

2 OctetsPROFILE_ID

2 OctetsPROFILE_SPECIFIC_TYPE

2 OctetsIM_VERSION

2 OctetsIM_SUPPORTED

20

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 Profibus DP

Other manuals for AC(V) 01.2

1

This manual suits for next models

1

Table of contents

Other AUMA Control System manuals

Popular Control System manuals by other brands

Balboa Instruments

Balboa Instruments VSP-VS510SZ-DCAH Tech sheet

Siemens

Siemens simatic c7-621 Hardware installation guide

Carrier

Carrier AQUASNAP 30RA/RH Operation & maintenance instructions

Mazak

Mazak STX SC L PLUS CONTROL Training manual

Highway Care

Highway Care BarrierGuard 800 Product and installation manual

Toshiba

Toshiba TOSDIC-CIE DS instruction manual