AUMA AC(V) 01.2 User manual

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2

HART

Device integrationManual

Read operation instructions first.

●Observe safety instructions.

Purpose of the document:

This document contains information for the commissioning staff of the distributed control system and DCS software

engineers.This document is intended to support actuator integration into the DCS via the communication interface.

Reference documents:

●Operation instructions (Assembly and commissioning) for the actuator

●Manual (Operation and setting) AC 01.2 actuator controls HART

Reference documents can be downloaded from the Internet (www.auma.com) or ordered directly from AUMA

(refer to <Addresses>).

Table of contents Page

41. Safety instructions................................................................................................................. 41.1. Prerequisites for the safe handling of the product 51.2. Range of application 51.3. Warnings and notes 51.4. References and symbols

72. General information on HART............................................................................................... 72.1. General information on HART 82.2. Basic characteristics 82.3. Communication technology 82.4. Data exchange 92.5. Topology - HART device network configuration 112.6. HART communication cable 122.7. Requirements on power supplies 122.8. Control & HART device categories 142.9. Protective functions 142.10. Device types

153. Commissioning...................................................................................................................... 153.1. Introduction 153.2. Parameter setting 163.3. Bus address (slave address) 173.4. Communication start 173.5. HART commands 173.6. HART communication monitoring 183.7. Calibration 4 –20 mA of HART interface 183.7.1. Adjustment of loop current or current trim 183.7.2. Range adaptation of process variables (Dynamic Variables)

204. Description of the data interface.......................................................................................... 204.1. Supported HART commands 204.1.1. Universal Commands 204.1.2. Common Practice Commands 204.1.3. Device Specific Commands 214.2. Dynamic variables 214.3. Device variables 214.3.1. Description of input data (signal from actuator)

2

Actuator controls

Table of contents AC(V) 01.2/AC(V)ExC 01.2 HART

264.3.2. Description of the output data (operation commands) 284.4. Device specific commands 284.4.1. Input data (process representation input) –signals from the actuator 334.4.2. Output data (process representation output) - operation commands 364.5. Status information 364.5.1. Description of status information 424.6. Further information on the data interface 424.6.1. Table of units 424.6.2. Unsupported functions (HART commands) 434.6.3. Further device data 434.6.3.1. Sampling Rates 434.6.3.2. Power Up 434.6.3.3. Reset 434.6.3.4. Self-test 434.6.3.5. Response times (Command Response Times) 434.6.3.6. Long Messages 434.6.3.7. Non-volatile memory 434.6.3.8. Modes 434.6.3.9. Write protection 444.6.3.10. Attenuation

455. Description of HART board................................................................................................... 465.1. Indications (indication and diagnostic LEDs)

476. Corrective action.................................................................................................................... 476.1. Troubleshooting 486.2. Diagnostics

497. Technical data......................................................................................................................... 497.1. HART interface

518. Appendix................................................................................................................................. 518.1. Performance features 518.2. Wiring diagram, example of “Actuator”device category, setpoint via AIN1 528.3. Wiring diagram, example of “Current Output ”device category, actual position value via

AOUT1 528.4. Parameters

70Index........................................................................................................................................

3

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART Table of contents

1. Safety instructions

1.1. Prerequisites for the safe handling of the product

Standards/directives The end user or the contractor must ensure that all legal requirements, directives,

guidelines, national regulations and recommendations with respect to assembly,

electrical connection, commissioning and operation are met at the place of installation.

They include among others standards and directives such as IEC 60079 “Explosive

atmospheres".

●Part 14: Electrical installations design, selection and erection.

●Part 17: Electrical installations inspection and maintenance.

Safety instructions/

warnings All personnel working with this device must be familiar with the safety and warning

instructions in this manual and observe the instructions given. Safety instructions

and warning signs on the device must be observed to avoid personal injury or property

damage.

Qualification of staff Assembly, electrical connection, commissioning, operation, and maintenance must

be carried out by suitably qualified personnel authorised by the end user or contractor

of the plant only.

Prior to working on this product, the staff must have thoroughly read and understood

these instructions and, furthermore, know and observe officially recognised rules

regarding occupational health and safety.

Work performed in potentially explosive atmospheres is subject to special regulations

which have to be observed.The end user or contractor of the plant is responsible

for respect and control of these regulations, standards, and laws.

Electrostatic charging Highly efficient charge generating processes (processes more efficient than manual

friction) on the device surface must be excluded at any time, since they will lead to

propagating brush discharges and therefore to ignition of a potentially explosive

atmosphere.

This also applies to fireproof coatings or covers available as an option.

Ignition dangers Gearboxes were subjected to an ignition hazard assessment in compliance with the

currently applicable standard according to ISO 80079-36/ -37.Hot surfaces,

mechanically generated sparks as well as static electricity and stray electric currents

were identified and assessed as major potential ignition sources.Protective measures

to prevent the likelihood that ignition sources arise were applied to the gearboxes.

This includes in particular lubrication of the gearbox, the IP protection codes and the

warnings and notes contained in these operation instructions.

Commissioning Prior to commissioning, imperatively check that all settings meet the requirements

of the application. Incorrect settings might present a danger to the application, e.g.

cause damage to the valve or the installation.The manufacturer will not be held

liable for any consequential damage. Such risk lies entirely with the user.

Operation Prerequisites for safe and smooth operation:

●Correct transport, proper storage, mounting and installation, as well as careful

commissioning.

●Only operate the device if it is in perfect condition while observing these instruc-

tions.

●Immediately report any faults and damage and allow for corrective measures.

●Observe recognised rules for occupational health and safety.

●Observe national regulations.

●During operation,thehousingwarmsupandsurfacetemperatures>60 °C may

occur.To prevent possible burns, we recommend checking the surface temper-

ature prior to working on the device using an appropriate thermometer and

wearing protective gloves.

4

Actuator controls

Safety instructions AC(V) 01.2/AC(V)ExC 01.2 HART

Protective measures The end user or the contractor are responsible for implementing required protective

measures on site, such as enclosures, barriers, or personal protective equipment

for the staff.

Maintenance To ensure safe device operation, the maintenance instructions included in this manual

must be observed.

Any device modification requires prior written consent of the manufacturer.

1.2. Range of application

AUMA actuator controls are exclusively designed for the operation of AUMA actuators.

Other applications require explicit (written) confirmation by the manufacturer.The

following applications are not permitted, e.g.:

●motor control

●pump control

No liability can be assumed for inappropriate or unintended use.

Observance of these operation instructions is considered as part of the device's

designated use.

1.3. Warnings and notes

The following warnings draw special attention to safety-relevant procedures in these

operation instructions, each marked by the appropriate signal word (DANGER,

WARNING, CAUTION, NOTICE).

Indicates an imminently hazardous situation with a high level of risk. Failure

to observe this warning results in death or serious injury.

Indicates a potentially hazardous situation with a medium level of risk.Failure

to observe this warning could result in death or serious injury.

Indicates a potentially hazardous situation with a low level of risk. Failure to

observe this warning could result in minor or moderate injury. May also be

used with property damage.

Potentially hazardous situation. Failure to observe this warning could result

in property damage. Is not used for personal injury.

Safety alert symbol warns of a potential personal injury hazard.

The signal word (here: DANGER) indicates the level of hazard.

1.4. References and symbols

The following references and symbols are used in these instructions:

Information The term Information preceding the text indicates important notes and information.

Symbol for CLOSED (valve closed)

Symbol for OPEN (valve open)

Via the menu to parameter

Describes the menu path to the parameter.When using the push buttons of local

controls, the required parameter can be quickly found on the display. Display texts

are shaded in grey: Display.

➥Result of a process step

Describes the result of a preceding process step.

5

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART Safety instructions

Warning signs at the device

The following warning signs can be attached to the device.

General warning sign

General warning of a danger zone.

Hot surface

Warning of hot surfaces, e.g.possibly caused by high ambient temperatures or strong

direct sunlight.

Electrical voltage

Hazardous voltage! Warning of electric shock. At some devices, the warning sign

additionally includes a time interval, e.g. 30 s. Once power supply is switched off,

you will have to wait for the indicated period. Only then may the device be opened.

6

Actuator controls

Safety instructions AC(V) 01.2/AC(V)ExC 01.2 HART

2. General information on HART

2.1. General information on HART

HART (Highway AddressableRemoteTransducer)isanopen communication protocol

allowing bidirectional data exchange between DCS and field devices on the basis

of analogue 4 –20 mA signals.It simultaneously provides digital transmission of

diagnostic, maintenance and process information from field devices to host (master)

systems in addition to analogue process value transmission.

HART is not a typical fieldbus but rather a protocol variant of digital field

communication based on analogue signal transmission while comprising many

functions of a fieldbus system.

HART has been part of the international fieldbus standards of IEC 61158 and IEC

61784 (CPF 9) since 2007.The Wireless HART variant was specified in 2009.

HART characteristics

HART offers a wide range of services and functions, with particular advantages when

combined with smart field devices:

●Point-to-point wiring with cable lengths up to 3,000 m

●Multidrop topology (line topology) available as an option (number of participants

typically ≤8).

●Using known conventional 4 –20 mA infrastructure for

- Remote access to inaccessible devices.

- Device configuration for field device commissioning.

- Device and fault diagnostics during active operation.

- Asset Management for field devices.

- Transmission of additional process values from and to the field device.

- Transmission of Primary Variable (PV) as precise digital process value

for adjustment/validation with the 4 –20 mA signal.

●Device integration within DCS using standardised technologies (e.g.EDD)

●Application facilities in explosive atmospheres

●Standardised and simple commissioning procedures (loop test and signal cal-

ibration)

Use and benefits for actuators

Figure 1: Operation commands and feedback signals

7

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART General information on HART

Figure 2: Services and diagnostic data

2.2. Basic characteristics

The HART interface superimposes and transmits all actuator parameters adjustable

and legible via local controls (e.g.for commissioning, diagnostics, status signals) as

digital instruction (command = write parameter, request = read parameter) to an

analogue input or output.

Furthermore, digital control commands (e.g.OPEN, STOP and EMERGENCY) can

be transmitted for actuator control.Within the device, these HART commands are

reconverted into binary control commands. In turn and on instruction, the actuator

sends the status of its own binary signal outputs, the actual value/setpoint at analogue

inputs/outputs as well as the acknowledgements on parameter changes as digital

telegram via the integral HART modem to the DCS or PLC.

2.3. Communication technology

For data exchange, HART always requires an analogue current signal 4 –20 mA

onto which the higher frequency digital HART signals are superimposed via FSK

modem (Frequency Shift Keying).Both frequencies 1,200 Hz and 2,200 Hz of the

superimposed signal correspond to the logic states 1 and 0.

Figure 3: HART signal

2.4. Data exchange

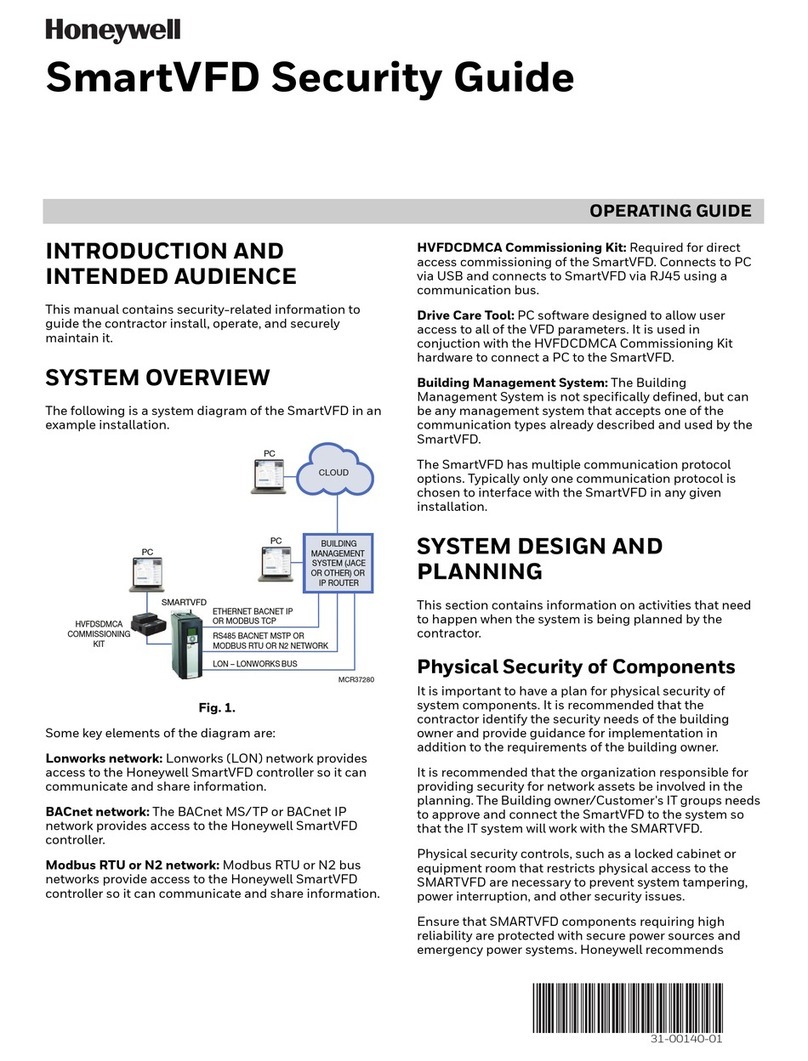

In HART applications, distinction is made between the DCS/PLC (master) and the

field device (slave). For communication between DCS/PLC and field devices, HART

uses a half-duplex system for request-response communication. Depending on the

8

Actuator controls

General information on HART AC(V) 01.2/AC(V)ExC 01.2 HART

actual process data length, complete date exchange whereby the master sends an

instruction telegramand the slave issues responses takesup to 0.5 seconds assuming

a transmission speed/baud rate of 1,200 bit/s. For point-to-point configuration, 2 to

3 telegrams can be exchanged.An average transmission time of 13 ms is accounted

for each process byte.

The HART protocol supports two hosts (masters), a primary master is generally a

distributed control system, the secondary master is typically a handheld terminal or

a laptop with HART modem for field configuration.Both hosts can act simultaneously.

After each transaction, representing the data exchange between host and field device,

one of the two masters can take over communication within a fixed and assigned

time window.

Figure 4: HART data transaction with request and response telegram

2.5. Topology - HART device network configuration

HART devices can operate in various network configurations.The most frequent

configuration is point-to-point connection.For this application, the master is only

connected to one HART field device.

Point-to-point connection

The following figure illustrates the point-to-point connection of AC .2 with HART

“Actuator”device category.PLC defines a setpoint via the 4 –20 mA analogue signal.

The signal power supply is outside the actuator.

Figure 5: Example of point-to-point connection

HART data is modulated onto the 4 –20 mA signal via HART modem.Generally,

the controllers (masters) send and receive a modulated voltage signal where the

fielddevices(slaves) send theirmessages via superimposed currents.HART current

signals are converted and inverted into the required voltage signals by a resistor

available within the current loop (internal resistance of power supply, line resistance,

9

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART General information on HART

input resistance of actuator, etc.).The total resistance of the current loop including

the cable resistance must amount to minimum 230 Ωand maximum 1,100 Ω. In

case the available resistance of the current loop is too low, a so-called communication

resistor must be integrated in series.Generally, communication resistors are rated

at approx. 250 Ω.

Device categories AC .2 actuator controls distinguish two HART variants, the device categories

“Actuator”and “Current Output”.When ordering AC .2 actuator controls, the type of

HART communication channel must be specified, either 4 –20 mA input or 4 –20

mA output.

When using AC . 2 device category “Actuator”, no further communication resistor is

required within the current loop for communication with the controller, since the HART

current input already offers a resistance of 250 Ω(low impedance).

Figure 6: Example wiring of HART device category “Actuator”

Example wiring of HART device category “Current Output”.The actuator issues the

actual value via the 4 –20 mA analogue signal, the signal power supply is contained

within the actuator.

Figure 7: Example wiring of HART device category “Current Output”

The actuator current output has a high internal impedance of approx. 40 kΩ(high

impedance).When using this concept and depending on the input impedance of the

used current input, an additional communication resistor might be required.

HART multidrop

HART allows for implementation of rarely used line topologies, comparable to the

classical fieldbus applications, called multidrop.For this operation mode, a so-called

polling address must be assigned to every single of maximum 8 HART devices,

arranged in parallel, preferably within the range of 1 –15.This operation mode does

not allow for analogue signal transmission.Communication is only digital and

sequential to every single end device.

The HART multidrop mode is provided for AC .2 actuator controls in variant “Current

Output”(high impedance).

10

Actuator controls

General information on HART AC(V) 01.2/AC(V)ExC 01.2 HART

Figure 8: HART multidrop

Characteristics of HART multidrop:

●Very slow request rate –0.5 seconds per device in sequential order

●Purely digital communication

●Address assignment required

●≤8 devices per line

●Useinputs/outputs with highimpedance(referto <Technicaldata> input imped-

ance/output impedance)

●Output current is set to 4 mA

Settings for multidrop

Settings at local controls of actuator controls (menu operation via push buttons):

1. Deactivate HART parameter Loop current mode:

Indication on display:

Customer settings M0041

HART M1238

Loop current mode M1254

2. Set HART polling address unequal to 0:

Indication on display:

Customer settings M0041

HART M1238

Address M1253

Information

These settings can also be performed via a Bluetooth device (via PC, laptop, ...) and

the AUMA CDT service software or the AUMA Assistant App.

2.6. HART communication cable

The correct selection of HART communication cable can be crucial. It depends on

length, cross section as well as ambient conditions if foreign signals might cause

interferences.The majority of all available field installations meets the HART

communication requirements without further adaptation requirement.

Installation criteria:

●Total current loop impedance including line impedance min.230 Ω, max.1,100

Ω.

●For disturbances and long cables, two-wire cables of min.0.5 mm² or AWG 20

with twisted wire pairs and common shielding are recommended.

●Unshielded cables with 0.2 mm or AWG 24 are sufficient when dealing with

short distances < 100 m.

For further information, refer to HART installation guidelines.

11

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART General information on HART

2.7. Requirements on power supplies

Power supplies used in 4 –20 mA HART installations must meet the following

specifications:

●Maximum residual ripple: (47 –125 Hz) = 0.2 V p-p

●Maximum sweep: (500 Hz –10 kHz) = 1.2 mV rms

●Maximum series impedance: (500 Hz –10 kHz) = 10 Ω

2.8. Control & HART device categories

AC .2 actuator controls distinguish two HART variants, the device categories

“Actuator”and “Current Output”.When ordering actuator controls, the type of HART

communication channel must be specified:4 –20 mA input or 4 –20 mA output.

Irrespective of the digital HART communication, all further binary and analogue inputs

and outputs remain available.Consequently, it is quite possible to operate the actuator

via binary control signals (e.g.OPEN, STOP, CLOSE and EMERGENCY) or via

analogue 4 –20 mA setpoint and to send binary as well as analogue signals via the

respective outputs to the DCS while HART communication is used for commissioning

and diagnostics.

Basically, the control commands can be exclusively sent from one defined interface.

The operator must specify which interface is to be used to execute this function.In

this respect, the device variants “Actuator”and“Current Output”differ.A more detailed

description of both variants is available hereafter.

"Actuator”device category

●HART communication and analogue setpoint definition via 4 –20 mA input

●Input impedance: 250 Ω(HART low impedance)

●Control commands via binary control inputs (option)

●Feedback signal on position value via separate 4 –20 mA output (option)

Operational settings for“Actuator”:

In typical applications, the actuator is controlled by means of analogue 4 –20 mA

setpoint via HART analogue input AIN. If this setpoint is to be controlled via HART,

parameter Loop current modeM1254 must be deactivated. Settings can be made

using all available interfaces, provided the corresponding access rights are available.

(parameter Customer settings M0041 > HART M1238 > Loop current mode M1254)

If parameter Loop current mode is deactivated, control commands can be directly

executed via HART. Analogue input current does no longer have an impact on the

setpoint.

Digital control inputs OPEN, STOP, CLOSE, EMERGENCY (refer to wiring

diagram) are deactivated, unless as they are activated via I/O INTERFACE input.

If these discrete inputs are activated, exclusive control on actuator controls are

assumed by these inputs.

Summary of “Actuator”control types:

●Parameter Loop current mode M1254 activated:

Analogue 4 –20 mA control signal for position setpoint

●Parameter Loop current mode M1254 deactivated:

Digital HART commands for position setpoint (0 –100.0 %) or for discrete op-

eration in directions OPEN and CLOSE

12

Actuator controls

General information on HART AC(V) 01.2/AC(V)ExC 01.2 HART

Figure 9:Wiring diagram, example of “Actuator”device category

Device category“Current Output”

●HART communication and analogue actual value/position feedback via 4 –20

mA output

●Output impedance: 40 kΩ(HART high impedance)

●Control commands via binary control inputs (option)

●Setpoint definition via separate 4 –20 mA analogue input (option)

When selecting the “Current Output”variant, it must be considered that the 4 –20

mA HART output is fed by the internal power supply and no external power supply

may be provided.

Operational settings for“Current Output”:

In typical applications, the actuator is controlled by means of discrete signals via

digital control inputs OPEN, STOP, CLOSE, EMERGENCY (refer to wiring

diagram).As an alternative, a setpoint can be defined via a separate 0 –20 mA

input. For this purpose, this input must be activated via a signal at the MODE input.

If the actuator is to be controlled via HART, the digital control inputs must be

deactivated by means of a discrete signal at I/O INTERFACE input.

As long as the parameter Loop current mode is activated, the actuator value or the

position value is signalled as analogue value via the HART 4 –20 mA output. If the

parameter Loop current mode is deactivated, the current output is fixed at 4 mA.

Refer to section <HART multidrop>.HART control commands can be used

irrespective of the Loop current mode setting.

Summary of “Current Output”control types:

●Parameter Loop current mode activated:

Analogue 4 –20 mA output signal for position feedback (point-to-point wiring).

Digital HART commands for position setpoint (0 –100.0 %) or for discrete op-

eration commands in directions OPEN and CLOSE.

●Parameter Loop current mode deactivated:

Analogue output signal for position feedback signal fixed to 4 mA (multidrop

wiring). Digital HART commands for position setpoint (0 –100.0 %) or for dis-

crete operation commands in directions OPEN and CLOSE.

13

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART General information on HART

Figure 10:Wiring diagram, example of “Current Output”device category

2.9. Protective functions

●All messages are transmitted via hamming distance HD = 4.

●Transaction errors are signalled by the slave by means of a Response Status

Byte

●Response monitoring:

HART communication will be monitored as soon as the control function has

been enabled for this interface.If no HART communication occurs after a defined

time (parameter Monitoring timeM1239), a defined actuator failure behaviour

is activated.Refer to <Device manual>

For monitoring time setting, refer to chapter <HART communication monitoring>.

Menu:

Customer settings M0041

HART M1238

Monitoring time M1239

●Access protection for important parameters:

HART interface settings, e.g. via display. Requires at least a “Service”(level 5)

user password.

●Adjustable failure behaviour

2.10. Device types

●HART Primary Master - continuously available, e.g.DCS/PLC

●HART Secondary Master - temporarily activated, e.g.handheld terminal device

or service laptop

●HART Slave - field device, measurement device, actuator, etc.

14

Actuator controls

General information on HART AC(V) 01.2/AC(V)ExC 01.2 HART

3. Commissioning

3.1. Introduction

Commissioning a HART installation is comparatively simple due to the conventional

4 –20 mA wiring.The planning of multidrop applications in turn requires observing

further steps like e.g.an addressing of participants.

After field device installation, the user can configure or program the field devices

(actuators) using a HART capable user software or a handheld terminal.Commands

defined in HART standard allow open communication between controllers and field

devices.These universal commands allow basic and homogeneous setting of all

certified HART field devices as well as reading the status or fault signals according

to HART standard notation.Access to specific services, information and parameters

of field devices is not possible via standard HART commands.For interpretation and

use of device specific functions by the controller, a driver software or a suitable

device description is required for each HART field device.Known and supported

technologies are DD or EDD device descriptions, FTD/DTM drivers or FDI packages.

Certification HART is an open internationally standardised communication protocol (IEC 61158

andIEC61784,CPF9).Conformity with HART specification and interoperability with

host systems of different manufacturers is tested using complex registration tests.

Only those devices will receive a HART registration certificate as proof which

successfully pass these tests.

Identification number

(device type) Each HART device type is identified by an unambiguous device type number.This

number is required to allow the HART user program to identify the types of connected

devices and to load the pertaining device drivers.Device types are centrally managed

by the Fieldcomm Group (FCG).

AUMA actuators with AC 01.2 actuator controls are listed with the FCG with the

following device type number:

●(Expanded) Device Type Code: 0xE1FD

●Model Name: AC 01.2/ACExC 01.2 AUMATIC

●Manufacturer Name: AUMA

●Manufacturer ID: 0x607C

Settings and displays on device

For diagnostics and configuration settings, the local display on actuator controls is

available.HART specific diagnostics and/or configuration settings can be performed

using the push buttons of the local controls:

●Customer settings M0041 > HART M1238

●Device configuration M0053 > HART M1242

●Diagnostics M0022 > HART M1238

For HART configuration settings via the local display, user level access rights of

minimum 4 = Specialist are required.Individual settings can only be modified locally

by the service staff.

3.2. Parameter setting

HART device programming is defined by the HART specification and the

manufacturer-specific instructions, the so-called HART commands, parameter and

status information. Settings can be made via HART commands and pertaining

information can be uploaded using these commands.

Figure 11: Structure of a HART telegram

15

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART Commissioning

Table 1: PurposeNumber of bytesName

Synchronising the data stream5 –20Preamble

Indicates the master number1Delimiter

Defines slave, master and starts burst mode1 –5Address

Reserved for protocol extensions (not used)0 –3Expansion Bytes

Figure value for the command to be executed1Command

Indicates the data field size1Byte Count

Communication and device statusMaster (0)

Slave (2)

Status Data

Data to be transmitted0 –253Data

Checksum of all bytes, from the start byte to the data bytes1Check Byte

Preamble For synchronising all participants, a HART telegram starts with an FF character

sequence counting a typical length of 5 bytes.The preamble is followed by the actual

HART message, starting with a delimiter.

Delimiter The delimiter or the start byte defines the type of message (who is the sender), the

position of the command byte counts as well as the addressing type used for the

message (short or long address).

Address HART distinguishes two addressing types, short address (polling address) and long

address (unique ID).The first byte always contains the master number, primary

master = 1, secondary master = 0. Besides commands 0 and 11 (identification of

participants), all HART telegrams use the long addressing via unique ID of the device.

Command This is a 1 byte figure to indicate which command is to be executed.

Byte Count Indicates the number of data bytes

Data This field is used to send data. All response telegrams contain minimum two status

bytes.

Check sum The check sum is calculated on the basis of XOR of all bytes. Starting with the start

byte and ending with the last data field byte.

3.3. Bus address (slave address)

Each HART device has an own globally unique long address, also called Unique

ID.For unique identification/establishment of connection, a short address is assigned

to each HART device called Polling address.For devices with polling address 0,

the analogue 4 –20 mA signalisation is active. For devices >0, only digital

communication is possible.

At initial contact, the connected HART devices and their short addresses are scanned

and identified. For this, the host system subsequently sends the identification

command 0 (Read Unique Identifier) to a previously defined address area of e.g. 0

–15. Connected devices respond with their unique ID.

The short address 0 is assigned to HART devices within point-to-point installations.

The short address configuration for HART devices in multidrop installation are

between 1 and 63.Polling address 63 is reserved for WirelessHART adapters and

I/O systems.However, WirelessHART adapters are also often preconfigured to

address 15.

Any communication between master and slave is performed after first identification

on the basis of the long unique ID.

Composition of the

unique ID Unique ID = "Expanded Device Type" + "Device Identifier"

Expanded device type M1261 = HART device type or identification number (refer to

FCG tables)

Device ident. no M1262 = Device serial number

Setting the short ad-

dress The short address can be set in the following ways:

16

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 HART

●Directly at local controls of actuator controls (menu operation via push buttons)

Indication on display:

Customer settings M0041

HART M1238

Address M1253

●Via Bluetooth (via PC, laptop, ...) and AUMA CDT software or AUMA Assistant

App

●Via HART using the controller or the hand-held terminal

Identification via device

tag In many cases, HART devices are identified via the descriptive designation, the

device tag.This device tag consisting of 10 characters can be configured for each

HART device. It is also possible to address a HART device or read the unique ID

(command 11) via the device tag.

The device tag can be set in the following ways:

●Directly at local controls of actuator controls (menu operation via push buttons)

Indication on display:

Diagnostics M0022

HART M1255

Device identification M1268

Manufacturer ID code M1260

●Via Bluetooth (via PC, laptop, ...) and AUMA CDT software or AUMA Assistant

App

3.4. Communication start

HART communication is usually started by a device scan to identify all connected

devices. After identification, acyclic or cyclic data access to the connected devices

can be started.

3.5. HART commands

HART communication is based on command exchange between master and slave.

HART specification makes distinction between three categories:

1. Universal Commands

Universal commands are understood and used by all field devices working with

the HART protocol (device designation, firmware no., etc.)

2. Common Practice Commands

Standard commands generally supported only be one group of HART field

devices.

3. Device Specific Commands

Device specific commands deal with functions limited to individual instruction

and device models.

AC 01.2 actuator controls support the instructions of HART protocol of revision 7.4.

3.6. HART communication monitoring

Connection monitoring HART communication will be monitored as soon as the control/operation function

has been released for this interface.If no HART communication occurs after a defined

time (parameter Monitoring time), a defined actuator failure behaviour is activated.

Monitoring time setting is made via the actuator controls display menu:

Indication on display:

Customer settings M0041

HART M1238

Monitoring time M1239

17

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART Commissioning

3.7. Calibration 4 –20 mA of HART interface

3.7.1. Adjustment of loop current or current trim

Actuator controls (“Actuator”device category) measures the applied analogue input

current within the range of 0 mA to 24 mA and supplies the value as “Raw_AI”process

data (raw value) for diagnostics.A trimmed (corrected) signal is generated from the

measured raw value within the range of 0 mA and 24 mA and provided as “PVAI”

process data for diagnostics.

A current trim is required to match the actuator current input with the controls (e.g.

PLC) or I/O module output. If controls issue a setpoint current of 4.0 mA and the

actuator indicates 4.2 mA, the current trim is used to adapt this input value to 4.0

mA.

Figure12:Schematic representation of“Actuator”analogue input current adjustment

This principle is inverted for an actuator current output and a controls input (PLC).

If the actuator sets a current value of 4.0 mA, controls (PLC) however indicate 4.2

mA, the actuator current output is adapted to 4.2 mA by the current trim.

Figure 13: Schematic representation of the analogue output current adjustment

Current trim must be performed in two steps:

1. Adjustment of lower current value close to 4 mA “Zero”(range 2 –6 mA), via

HART command 45 (Trim Loop Current Zero) possible or via display

2. Adjustment of upper current value close to 20 mA “Gain”(range 18 –22 mA),

via HART command 46 (Trim Loop Current Gain) possible or via display

3.7.2. Range adaptation of process variables (Dynamic Variables)

Theanalogueloopcurrent(inputor output current) is transformed via rangeadaptation

to the dynamic process variable PV and SV specifically the setpoint or actual position

in %.

The following limit values are required for adapting the 4 –20 mA loop current to the

value range of the dynamic variable:

●Lower RangeValue --> process value in % for loop current of 4 mA

●Upper Range Value --> process value in % for loop current of 20 mA

These values can be configured via the HART interface using commands 35 –37

and 135 –137, refer to HART specification.

The values can be set via the display in the menu for Device configurationM0053 >

HARTM1242.

Setting procedure

LRV always represents the setpoint for 4 mA in %. URV represents the setpoint for

20 mA. It is possible to represent any input or output current range to any desired

process value (setting range/actual position).

The allowed value range is –250 % to 250 %

18

Actuator controls

Commissioning AC(V) 01.2/AC(V)ExC 01.2 HART

Example of inverse oper-

ation Set LRV = 100 % (4 mA value), set URV = 0 % (20 mA value)

Example:Increasing the current resolution (current loupe) for a limited setting

range:

Current range 4 –20 mA to be represented to setting range 20 % bis 60 %.

Set LRV = 20 % (4 mA value), set URV = 60 % (20 mA value)

Example: Representation of setting range to a limit current range, Split Range

Setting range 0 –100 % is to be represented to 4 –12 mA (0 to 50 % of 16 mA

current range).

Set LRV = 0 % (4 mA value), set URV = 200 % (20 mA value)

Setting range 0 –100 % is to be represented to 12 –20 mA (50 –100 % of current

range)

Set LRV = -100 % (4 mA value), set URV = 100 % (20 mA value).

Figure 14: Calculation formula for range adaptation:

The following applies: X = PV in % @ x mA ;Y = PV % @ y mA

Corresponding settings for the output (process value of actual position).Here to limit

(to reduce) the measurement setting range (actual position) and/or to configure

inverse operation.

19

Actuator controls

AC(V) 01.2/AC(V)ExC 01.2 HART Commissioning

4. Description of the data interface

4.1. Supported HART commands

4.1.1. Universal Commands

The following specifications are to be considered for AC 01.2 actuator controls:

●Command 3 (Read Current and Dynamic Variables):reads two dynamic vari-

ables (PV and SV) with 14 bytes within the response telegram.

●Command 14 (Read Primary Variable Sensor Information): units for sensor

limits and minimum span are fixed in percent.

●Command 48: ready 25 bytes within response telegram.

4.1.2. Common Practice Commands

The following commands are supported:

Table 2:

Command

Read Device Variables33

Write Primary Variable Range Values35

Enter/Exit Fixed Current Mode40

Perform Master Reset421)

Trim Loop Current Zero45

Trim Loop Current Gain46

Read Dynamic Variable Assignments50

Read DeviceVariable Information54

Read Analog Channel and Percent of Range60

Read Analog Channels62

Read Analog Channel Information63

Write Analog Channel Range Value65

Read Analog Channel Endpoint Values70

Squawk72

Find Device73

Write Device Variable79

Set Real-Time Clock89

Read Real-Time Clock90

Read Device Communication statistics95

Read Condensed Status Mapping Array523

Command 42 performs a reboot of actuator controls.During start-up, actuator controls are not

available for HART communication.

1)

4.1.3. Device Specific Commands

The following commands are supported:

Table 3: DescriptionCommand

Write Operation Command128

Read Input Data130

Read Software Version131

Reset to Factory Defaults132

Reset Operational Data133

Reset HART configuration134

20

Actuator controls

Description of the data interface AC(V) 01.2/AC(V)ExC 01.2 HART

Other manuals for AC(V) 01.2

1

This manual suits for next models

1

Table of contents

Other AUMA Control System manuals

Popular Control System manuals by other brands

Balboa Instruments

Balboa Instruments VSP-VS510SZ-DCAH Tech sheet

Siemens

Siemens simatic c7-621 Hardware installation guide

Carrier

Carrier AQUASNAP 30RA/RH Operation & maintenance instructions

Mazak

Mazak STX SC L PLUS CONTROL Training manual

Highway Care

Highway Care BarrierGuard 800 Product and installation manual

Toshiba

Toshiba TOSDIC-CIE DS instruction manual