Barrier Systems by Lindsay +1 (888) 800-3691 (U.S. toll free or +1 (402) 829-6800 - ECN 60881 5

ARMORGUARD® BARRIER

INTRODUCTION

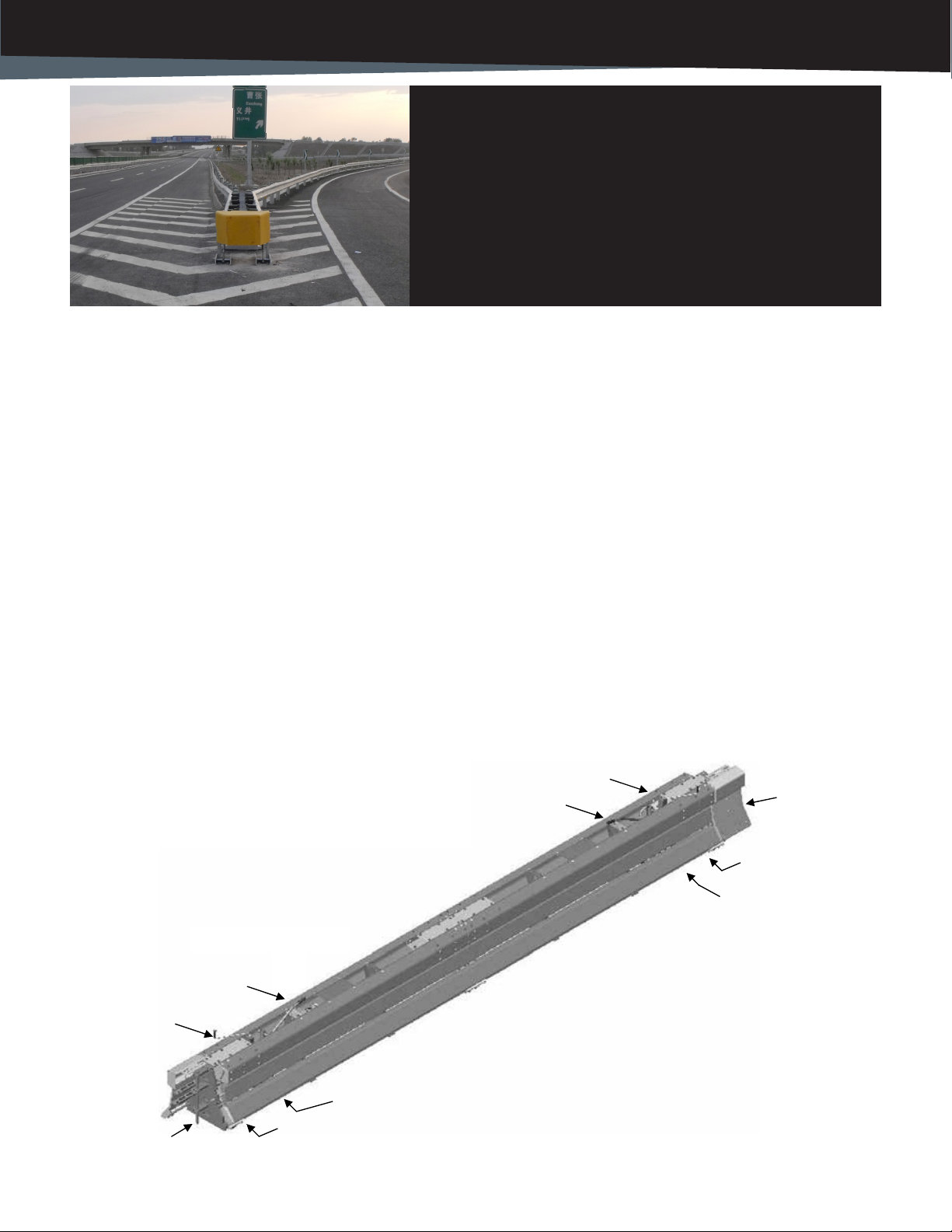

The ArmorGuard Barrier has been fully tested in

accordance with the evaluation parameters contained

in NCHRP Report 350 (Test Level 2 and 3).The system is

a heavily reinforced steel barrier that was designed to

oer a practical solution for including positive barrier

separation in short-term construction work zones and

controlled access points on long term construction

projects.

The system is ideal for locations where safety and

barrier portability are paramount.Freestanding barrier

sections come in 8.5 meter (28 ft) lengths and multiple

sections can be quickly interlocked to form a portable

barrier wall in minutes.

Individual links or multiple connected sections can be

raised onto wheels with a manual jack. No electrical

power or sophisticated control systems are required.

The barrier can be easily deployed or repositioned

by hand or with a vehicle to positively separate and

protect both workers and motorists. You can easily

create a portable crashworthy barrier for work zones

with controlled access for vehicles and equipment.

The system can be deployed on a level or sloped (≤8 %)

smooth surface (concrete or asphalt pavement) or on

any relatively smooth surface (gravel on base) capable

of supporting the weight of the system.

SYSTEM OVERVIEW

Longitudinal barriers are highway safety devices whose

primary functions are to prevent vehicular penetration

and to safely redirect errant vehicles away from

roadside or median hazards. The ArmorGuard Barrier is

used as a portable longitudinal barrier. Each 8.5 meter

(28 ft) section is hinged at both ends and a manual jack

system to raise the gate section onto wheels. A steering

wheel is located on both ends of each barrier section.

The steering wheel is attached to a tiller handle located

at the top of the barrier that can be used to steer the

link section in virtually any direction.

With the tillers pointed in the same direction multiple

sections of barrier can be simultaneously moved.

Large systems of barrier can be quickly moved to a new

lane position or to the curb or median using a vehicle

equipped with a special roller device (see Figure 16).The

system is approximately 700 mm (28”) wide, 830mm

(33“) high and 8.5 meters (28 ft) in length. The system

can be easily and quickly deployed or stored without

expensive electrical power supplies or sophisticated

control systems.

REQUIRED TOOLS

ArmorGuard Barrier sections are delivered to the jobsite

fully assembled and ready for service. No assembly is

required.

Manually Lifting a Section:

• The manual lifting system allows a section to

belifted with NO tools.

For General Operations:

• Truck mounted wheel assembly (for lateralmoves

with a vehicle)

• Come-along (for steep slope operations)

• Chain and clevis (for loading and unloading)

• Pry/construction bar

BEFORE INSTALLATION

Placement and use of the ArmorGuard Barrier should

be accomplished in accordance with the guidelines and

recommendations set forth in the “AASHTO” Roadside

Design Guide,”FHWA memoranda and other state and

local standards for longitudinal barrier.

The system is a highly engineered safety device made

up of a relatively small number of parts. Before starting

use of the system, become familiar with the basic

elements that make up the system.

Before beginning the use of the system, check

the packing list to be certain that all of the system

components were included in the shipment. If any

parts are found to be missing or damaged call the

Lindsay Transportation Solutions Customer Service

Departmentat (888) 800-3691 (U.S. toll free) or (707)

374-6800.