Auper TM6400 Installation guide

Installation and programming guide

TM6400

64 CHANNELS FLOW MONITORING SYSTEM

AND TRANSMITTER

GENERAL INFORMATION

FCC INFORMATION

This device complies with Part 15 of FCC rules. Operation is subject

to the following two conditions:

(1) This device may not cause harmful interference and, (2) this

device must accept any interference received including interference

that may cause undesired operation.

Note: The user is cautioned that any changes or modifications not

expressly approved by the party responsible for FCC compliance

could void the user’s authority to operate the equipment.

No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written permission of

Auper Electronic Controls Inc.

LIMITED 5YEAR WARRANTY

Auper Electronic Controls Inc. warrants that this product is in good

working condition, according to its specifications at the time of the

shipment, for a period of FIVE (5) years from the date of purchase.

Should the product, in Auper Electronic Controls Inc opinion,

malfunction within the warranty period, Auper Electronic Controls Inc.

will repair or replace the product without charge. Any replaced parts

become the property of Auper Electronic Controls Inc. This warranty

does not apply to the software component of a product or a product

which has been damaged due to an accident, misuse, abuse,

improper installation, usage not in accordance with product

specifications and instructions, natural or personal disaster or

unauthorized alterations, repairs or modifications.

THIS WARRANTY IS LIMITED TO REPAIR OR REPLACEMENT (AT

AUPER’S OPTION) ONLY AND DOES NOT INCLUDE ANY LABOR

OR TRANSPORTATION CHARGES OR COMPLIANCE WITH ANY

FEDERAL, STATE OR LOCAL LAWS, CODES OR REGULATION.

TM600 FLOW TOTALIZER AND TRANSMITTER

2|P a g e

Notice of any claimed breach of said Warranty must be promptly given

to the Auper authorized dealer from whom the product was purchased

or leased. Upon request, all systems or parts which are claimed to be

defective must be made available for inspection by and/or return to (at

AUPER’S option) such authorized dealer and/or Auper. No repair or

replacement under said warranty will extend the original warranty

period.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER

WARRANTIES, ORAL OR WRITTEN, EXPRESS OR IMPLIED,

INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR ANY PARTICULAR PURPOSE.

LIMITATIONS

All warranty for this product, expressed or implied, are limited to five

years from the date of purchase and no warranty, expressed or

implied, will apply after that period. No warranties for this product

expressed or implied will apply to any person who purchases the

product in used condition. The liability of Auper Electronic Controls

Inc. with respect to any defective product will be limited to the repair

or replacement of such product.

In no event shall Auper Electronic Controls Inc be responsible or liable

for any damages arising

(a) from the use of the product;

(b) from the loss of use, revenue or profit of the product; or

(c) as a result of any event, circumstances, action or abuse beyond

the control of Auper Electronic Controls Inc.; whether such damage be

direct, indirect, consequential, special or otherwise and whether such

damages are incurred by the person to whom this warranty extends or

a third party.

DISCLAIMER OF OTHER WARRANTIES AND LIABILITIES

While all reasonable care has been taken in preparation of this

product, it is provided “as is,” without warranty as to performance or

fitness except as expressly stated above. The entire risk as to the

quality of output developed with this product is assumed by the user.

Auper Electronic Controls Inc does not warrant that the software or

system will meet any particular requirements of the user, other than

as expressly stated above, and specifically denies any liability for

incidental or consequential damages resulting from the use of this

software or system.

Auper Electronic Controls Inc also specifically denies all liability for

any technical or editorial omissions in its product documentation, and

for any incidental or consequential damages resulting from the

furnishing, performance or use of its documentation.

TM600 FLOW TOTALIZER AND TRANSMITTER

TM6400 Installation & User guide 4|P a g e

TM6400

Real-time flow monitoring system

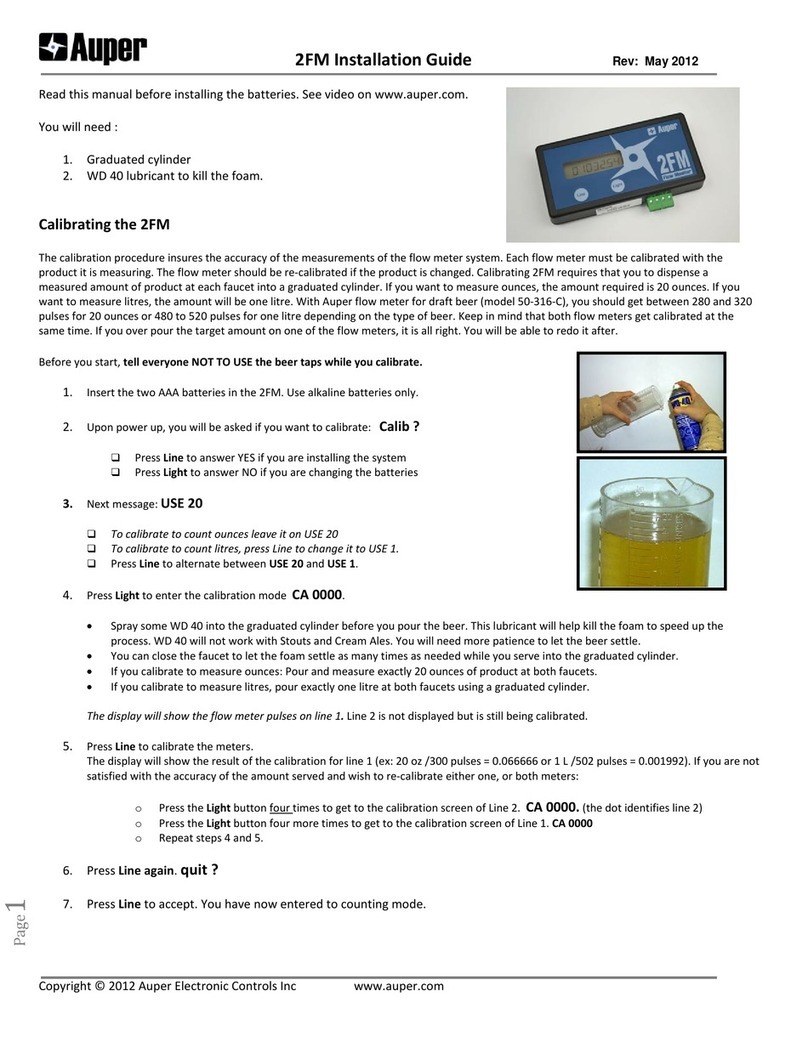

Package

TM6400 control unit

12 Volts DC transformer @ 1.5 amp min

Flow meter collector box (1 of 4)

25 ft (7.62 m) flow meter collector cable

10 ft (3 M) serial cable or Cat 5 network cable

OPTIONAL

WiFi adapter

USB to serial adapter

Serial printer

Draft Manager Live software

TM6400 FLOW MONITORING SYSTEM

TM6400 Installation & User guide 5|P a g e

INSTALLATION

POSITIONING YOUR SYSTEM

The TM6400 being a control system, should receive the same

installation considerations as an alarm system. It should be installed

in such a way as to be tamper proof that you choose to install it at the

bar, outside the beer cooler or, in the manager’s office. Cables and

connections should be protected and secured out of reach. The

power source should not be installed where it can easily be

disconnected. Do not connect the TM6400 power source to an

electrical outlet that can be turned off at night.

COMMUNICATION

The TM6400 is equipped with two programmable serial ports and an

Ethernet adapter to connect it to a computer network.

The RS-422 port serial port connector is a RJ11 jack (phone jack).

The RS-232 port connector is a Dsub 9 pin connector (male)

RS-422 SPECIFICATIONS

Standard EIA RS-422 Physical Media Twisted Pair Network

Topology Point-to-point

Maximum Distance RS-422 1000 metres (3000 ft)

Mode of Operation Differential

Maximum Baud Rate RS-422 115.2 Kbytes

TM600 FLOW TOTALIZER AND TRANSMITTER

6|P a g e

Voltage Levels −6V to +6V (maximum differential Voltage)

Mark(1) Negative Voltages

Space(0) Positive voltages

Available Signals Tx+, Tx-, Rx-, Rx+ (Full Duplex)

RS-422 connector type RJ11

Using RS-422 and the Auper AP821 RS-422 eight port hub,

you can link several Auper metering systems to the same RS-

232 serial port or USB port of a computer or printer.

RS-232 SPECIFICATIONS

The RS-232 port can be used with one system connected directly to a

serial port of a computer running with the Draft manager software.

Maximum distance RS-232 15.25 metres (50 ft) with straight

cable or 44 metres (147 ft) using UTP Cat 5 cable

RS-232 connector type DB9 male

Maximum Baud Rate RS-232 115kbit/s

ETHERNET ADAPTER

The TM6400 is available with an optional Ethernet adapter you can

use to connect one, or several TM6400, directly to your computer

network to use the Draft Manager Live software. Once connected to a

network port, the adapter can be found and configured by remote

login by our technicians from any PC on the same network. This is

done at the same time as the software installation.

The system is also equipped with a real-time interface. The TM6400

will send the amount served through the Ethernet or serial port two

seconds after the flow meter has stopped recording following a

special communication protocol. To use this feature, you must use the

Draft Manager Live software.

TM6400 FLOW MONITORING SYSTEM

TM6400 Installation & User guide 7|P a g e

RED LED POWER FAIL INDICATOR

The red LED on the TM6400 will flash to signal that there was a

power failure. To stop the LED from flashing you will need to enter

your administrator code.

CONNECTING THE FLOW METERS

Follow the instruction sheet supplied with the flow meters for complete

step by step instructions on how to install the flow meters. Videos are

also available on the Auper YouTube channel accessible from the

web site. The flow meters will be connected to one or 4 flow meter

collector box. The collector boxes are designed to be mounted in beer

coolers. Since the flow meters are supplied with a 25 ft (7.6 M) cable,

you should try to position each collector box in the beer cooler to

reach as many flow meters as possible. Flow meter cables can be

extended should you need to.

WARNING:

The power to the collector boxes comes from the TM6400 through the

collector cables. Always disconnect the power to the TM6400 when

working on the collector(s) or, when connecting or disconnecting the

collector cables.

Figure 1 TM6400 Collector box

TM600 FLOW TOTALIZER AND TRANSMITTER

8|P a g e

One collector box is able to take

up to 16 flow meters. Up to four

collector boxes can be connected

to one TM6400 for a total of 64

flow meters per system.

You will connect the collector

boxes to the TM6400 using a

regular Cat 5 network cable

terminated with RJ45 connectors.

Cables are available for up to 150

ft (46M). Longer cables can be made on demand and can reach 300 ft

(100 M). This is the same kind of cables used for computer networks.

You can find them in computer stores or have them installed by local

computer network contractors. However, you must not connect the

collector cables to the computer network and each cable should

be tested priot to connecting it to the collector and TM6400

system..

TM6400 FLOW MONITORING SYSTEM

TM6400 Installation & User guide 9|P a g e

There are two channels on the TM6400 each able to take one or 2

collector boxes. Channel 1 on the TM6400 (flow meters No.1 to 32)

will take one or two collector boxes. The second collector boxe (flow

meter 17 to 32) connects to the first collector box using the OUT

connector to the IN connector of the first collector box. The same

goes with channel 2 for flow meters 33 to 64.

The ends of flow meter cables have been stripped at the factory. Twist

the wire and then pull the insulation off the wire. Cut the copper wire

to get ¼ in (6mm) exposed only.

Auper flow meters do not need an external power source. There is no

voltage going to the flow meters so you cannot damage them even if

you touch the wires. There is no positive or ground either. You do not

have to worry about polarities.

TM600 FLOW TOTALIZER AND TRANSMITTER

10 |P a g e

Connect the flow meters to terminals 1 to16 and tighten the screws to

secure the connection. DO NOT OVER TIGHEN AS YOU MAY CUT

THE WIRE.

Inspect your connections before closing the cover to make sure that

no wires are touching each other. If two wires are touching, the flow

meter signal will be shorted and the flow meter will not send any

signal to the TM6400.

Connect the network cable to the collector box. Secure all your cables

using cable ties. Loose wires should be secured using cable ties.

TM6400 FLOW MONITORING SYSTEM

TM6400 Installation & User guide 11 |P a g e

CONNECTING THE TM6400

Warning: Although the collector box cable is the same as computer

network cables, the collector box is not a network device. DO NOT

CONNECT THIS CABLE TO ANY SWITCH, ROUTER OR OTHER

ETHERNET DEVICE.

Run the Cat 5 network cable between the junction box and the

TM6400 system.

Securing the connector

Use small cable ties to secure the

connector in place. Slip the cable tie

between the connector’s body and the

tab. The cable tie will prevent the tab

from being pressed thus preventing

anyone from disconnecting the cable.

Securing the flow meter cables and

collector box cables will prevent people

from tampering with the flow meter system. You should visually

inspect the cables regularly.

POWER SUPPLY

Use a 12 Volts DC transformer at minimum 1.5 A to power the

TM6400.

Connect the transformer to a power outlet. Avoid using inexpensive

power bars as the transformer may fall and disconnect. Make sure

the power source cannot be disconnected by the staff. A UPS (battery

backup) is an added security since it will supply power to a TM6400

for a long time in case of power failures insuring continuous power to

the unit.

TM6400 FLOW MONITORING SYSTEM AND TRANSMITTER

TM6400 Installation & User guide 12 |P a g e

POWER UP AND SET UP

The button serves several functions.

1. The numbers will be used for passwords.

2. Arrow signs pointing left and right will be used to move the

cursor, select the line numbers or ports viewed.

3. The minus and plus sign are used to increase or decrease

values.

4. The E (enter) button will be used to validate a choice.

5. The M button will be used to change mode.

6. The LED will blink in case of power loss.

Passwords:

Two different passwords can be programmed

Administrator

Line cleaning

The default factory passwords are 1 2 3 4 followed by E

(enter).

PRESS AND HOLD M and then Press E to enter the programming

modes.

You will be asked to enter a password after your selection.

1.RESET COUNTERS

Press 1 followed by the password and press E.

The system will clear the 64 counters. The counters should not be

cleared when using the software.

TM6400 Installation & User guide 13 |P a g e

2.CLEANING MODE

Press 2 followed by the password and press E.

This puts the system in line cleaning mode. The counters are disabled

when left in this position.

Press 6 (M) to exit.

3. SET UP

Press 3 followed by the password and press E.

1 IMPULSE MODE

Press 1 to enter this mode.

From left to right, 16 dots representing flow meters 1 to 16.

Press the arrows left or right to move the bank of flow meters showed

on display (1 to 16, 17 to 32, 33 to 48, 49 to 64)

The numbers below the pulses (4, 8, 12. 20, 24 ….) followed by a bar

are indicators to help you determine which flow meter number you are

looking at.

When a flow meter is connected to a line, the corresponding

dot is up.

If no flow meter is connected to a line, the corresponding dot is

down.

When a flow meter detects liquid flowing through it, the

corresponding dot will alternate up and down.

If a flow meter is installed backward, the corresponding dot will

be up but will not alternate when product is flowing.

14 |P a g e

You can verify that your flow meters are connected and registering

by serving a little bit of beer at each faucet.

If you had not yet removed the air pocket from your beer

lines, now is the time to do it.

Press M to exit. [Pulse done?]

Press E to confirm.

2. Calibration (Please read carefully)

The TM6400 can be set to measure ounces, litres, gallons etc... To

calibrate, you will serve a measured amount of liquid into a graduated

cylinder during which time the system will count the number pulses

sent by the flow meter. The initial sampling value on display is 20.0

(for 20 Oz).

If you plan on counting ounces leave it there. 20 ounces measured in

a graduated cyclinder at each beer tap is a sufficient amount to

calibrate the metering system accurately. Less will reduce the

accuracy and more is not necessary.

To count litres, you could use a sampling value of 01.0 liter but a half

litre (00.5) is sufficient to calibrate the metering system accurately.

Less will reduce the accuracy and more is not necessary.

To count one for the amount served in a glass (a pint), use a sample

value of 01.0.

The cursor can be moved left and right using the arrow buttons.

Use the + and - to increase or decrease the value.

When you have selected the sampling value to be measured in a

graduated cylinder, press M to start.

How to sample:

TIP: For draft beer, you can kill the foam by spraying WD40 into the

graduated cylinder before serving. You can stop to let the foam settle

down when you are in calibration mode. WD40 does not work with

Stouts and Cream Ales. DISPOSE OF THE CONTENT OF THE

CYLINDER INTO THE SINK. DO NOT SERVE!!!

TM6400 Installation & User guide 15 |P a g e

Serve and measure as accurately as possible the sampling value

using a graduated cylinder at each beer tap. You should calibrate

when the bar is closed. Serving beer to customers while trying to

calibrate the system may cause errors and inaccurate measurements.

After you have served the amount, you can calibrate the flow meters

all at once or, a few at the time. The number of flow meter pulses

registered by the flow meter after the sample value has been served

will be on display to the right of the flow meter number.

Use the arrow buttons to display the other flow meters.

Press the No.4 button (+) to calibrate the flow meter on display only.

Press the E button to calibrate all the flow meters that have pulses

registered after serving the sampling value.

The value on the right will change to the new calibration value. You

can view the calibration values of each line by pressing the arrow

buttons.

In calibration mode, when beer has not been served at some beer

taps, the registered pulses will remain “0000”. The system will not

recalibrate even if you press E to calibrate ALL. Therefore, you can do

some of them, press E to calibrate and move on to other beer taps as

long as ones already calibrated are not used.

RE-SAMPLING

If you have exceeded the amount to measure at one or more of the

beer tape, note which of the taps and move on to measuring the other

ones. After pressing the E button to calibrate all the flow meters, you

can come back and resample the one(s) you are not satisfied with.

Press M to exit calibration mode

Press E to confirm.

16 |P a g e

3. ACCESS

Press 3 to change the two passwords. We recommend using a

password that is simple and easy to remember.

If you do not want to change the first password (administrator), press

E to skip.

Buttons No. 1 2 3 4 and 6 can be used to enter a password up to 7

digits long.

Press and hold M while pressing E to delete the last number entered

to make corrections.

Press E to validate your entry and exit.

4. COMM

Press 4 to enter COMM mode.

System number 00

The system number is used to communicate with the Draft Manager

Live software. The default number is 0. If you have one TM6400,

leave it at 0 since the default number in the software is also 0. If you

have more than one TM6400, you can change the number of the

other systems to 1, 2 3 etc…. Each TM6400 has to be set with a

different number when on the same network. Two systems with the

same number will cause an error since both will respond to the same

command sent by the software.

Press + or - to increase or decrease the system number.

Press M to go to the next mode

Use the Arrows to select the port used to communicate with the

computer.

Choose RS232 if you connect the TM6400 directly to a PC using a

serial 9 pin to USB cable.

Choose RS422 if you connect the TM6400 to an Auper AP821 HUB to

link several system to the same RS-422 network.

TM6400 Installation & User guide 17 |P a g e

Choose Ethernet link if you connect the TM6400 directly to your

computer network using the Ethernet switch or router.

Choose WIFI link if your TM6400 is equipped with this option.

Press the + or – button to change the baud rate which is the speed of

transmission between the TM6400 and the PC.

9600 is the default Windows baud rate. If you change it in the

TM6400, it has to be changed in the software as well.

The TM6400 is designed to operate at 115.2 K for a much faster

transmission rate.

Press M to go to the next mode.

5. FIRMWARE

This mode serves to identify the firmware version and micro processor

unit installed in your TM6400.

Press M to exit.

The system asks [COMM. DONE?]

Press E to exit COMM mode.

OPERATION

RUN MODE

In Run mode, you see the counters on display.

Press the arrow buttons to view the other counters.

Press M to select one of two options:

Press 1 to print a report to a serial printer.

Press 2 to reset the power fail counter.

Enter the password and press E to validate.

18 |P a g e

ANNEX

SERIAL PRINTER SETTINGS

Baud rate: 9600 to 115.2 K

Parity: none

Stop bit: 1

Handshaking: Xon/Xoff

Print columns: 40

USB TO SERIAL CONVERTER

Most computers are not equipped with 9-pin serial ports. A USB to

serial adapter must be used. Drivers are provided with the converter

and must be installed on the computer. Windows will assign the serial

port automatically. You can find to which port your converter has been

assigned at:

Control panel/system/device manager/ports (Com & LPT)

Default Windows serial port settings:

9600 bps

bits

no parity,

2 stop bits

Flux control to none.

P/N: 70-080

Use with Auper null modem serial cable P/N: 70.010

USB to serial converter

TM6400 Installation & User guide 19 |P a g e

RS-422 SERIAL PORT CONNECTIONS

You will use the RS-422 port for the following reasons:

You do not have an available computer network to use the

network adapter.

You wish to connect your TM6400 to a computer more than

150 ft (50M) away.

You have more than one metering system that you want to

connect to the same computer or printer.

Short distance RS-422 connections (no more than 50 ft/ 15M) can be

made using flat modular cables. The cables will connect directly from

the system(s) into the AP821 hub. (Order the cables separately P/N

70-040-X). Modular cables are not twisted and offer no protection

against ambiant noise.

Long distance RS-422 connections can be made using UTP Cat5e 2

pair cable terminated with RJ11 jack. You can order those from the

factory.The cables must be inverted if you make your own.

P/N: 70-042-X (X = length)

RJ11 jacks

RS422 modular cable

Table of contents

Other Auper Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Satec

Satec expertmeter EM720 Operation manual

Bosch

Bosch GTL 3 Professional Original instructions

Endress+Hauser

Endress+Hauser Prosonic M FMU42 operating instructions

Altana

Altana BYK wave-scan 3 operating instructions

VOLTCRAFT

VOLTCRAFT HygroCube 100 operating instructions

Wisi

Wisi OL 55 0000 operating manual