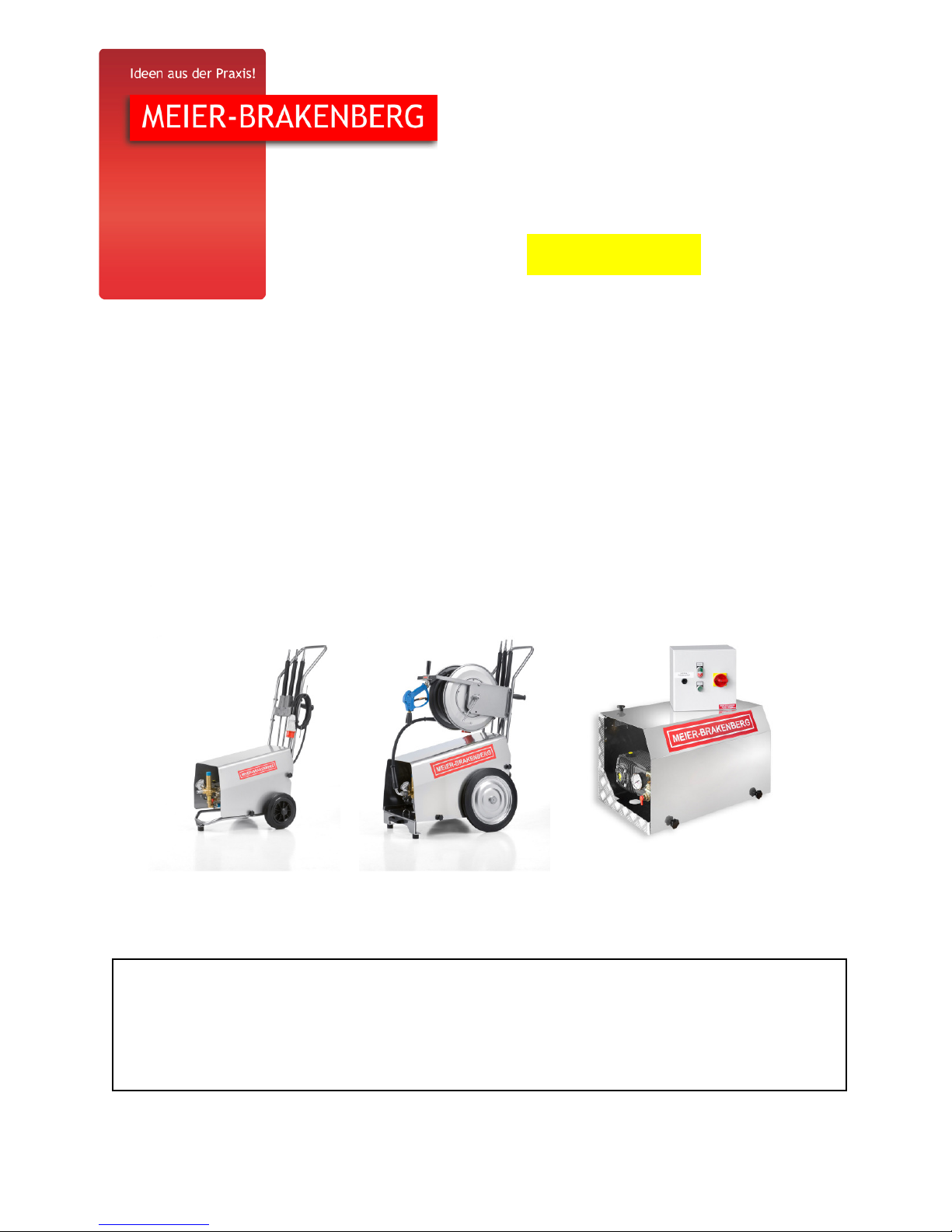

MEIER-BRAKENBERG MBH SERIES User manual

High-pressure cleaner

- mobile – cold water -

Manual

for type series MBH:

MBH1260K MBH1800/2400 MBHST1260/1800/2400

MEIER-BRAKENBERG GmbH & Co. KG

Brakenberg 2 ● 326 Extertal ● Germany

Tel: +4 (0)52 62/ 3 -0 ● Fax: +4 (0)52 62/ 3 3

E-mail: [email protected]

Internet: www.meier-brakenberg.de

Soaking units ● Disinfection ● Animal weighing machines ● Intensive cleaning ● Hihg-pressure cleaner ● Stable cooling ● Watering units

page 2 of 11

Contents

1. Introduction ...................................................................................................................2

2. Use ..............................................................................................................................3

3. Safety regulations ............................................................................................................3

4. Start of operation ............................................................................................................4

4.1 Components of high pressure cleaner ................................................................................4

4.2 Oil level check ............................................................................................................4

4.3 Power supply ..............................................................................................................5

4.4 Water supply ..............................................................................................................5

4.5 Starting the cleaner .....................................................................................................5

4.6 Function Start/Stop model .............................................................................................6

5. Mode of operation ............................................................................................................7

6. Shutdown ......................................................................................................................7

7. Maintenance ...................................................................................................................7

7.1 Before each use ..........................................................................................................7

7.2 Service note on high-pressure pump ..................................................................................7

7.3 Oil level high-pressure pump (check regularly) .....................................................................7

7.4 Filter .......................................................................................................................8

8. Standard accessories .........................................................................................................8

8.1 High-grade steel cover ..................................................................................................8

8.2 Hose coiler ................................................................................................................8

8.3 Special lances .............................................................................................................

1. Intro uction

Dear customer, please read and follow this manual before use. Keep this manual for later use or subsequent

owners. Please read the safety regulations before operation!

Guarantee: 12 months when used and maintained! Parts subject to wear and tear excluded.

Liability: The user is responsible for the appropriate use and maintenance of the high-pressure cleaner.

The manual must be directly accessible to the operator to ensure best possible operation and compliance with

the safety regulations (see passage 3).

The high-pressure cleaner is constructed with tested components acc. to the regulations for liquid blasters

("Richtlinien für Flüssigkeitsstrahler") and the Equipment Safety Act ("Gesetz über technische Arbeitsmittel").

Please observe the relevant local directives regarding liquid blasters!

page 3 of 11

2. Use

High-pressure cleaners of type series MBH are exclusively for the indoor use of hog and chicken houses.To

be used only with water. Hot water feed (up to 40 °C) increases cleaning effect.

Use only accessories and spare parts approved by MEIER-BRAKENBERG. Mind the correct jet size when

using and/ or changing jets and dirt blasters!

3. Safety regulations

Safety devices are intended to protect the user and should not be disabled or bypassed in their

function.

The high-pressure cleaner must be used only by trained persons who are perfectly familiar with the

function of the device. The following safety rules must be observed before starting up the device

and during the operation:

- The device's workplace must be free of dirt and grease during operation to ensure safe use for the

person (or persons).

- The cleaning staff may only operate the device when standing firm on the ground. Cleaning while

the user is on ladders, platforms or other elevations is strictly prohibited!

- Use only approved and non-aggressive mixing mediums or liquids.

- The reaction of the wash and spray liquid must be safe with the object to be washed. When working

in confined areas be aware of any possible occurrence of gases or vapors.

- Do not spray-wash the device!

- For maintenance and repair work, turn off the device and disconnect from mains!

- Make sure that the high-pressure hose is not bent, damaged, being passed over or even

destroyed.

- Defective high pressure hoses must be replaced with original hoses. They must comply with the

"Guidelines for Liquid Blasters". Do not use hydraulic hoses.

- The torch gear must not be fixed in turn-on position.

- Secure the torch with the safety catch during breaks. The safety catch on the torch prevents

unintended power-on of the device.

- Do not point the water jet on persons or live animals.

- Do not adjust the maximum limit of the circulation valve.

- Operation is prohibited in explosion hazardous areas. For use in hazardous areas (e.g. filling

pumps), observe the appropriate safety precautions.

- Do not use the equipment when others persons are within range, unless they are wearing protective

clothing. Do not point the jet at yourself or others person to clean clothes or footwear.

page 4 of 11

-The ejected water of the high-pressure jet produces repulsive force on the handgun. Hold the

spray lance and steel pipe with both hands to ensure firm stand.

-A competent person (customer service) must check the high-pressure cleaner at least every 12

months to verify whether a continued safe operation is ensured.

All repair work must be carried out by qualified personnel. Moreover, observe the following operating

rules: "Richtlinien für Flüssigkeitsstrahler" .

Source: Carl Heymanns Verlag

Gereonstraße 18-32

50670 Köln

Germany

Please observe the relevant local directives regarding liquid blasters!

Caution :

Apart from the repulsive force the wrist is affected by torsional movement during ejecting.

4. Start of operation

4.1 Components of high pressure cleaner

1. Chassis frame MBH: - frame aluminium MBH1260K:- Frame and cover high-alloyed steel

- cover high-alloyed steel - wheels 250 mm

- wheels 420 mm - handle high-alloyed steel

- handle high-alloyed steel

Wall bracket MBHST: - bracket aluminium

- cover high-alloyed steel

Optional: high-grade steel hose coiler

2. Drive motor, high-pressure pump

3. Circulation control / manometer

4. Spraying device

5. Electrical connection

4.2 Oil level check

Check the oil level on the front side at the high-pressure pump of the cleaner. The oil level must be in the

middle of the oil level indicator. Refill if necessary.

Suitable oil: SAE 10W-60 fully synthetic (Item.-No.: WB0011-01)

page 5 of 11

4.3 Power supply

Electricity must be connected by an electrician.

Caution: Verify that the voltage stated on the type plate complies with the voltage of the power

supply. Unsuitable extension cables can be dangerous. For outdoor operation use only

approved and correspondingly marked leads.

4.4 Water supply

-For connection values refer to type plate. In case the usual water line does not supply sufficient water

to the cleaner, use a feed tank to prevent shortage of water in the pump.

Suction from the water pipe estroys the pump!

-When operating in suction process from a feed tank use a 1 1/2 " suction hose of max. 5 m with

suction coupling.

-Devices with control (start/stop automatic): backfitting is require for suction process!

Cleaners with backfitting kit (see point 4.6): When operating in suction process from a feed tank use

a 1 1/2 " suction hose of max. 5 m with suction coupling.

-The water pressure of the feed line must be between +2 bar and +10 bar.

-Observe the regulations of the water supply company.

d

-There is a filter screen between the Geka-coupling and the high-pressure pump. Check the screen

regularly and clean the screen if applicable.

d

-Connect with a pressure and suction resistant water hose with fabric lining to water supply.

-Connect to the water connection of the device and the building’s water tap.

-Attention: If there is mounted an non-return valve in the water-supply line, it has to be installed an

expansion tank between non-return valve and presusre cleaner! Otherwise componentens of the

pressure cleaner can be damaged!

4.5 Starting the cleaner

-Couple hoses and electrical connection.

-Open water tap!

-Activate high-pressure torch and wait until water pours out without air entrapment, close torch.

d

-Turn on operating switch.

d

-Start the evice with the operating switch on "star" position an switch over to "triangle" after a

short start-up perio .

CAUTION: Operate the motor only in "triangle" position when using cleaning mo e.

- The device is now ready for operation.

-Pressure must build up immediately!

-In case of no pressure build-up check:

jet „clean“

feed line filter blocked (unsufficient water supply)

-The rotational direction of the high-pressure pump is irrelevant!

This manual suits for next models

6

Table of contents

Other MEIER-BRAKENBERG Pressure Washer manuals