Index

Chapter 1 General Information..................................................................................................4

1.1

Manual Keeping ...........................................................................................................4

1.2

Obligation in case of malfunction.................................................................................4

1.3

Cautions for the safety of the operator..........................................................................5

1.4

Warnings ......................................................................................................................5

Chapter 2 Product Identification..............................................................................................6

2.1

Warranty.......................................................................................................................6

2.2

Technical Service.........................................................................................................6

Chapter 3 Packing, Transport and Storage...........................................................................7

3.1 Packing..........................................................................................................................7

3.2 Lifting and Handling.....................................................................................................7

3.3 Storage and Stacking of the Package ............................................................................7

3.4 Delivery and check of packages....................................................................................7

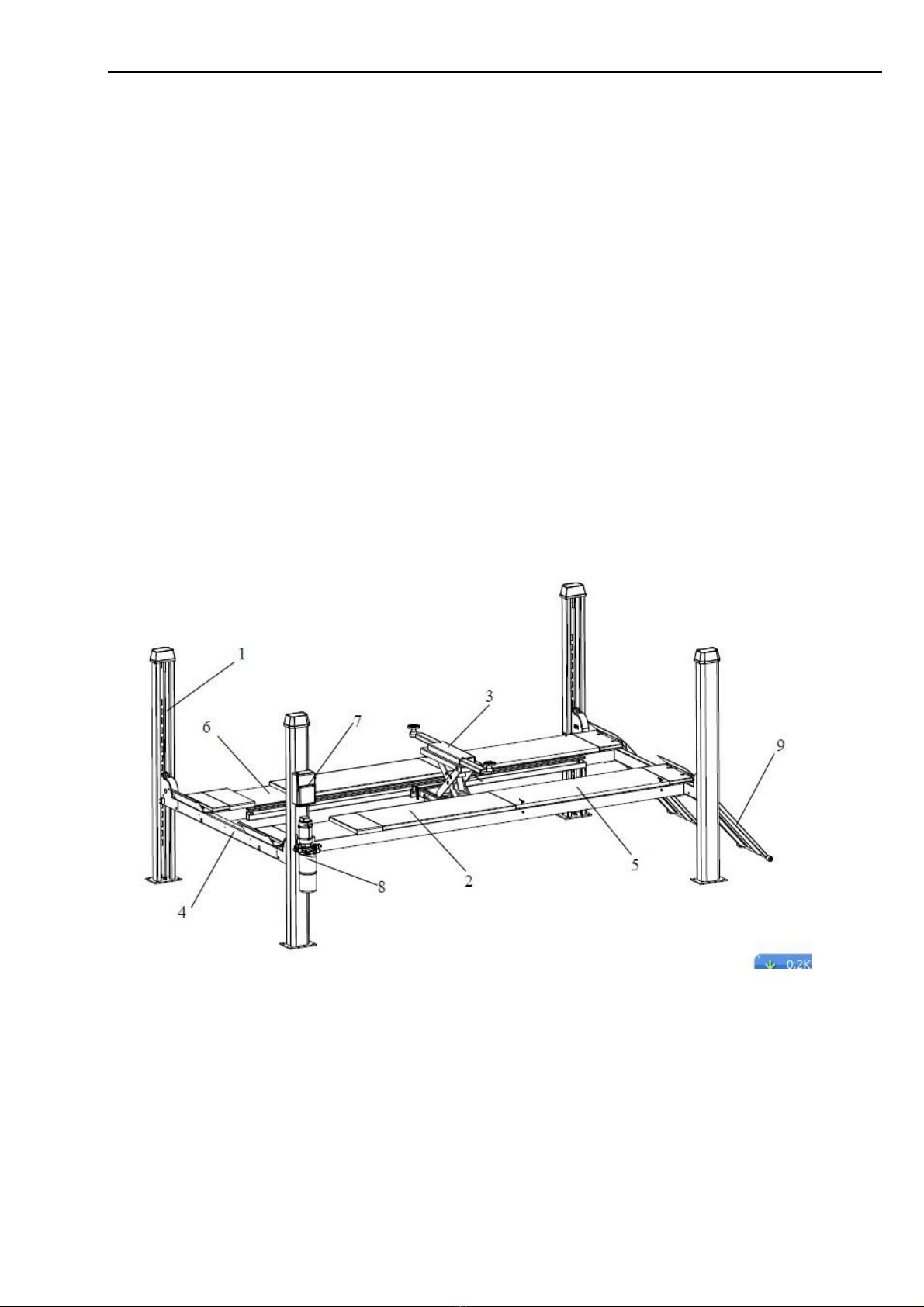

Chapter 4 Product Description.................................................................................................8

Chapter 5 Technical Specification...........................................................................................9

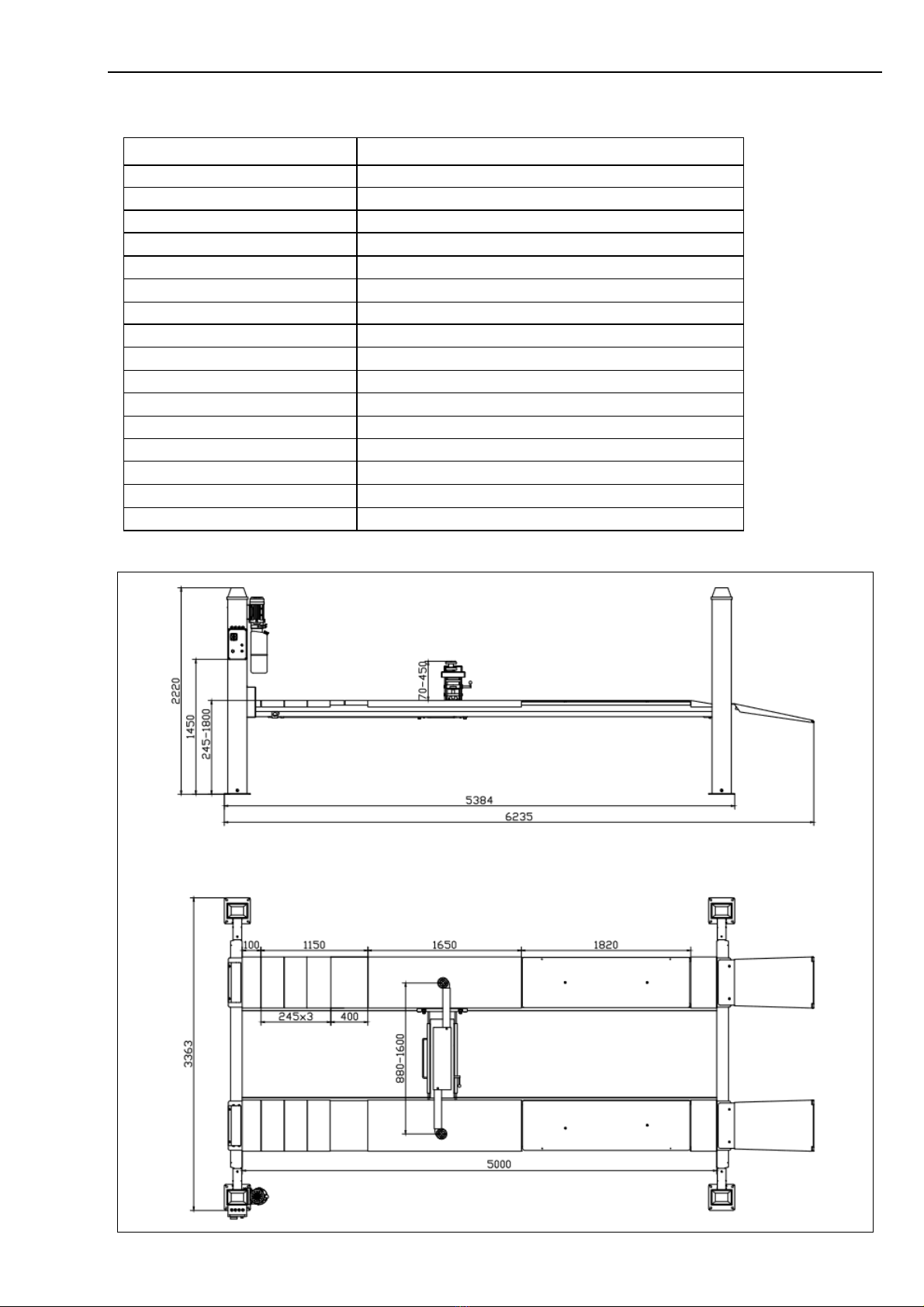

5.1 Technical Data................................................................................................................9

5.2 Lift Dimension Rough Drawing.....................................................................................9

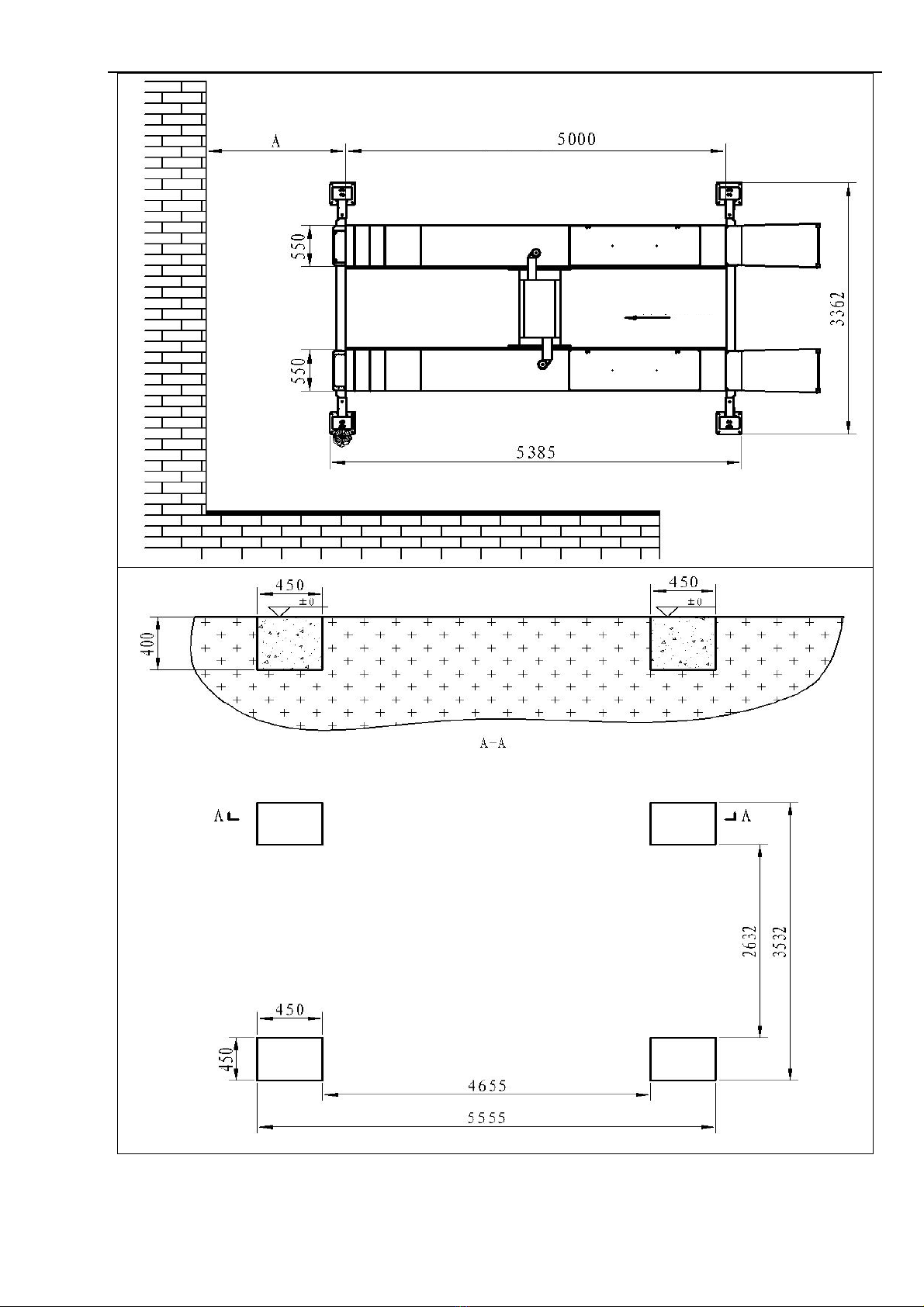

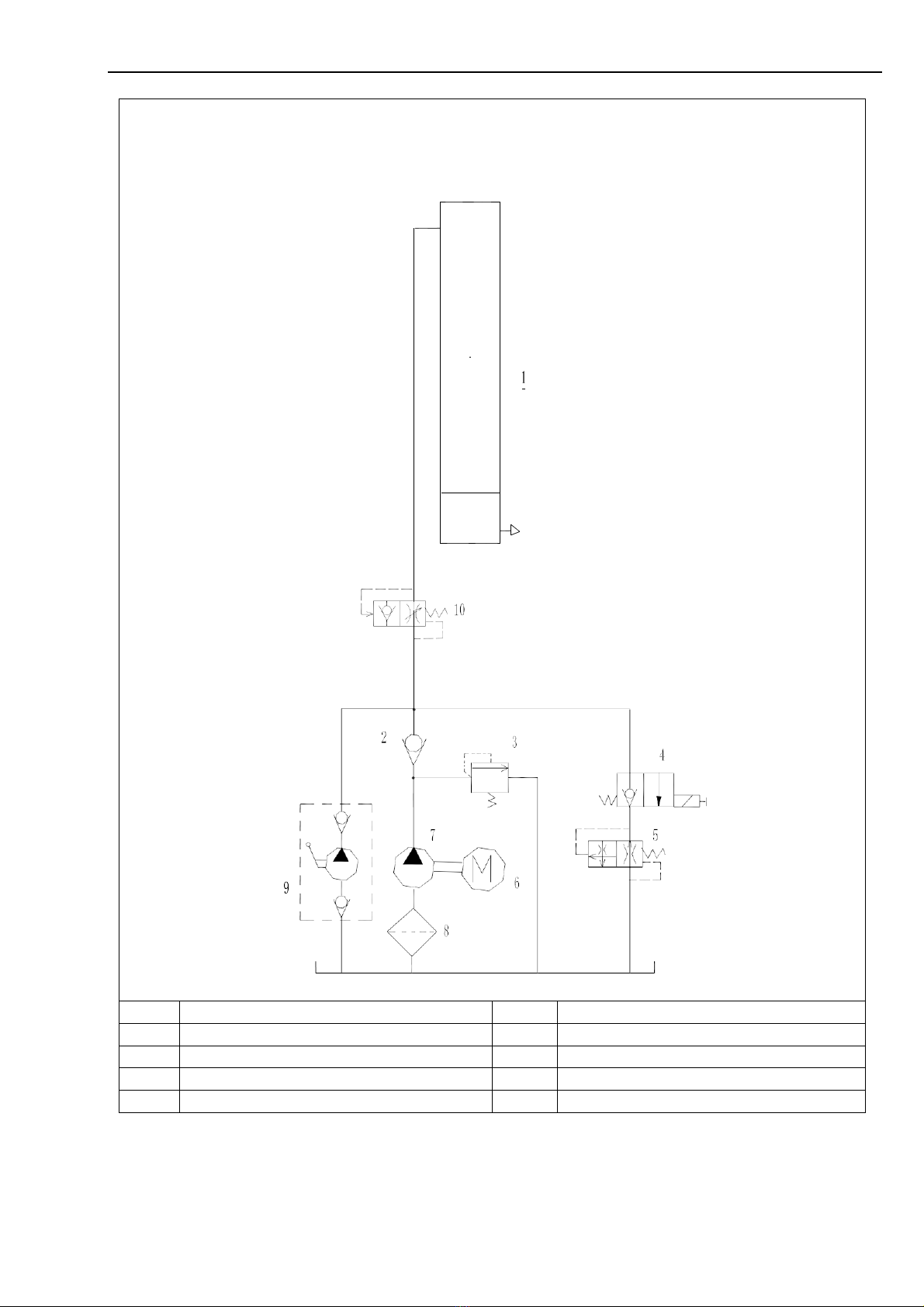

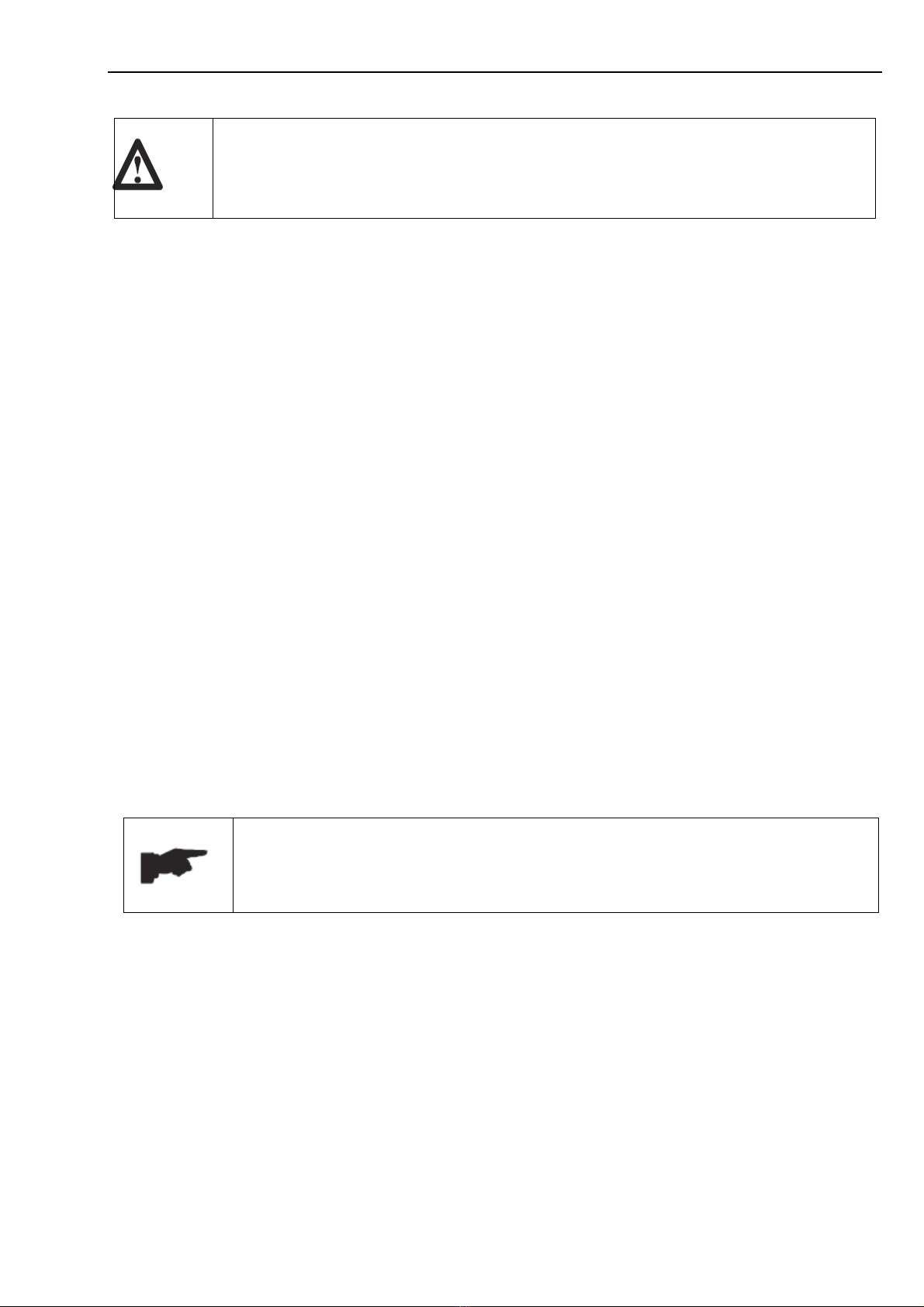

5.3 Hydraulic Drawing.......................................................................................................11

5.4 Electrical Drawing (380V/400V-3Ph) .........................................................................12

5.5 Wiring Diagram............................................................................................................13

5.6 Pneumatic Drawing......................................................................................................15

Chapter 6 Safety.........................................................................................................................16

6.1 General Warnings.......................................................................................................16

6.2 Risk for the people .....................................................................................................16

6.3 Personnel Crushing Risks...........................................................................................16

6.4 Risk of the Vehicle falling from the lift.....................................................................17

6.5 Slipping Risk..............................................................................................................17

6.6 Electrocution Risk......................................................................................................17

6.7 Risk Resulting from improper lighting ......................................................................17

6.8 Risk of breaking component during operation...........................................................17

6.9 Risk for unauthorized uses.........................................................................................18

6.10 Risk during vehicle lifting and working.....................................................................18

Chapter 7 Installation................................................................................................................19

7.1 Tools for installation ..................................................................................................19

7.2 Checking for room suitability ....................................................................................19

7.3 Lighting......................................................................................................................19

7.4 Installation surface .....................................................................................................19

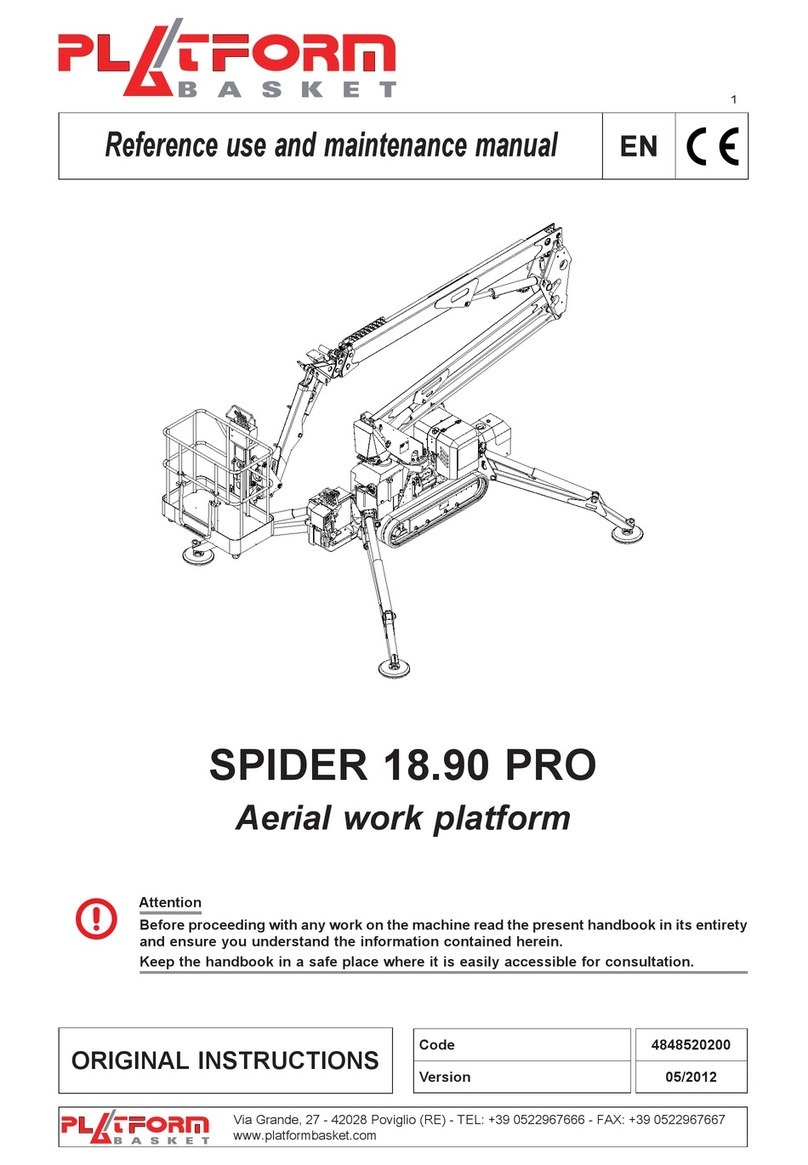

7.5 Site Layout .................................................................................................................19

7.6 Installation of runways and transverse beans.............................................................20

7.7 Steel Cable Routing Plan (Very Important)...............................................................21

7.8 Installation of safety Lock..........................................................................................23

7.9 Installation of the columns.........................................................................................24

7.10 Anchoring the columns ..............................................................................................24

7.11 Hydraulic system connection......................................................................................25

7.12 Installation of Jack......................................................................................................25

7.13 Pneumatic system connection ....................................................................................26

7.14 Make the electrical hookup to the power unit............................................................26

7.15 Start up .......................................................................................................................26

7.16 Check and adjustment ................................................................................................27

7.17 Limit switch installation.............................................................................................27

7.18 Accessories Installation..............................................................................................28

7.19 Check with load..........................................................................................................28

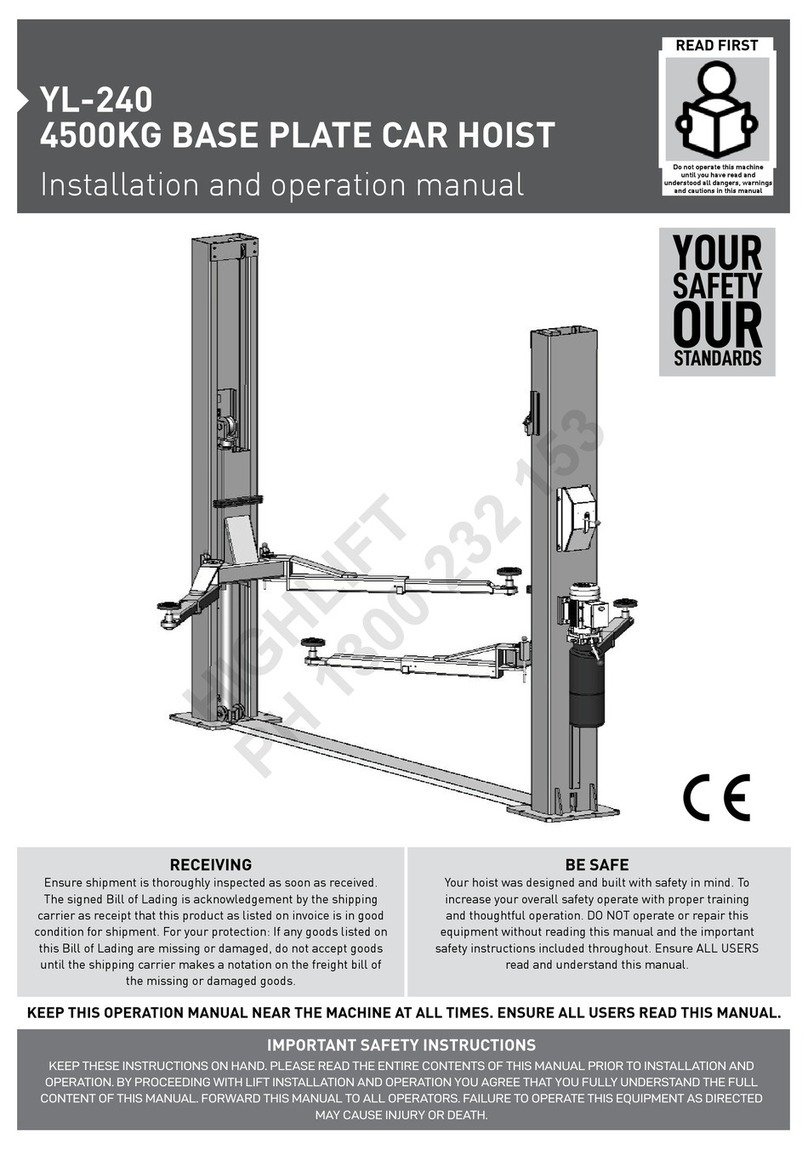

Chapter 8 Operation and Use..................................................................................................29