AUSTEM ESS 3kW User manual

Document : ESS-Model000-20180514

INSTALLATION & OPERATION

MANUAL ( 3kW )

Contents

1. Safety Instructions

1.1 General Safety Information

1.2 Important Safety Information

2. Product

2.1 Model classification code

2.2 Product features

2.3 Dimensions

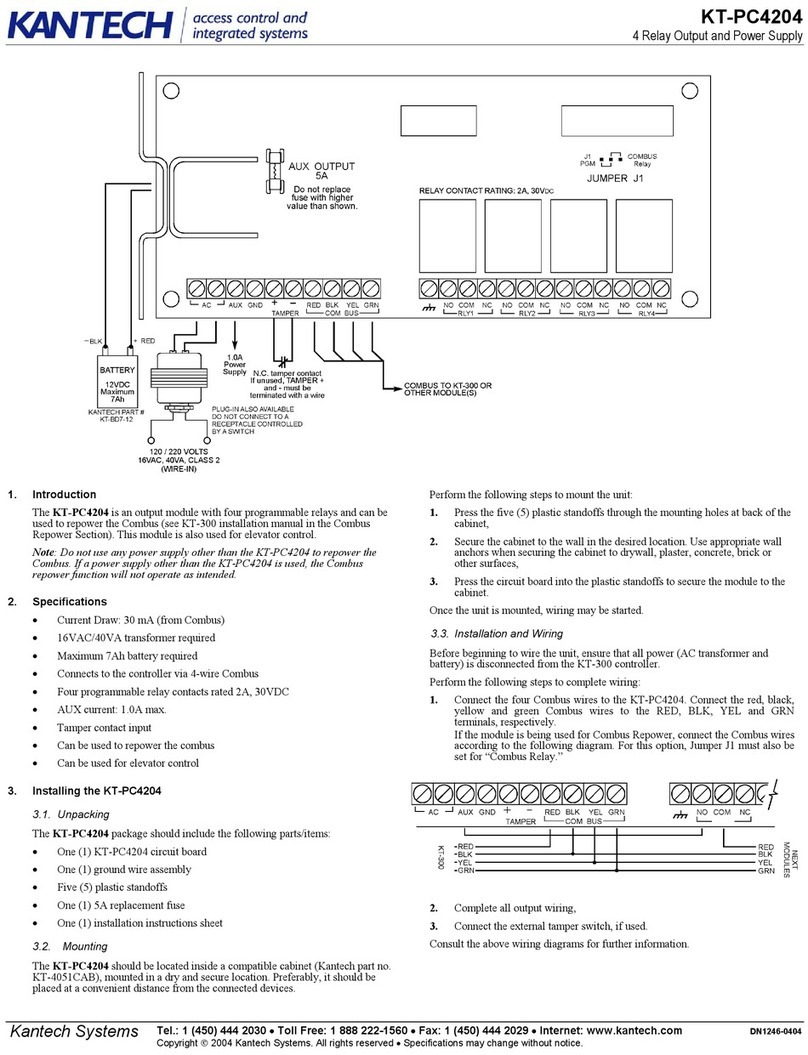

3. Installation and Wiring

3.1 Moving a product

3.2 Installation

3.3 Repair product

3.4 Wiring

3.5 Terminal block shape

4. Operation

4.1 KEYPAD

4.2 Functional group

4.3 Detail of function

4.4 System protection function

4.5 Basic operation and stop

5. Product Specification

5.1 Product specifications

6. Inspection and Caution

6.1 Inspection

6.2 Caution of usage

7. Quality Assurance

Installation Manual

Be sure to read this manual and other references thoroughly before installation.

1. Safety Instructions

◐Be sure to read this manual and other references thoroughly before installing, operating

and repairing.

◐Be sure to acquire all knowledge of machine, safety information and precautions.

◐The following warning symbol used in the manual recommends your attention in order to

prevent personal injuries or dangerous situations.

Warning

In case of violation of the instructions, dangerous situation may occur and the possibility of death

or serious injury is expected.

Caution

In the event of improper handling, a dangerous situation may occur, the possibility of serious

injury or minor injury is expected, or material damage is expected.

In addition, even if the matters described in the cautionary note, depending on the circumstances,

there is a possibility of being associated with serious consequences.

Please be sure to observe the contents of some important details.

◐This manual does not cover "DANGER", "CAUTION", but the items you wish to observe

are indicated in the related items.

1.1 General safety information.

C

A

U

T

I

O

N

• Do not install near flammable materials. Do not place flammable materials near electronic

device.

• Rain, water, dust and oil have to avoid during installation and operation. Please avoid corrosive

and flammable gas, liquids, metallic debris and flour are entering the electronic device.

• Keep, Store and Move it within the range of -10°C to +40°C in ambient temperature.

• Do not touch the inside of the product within 15 minutes after turn off.

• Wait for the internal capacitor to discharge completely.

• Do not switch the power during operation.

• The wiring of the control part and the power part are separated to avoid mutual interference.

• Disconnect the input power(PV cell) and the output power when the product fail.

• Do not insert screws, metal objects or foreign material into the product.

1.2 Important safety information.

D

A

N

G

E

R

• Do not repair the device without permission of expert.

• To avoid electric shock, Do not touch the high voltage terminal inside the electronic device.

• Be sure to fix the safety cover before connecting the product.

• Do not open the cover during operation.

• When performing wiring work or periodic inspections, turn off the power and check the DC voltage

after 10 minutes and check that it is discharged.

• If the wire is damaged, eletric shock will be occured.

• Do not place heavy objects on the wire, it may cause heavy pressure.

• Do not switch with wet hands, it may cause an electric shock.

2. Product

Caution

It is important to familiarize yourself with the functions and operation of the product through the

manual in order to use the device correctly.

Incorrect handling can cause damage to the product or accidents. Please read this manual

carefully before use.

2.1 Model classification code

◐

ESS Series are classify as rated output.

2.2 Product features

• This is an energy storage system using a battery. It uses PV power and night electricity to charge the

battery.

• Utilizing the generated PV power to the maximum, the grid energy storage discharge is executed at the

planned time and the output is single phase 2 wire system.

• Maximum power point tracking control is performed to maximize the power generated from the PV cell.

• You can set the optimal operating condition through the LCD key and check the operation status of the

system conveniently.

• High efficiency and low distortion rate are achieved through optimal control and design using high

performance semiconductor devices.

• It has UPS (Uninterruptible Power Supply) function that can supply emergency load power in case of power

failure.

2.3 Dimensions

◐

Displays the external dimensions of each model.

Model W H D

ESS(3kW) 446 630 150

※

Dimensions are subject to change without notice to improve the performance of the product.

3. Installation and wiring

3.1 Moving a product

Caution

It is important to lock the cover before moving.

Incorrect handling can cause damage to the product or accidents.

3.2 Installation

C

A

U

T

I

O

N

[Place of installation]

Information to keep in mind when installing the product.

• Avoid places where humidity is high and moisture penetration is may be concerned.

• Avoid places where explosive gas, flammable gas, liquid or dusty.

• Avoid places where difficult to repair and check.

• Avoid places where difficult to dissipate heat by the product.

• Avoid places where easy to be affected by noise, or difficult to separate from device.

[Ambient temperature]

• To maintain the product stable for a long period of time, the ambient temperature should be

carefully monitored. Generally temperature is allowed -10°C to +40°C, install in a place that satisfied

these conditions.

• If the ambient temperature exceeds this range(10°C to +40°C) due to the heat from operation, cool

it with a cooling equipment.

• PCS dissipate heat from operation, please secure enough space to prevent thermal saturation.

[Humidity]

• If humidity is high, it may cause oxidation corrosion of the metal parts and insulation failure may

occur.

• Install in a place where the relative humidity is less than 95% and be caution to prevent

condensation.

[Installation environment]

• Install in a place free from flammable gas, corrosive gas, oil or water. Also, do not allow conductive

dust such as iron powder to enter.

[Vibration]

• Install in a place with low vibration.

• Install in a place where the vibration acceleration is 20 ~ 50Hz (less than 0.2G) less than 20Hz(less

than 1G).

• When installing in a place with large vibration such as vibrator, carrier, etc. Take anti-vibration

measures by using anti-vibration rubber.

[Space]

• Ensure sufficient space around the installation site to prevent the cooling effect of the product from

deteriorating.

3.3 Repair product

• In order to repair, all covers must be fastened. Follow the instructions when repairing the product. Incorrect

handling can cause damage to the inverter and accidents.

• It should be tilted horizontally or vertically up to 15° within the wall, mount the floor with 6 fixing bolts on the

hard surface.

3.4 Wiring

In order for the product to operate stably and fully perform, it is necessary to pay attention to the following

regarding installation.

C

A

U

T

I

O

N

• Wiring must be done by a qualified technician.

• Before working, open the breaker on the output side and shut off the input of the PV cell.

• Make sure that the product is turned off before working.

• If the product is turned off after operation, wait about 10 minutes before wiring.

• Ground the ground terminal.

• Connect the earth terminal of the power terminal block to the earth pole(Resistance must be less

than 100[Ohm] with a wire of 4mm3or more.

• Do not share the ground wire with the power unit. It may cause electric shock and ground fault.

• Connect the PV input power to the input terminals (+) and (-) of the product and turn on the power.

• Connect the power supply of the system so that the phase rotation should be clockwise

• If you want to change the wiring due to an abnormal situation, perform the wiring work after the

charged voltage is completely discharged.

• When wiring, make sure that there are no wire fragments, bolts, nuts and etc. inside the product.

※Recommended wiring standard.

Capacity PV +,- Wiring Ground Load Battery Grid

3kW 6 SQ 4 SQ 6 SQ 25 SQ 6 SQ

5kW 6 SQ 4 SQ 6 SQ 25 SQ 6 SQ

Caution

For the grid-connected type inverters, resistance must be less than 100[Ohm].

3.5 Terminal block shape

Terminal name Explanation

FG Grounding terminal

PV +

Connect with (+) of PV cell

PV - Connect with (-) of PV cell

BATTERY + Connect with (+) of battery

BATTERY -

Connect with (-) of battery

GRID H Connect with High of Grid

GRID L Connect with Low of Grid

LOAD H Connect with High of Load

LOAD L Connect with Low of Load

Caution

• Make sure PV + and PV – must be connected in accordance with polarity.

• Make sure BATTERY +, BATTERY- must be connected in accordance with polarity.

• If the above instruction is not connected properly, there is a risk of damage to the product.

Operation Control

Be sure to read this manual and other references thoroughly before installation.

4. Operation

4.1 KEYPAD

◐All functions are composed of software using DSP Chip, and system related variables are set with

KEYPAD.

Type Key function

1. Enter or exit to menu

2. Move from the submenu to the upper menu

3. Cancel the set data

4. Move the digit position in the menu

1. Setting

2. Submenu selection

3. Confirm the set data

4. Stop and operation of the system.

1. Up arrow key

2. Increase value when input a data

3. Change the menu type and display

1. Down arrow key

2. Decrease the value when input a data

3. Change the menu type and display

◐LED display

LED Type Function LED Type Function

100%

Current battery charge status

(SOC)

GRID

Lights up when the system is in normal operation

80% PV

Lights up when PV power is connected

60% INV

Lights up when the inverter is operating in the system

40% FAULT When system failure occurs

20%

*

The LCD backlight turns on for 30 seconds when the keypad key is pressed.

*

If you do not operate the key for more than 30 seconds in Menu mode, it will switch to the display mode automatically.

◐

LCD display

• Display can be switched by UP / DOWN key.

• LCD 2-LINE 16 CHARACTER, the first line shows the operation status and generated power, and the other

shows various internal variable values.

• The display frame (A, 1) of LCD shows RUN / STOP which is the operation status, (B, 1) is current

generation power, (C, 1) is RD / PF, Discharge status Indicates CHA / DCH.

• RD (READY) SMS Normal input power, PF (POWER FAILURE) indicates abnormal input power. When a

number appears, it indicates transient time (SECOND) to normal operation. In addition, CHA (CHARGE)

indicates the charge status DCH (DISCHARGE) discharge status. The values of the internal variables in the

second line are as follows and displayed in real units.

A B C

[ Screen Frame 1]

Battery Voltage, Power, Current

[ Screen Frame 2]

Year, Date, Time

[ Screen Frame 3]

Cumulative power generation amount of inverter

[ Screen Frame 4]

Cumulative received power amount of inverter

[ Screen Frame 5]

Cumulative power supply amount of load side

[ Screen Frame 6]

Cumulative received power amount of Power Grid

[ Screen Frame 7]

Cumulative power generation amount of Power Grid

[ Screen Frame 8]

Cumulative power generation amount of PV

[ Screen Frame 9]

Accumulated discharge amount of battery

[ Screen Frame 10]

Accumulated charge amount of battery

[ Screen Frame 11]

DC-LINK Voltage, HeatSink Temperature

[ Screen Frame 12]

Load Voltage, Power, Current

[ Screen Frame 13]

Power Grid Voltage, Power, Current

[ Screen Frame 14]

Inverting Frequency, Voltage, Current

[ Screen Frame 15]

PV Voltage, Power, Current

[ Screen Frame 16]

Battery Charge status, Internal temperature

* It may change without notice to improve quality.

4.2 Functional group

◐Use the four keys to set the parameter setting value.

Menu

Level 1

Menu

Level 2

Default(Setting) Remarks

3 kW 5 kW

Operation

set

Max chrg Vtg 57.6[V] (54.4[V]) 115.2[V] (108.8[V]) Max Charge Voltage

Max chrg cur 10.0[A] (50.0[A]) 10.0[A] (25.0[A]) Max Charge Current

Max dchrg cur 75.0[A] 45.0[A] (60.0[A]) Max Discharge Current

Bat run Vtg 48.0[V] 96.0[V] Battery Run Voltage

Bat low Vtg 44.0[V] 88.0[V] Battery Low Voltage

Bat over Vtg 60.0[V] 120.0[V] Battery Over Voltage

Fault high Vtg 242.0[V] 242.0[V] Grid/Load High Voltage

Fault low Vtg 194.0[V] 194.0[V] Grid/Load Low Voltage

Fault high Freq 0.8[%] 0.8[%] Grid/Load High Frequency

Fault low Freq 1.1[%] 1.1[%] Grid/Load Low Frequency

PV over Vtg 510[V] 510[V] PV Input and Output

PV run Vtg 150[V] 150[V] PV Run Voltage

PV stop Vtg 100[V] 100[V] PV Stop Voltage

Total Grid_R 0.0[KWh] 0.0[KWh] Received Total Grid Power

Total Grid_T 0.0[KWh] 0.0[KWh] Generated Total Grid Power

Total Load 0.0[KWh] 0.0[KWh] Supplied Total Load Power

Total PV 0.0[KWh] 0.0[KWh] Generated Total PV Power

Total Bat chrg 0.0[KWh] 0.0[KWh] Charged Total Battery Power

Total Bat dchrg 0.0[KWh] 0.0[KWh]

Discharged Total Battery Power

Total Inv_R 0.0[KWh] 0.0[KWh] Received Total Inverter Power

Total Inv_T 0.0[KWh] 0.0[KWh]

Generated Total Inverter Power

OC_Level 1 300[%] (200[%]) 300[%] (200[%])

Calibration

set

Rated ESS Pwr 3.1[kW] 5.0[kW]

Rated Line Vtg 220[V] 220[V]

Rated PV Vtg 350[V] 350[V] (360[V])

Rated Bat Vtg 48.0[V] 96.0[V]

Operation

set

PV Vtg Gain 100[%] 100[%]

PV Cur Gain 100[%](95[%]) 100[%]

Grid Vtg Gain 100[%](99[%]) 100[%]

Grid Cur Gain 100[%] 100[%]

Bat Vtg Gain 100[%] 100[%]

Bat Cur Gain 100[%](98[%]) 100[%]

Inv Cur Gain 100[%] 100[%]

Load Vtg Gain 100[%](99[%]) 100[%]

DC Link Gain 100[%] 100[%]

Cur Ctrl Gain 100[%] 100[%]

Load cur Gain 100[%] 100[%]

Leak Cur Gain 100[%] 100[%]

HS NTC OH 85[˚C] 85[˚C] HS NTC Blocking Temperature

MPPT Power 2.5[W] 2.5[W]

Menu

Level 1

Menu

Level 2

Default(Setting) Remarks

3 kW 5 kW

Operation

set

OL count Level 110[%] 110[%]

Out Vtg offset 100[%] 100[%]

Antilsland Gain 100[%] 100[%]

Bat Dchrg Rate 100[%] 100[%]

Max Inv CD Rate 100[%] 100[%]

Calibration

set

Auto / manual Auto Run Auto Run Auto / Manual

Line frequency 60[Hz] 60[Hz] Power Grid Frequency

Baud Rate 19200 19200 Communication Speed

Grid Reverse ON(off) ON(off) Reverse Transmission Set

Operation Mode Normal Normal Run mode

Self off [on / off] Self sys on(Self sys off)

Automatic Stop Function Setting

Etc. set

System ID number 0[ID] (1[ID]) 0[ID] (1[ID]) ID Number

PV Sw freq 15.0[KHz] 15.0[KHz]

Inv Sw freq 15.0[KHz] 15.0[KHz]

Bat Sw freq 15.0[KHz] 15.0[KHz]

Drive Fault Cnt 1[Num] 1[Num]

Menu Secret Num 7755[Num] 7755[Num] Password Setting

Line Trans Time

10[Sec] (300[Sec]) 10[Sec](300[Sec])

Run Delay Time

Self Off Time 20[Min] 20[Min] Automatic Stop Time

Grid pwr lmt 2.0[Kw] 2.0[Kw] Grid Charging Power Setting

SOC Low Lmt 20[%] 20[%] Battery Protection Capacity

Bat capacity 200[Ah] (100[Ah]) 200[Ah] (100[Ah]) Battery Capacity

Sch chrg run 21:00[h:m] 21:00[h:m] Charge Start Time

Sch chrg stop 06:00[h:m] 06:00[h:m] Charge Stop Time

Sch Dchrg Run 08:00[h:m] 08:00[h:m] Discharge Start Time

Sch Dchrg Stop 18:00[h:m] 18:00[h:m] Discharge Stop Time

Initialize Parameter initiial Set all variables to default values.

Fault initialize

Erase all previous fault status information.

Fault scan It is possible to obtain information on 75 fault conditions that

have occurred in the past.

Date Set

Year 0 0

Set the current year, month, day

hour, minute, and second

Month 0 0

Day 0 0

Hour 11 11

Min 35 35

Sec 53 53

* The default value and the setting value can be different.

4.3 Detail of function

◐MPPT(Maximum Power Point Tracking) control and operation method

• The output characteristics of the PV cell change according to the surrounding temperature, humidity, and

the amount of sunlight radiation. So that, PV cell operates with the MPPT control, and the PV cell starts the

MPPT DC-DC converter at the PV power rated voltage. When the voltage is reached at Maximum Power

Point, MPPT DC-DC converter is stopped.

• There are automatic mode and manual mode for operation. In automatic mode, ESS operates automatically

by detecting the voltage of PV cell. In addition, inverter operates and stops automatically from voltage of the

PV cell. In this mode, inverter start to operates at sunrise and stops at sunset.

• During discharge, output of ESS is would be maximum power of discharge and power from PV cell. But,

power from PV cell control power of discharge.

• After power of PV cell is produce to load, then charge battery.

• During charge, battery is charged by receiving power from the grid. If there is electricity generated from the

PV cell, it will be used to charge the battery. If PV power still remains, it will be discharged through the ESS.

• The current which generated by the solar cell is limited to the set maximum PV power.

• The maximum limit value of DC-Link for maximum solar cell voltage and maximum power point tracking is

limited by below the set DC over-voltage.

• Total PV power generation is cumulatively recorded.

◐Battery voltage control

• Battery is charging with the maximum charging current, up to the maximum charging voltage with constant

voltage - constant current charging.

• When the battery discharges to the minimum discharge voltage during discharging, it stops ESS and

generates low voltage signal.

◐Line monitoring

• Judgement about normal or abnormal of line voltage is determined as Line-over-voltage at high voltage

with voltage difference from normal voltage, and Line-under-voltage at low voltage, and make ESS is stop

•If the frequency of the Line voltage falls outside the upper(Line over-frequency) and lower(Line under-

frequency) limits with the specified value(Line frequency), ESS would be stop.

• In order to operate power generation in the normal line condition, it is operated after the line transfer time

has elapsed.

• Fault voltage time indicates the voltage response time of the over-voltage or under-voltage protection of

the grid voltage. Also, Fault frequency time indicates the frequency response time of the over-frequency or

under-frequency protection of the grid frequency.

• Anti-island speed is a function that adjusts the degree of frequency deviation in the independence

prevention function. It can control the fault frequency time and the independence prevention time. If Increase

this value, stand-alone operation prevention time would be short.

• In order to control the power factor during system operation, it can be controlled through phase shift.

◐Fine calibration

• If a conversion gain is not set correctly when inputting or outputting numerical values from Analog data, an

error will occur. At this time, it is necessary to readjust the conversion gain.

• The current control gain can adjust the amount of current control by adjusting the feedback amount of line

current control.

4.4 System protection function

◐When an error occurs, buzzer is sounds, system is stops, and alarm history is saved.

◐System fault function

Type Description

OverHeat When the temperature of the heat sink becomes 35°C, the fan turns and a fault occurs

when the HS NTC OH(default: 25°C) is exceeded.

DC over vtg. Fault occurs when DC-link voltage exceeds PV Over voltage(default: 510V)

Overload It occurs when it exceeds 110% of the rated current and lasts for 1 minute or more.

OC inverter Inverter overcurrent detection

IGBT error Fault occurs when IGBT error signal of Drive board is detected for Driver fault cnt only

PV over vtg. Fault occurs when PV over voltage(510V) is larger than setting value

Island Fault occurs when anti-island is detected due to grid system outage

OV inverter Fault occurs when grid voltage is above Fault high volt(Def. 11%) setting value

UV inverter Fault occurs when grid voltage is below Fault high volt(Def. 12%) setting value

OF inverter Fault occurs when grid frequency is above Fault high freq(Def. 2.0%)

UF inverter Fault occurs when grid frequency is below Fault low freq(Def. 2.0%)

OC PV PV over current detection

Battery OC Battery over current detection

Battery OV Battery over voltage detection

Battery UV Battery under voltage detection

OC Grid over current detection(Grid to battery, battery to grid)

AD Offset err When the analog sensing circuit value is abnormal (sensing circuit failure)

EEPROM Fail Errors in EEPROM Read or Write

4.5 Basic operation and stop

◐Operation

1. Check, there is no abnormality in the entire wiring.

Make sure that the polarity of PV array input and battery input is correct.

The system may be damaged at the time of incorrect connection.

2. If there is no abnormality, switch on the circuit breaker on PV input side and battery input side to enable

KEYPAD.

3. Set the parameter value as LCD and KEYPAD according to usage conditions.

Be sure to set the calendar clock.

4. The <GRID> LED lights up when the AC circuit breaker is turned on.

5. In Automatic mode, operation starts automatically after the set switching time. Press ENTER (SET) key to

start operation without waiting time.

In Manual mode, operate with the RUN button. It can be set in Select Set Auto / Manual. Operational

information can be checked through the LCD screen.

6. Normal / Schedule can be set in Operation Mode of Select Set menu,

1) Normal mode, the connected load will discharge through the battery or charge the battery through the

GRID or PV.

2) Schedule mode, the charging / discharging time set in Etc.set can be generated from the battery or PV

through the GRID, or the battery can be charged through the grid or PV power.

◐How to set the mode

①Normal mode(Default setting)

Menu ►Select Set ►Operation Mode ►Normal

• Grid-connected type : It is possible to charge the battery with PV and supply the power from grid to load.

Battery and PV power supply during blackout.

• Stand-alone :

It can be powered by PV and battery. In the absence of PV power, the battery will discharge.

②Schedule Mode(Exclude standalone products)

Menu ►Select Set ►Operation Mode ►Schedule

Menu ►Select Set ►Grid Reverse ►On(Grid power generation function)

•Setcharging time and amount of charge

Menu ►Operation set ►Max chrg cur ►30.0A(Current value setting)

Menu ►Etc. set ►sch chrg run ►21:00

Menu ►Etc. set ►sch Dchrg stop ►06:00

• Set charging time and amount of charge

Menu ►Calibration set ►Max chrg cur ►30%(Discharge amount setting “%”)

Menu ►Etc. set ►sch chrg run ►08:00

Menu ►Etc. set ►sch Dchrg stop ►18:00

• Grid-connected type

- Charging time : Charge the battery using the grid and PV power.

- Discharging time : Discharges to the grid using battery and PV power.

◐Stop

• Press the KEYPAD <ENTER (SET)> key to stop the inverter.

• Turn OFF the load side circuit breaker and AC circuit breaker. If the grid power is cut off, the system will go

into the standby state without charging or discharging the system. If the AC circuit breaker is not turned OFF,

it will automatically restart after the automatic switching time elapses.

• Turn off the DC input circuit breaker for PV input and turn off the battery input breaker. The charged voltage

inside the inverter gradually discharges. Since it takes about 10 minutes to completely discharge the battery,

check whether the voltage charged in the condenser is fully discharged for the purpose of internal inspection.

◐When a system error occurs, the <FAULT> LED will be lit and you can check the information via the LCD

screen.

5. Product specification

5.1 Product specification

Classification Characteristics and Specifications

Capacity(kW) 3KW 5KW

PV

MPPT voltage range 100~400 Vdc

Maximum input voltage 500 Vdc

Input control method MPPT(Maximum Power Point Tracking) control

Maximum input current 15A

Battery Voltage 48V 96V

Maximum input current 70A 60A

AC Output

Rated voltage 100V / 200V / 220V / 230V / 240V

Rated frequency 50Hz / 60Hz

Number of phase Single phase 2 wire

Harmonic distortion Less than 5%

Power factor 95% or more

Current THD Less than 3% each, less than 5% of total

TOPOLOGY Transformer-less type

Protection Inverter protection Input over voltage, Output over current, Overloaded, Overheat

Protection Over voltage, Low voltage, Over frequency, Low frequency

Measurement Voltage, Current, Frequency, Run mode,

Temperature, External temperature.

Control

DC – DC conversion, Dc – AC conversion, Voltage, Current, Frequency

Communication RS485(Converter available)

Operating temperature range -10°C ~ +45°C

Operating humidity range 30 ~ 85% RH(No condensation)

Size(W/H/D) 446 X 630 X 150(mm)

6. Inspection and caution

As an electronic device equipped with advanced semiconductor elements, ESS has the possibility of

breakdown due to the influence of surroundings such as temperature, humidity and vibration and parts

gradually aging year by year. In order to prevent this, always inspect it.

6.1 Inspection

D

A

N

G

E

R

• Check operating environment of the installation site is appropriate.

• Check the cooling system for any abnormality.

• Check for abnormal vibration or noise.

• Check for overheating or discoloration.

• Check that bolts, nuts, etc are not loose or corroded.

• Check screws, bolts, etc. may become loose or rusty in high vibrate environments, so tighten or

replace them.

• Inspect the inside of the product for foreign matter, and remove it.

• Check the tightness and contact of each connector and connection for any abnormality.

6.2 Caution

D

A

N

G

E

R

• Do not modify the inside of the product.

• Incorrect terminal connection or incorrect polarity(+/-) may cause damage to the product.

• Do not wire the power supply incorrectly, short-circuit, or disassemble or heat the unit. There is a

risk of rupture or ignition.

• Do not touch the terminals during operation. There is a risk of electric shock.

• Be sure to check the input / output signal with safety. Failure to do so may result in personal injury

or damage to the product or other equipment.

• Do not set, adjust, change and etc, during operation. Operation error may result in damage to the

machine or an accident.

• Do not contact the product immediately after operation. After the power is turned off, the large

capacity condenser in the power circuit is charged with power.

• If the protective function of the product has occurred due to the occurrence of a fault condition,

remove the cause of the fault and re-operate. If the protection function continues to operate, it may

shorten the life of the product or damage it.

7. Quality assurance

◐Quality assurance

Warranty

SERIAL NO.

Product name

Model name

Date of purchase

Warranty period 3 years from date of purchase

Customer

Name Address.

Tel .

Vendors

Company Address.

Tel .

◐Please fill in the blank when you sell the product.

◐We will repair or replace the product in case of performance or functional defect in normal use within the

warranty period.

◐In the following cases, we will not be subject to the warranty period and will be replaced and repaired for

a fee.

1) Damage caused by intention or negligence of the consumer.

2) Failure caused by repair at a place other than our designated service center.

3) Failure due to abnormal power supply or defective connection device.

4) If the consumable part has reached its end of life and needs to be replaced.

5) Failure or defect of product due to natural disaster.

◐You will be charged for the fee when you make business trip repair.

◐Warranty is only applicable in S.Korea.

◐Warranty can not be reissued. Please keep it with the instruction manual.

Table of contents

Popular Power Supply manuals by other brands

Antec

Antec NeoPower 650 Blue Manual Del Usuario

DeWalt

DeWalt XR FLEXVOLT DCB500-QS Original instructions

PeakTech

PeakTech 1320 Operation manual

Broadata Communications

Broadata Communications Link Bridge LBC-24PI user manual

Helios

Helios KWL-KS WE Installation and operating instructions

HP

HP 6235A Operating and service manual