Iniven IP-40 User manual

GEN-1

(INIVEN)

DIVISION OF CONOLOG

CORP.

INSTRUCTION MANUAL

IP-40

POWER SUPPLY

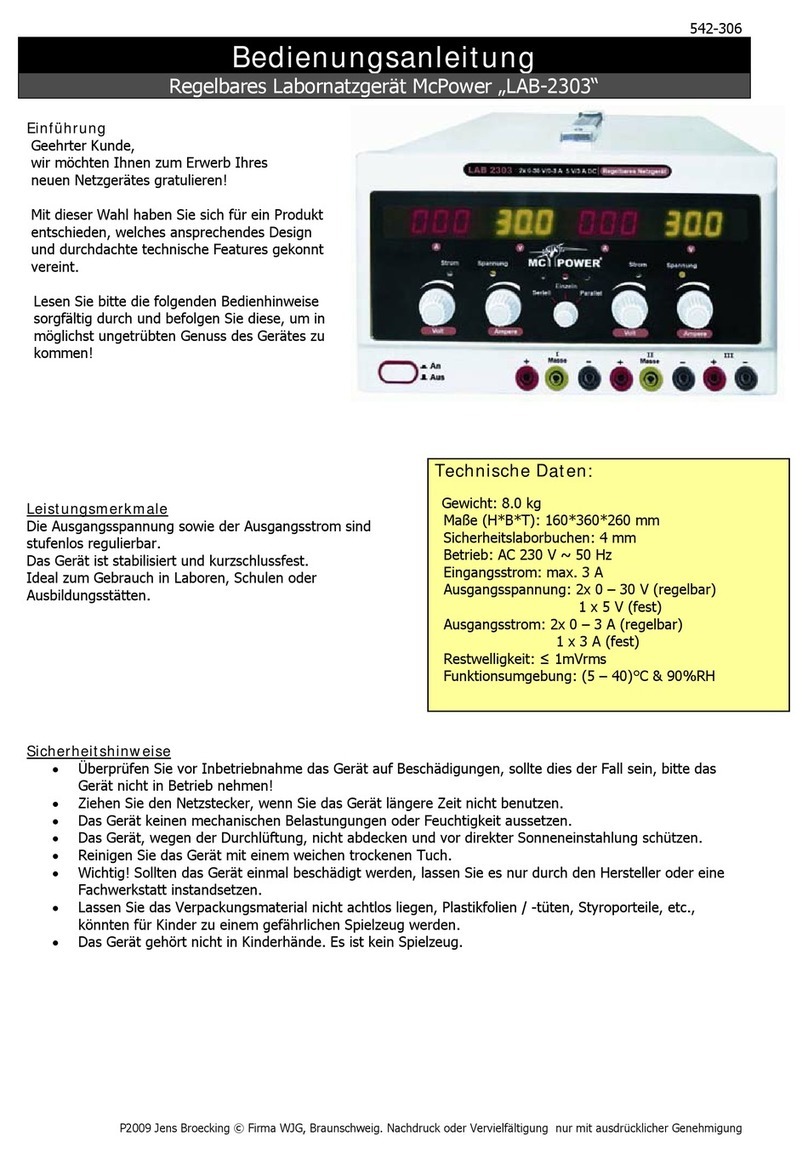

Fig.

1.

IP-40

DESCRIPTION: The IP-40 is aseries of Regulated Switching Power Supplies for use within the

INIVEN GEN 1style chassis. The IP-40

is

available

in

awide range of input voltages: 115VAC,

125VOC, 48VOC, 24VOC each providing aregulated +12VOC.

FEATURES:

•Front panel mounted LEO which indicates status of output

OC

voltage.

•On/Off switch

on

front panel for ease of system operation.

•Wide range of input voltages.

SPECIFICATIONS:

Input Voltages

115VAC

125VDC

48VDC

24VDC

Operating Ranges

92VAC to 138VAC

100VDC to 150VDC

38VDC to 58VDC

19VDC to 29VDC

,.

Output Voltage: +12VDC ±20% @3amps

Output Ripple: 50mV peak Max.

Efficiency: 80% at full load typical

Isolation: 5000VDC from input to output

Environmental Requirements: Temperature Range: -30 to +70 C(-22 to +158

F)

Relative Humidity:

95% maximum, non-condensing at 40 C(104

F).

Physical: Weight: 2.51bs (1.134Kg) Dimensions: 1.5" (38mm)

W,

5.25" (133mm)

H,

13"

(330mm) 0

OPTIONS:

IP-40-XXX

IP-40R-XXX

IP-40RC-XXX

Standard Power Supply

Power Supply with Relay

Power Supply with Relay and Charging Circuit

XXX-Insert Input Voltage

SAFETY:

Standard safety precautions must be followed at all times when installing, operating,

servicing, and repairing this equipment. INIVEN/CONOLOG CORP. assumes no Iiability for

failure to observe standard or specifically noted safety requirements or to use this equipment

for purposes other than intended.

GROUNDING:

Asuitable ground

is

required to reduce the hazard of shock. Refer to the enclosed module, chassis,

and/or cabinet wiring diagram for ground connection locations.

ENVIRONMENT:

Operation of any electrical equipment

in

any area containing gases, fumes, wet, or damp

is

apotential safety hazard. Necessary precautions should be taken.

MANUAL:

Operators and maintenance personnel should read this manual before installing the equipment

and placing it

in

service. Only properly trained personnel with proper tools and equipment

should operate, maintain, repair, or service this equipment.

SHOCK:

Potentially dangerous electrical shock can occur whenever working

on

this product. Protective

measures and safety procedures should

be

observed at all times.

NOTE:

The IP-40 Series Power Supplies Contain HIGH VOLTAGES.

00

not handle components with Power Applied to the Unit

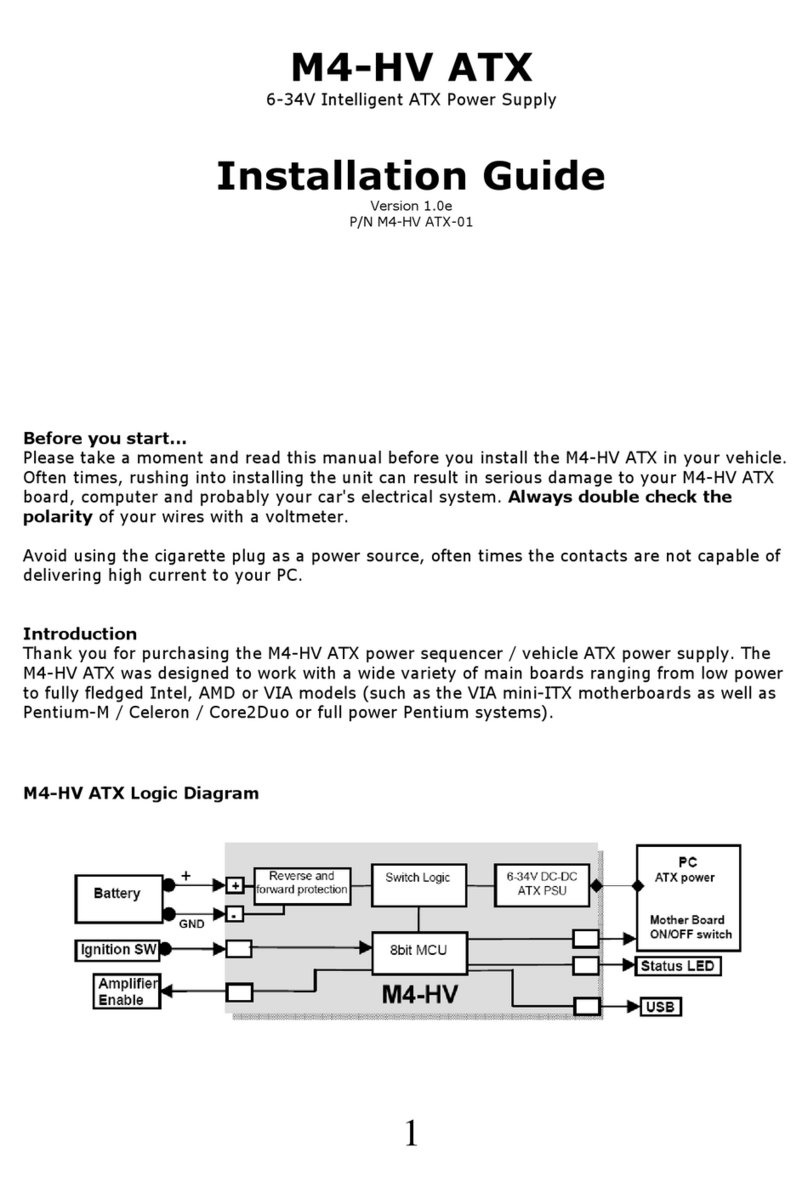

THEORY OF OPERATION:

GENERAL: The IP-40 series of switching type supplies convert the rated input power into

+12VOC

INPUT: The input voltage, dependent upon the version purchased, is applied to the power

supply via the On/Off switch, S1. Fuse

F1

provides protection from input and output current

overloads.

EMI

FILTER: Transformer

T1

and associated components

C1

through C5 form amulti-function

filter. This filter reduces line noise

on

the power source from entering the supply

as

well as

filtering switching noise generated within the supply from returning to the source.

RECTIFIER:

On

AC

units

CR1

and C6 rectifies the 60Hz power. The rectifier circuit is

omitted

on

OC

input units.

PULSE WIOTH MOOULATOR (PWM): The PWM (U1) is powered from 15V produced by

01

and associated circuitry. Resistors

R3,

R4

and C12 provide asoft start for

U1.

The PWM

switches at a50kHz rate. The switched signal is

fed

to

04

via

02

and

03.

This signal then

modulates the source voltage through T2.

U3

provides the reference voltage for under and over vo!tage protection which controls op-

amp U4. Potentiometer R10 is afactory adjustment which sets the +12V level.

Voltage feedback to the PWM

is

optically coupled

in

U2 to provide input/output isolation.

OUTPUT:

07

rectifies the +12V section of transformer T2. Output filtering

is

accomplished

via L

1,

C18 and C19 for the 12V output.

SWl

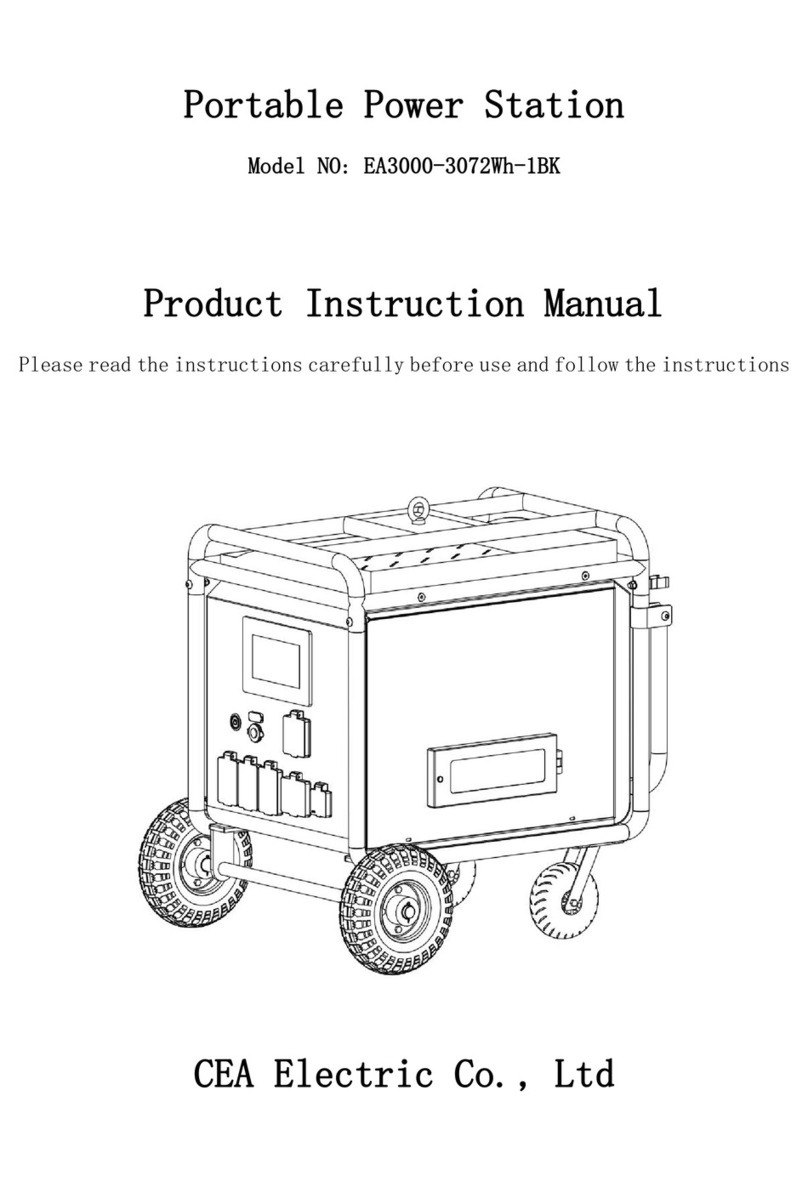

Fig.

2.

Controls &Indicators

Table 1. Controls and

Indicators

DS2 Indicator, Power On, 12V output

SW1

Switch, On/Off

F1

Fuse

R10 Variable resistor, output voltage level adjustment

@ @ @ @

@@

1+12VDC DUTPUT +12VDC DUTPUT +12VDC DUTPUT

2

CDMMON

COMMON

COMMON

8.

-BATTERY

(~/i)

@®

NC}

ARELAY +BATTERY

®0

NO

NC}

@0 ARELAY

NO

@@

12

(8)@ 115VAC INPUT 115VAC INPUT

14 15 - } 125VDC INPUT

-}

125VDC

INPUT : } 115VAC INPUT

16 +

48VDC

INPUT +

48VDC

INPUT

24VDC

INPUT

24VDC

INPUT

@@

@@

@ @

IP-40

IP-40R

IP-40RC

Fig.

3.

Terminai Block

/

INSTALLATION:

UNPACKING: This equipment may

be

supplied loose, mounted

in

an

individual chassis 'stacked

interconnected chassis, or as part of arack or cabinet. Follow the procedure for the type of system

supplied.

Loose and/or equipment mounted

in

an

individual chassis will

be

packed

in

its own shipping carton.

Inspect the carton for possible damage

in

transit. Open each carton carefully and remove the

contents. Inspect the equipment for possible damage. Verify all items of value have been removed

prior to discarding any packing materia!.

NOTE: It is suggested the carton

be

retained for possible onward shipment.

Interconnected chassis or equipment supplied

in

racks or cabinets will

be

supplied

in

special

boxes, wood crates, or if shipped via airride

van

without any case. Inspect the crate or other

packing for possible damage

in

transit. Carefully remove the equipment from the container and

inspect it for possible damage. Verify ali items of value have been removed from the crate prior

to discarding any packing material and refer to the note above.

Should transit damage be found please notify INIVEN immediately.

MOUNTING: After unpacking follow the appropriate mounting procedure.

Loose module: (The following

is

for new installations replacement of

an

existing module will have

the terminai block already mounted. Each new unit is shipped with the terminai block plugged into

the rear of the unit. There are also four 6-32 screws shipped with it to mount the terminai block to

the chassis. Locate the desired position within the chassis for which the module

is

to

be

placed.

Viewing the chassis from the front, the recommended arrangement

is

apower supply

on

the extreme

left then followed

by

transmit and or receive modules working towards the right of the chassis.

Interconnected Chassis or equipment mounted on shipping rails

is

to

be

mounted similar to

an

individual chassis. When shipping rails are provided the equipment

is

to

be

placed near the desired

location. Remove the screws holding the shipping rails and then remove the rails. Slide the equipment

into the rack or cabinet and secure

it

with proper screws for the mating hardware being used.

Tighten all screws.

Systems provided

in

arack or cabinet from the factory must

be

secured to the floor or wall

as

required. Mounting hardware is not supplied due to the various surfaces and mounting methods.

CAUTION: EQUIPMENT MOUNTED

IN

SWING RACK TYPE CABINETS MUST BE SECURED

TO

THE MOUNTING SURFACE PRIOR

TO

OPENING THE SWING RACK

TO

PREVENT THE

CABINET FROM FALLlNG.

VENTILATION: Proper ventilation

is

required for most electronic equipment. Enclosed cabinets

or rooms where this equipment is mounted should be kept at temperatures within the limits of the

equipment. Operation above these limits may affect reliability.

ELECTRICAL CONNECTIONS: User connections are made via the terminai blocks on the rear

of the chassis. Each unit

in

the Gen 1SERIES of equipment will contain these connections

in

the

instruction manual for the specific individual module.

On

equipment supplied wired from the factory

or

on

wired chassis and cabinets

an

"as supplied" drawing will

be

included with the equipment.

External wiring should

be

in

accordance with the "as supplied" drawing when supplied.

For safety reasons power on the leads to be connected to the unit are to be de-energized

during installation.

Methods of making the wiring connections to the terminai blocks vary and based

on

local

practice. It

is

suggested number 20 AWG size insulated wire, stripped portion tinned,

be

used.

Approximately 1/4" of the insulation is to

be

removed and inserted

in

the terminai block.

•Module power and tone lines may be daisychained should the application require.

•Tighten ali connections and insure exposed wires do not touch each other or the chassis.

MAINTENANCE:

ALL

SAFETY PROCEDURES ARE TO BE STRICTLY ADHERED TO AND ONLY QUALlFIED

MAINTENANCE, OPERATORS, OR SERVICE PERSONNEL ARE TO PERFORM WORK ON THIS

EQUIPMENT.

L1FE

THREATENING VOLTAGES AND CURRENTS ARE PRESENT WITHIN THIS

EQUIPMENT. OBTAIN ALL REQUIRED APPROVALS PRIOR TO PLACING

IN

OR OUT

OF

SERVICE.

If factory assistance is required INIVEN has set up atoll free number (1-800-526-3984) for

sales and service information. Should amodule require repair, please call for

an

RMA number

and have the model number(s) available.

Circuit

Symbol

C1

C2, 3

C4, 5

C6

C7,

9,

14,

19,20,

25

C8

C10

C11

C12, 13

C18

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10

R11

R12,

13

R15

R17

R19

R20

CR1

01

02,

8

03

07

OS1

01

02

03

U1

U2

U3

U4

SW1

T1

T2

L1

F1

Table 1. Replaceable parts Ip·40

Description

CAPACITORS:

Capacitor, metalized polycarbonate,

.1

uF,

300V,+/ 5%

Capacitor, ceramic,

.001

uF,

6KV,+/20%

Capacitor, metalized polycarbonate, .39uF, 300V, +/5%

Capacitor, electrolytic, 220uF, 250V, +/20%

Capacitor, ceramic,

.1

uF,

100V,

+/10%

Capacitor, tantulum,

10uF,

35V,

+/20%

Capacitor, ceramic, 330pF, 1

KV,

+/10%

Capacitor, polystyrene, .0027uF,

100V,

+/3%

Capacitor, tantalum, 4.7uF,

35V,

+/20%

Capacitor, electrolytic, 2200uF,

25V,

+/-20%

RESISTORS:

Resistor, carbon,

51

K,

1watt, +/5%

Resistor, metal film, 8.2K, 1/4 watt,

+/1

%

Resistor, carbon, 22K, 1/4watt, +/5%

Resistor, carbon, 68K, 1/4watt, +/5%

Resistor, carbon, 4.7K, I/4watt, +/5%

Resistor, carbon, 10K, 1/4watt, +/5%

Resistor, carbon, 100K, 1/4watt, +/5%

Resistor, carbon,

5.1

K,

1/4 watt, +/5%

Resistor, metal film, 10.5K, 1/4watt,

+/1

%

Potentiometer

Resistor, metal film, 6.04K, I/4watt,

+/1

%

Resistor, metal film, 8.25K, 1/4watt, +/1%

Resistor, carbon, 560n, 1/4watt, +/5%

Resistor, carbon, 510n, 1/4watt, +/5%

Resistor, carbon, 240n, 1/2watt, +/5%

Resistor, carbon, 1n 1watt, +/5%

SEMICONDUCTORS:

Rectifier, full wave bridge

Oiode, Zener,

16V,

5watt

Oiode

Oiode, Fast Switching

Oiode

LEO,

Red

Transistor, NPN

Transistor

Transistor

IC,

Pulse Width Modulator

Optic Isolator

IC,

Precision Voltage Reference

IC,

Operational Amplifier

MISCELLANEOUS COMPONENTS:

Switch, SPST Panel Mount

Inductor

Transformer

Inductor

Fuse,

2A

INIVEN Part

Number

MPC32G104J

0102M66Z5UUABEM

MPC32G394J

LLK2E221 MHSA

CMX7RE104K

OT35V106M

0331 K20Z5FNAAEM

PS32E272H

OT35V475M

UVX1

E222MHA

RCF32J513

RN5508201 F

RCF07J223

RCF07J683

RCF07J472

RCF07J103

RCF07J104

RCF07J512

RN55C1052F

3299W-1-102

RN55C4751F

RN5508251F

RCF07J561

RCF07J511

RCF20J241

RCF32J1R

3N256

1N5353B

MUR1100E

1N914

MUR1610CT

550-0101-003

MJH16002

2N4401

2N4403

MC34060

4N36

REF-02CZ

TL081CP

XR116AOO

E3495A

CC2153-00

CC2018-01

3AG-2AMP

NOTES

NOTES

WARRANTY AGREEMENT

We

hereby certify that the INIVEN product line carries awarranty for any part which

fails during normal operation or service for

12

Years.

Adefective part should

be

returned

to the factory, shipping charges prepaid, for repair f.o.b. Somerville, New Jersey.

In

case

INIVEN cannot promptly return the unit to you, it will endeavor to provide aloaner until

the repair or replacement

is

returned to you. Any unauthorized repairs or modifications

will void the warranty. This warranty is contingent upon the commercial availability of parts

as purchased by INIVEN. However,

in

the event that failure is less than two years from

the date of delivery of the product, INIVEN will accept full responsibility.

INIVEN 5

Columbia

Rd.

Somerville,

NJ 08876

PRINTED

IN

U.S.A.

INIVEN TM 5Columbia

Rd.

Somerville, NJ 08876

908-722-3770

FAX

908-722-5461 800-526-3984

Table of contents