Austria Email RWT User manual

OPERATING AND

INSTALLATION INSTRUCTIONS

RWT

Misprints and technical changes reserved.

Please forward this on to the user!

RIBBED PIPE HEAT EXCHANGER

Id.Nr.: 179390-5

RIBBED PIPE HEAT EXCHANGER RWT

2 • Id.Nr.: 179390-5

The heating coils are suitable for the heating of hot water storage tanks with the following heating

media:

Heating water, district heating water, district heating steam

Thermal media such as

Antifrogen L, Antifrogen N, PKL 100, PKL 300

Maximum permissible internal operating pressure: 10.0 bar

Maximum permissible external operating pressure: 10.0 bar

Maximum permissible operating temperature: 95 °C

Description

Copper ribbed pipes are manufactured as seamless pipes using a process similar to thread rolling and

all connection points are hard soldered with silver solder. After soldering the heating coils are electro-

plated with tin, coiled into a spiral form and tted with a complete set of insulating connection screw

joints and mounted, electrically isolated, on a ange plate.

For the reduction of thermal radiation the ange is covered by a lacquered cover of steel plate with a

soft foam inlay on the inside. The compact design makes it possible to house high performance heat-

ing coils in the lowest area of the hot water storage tank. This is connected to an optimal exploitation of

the entire storage volume for thermal absorption. In this way an advantageous circulation of the storage

water for heat exchange purposes is also achieved. In addition the heating coils are characterised by

a low degree of pressure loss on the inside of the pipe.

In general a circulation pump is required for the heating of the storage tank, which circulates the heat-

ing medium between the heat generator and the heating coil. By switching the circulation pump on and

off via the temperature regulator, the temperature of the storage water can be regulated.

For installation in upright storage tanks, the ATR charging pump regulator + thermometer combination

is suitable for this purpose.

Heating coils can also be arranged in the upper section of the hot water storage tanks and can be used

for re-heating the storage water or for thermal extraction.

Through the installation of several independent heat exchangers it is possible to set up multivalent

(connection to various energy supply systems) systems (e.g. in the upright storage tank product line,

FFM).

RIBBED PIPE HEAT EXCHANGER RWT

Id.Nr.: 179390-5 • 3

Utilisation

Naturally it is possible to upgrade both new storage tanks, regardless of whether these are galvanized,

enamelled or plastic coated, and existing systems through the installation of RWT-type ribbed pipe heat

exchangers.

In case of extremely hard water and operation of the storage tank at temperatures above 60 °C, precau-

tions should be taken in the form of de-calcication systems or else by implementing a regular cleaning

regime (see Maintenance).

Installation Method

RWT-type ribbed pipe heat exchangers are usually installed horizontally in the upright storage tank.

With due regard to the particular issues of system bleeding when installing from below, they can also

be installed vertically, either from below or from above, whereby the changed ow characteristics need

to be taken into consideration.

One thing to consider is that changes to the lengths of connection pipes due to temperature uctuations

need to be allowed for by expansion elements or suitable pipe conduits.

Electrically Isolated Installation and Connection Fittings

In general, magnesium or stray current anodes are built in to enamelled or plastic coated hot water stor-

age tanks of steel in order to protect the base metal from corrosion at points with an insufcient coat-

ing. This cathodic corrosion protection is put at risk through the installation of electrically non-insulated

heating coils, whereby the anodes will be exhausted within in a relatively short time. The faulty areas

combine with the ner material of the heating coils to produce a galvanic element, which can lead to a

rapid dissolution of the base material at the faulty area. Insulated connection ttings prevent the genera-

tion of these galvanic elements thereby making a signicant contribution to the corrosion protection of

coated steel hot water storage tanks.

A protective current bleeder resistor is integrated into the heat exchanger to protect it from current leak-

age corrosion.

Our insulated screw ttings isolate the heating coils both from the walls of the storage heater and from

the metal connection pipework and therefore comply with DVGW- Worksheet W 511.

Corrosion Protection with Mixed Installations

The corrosion resistance of the copper to drinking water has been proven through long-term usage.

In particular, Cu has proved to be an especially good material in the frequently encountered chloride

contents of drinking water. In addition, the heating coils meet the conditions set out in DIN 1988 and

DIN 4753.

If copper comes into contact with water, the copper ions are released into the water. The copper pipes

are not at risk as, within a short period, a bonded protective layer is formed.

However these copper ions released into the water can quickly lead to corrosion damage in down-

stream galvanized steel pipes.

Therefore to avoid corrosion problems in relation to mixed installations, heating coils are externally elec-

troplated with tin.

RIBBED PIPE HEAT EXCHANGER RWT

4 • Id.Nr.: 179390-5

Installation

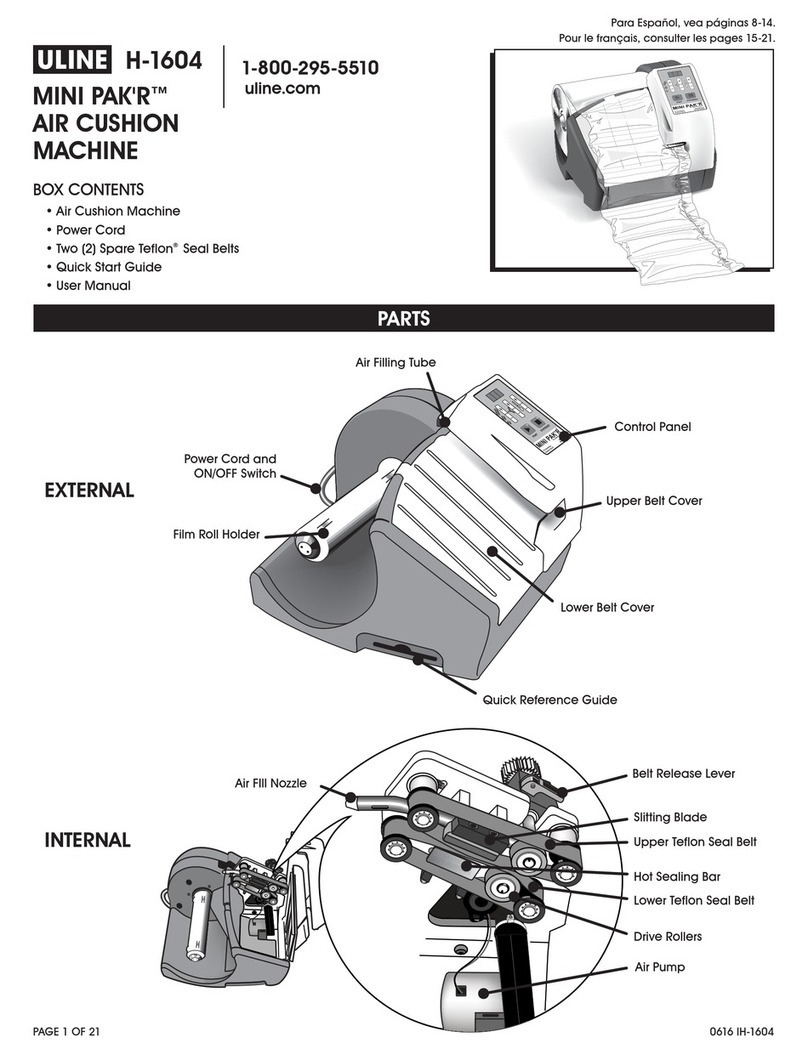

Unscrew the insert 14 from the connection fitting 6with the complete electrically insulated pipe screw joint

(4, 15, 16, 17, 18), remove the cover 3, carefully install the flange plate 19 (in so doing the ribs of the heat

exchanger should not be bent when inserting it into the storage tank), place the flange seal in the plastic

support disk and press it into position in the flange with 8 M12 x 35 screws, and/or 8 M12 nuts for flanges

with Ø = 180 (RWT 1-110) or else with 12 M12 x 35 screws and/or M12 nuts for flanges with Ø = 240

(RWT 2-230, -360, -450). Tighten diagonally to a maximum torque of 3.5 mkp.

Caution: When tightening the screws and/or nuts the protective current bleeder resistor1attached to the

brass tab 11must not be damaged.

Fit the soft foam disc 13 (thermal insulation) and the lacquered cover 3 (for insulation purposes both plas-

tic sleeves 2must be mounted in the cover 3). Seal in the inlay 14 with the cap nut 17 and the mounted

insulating clip 15 and screw it onto the connection fitting 6 till flush with the plastic sleeve 2 and insert the

insulating sleeves 4 into the inlay 14 and the connection nipple 18.

Construct the heating circuit inflow plumbing and seal it at the connecting nipple 18. Screw the cap nut

17 to the connection nipple 18. The hexagonal surface on the connection nipple 18 is for holding with a

spanner to counter the screw fastening motion. Maximum torque = 1.5 mkp.

1 Resistance 620 Ω 6 Connection Fitting 11 Brass Bar 16 O-Ring

2 Plastic Insulator 7 Insulating Sleeve 12 Hexagonal Nut 17 Cap Nut

3 Cover 8 O-Ring 13 Foam Disc 18 Connecting Nip-

ple

4 Insulating Sleeve 9 Plastic Bracket 14 Insert 19 Flange Plate

5 Heat Exchanger 10 Swash Plate 15 Insulating Clip

Servicing

In the case of extremely hard water, the removal of the boiler scale accumulating in the storage tank's inner

boiler must be performed by a professional after one or two years of operation. Cleaning is achieved by

removing the ribbed pipe heat exchanger so that the lime-scale covered can be carefully chipped off or

else cleaned in a container of boiler scale solvent.

Finally the heater exchanger must be rinsed thoroughly.

This device is not designed to be operated by people (including children) with limited physical, sensory

or mental capacities or who lack the requisite experience and/or knowledge, unless they are supervised

by a person responsible for their safety or have been instructed in the operation of the device by him/her.

Children should be supervised in order to ensure that they do not play with the device.

RIBBED PIPE HEAT EXCHANGER RWT

Id.Nr.: 179390-5 • 5

Warranty, Guarantee and Product Liability

The warranty is granted in accordance with the statutory provisions of the Republic of Austria, as well as of the EU.

1. A condition for the operation of guarantee services by the product manufacturer (hereinafter referred to as the PM) is the presentation

of the paid invoice for the purchase of the device for which the guarantee service is being invoked, whereby the identity of the device in

terms of type and serial number must be taken from the invoice and must be produced by the claimant. This is subject exclusively to

the PM‘s general terms and conditions of business and sales and delivery conditions.

2. To the extent required by law and/or the installation and operating instructions, the assembly, installation, connection and commissi-

oning of the device in question must have been carried out by a licensed electrician and/or installer with due regard to the necessary

instructions for this. The storage tank (without external covering or plastic external covering) must be protected from direct sunlight in

order to prevent discolouring of the polyurethane foam and any possible warping of plastic components.

3. The room in which the equipment is operated must be free of frost. The assembly of the equipment must be carried out at a location

which can be reasonably expected i.e. the equipment must be easily accessible and replaceable in the event of necessary mainte-

nance, repair and possible replacement. The costs for any necessary changes to the structural conditions (e.g. doors and corridors too

narrow) are not covered by the guarantee and warranty offered and shall therefore be refused by the PM. When setting up, installing

and operating the water heater in unusual places (e.g. lofts, living quarters with water sensitive ooring, store rooms etc.) potential water

leakage must be taken into consideration and therefore a device for capturing and draining off any leaked water must be provided in

order to prevent secondary damage in the sense of the product liability provisions.

4. The warranty shall not apply in the following cases:

Improper transportation, normal wear and tear, deliberate damage or damage through negligence, any application of force whatsoever,

mechanical damage or damage due to frost or resulting from exceeding the operational pressure stated on the rating plate even

once, the use of connection ttings that do not comply with the applicable standards or non-functioning storage tank connection

ttings, as well as unsuitable and non-functioning operating ttings, glass or plastic part breakage, any colour differences, damage

through improper use, particularly by failing to observe the operating and assembly instructions (operating and installation instructions),

damage caused by external inuences, connection to the wrong voltage, corrosion damage due to aggressive waters not suitable as

drinking water in accordance with national guidelines (such as the Austrian Drinking Water Ordinance TWV – BGBI. II no. 304/2001),

Deviations of up to 10 K in the stated hot water temperature compared to the actual drinking water temperature from the storage tank

(hysteresis of the regulator and possible cooling as a result of pipelines), continued use in spite of a defect, unauthorised modications

to the device, installation of additional components which have not been tested with the device, improperly performed repairs, insuf-

cient conductance of the water (at least 150 μS/cm), operational wear and tear of the magnesium anode (consumable part), natural

limestone formation, water deciency, re, ood, ooding, lightning strike, excess voltage, power failure and other force majeure, use

of non-original and third party components, e.g. heating rod, protective anode, thermostat, thermometer, nned tube heat exchanger

etc. components installed in a way that is non-insulated with regard to the storage tank, inux of foreign material and electrochemical

installations (e.g. mixing installations), non-observance of the planning documents, late and non-documented renewal of the installed

protective anode, faulty installation and connection of the external current anode (e.g., no permanent power supply), lack or improper

cleaning and operation as well as deviations from the standard, which only slightly impair the value or the functionality of the device.

Furthermore, the original installation at the place of assembly may not be altered or retrotted before an inspection by the manufacturer

or a commissioned expert. Any changes to the original installation on site will result in the immediate exclusion of all possible claims from

the warranty or guarantee as well as product liability claims. In addition, as a matter of basic principle, all regulations set out in ÖNORM

B 2531, DIN 1988 (EN 806), DIN 1717, VDI 2035 or the corresponding national regulations and legislation must be complied with.

5. In case of a justiable claim, this must be reported to the nearest PM customer services centre. They shall reserve the right to decide

whether a faulty component should be replaced or repaired and/or whether a faulty device will be exchanged for a fault-free device

of the same value. In addition the PM expressly reserves the right to demand that the customer return the device to which the claim

applies. The date of a repair or an exchange will be dened by the producer within 5 days!

6. Repairs under the guarantee may only be carried out by people licensed to do so by the PM. Exchanged parts shall become the

property of PM. Should any repairs to the water heater be required following necessary service works these shall be invoiced to the

customer as repair and pro-rata materials costs.

7. All warranty claims shall expire in the event of unauthorised third party interventions, even if these are carried out by a licensed installer.

The acceptance of costs arising from repairs carried out by third-parties shall be subject to the PM having been requested to x the

fault and having either failed to meet their exchange or repair obligations or not having done so within a reasonable period.

8. The guarantee period shall neither be renewed nor extended as a result of the services in response to claims under the guarantee or

warranty, or service and maintenance work.

9. Transport damage shall only be inspected and perhaps recognised if these are reported to the PM in writing within one working day of

delivery.

10. To the extent permissible by law, any claims over and above provisions made in the guarantee, such as in particular those relating to

compensation for damages and consequential losses, are excluded. Pro-rata labour hours for repairs, as well as the costs of restoring

the system to its original condition must be paid by the customer at the full rate. The guarantee offered shall only cover the repair or

replacement of this device in accordance with this guarantee statement. The provisions of the PM‘s sales and delivery conditions shall

continue to apply in full provided that they are not modied through these guarantee conditions.

RIBBED PIPE HEAT EXCHANGER RWT

6 • Id.Nr.: 179390-5

11. Services not provided within the framework of these guarantee conditions shall be invoiced to the customer.

12. A precondition for the fullment of these guarantee provisions by the PM is that, on the one hand the device has been fully paid for and,

on the other hand, that the claimant has fully complied with all of his obligations towards the reseller.

13. A guarantee shall be provided for the enamelled internal boiler for water heaters, with no diminution of the guarantee provisions in

accordance with Points 1 to 12 for the period offered following delivery. If the guarantee conditions are not met then the legal warranty

conditions of the country to which the goods have been delivered shall apply.

14. For the attainment of claims in accordance with Austrian product liability legislation, it should be noted that:

Any possible claims from the product liability stated above which deal with damage caused by a failure of a product (e.g. a person

receives bodily injury, health is damaged or some other bodily part is damaged by the product), are only justied when all the prescribed

measures and requirements which are needed for error-free and standard compliant operation of the device have been fullled. This

includes for example the mandatory and documented replacement of the anode, connection to the correct operating voltage, damages

arising from improper operation are to be avoided etc. These provisions are to be derived from the fact that, had all instructions been

complied with (standards, installation and operating instructions, general guidelines etc.) the fault in the device or product that caused

the secondary damages would not have arisen. Furthermore, it is indispensable that the necessary documentation, such as for example

the designation and manufacturer number of the storage tank, the seller‘s invoice and the concessionaire who performed the sale as

well as a description of the fault are submitted for the inspection of the allegedly faulty storage tank in the technical laboratory (absolutely

necessary as a trained professional will inspect the storage tank and analyse the cause of the fault). To avoid any confusion regarding

the storage tank during transportation, it must be provided with a clearly legible label (preferably with the address and signature of the

end user). Furthermore, the original installation at the place of assembly may not be changed, converted or dismantled before being

inspected by the manufacturer or an appointed expert.

Any change to the original assembly situation on-site will lead to the immediate exclusion of any claims arising from the warranty, gua-

rantee or product liability.

A corresponding photographic record is required showing the extent of the damage, the installation details (cold water input, hot water

output, heater ow and/or back-ow, safety ttings, and, if applicable, expansion vessel) as well as the faulty area of the storage tank.

In addition the PM expressly reserves the right to demand the provision of any documentation, the device or device components by the

customer deemed necessary to clarify the situation. A prerequisite for the performance of services under the heading, Product Liability,

is that it is incumbent upon the damaged party to prove that the damage was caused by a product of the PM. Claims made in line with

the Austrian Product Liability Act are only valid for the sums above the rst EUR 500 (excess). Until such time as the entire situation and

circumstances have been claried as well as until such time as the cause that resulted in the damages has been clearly identied, the

PM decidedly rejects any potential culpability. Failure to follow the operating and assembly instructions as well as the relevant standards

is considered negligence and shall leads to a liability exclusion in the eld of compensation for damage.

The gures and data are not binding and may be amended without notice in the interest of technical improvement.

Misprints and technical changes reserved.

RIBBED PIPE HEAT EXCHANGER RWT

Id.Nr.: 179390-5 • 7

Notes

Id.Nr.: 179390-5

Austria Email AG

Austriastraße 6

A-8720 Knittelfeld

Telefon: (03512) 700-0

Fax: (03512) 700-239

Internet: www.austria-email.at

E-Mail: of[email protected]

Austria Email in your area?

For addresses and telephone numbers of our subsidiaries,

visit our homepage at www.austria-email.at

Print errors and changes of all kinds are reserved.

Reproduction prohibited.

Table of contents