AUTEC Dymanic Series User manual

AUTEC Dynamic Series

LIARME01-00.fm Part D: ARM receiving unit

D - 1

ENG

DYNAMIC SERIES

Part D: ARM receiving unit

INDEX

1 Description ........................................................................................................... D - 2

3 Technical data sheet ........................................................................................... D - 3

4 Plates .................................................................................................................... D - 4

5 Light signals ........................................................................................................ D - 4

6 Values of proportional outputs .......................................................................... D - 7

7 Data memory backup ........................................................................................ D - 10

8 Malfunction signalled by the receiving unit .................................................... D - 11

Dynamic Series

Part D: ARM receiving unit

Description

D - 2

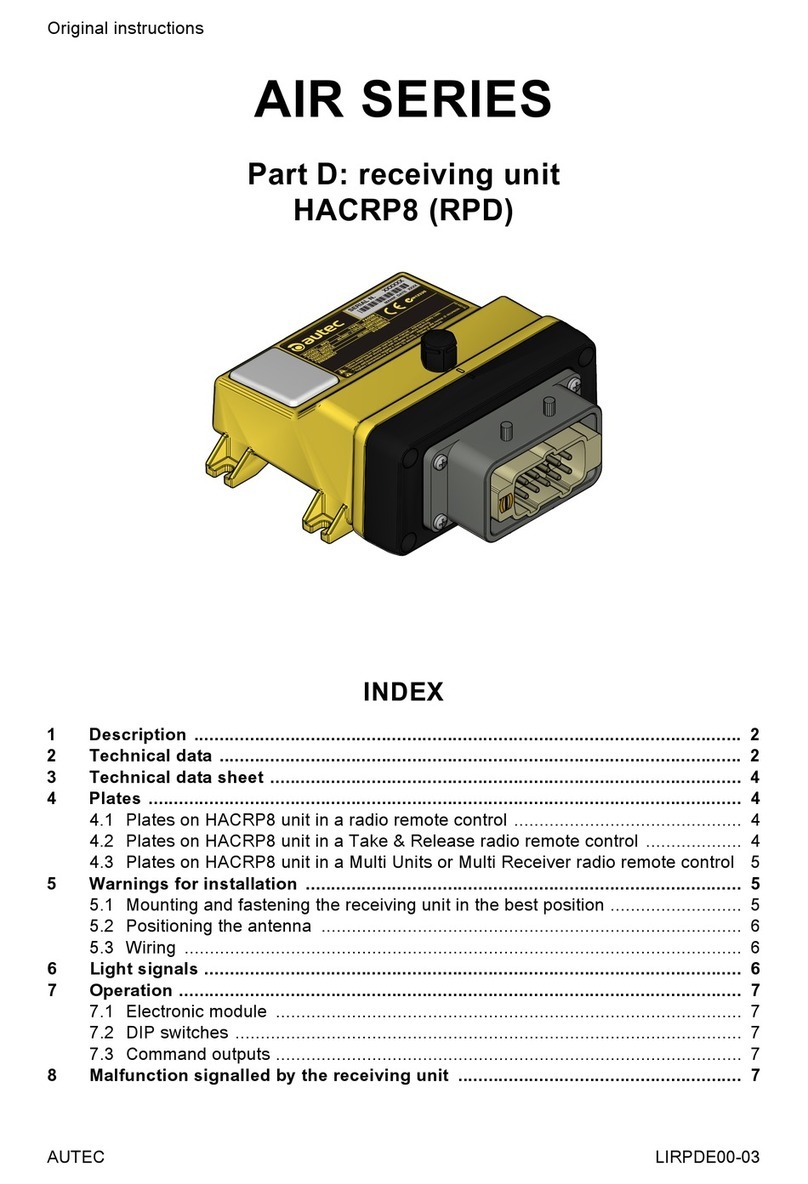

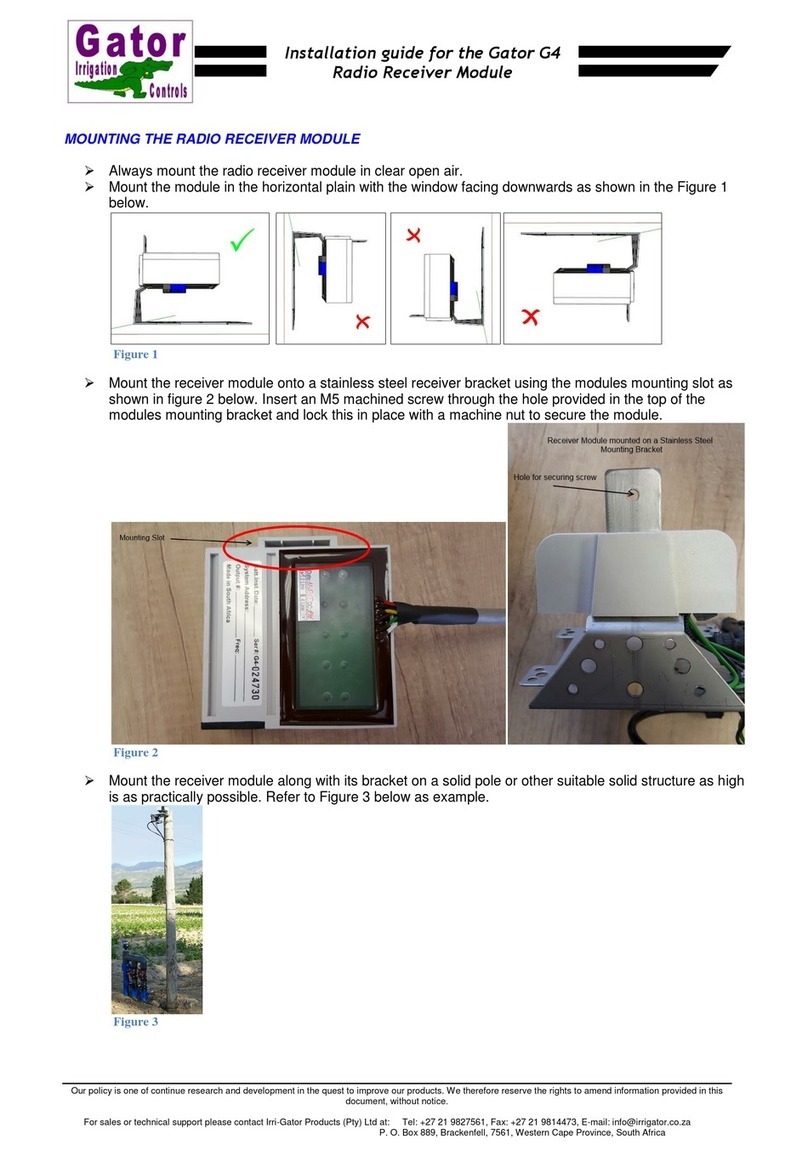

1 Description

The receiving unit communicates with the machine through the outputs and their

wiring and/or through a CAN network (of which it is a slave node).

The STOP (STP_1 and STP_2) and SAFETY (SAF_1 and SAF_2) outputs are

some of the receiving unit's outputs.

Amounting holes Gfuse F1

Bantenna Hfuse F2

CLEDs Lfuse F3

DTEACH pushbutton Mfuse F4

Econnector for cable control Nfuse F5

Fplug PDTK connector (for data memory)

QIDK (for address key)

RBKK connector

(for backup data memory)

A

B

F

A

C

E

E

D

G H

L

M

N

P

Q R

Mother board

Technical data sheet

AUTEC Dynamic Series

LIARME01-00.fm Part D: ARM receiving unit

D - 3

ENG

2 Technical data

Power supply ......................................................................................................... 8-30 V

Antenna ................................................................................................................ dedicated

Rated current of outputs STOP_1 and STOP_2 ........................................... 7.5 A (30 V )

Rated current of output SAF_1 ..................................................................... 7.5 A (30 V )

Rated current of output SAF_2 ........................................................................ 3 A (30 V )

Rated current of digital outputs ........................................................................ 4 A (30 V )

Rated current of analogue outputs (PWM) ...................................................... 2 A (30 V )

Rated current of analogue outputs (voltage) .............................................. 10 mA (28 V )

Protection SAF_2 (fuse F1) ............................................................. 3 A (32 V , autofuse)

Protection of power supply (fuse F2) ............................................. 7.5 A (32 V , autofuse)

Protection STOP_1 (fuse F3) ....................................................... 7.5 A (32 V , autofuse)

Protection STOP_2 (fuse F4) ....................................................... 7.5 A (32 V , autofuse)

Protection SAF_1 (fuse F5) .......................................................... 7.5 A (32 V , autofuse)

Housing material ............................................................................................ PA6 (20% fg)

Protection degree ....................................................................................... IP65 (NEMA 4)

Dimensions ............................................................. 200 x 230 x 95 mm (7.9 x 9.1 x 3.8 In)

Weight ............................................................................................................. 3 kg (6.6 Lb)

3 Technical data sheet

The technical data sheet contains the wiring diagram showing the connection be-

tween the receiving unit and the machine.

It also contains the transmitting unit configuration and shows the matching be-

tween commands sent and machine functions/movements.

The technical data sheet must be filled in, checked and signed by the installer,

who is responsible for a correct wiring.

The technical data sheet must be kept together with this manual (always keep a

copy of this data sheet for administrative purposes).

The wiring of the receiving unit outputs must always reflect the wiring indi-

cated in the technical data sheet.

Dynamic Series

Part D: ARM receiving unit

Plates

D - 4

4Plates

The receiving unit has two plates.

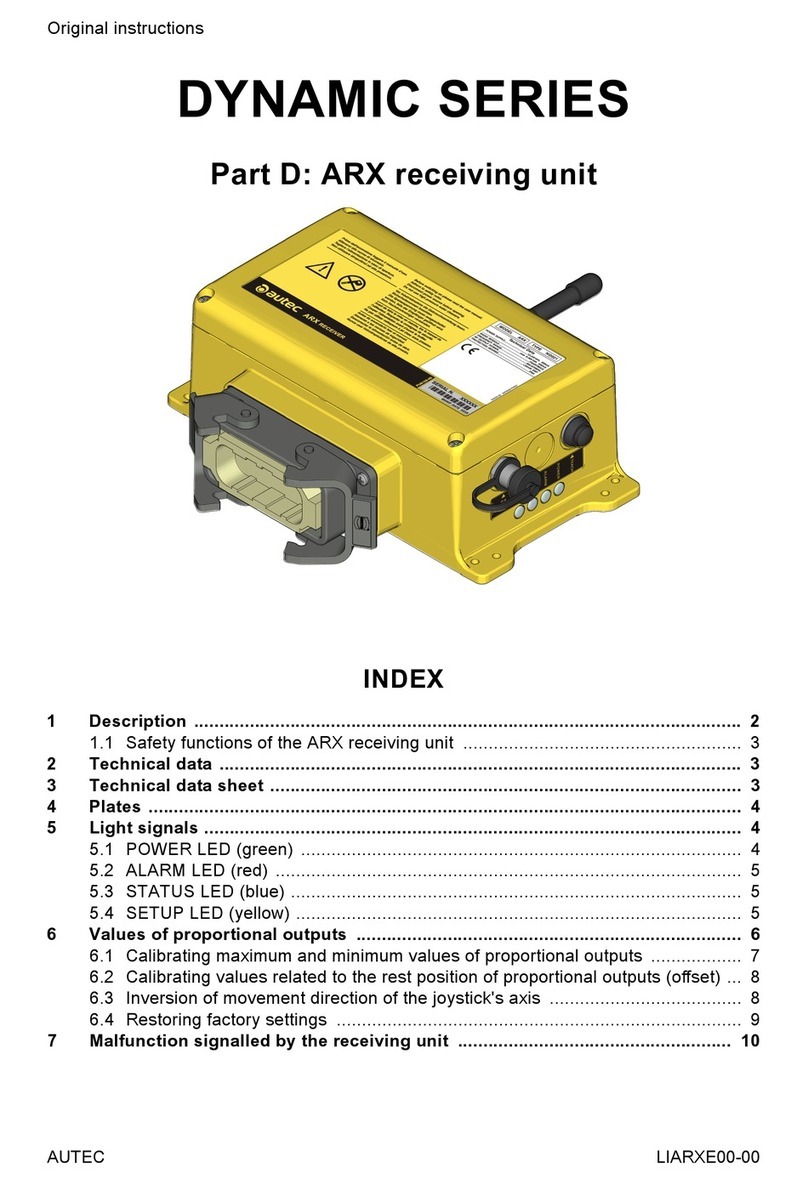

5 Light signals

The ARM receiving unit has six

LEDs:

- POWER is green

- ALARM is red

-STATUSisblue

- RUN is green

- ERR is red

- SETUP is yellow.

1. POWER LED (green)

The POWER LED indicates the status of the receiving unit and of the radio link.

2. ALARM LED (red)

Plate Position Content

radio remote control

identification plate

On the cover of the receiving

unit

Radio remote control serial

number, bar code (S/N) and

manufacturing year.

technical data plate On the cover of the receiving

unit

MODEL, TYPE and main

receiving unit technical data,

marking and possible radio

remote control marks.

The POWER LED ... Meaning

... is off The receiving unit is switched off.

...blinks Radio link has been built.

... is on No radio link.

Light signals

AUTEC Dynamic Series

LIARME01-00.fm Part D: ARM receiving unit

D - 5

ENG

The ALARM LED warns about anomalies in the receiving unit.

3. STATUS LED (blue)

The STATUS LED warns about anomalies on the outputs or on the power supply

and indicates the reception of data from the transmitting unit.

4. RUN LED (green)

The RUN LED indicates the status of the communication between the receiving

unit and the CAN network Master node.

RUN LED signals reflect the guidelines of the CANopen®, standard, CiA recom-

mendation 303-3.

The ALARM LED ... Meaning

... is off The receiving unit works correctly.

... blinks once Error on the STOP outputs.

... blinks twice Error on the SAFETY outputs.

... blinks three times Error on the outputs corresponding to direction com-

mands.

... is on The receiving unit does not work correctly.

The STATUS LED ... Meaning

... is off No radio link.

... blinks slowly Over-voltage on power supply.

... blinks fast The receiving unit receives data from the transmitting

unit.

... is on Over-current in one of the PWM analogue outputs.

The RUN LED ... Meaning

... is off The receiving unit does not work as a CAN network

node.

...blinks The receiving unit does not send commands in the

CAN network.

... is on The receiving unit is working correctly as a node in the

CAN network.

Dynamic Series

Part D: ARM receiving unit

Light signals

D - 6

5. ERR LED (red)

The ERR LED indicates the status of the CAN communication.

ERR LED signals reflect the guidelines of the CANopen®standard (CiA recom-

mendation 303-3).

6. SETUP LED (yellow)

The SETUP LED shows the status of the data memory and of the address key,

depending on the receiving unit's working status.

The ERR LED ... Meaning

... is off The CAN communication is working correctly.

...blinks The CAN communication does not work correctly.

... is on No CAN communication.

The SETUP LED ... Meaning

... is off The receiving unit works correctly.

... blinks once Error on the address key.

... blinks twice Error on the data memory.

... blinks slowly three times

Calibration of the rest position values for proportional

outputs (see paragraph 6.2) or the procedure "Copy

data memory" (see chapter 7) is being performed.

... blinks quickly

three times

The receiving unit is saving data set with the REMOTE

SETUP procedure (see chapter 6).

... blinks four times Inversion of movement direction of the joysticks axis is

being performed (see paragraph 6.3).

... blinks slowly A data memory is connected to the BKK connector.

... blinks fast

This signal has two meanings, depending on the cur-

rent working status:

- the receiving unit is restoring factory settings (see

paragraph 6.4)

- an error occurred during the “Data memory backup”

(see chapter 7).

... is on

Calibration of maximum and minimum values of pro-

portional outputs is being performed (see

paragraph 6.1).

Values of proportional outputs

AUTEC Dynamic Series

LIARME01-00.fm Part D: ARM receiving unit

D - 7

ENG

6 Values of proportional outputs

Proportional outputs in the ARS receiving unit are factory set: values are given in

the technical data sheet.

The REMOTE SETUP procedures is used to modify:

- maximum and minimum values of proportional outputs (see paragraph 6.1),

- values related to the rest position of proportional outputs (offset) (see

paragraph 6.2),

- direction of movements of joystick's axis (see paragraph 6.3).

The REMOTE SETUP procedure

can only be performed by skilled

and properly trained personnel.

During the REMOTE SETUP proce-

dure, pay particular attention to

the machine behaviour, as it

moves as a response to acting on

the actuators.

It is possible to restore factory set-

tings at any time, if necessary (see

paragraph 6.4).

6.1 Calibrating maximum and minimum values of proportional out-

puts

1. Start up the radio remote control.

2. Press the TEACH pushbutton in the receiving unit and do not release it until

the SETUP LED illuminates.

3. Set the desired values as follows:

- To set the maximum value, move the joystick to the maximum range of the

semi-axis to be calibrated. Maintain the position and use the TEACH selec-

tor on the transmitting unit to set the desired value.

- To set the minimum value, move the joystick slightly out of the rest position

of the semi-axis to be calibrated. Maintain the position and use the TEACH

selector on the transmitting unit to set the desired value.

- After calibrating one joystick, press the STOP pushbutton to save calibra-

tions. Calibrations are saved in the data memory on the DTK connector.

- To set other values, unlock the STOP pushbutton, press the START push-

button and repeat actions described in point 3..

4. To leave the procedure, press the TEACH pushbutton on the receiving unit

and do not release it until the SETUP LED switches off.

SETUP LED in

the receiving unit

TEACH

pushbutton in the

receiving unit

Dynamic Series

Part D: ARM receiving unit

Values of proportional outputs

D - 8

If the proportional outputs are activated by actuators that are not joysticks (i.e. po-

tentiometer, switch), calibrate maximum and minimum values according to the

abovementioned procedure.

If a speed selector is present on the transmitting unit, minimum and maximum

values have to be calibrated for each of the selector positions.

If inputs are used in the receiving unit to select different speeds, calibration must

be performed while these inputs are active.

6.2 Calibrating values related to the rest position of proportional

outputs (offset)

1. Start up the radio remote control.

2. Press the TEACH pushbutton in the receiving unit and do not release it until

the SETUP LED illuminates.

3. Activate and release the “TEACH +” command related to the corresponding

switch on the transmitting unit.

4. Press and release the START pushbutton.

5. Repeat actions described in points 3. and 4. until the SETUP LED on the re-

ceiving unit starts blinking three times.

6. Set the desired values as follows:

- Move the joystick out of the rest position of the axis to be calibrated. Main-

tain the position and use the TEACH selector on the transmitting unit to set

the desired value.

- After calibrating one joystick, press the STOP pushbutton to save calibra-

tions. Calibrations are saved in the data memory on the DTK connector.

- To set other values, unlock the STOP pushbutton, press the START push-

button and repeat actions described in point 6..

7. To leave the procedure, press the TEACH pushbutton on the receiving unit

and do not release it until the SETUP LED switches off.

If the proportional outputs are activated by actuators that are not joysticks (i.e. po-

tentiometer, switch), calibrate values related to the rest position according to the

abovementioned procedure.

Values of proportional outputs

AUTEC Dynamic Series

LIARME01-00.fm Part D: ARM receiving unit

D - 9

ENG

6.3 Inversion of movement direction of the joystick's axis

1. Start up the radio remote control.

2. Press the TEACH pushbutton in the receiving unit and do not release it until

the SETUP LED illuminates.

3. Activate and release the “TEACH +” command related to the corresponding

switch on the transmitting unit.

4. Press and release the START pushbutton.

5. Repeat actions described in points 3. and 4. until the SETUP LED on the re-

ceiving unit starts blinking four times.

6. Set the desired values as follows:

- Move the joystick out of the rest position of the axis to be calibrated. Main-

tain this position and activate once the “TEACH +” command related to the

corresponding switch on the transmitting unit.

- After calibrating one joystick in the transmitting unit, press the STOP push-

button to save calibrations. Calibrations are saved in the data memory on

the DTK connector.

- To set other values, unlock the STOP pushbutton, press the START push-

button and repeat actions described in point 6..

7. To leave the procedure, press the TEACH pushbutton on the receiving unit

and do not release it until the SETUP LED switches off.

6.4 Restoring factory settings

This procedure is used to restore factory settings for the proportional outputs.

1. Ensure that the transmitting unit is switched off.

2. Power on the receiving unit.

3. Press the TEACH pushbutton and do not release it until the SETUP LED illu-

minates.

4. Press the TEACH pushbutton three times and do not release it at last pres-

sure; the SETUP LED blinks fast: this indicates that factory settings are being

restored.

5. Release the TEACH pushbutton when the SETUP LED is steadily illuminated

again.

If the TEACH pushbutton is released before the SETUP LED is steadily illumi-

nated, factory settings of proportional outputs will not be restored.

6. To leave the procedure, press the TEACH pushbutton on the receiving unit

and do not release it until the SETUP LED switches off.

Dynamic Series

Part D: ARM receiving unit

Data memory backup

D - 10

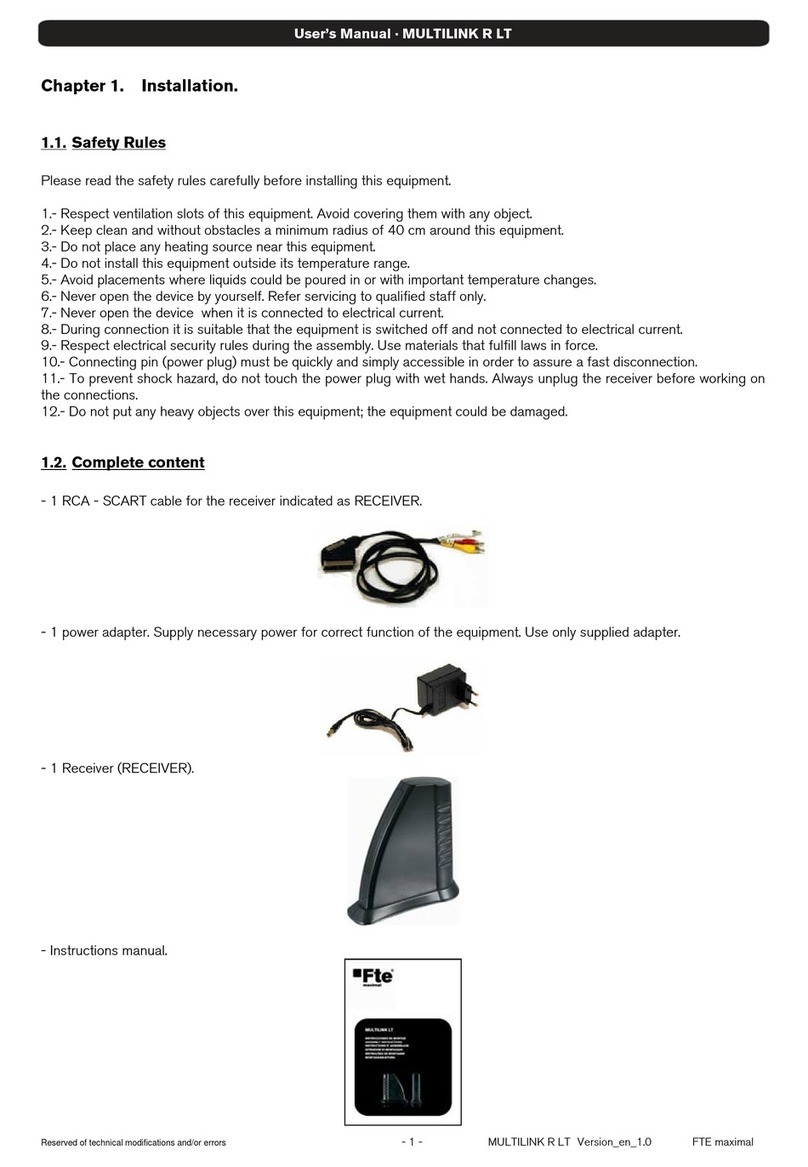

7 Data memory backup

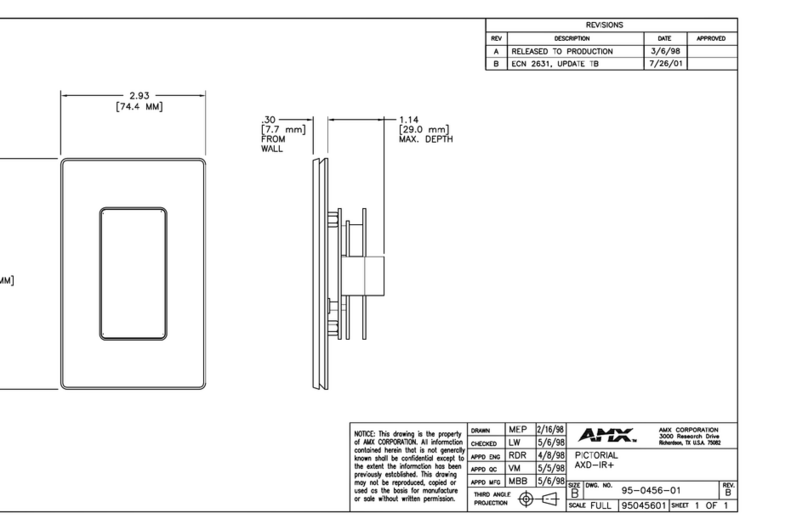

The receiving unit has two data memories: one is in the DTK connector on the

mother board and one is attached inside the cover (backup data memory).

When data of proportional outputs are modified, they are saved in the data mem-

ory present in the DTK connector.

The data memory in the DTK connector can be copied into a backup data mem-

ory. This is useful in case you need to restore the information contained. In this

case, use the data memory attached inside the cover.

If one of the data memories is lost or damaged, ask the machine manufacturer

for a new one.

Please note that information contained in the data memory in the DTK connector

overwrites the data memory of the BKK connector during the backup procedure.

Perform the following steps to copy the information of the data memory.

1. Make sure that the transmitting unit and the receiving unit are not powered.

2. Open the receiving unit

3. Make sure that a data memory is plugged in the DTK connector

4. Insert the memory attached inside the receiving unit cover in the BKK connector

5. Close the receiving unit

6. Power on the receiving unit: the SETUP LED blinks slowly

7. Press the TEACH pushbutton: the SETUP LED blinks fast (indicating that data

are being copied); release the button when the LED starts blinking slowly

again.

If the TEACH pushbutton is released before the SETUP LED starts blinking

slowly again, data contained in the data memory will not be copied.

8. Remove power from the receiving unit.

9. Open the receiving unit, remove the data memory from the BKK connector and

attach it inside the cover.

DTK connector

BKK connector

IDK connector

Malfunction signalled by the receiving unit

AUTEC Dynamic Series

LIARME01-00.fm Part D: ARM receiving unit

D - 11

ENG

10.Close the receiving unit.

8 Malfunction signalled by the receiving unit

Use the light signals on the receiving unit to identify the radio remote control mal-

function.

If the problem persists after the suggested solution has been carried out, contact

the support service of the machine manufacturer.

Signals Possible

reason Solutions

The POWER LED is

off.

The receiving unit is

switched off.

Make sure that fuse F2 is intact.

Correctly plug in the connecting plug

and power on the receiving unit.

The POWER LED is

on. No radio link. Bring the transmitting unit close to the

receiving unit.

The ALARM LED

blinks once.

Error on the STOP out-

puts.

Make sure that fuses F3 and F4 are

intact.

Correctly plug in the connecting plug.

Make sure that the STOP outputs are

wired correctly.

The ALARM LED

blinks twice.

Error on the SAFETY

outputs.

Make sure that fuses F1 and F5 are

intact.

Correctly plug in the connecting plug.

Make sure that the SAFETY outputs

are wired correctly.

The ALARM LED

blinks three times.

Error on the outputs

corresponding to direc-

tion commands.

Contact the support service of the

machine manufacturer.

Make sure that the outputs of direc-

tion commands are wired correctly.

The ALARM LED is on.

The receiving unit

does not work correct-

ly.

Contact the support service of the

machine manufacturer.

The STATUS LED

blinks slowly.

Over-voltage on power

supply.

Make sure that the receiving unit

power supply is within the voltage lim-

its provided in the technical data.

The STATUS LED

blinks fast and irregu-

larly.

The receiving unit

loses some data sent

by the transmitting

unit.

Bring the transmitting unit close to the

receiving unit.

If this signal persists, contact the sup-

port service of the machine manufac-

turer.

Dynamic Series

Part D: ARM receiving unit

Malfunction signalled by the receiving unit

D - 12

The STATUS LED is

on.

Over-current in one of

the PWM analogue

outputs.

Contact the support service of the

machine manufacturer.

The RUN LED blinks.

The receiving unit

does not send com-

mands in the CAN net-

work.

Contact the support service of the

machine manufacturer.

The ERR LED blinks. CAN communication

error.

Contact the support service of the

machine manufacturer.

The SETUP LED

blinks once.

Error on the address

key.

Contact the support service of the

machine manufacturer.

The SETUP LED

blinks twice.

Error on the data mem-

ory.

Replace the data memory on the DTK

connector with the backup data mem-

ory attached inside the cover (see

chapter 7).

The SETUP LED

blinks slowly.

A data memory is con-

nected to the BKK con-

nector.

If you are not performing a backup of

the data memory, remove the memo-

ry from the BKK connector (see

chapter 7).

Signals Possible

reason Solutions

Table of contents

Other AUTEC Receiver manuals

Popular Receiver manuals by other brands

Dakota Micro

Dakota Micro AgCam EnduraCam DMAC-2USB user manual

Senrun

Senrun ER218-2 instruction manual

Sony

Sony TA-E9000ES - Stereo Preamplifier Service manual

Shenzhen Fenvi Technology

Shenzhen Fenvi Technology RC732-DVR user manual

Linear

Linear XR-4 installation instructions

Spektrum

Spektrum DX8 instruction manual