Autex Acoustics Acoustic Timber Panel Configuration guide

These install instructions are of a general nature and are to be referred to when installing Acoustic Timber™

Panel™and Raft™, as Acoustic Timber requires slightly different treatment. Please refer to the install instructions

for the selected product as well as the below instructions.

These install instructions are designed to assist suitably experienced tradespeople in the installation of Acoustic

Timber products to a high standard in common wall and ceiling applications.

For installation support, contact your account manager before you start.

Autex Acoustics® recommends that all persons engaged in the installation of Autex Acoustics products have full

knowledge of the product and installation procedure as set out in the most recent edition of the manufacturer’s

instructions, and related documents. Copies of these documents are available on request or from the Autex

Acoustics website.

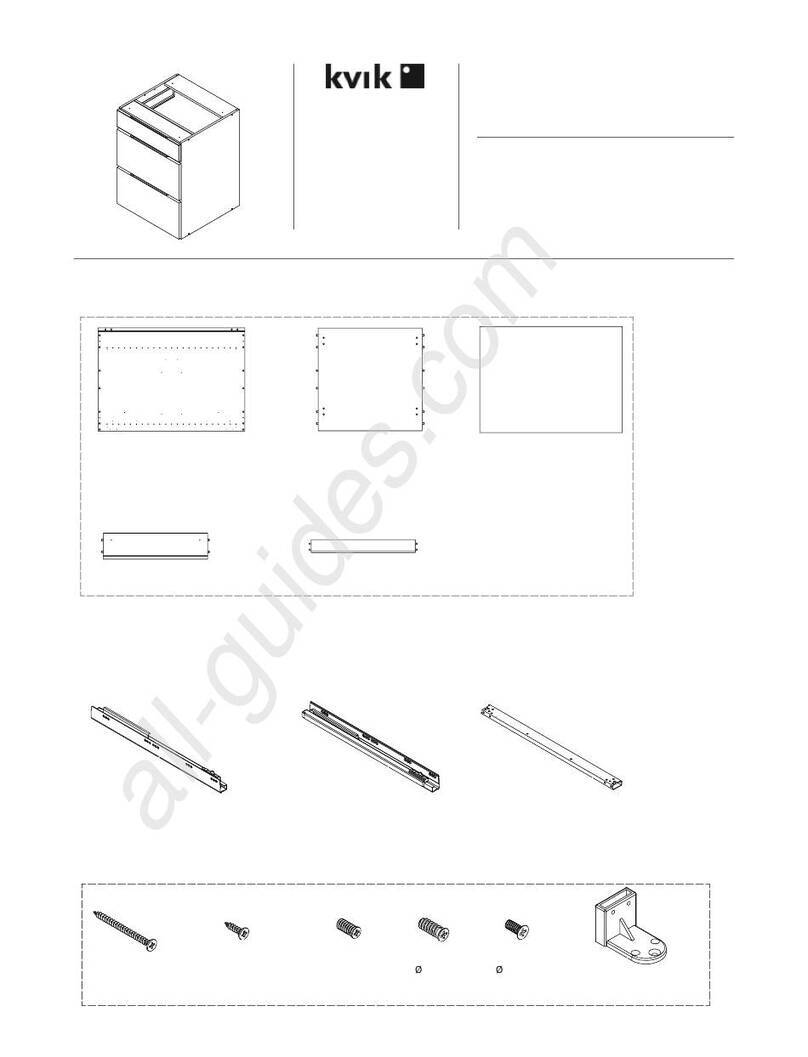

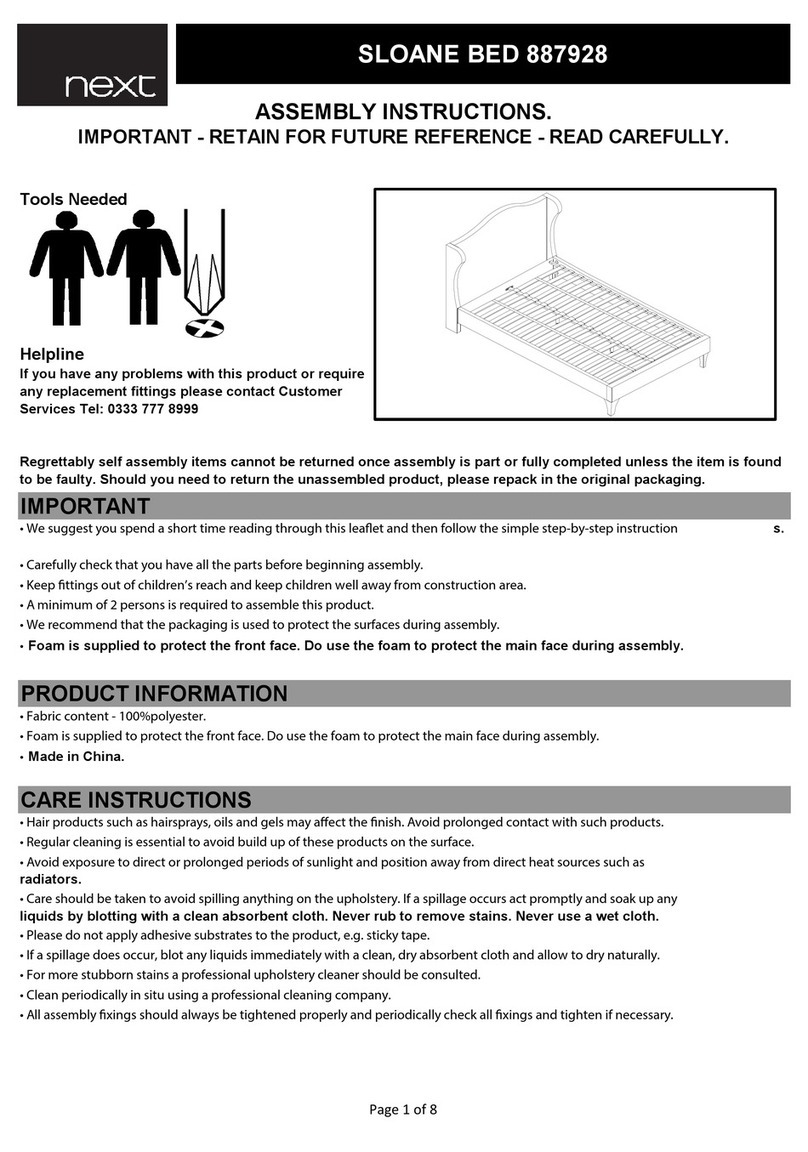

Before starting the installation of Acoustic Timber,

check that the materials have been supplied as

ordered and are free from damage or faults. Check

colors and product labels to ensure the product

has been supplied correctly. Where multiple sheets

of Acoustic Timber are required, it is important to

check that all product is supplied from one batch.

Due to batch to batch variation, we do not

recommend joining different batch lots as this

could result in color variation.

Any variations must be reported to Autex Acoustics

prior to commencing the installation.

Always ensure that the shop drawings have been

signed off before ordering and installing. If you

notice any inconsistencies, please contact your

account manager. No claims will be accepted

where the job continues with obvious faults

and no consultation with Autex Acoustics has taken

place.

Inspection

Transportation, storage

and handling

Install InstructionsAcoustic Timber™

autexglobal.com

Autex Acoustics recommends that all persons engaged in installing Acoustic Timber have full knowledge

of the product and installation procedure as set out in the most recent edition of the manufacturer’s

instructions and related documents.

Manufacturer’s documents relating to work in this section are:

• Acoustic Timber Panel Data Sheet

• Acoustic Timber Raft Data Sheet

• Acoustic Timber Panel Manufacturer's Guarantee

• Acoustic Timber Raft Manufacturer's Guarantee

• Acoustic Timber Install Instructions

• Cube™ Install Instructions

• Frontier Install Instructions

Copies of the above documents are available on request or from the Autex Acoustics website.

Manufacturer’s

documents

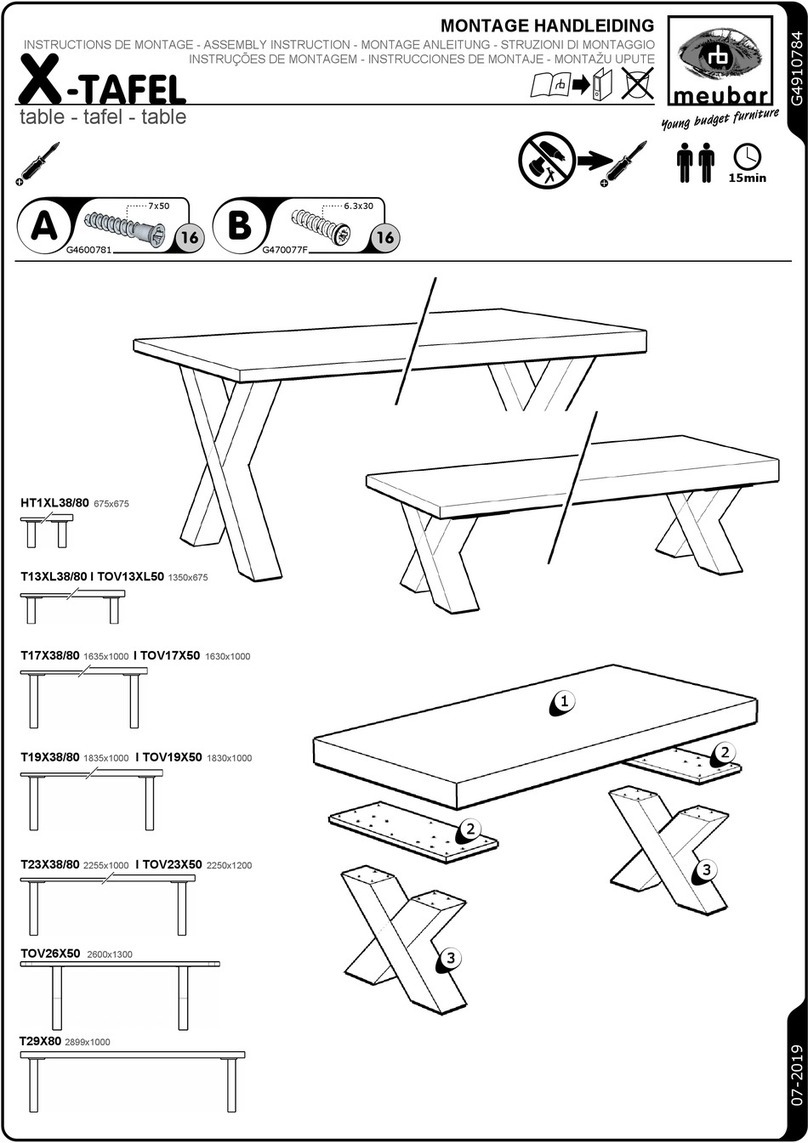

For Acoustic Timber Raft Beam 100 and Beam 250 install instructions, please refer to pages 15 - 29 of our

Frontier™ Install Instructions.

Acoustic Timber™Raft™

Acoustic Timber must be transported, stored,

and handled with care. Acoustic Timber should

be kept dry and stored indoors. Avoid delamination

or distortion, and protect edges from being

crushed. Do not accept damaged product.

If the product arrives damaged, note the condition

on the freight documents and contact Autex

Acoustics immediately.

Goods signed as received in ‘good condition’ will

not be the responsibility of Autex Acoustics. Always

transport and store Acoustic Timber on a flat,

clean, and dry surface.

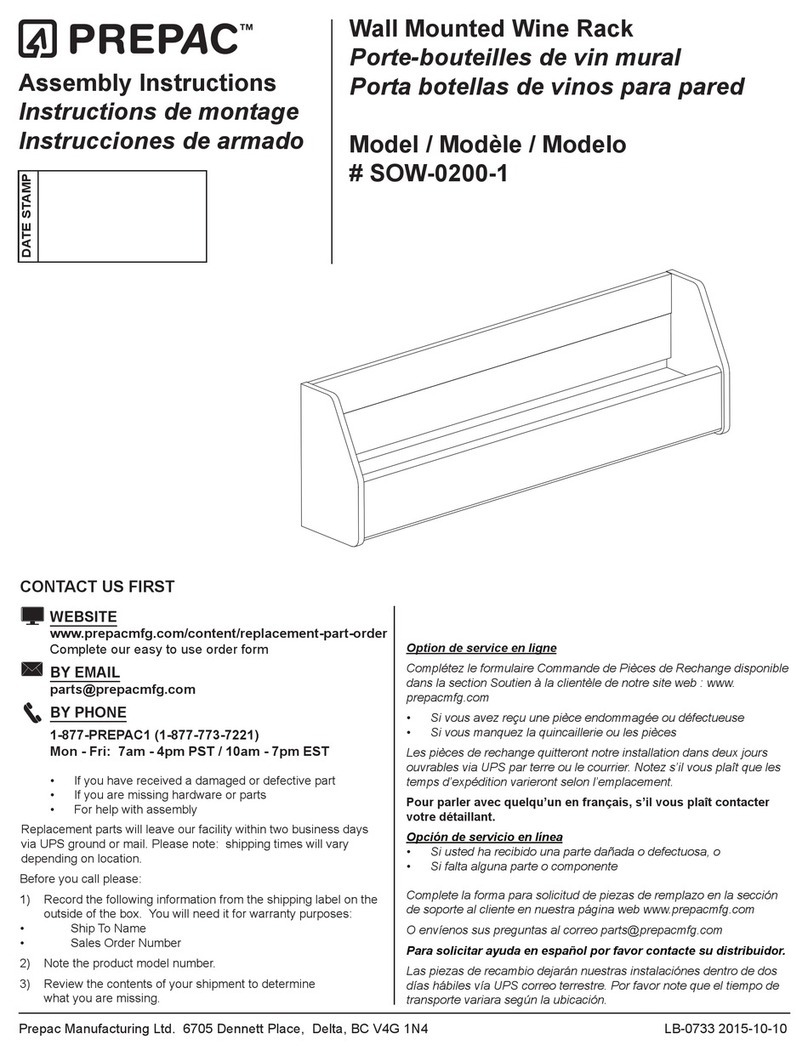

Acoustic Timber Panel should always be installed

in accordance with these install instructions,

and as per the specification detail and customer

requirements. If there is conflicting information, you

must seek clarification from all appropriate parties

before proceeding with the work. It is imperative

that the installation is planned before cutting any

product. We recommend that you “measure twice

and cut once”. For further information, please refer

to the Cube install instructions.

Do not rub the panel surface at any point during

installation as rubbing may cause surface wear.

Do not step on the panel surface. Avoid scratching

the panel surface. Ideally Acoustic Timber Panel

should be installed in low traffic areas to avoid

damage to the surface. If you have any concerns

about the install location, please contact your

account manager.

Joins should ideally always be vertical, clean, and

flat with no gaps or visible compression marks.

Panels will be manufactured ready for butt joining

along the vertical joins.

We recommend cutting through the face of the

Acoustic Timber Panel using a straight edge to

ensure a straight cut. Where possible, please place

the straight edge on the excess of the panel to

reduce friction and rubbing on the part of the panel

that is to be installed.

In instances where Acoustic Timber Panel is being

used in conjunction with other Autex Acoustics

or externally supplied components, please take

extra care when applying these to the Acoustic

Timber Panel.

Lay a drop cloth on the floor when removing the

product from its packaging to protect the panel

surface from any contamination and friction.

Avoid contaminating the panel surface with

adhesive, solvents, or any other chemicals during

installation. In the case of adhesive spills or

surface contamination, do not clean the surface

with any liquid. Consult a specialist cleaning

company immediately.

Installing Acoustic

Timber™Panel™

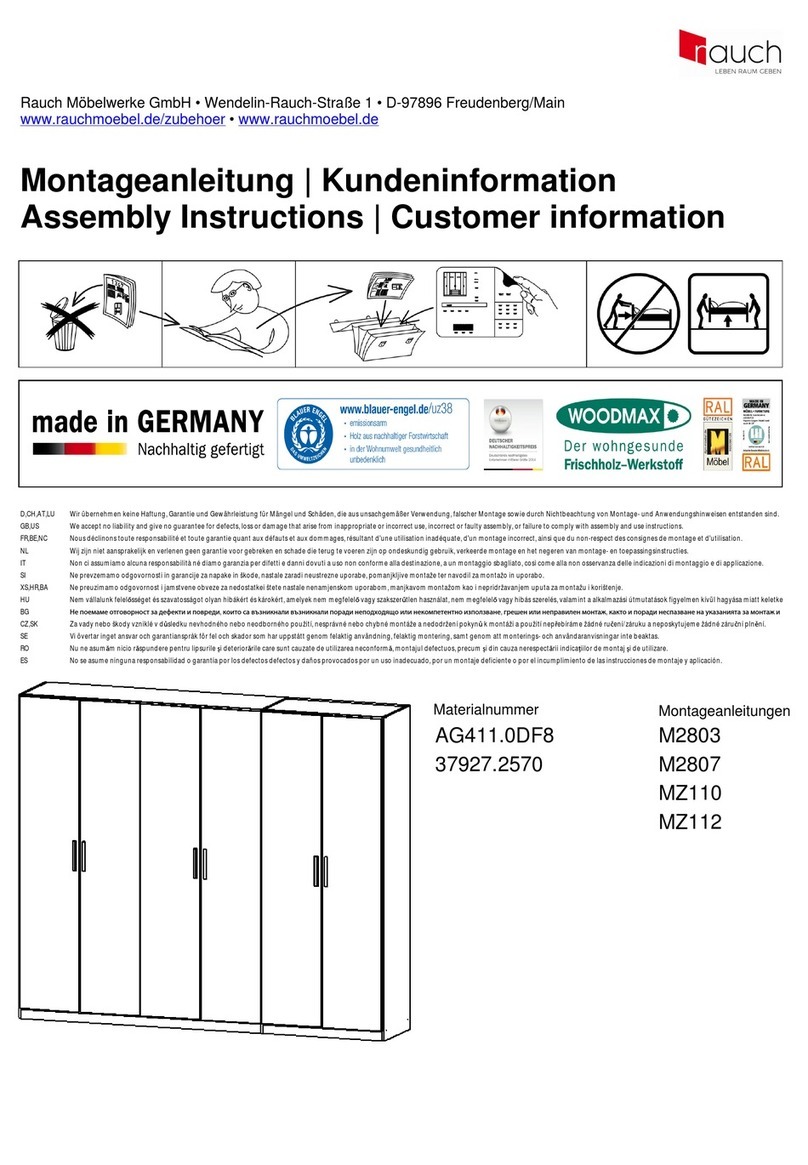

Autex Acoustics recommends a contact-type

adhesive or full curing panel adhesive for applying

Acoustic Timber Panel to most common substrates.

Prior to commencing work, we recommend

contacting your local adhesive supplier with

samples of the Autex Acoustics products you are

installing and the specification of the substrates

you are installing to. It is the installer’s responsibility

to ensure that any adhesive is fit for the intended

purpose. It also is the installer’s responsibility to

ensure that the substrate is fit for the application

of adhesives and Autex Acoustics products. For

information regarding adhesive suppliers, please

contact your Autex Acoustics account manager.

Please take extra care when using adhesives as

the printed side of the panels cannot be cleaned

with a citrus cleaner in the way our standard

products can.

We recommend using a guard to avoid overspray.

Fit the product to the wall and apply pressure by

hand. Apply even pressure to ensure adequate

adhesive transfer and a strong bond. Be careful not

to abrade the surface when making contact with

the Acoustic Timber. Do not use a roller to apply

pressure on the surface.

Recommended

adhesive

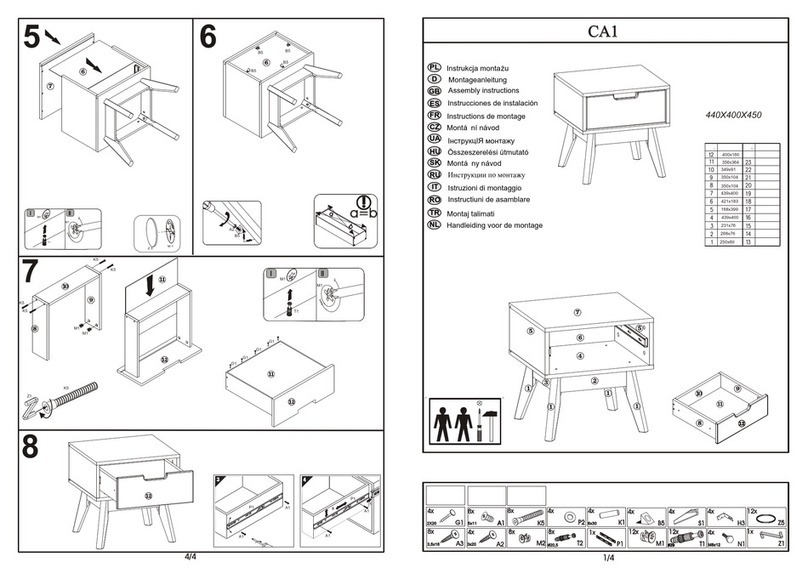

Fixtures Remove cover plates, light fittings and other fixtures

as the work proceeds. Replace, plumb, square and

true to line as the work is completed.

Note: All electrical plumbing, fire safety appliances

and fittings should only be removed and

re installed by an appropriately qualified person.

Acoustic Timber is a semi-rigid product that can be

damaged if not handled with care. Avoid bending

the packs and panels as this could cause creasing.

Do not store or drop the panels on their corners or

edges as this will cause damage.Clean cloth gloves

are ideal when handing panels to avoid soiling.

On-site panel care

Before work commences, all joins, gaps and cracks

in the wall/ceiling substrate must be taped with

propriety sealing tapes to eliminate the ingress of

dust and foreign particles travelling from the cavity

into the installed product over time. Ensure that the

substrates, backgrounds and adjoining surfaces

will allow work to reach the required standard.

Autex Acoustics recommends that the wall/ceiling

surfaces be prepared to a minimum Level 3 finish.

Very porous surfaces may need to be sealed prior

to applying the adhesive. Gloss and semi-gloss

finishes should be lightly sanded and dusted clean

prior to application of the adhesive. All surfaces

must be clean, dust-free and dry as dust and

moisture will adversely affect the adhesive and may

result in lack of adhesion.

Wall and surface

preparation

autexglobal.com

autexglobal.com

IA_AT_Acoustic Timber Panel Install Instructions US_Feb22_RC

An ISO 9001, ISO 14001 and ISO 45001 certified company. The brand names and logos mentioned herein are registered or unregistered trademarks either owned or used under license by Autex

Industries Limited or other members of the Autex Group. The contents of this document are protected by Copyright 2021 Autex Industries Ltd. All Rights Reserved. It is the user’s responsibility to

determine if the product and information presented in this document is suitable for the intended application by engaging a suitably qualified consultant. The information contained in this document

is correct to the best of our knowledge at the date of its publication. To verify that this document is the most current publication please check our website or contact your Autex account manager.

Autex Industries Ltd

702-718 Rosebank Rd

Private Bag 19988

Avondale 1746, Auckland

New Zealand

Freephone 0800 428 839

Phone +64 9 828 9179

Fax +64 9 828 5810

Autex Australia Pty Ltd

166 Bamfield Road

PO Box 5099

West Heidelberg, Melbourne

VIC 3081, Australia

Freephone 1800 678 160

Phone +61 3 9457 6700

Fax +61 3 9457 1020

Autex Acoustics Ltd

Unit J4, Lowfields Way,

Lowfields Business Park,

Elland, West Yorkshire

Hx5 9Da

United Kingdom

Phone +44 0 1422418899

Autex Acoustics LLC

1630 Dan Kipper Dr,

Riverside, CA 92507

United States of America

Phone +1 424 203 1813

Leave work to the standard required by following all listed procedures. Leave work secure, smooth and

free of air bubbles, wrinkles, gaps, stains, and blemishes. Remove debris, unused materials, and waste

from the site.

Localised high temperature conditions may be

present in the following situations, which may be

detrimental to wall and ceiling linings:

Including, but not limited to:

• Radiant heaters

• Lighting

• Heat pumps

• Reverse cycle air conditioners

• Solid fuel stoves

All appliances including lamps, luminaires and

their associated ancillary gear should be installed

so as not to cause the Acoustic Timber surface

temperature to rise above 176°F.

On completion

For more information, contact your Autex Acoustics account manager or visit our website

www.autexglobal.com

Service

Penetrations The fire and acoustic performance of walls and

ceilings can be reduced by penetrations for

plumbing, electrical switches, light fittings etc.

For walls or ceilings that require a Fire Resistance

Level (FRL) and/or are acoustically sensitive, it

is recommended that, wherever possible, such

penetrations are avoided. Where penetrations are

necessary, only appropriately rated proprietary

sealants and fittings should be used.

If unsure, we recommend consultation appropriately

qualified person is undertaken to ensure the

buildings performance objectives are maintained.

Heat generating devices

This manual suits for next models

1

Other Autex Acoustics Indoor Furnishing manuals