AUTINOR MBV 191 User manual

1

Client's name

:

Controller

No

:

Client's

No

:

AUTINOR

Site manual

Frequency drive

MANUAL MBl91-2.VEC. P.A CAB

+

PAL.

TRI.

DIR.

SP

Programme

:

VSCVOO 190499

«

VEC V03

-

10/03/99

))

BA1

91

-

VI

7 12/03/97

Version of

13

October

1999

WARNING

This manualis deemed correct on going to press. It is linked to the program version shown on the front

page, however this version may evolve without influencing the contents of this manual, which may in

itself bechangedwithout priorwarning.

The information contained has been scrupulously checked. However AUTINOR declines al1

responsibilityfor error or omission.

Should you notice any discrepancy or unclear description, or if you have any suggestions, we would

appreciateyour written comments (by mail or fax) to

:

Société AUTINOR

Z.A. Les Marlières

59710 AVELIN

n

[33103-20-62-56-00

[33] 03-20-62-56-41

This manual is the property of AUTINOR, from whom it may be bought (at the above address). It may

however byfreely copied in order to communicateinformationto those who might need it.

We can only authorise a complete copy, without addition nor removal of information

Where quotationsare taken, the following at least must be noted

-

the Company name of AUTINOR,

-

the programversion to which it refers,

-

the numberand date of the originaledition.

ELECTROMAGNETICCOMPATlBlLlTY

Since the 1st January 1996 al1 lift installations are obliged to respect the essential requirements of the

European Directive891336lCEEconcerning ElectromagneticCompatibility (EMC).

The ME3497

VECTOR

is only one component of an installation

;

it is therefore not obliged to show the

C

<

marking as stated in this directive. However in order to allow you to write your

declaration of

conformity,

and according to professional rules, al1

AUTINOR

controllers are supplied with an

engagementofconformity.

Your declarationof conformity can only rest on this engagement.

if the

NIBIS1

VECTOR drive has been installedexactly as advised inthis manual.

O

Copyright 1999

AUTINOR

All rights reserved.

MBI91

VECTOR

Site

manual

page

5

CONTENTS

Preamble

.........................................................................................................

7

How to install the controller cabinet

..............................................................

8

Minimum connections necessary for ini.tial movement

....................................

12

.............................................................................................

Power-up 14

Frequency drive parameter 1diagnostic communication device

.........................

17

Controller parameterldiagnosticcommunication device

...................................

21

....................................

Safety lane wiring

....

......................................................

27

Machine room wiring

....................................................................................

28

Landing wiring

............................................................................................

29

Car wiring

........................................................................................................

30

Direct three phases door operator, front and rear doors

...................................

31

Setting-up the slotted tape and brackets

............................................................

32

Automatic set-up of levels

...............................................................................

33

What to know before starting off at full speed

.................................................

37

................................................................

Parameters adjustment at full speed 40

-

Adjustment of the synchronous speed

...................................................

40

-

Automatic adjustment of the up stopping precision

.....................

..

.......

40

-

Automatic adjustment of the down stopping precision

..........................

40

-

Adjustment of the direct approach precision

...........................................

41

-

Automatic adjustment of the hysterisis zone

........................................

41

Positioning the EM magnet

....

.

...................

.......................................

42

Parameters to be adjusted on site

.....................................................................

43

Parameters table

Controller parameters

..

44

.

...............................

.......................................

Parameters concerned the slotted tape 47

.

................................................

Frequency drive parameters

...

48

.

.....................................

..........................

Inputs1outputs table

Controller Inputs 1outputs

...

57

.

..........................

....................................

-

Frequency drive Inputs 1outputs

..........................................................

58

Fault codes list

.....................

...

....................................................................

65

Location of terminal blocks and function of fuses

..............................................

69

Electric diagrams

...........................................................................................

71

Addi.tional items

..............................................................................................

75

.

Indicators

.............................................................................................

.

Non standard wiring (H.S.)

...........................

..

..................................

.

Multiplex

.......................

..

....................................................................

x

.

Further evolutions and improvements

...................................................

MB191VECTOR Site manual page

7

The

ME3191

VECTOR controls lift motor whose speed

can reach3 mls.

The Motor must be equippedwith

a double beam incrementalencoder, 500

to

2500 point per turn,

output

voltage

10V-30V.

The Lift can work with a direct approach providedthe controller gives a

very accurate

slow down signal.

The

ME3191

VECTOR

can generate

5

speeds,

V2, VI,VO, VINS

and

VISO.

RANGE

OF

MB39i

VECTQR

PRODUCTS:

IMPORTANT

:

Model2:

...........

Model 3

:

...........

Model 4:

...........

Model5:

...........

Model6:

...........

Model 7

:

...........

Model 8

:

...........

Model 9

:

...........

The current values shown in the table take into account the fact that the motor

is not equipped with an inertia hand-wheel.

MaximalValues

20Ain415V-

11

HP-8kW

30 A in415V- 16,5 HP

-

12kW

40A in 415V-20 HP

-

15kW

50Ain415V-27,5HP-20kW

70Ain415V-39HP-28,5kW

90 A in 415V

-

50 HP

-

37 kW

110A in 415V

-

61 HP

-

45 kW

160A in 415V

-

89 HP

-

65 kW

All the

MBI9I

VECTOR are equipped with a

3

phase network current filter, Motor filter, Regenerative

resistors and contactors.

Handling advice

for

eauipment

:

..

Whatever fhe

load,

handling

operations

can

be

dangerous

(collision,

dropping,

crushing,

.).

Whenever

possible

use

mechanical handling

rafher

fhan

manual

handling.

When

manual

handling

can not

be

avoided,

respecf

the

rules.

At

Europeon Ievei. these rtlJes a18 set ouf in the Directive

90/269/CEE.

Council Direclivçil dated

'?3

May

1990

«

concen?i!?g

1nif~^lMï?û1

heafh and safefy instructions for rnanual Ioûd

handling

with rkks, fo the workçilr, no!a&iy in

the

lower spiral area

».

Safetv

measures:

Respect the instructions which were given tsysu

&y

your hierarchy for the use of the individual

protection equipments (gloves, shoes, gfasses

....

anfi-fails device).

MBI91

VECTOR

Site manual page

8

HOW TO INSTALLTHE CONTROLLER CABINET

(114)

0

FURTHER

BASE

Controller dimensions

:

L

=

750 mm,

H

=

1050 mm, D

=

300 mm

Controller dimensions with a lot of Extra Items

:

L

=

900 mm,

H

=

1050 mm, D

=

300 mm

Separate Boxfor morethan

4

Breaking Resistors

:

L

=

320 mm,

H

=600 mm, D

=

250 mm.

Protectionagainst electrical shocks

:

IP 31

Equipmentweight

:

approximately 60 Kg

Don'tforget than the EN-81 part 1 Standard

§

6.3.2.1 (a), amended by

British nationalvariation BS 5655

§

V.3.14 requiresthat

:

6.3.2.1

The dimension of machine room shall be suffïcient to permit easy and safe access for servicing

personnel toa//components, especiallythe electrical equipment.

Inparticular there shall beprovided

:

(a)a clear horizontal area in front of thepanels and the cabinet. Thisarea is defined as follows

:

(N,c)

depth,

measured from external surface of the enclosures, at least

0.9

m.

This distance may be reduced to

0.6

m in front of protruding controls (handles,etc.).

width,

the full widthof panel or cabinets by

2.14

m high.

MB191

VECTOR

Site manual page9

CONTROLLER POSITION

AND ELECTROMAGNETIC COMPATIBlLlTY

(214)

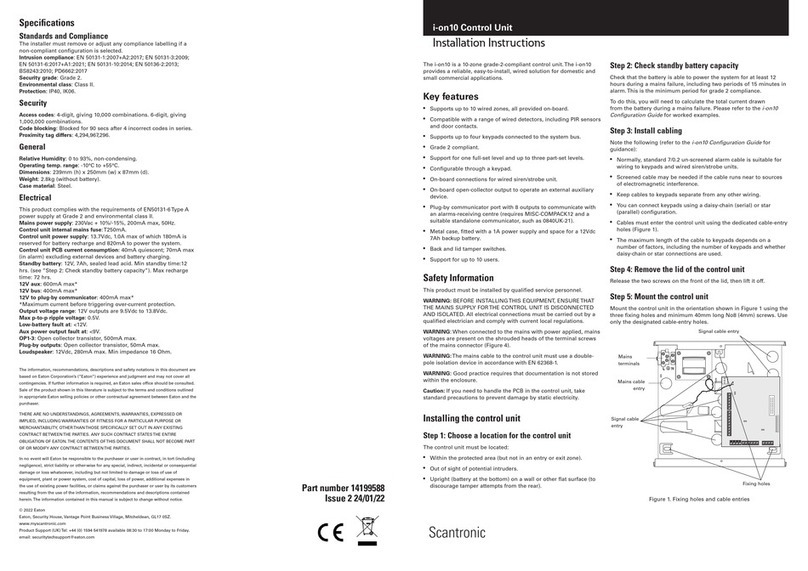

When the machine room supports or is near a

radio or television reception

aerial,

do not putthe controller cabinet inthe aerial receivingzone (figure 1).

BAD

!

GOOD

!

Figure

1

Placingthe frequency driveoutside the aerialreceivingzone

If you can not find a suitable place for the frequency drive cabinet,

get the aerial

moved

!.

Ifthat is not possible, contact

AUTINOR

who will decide along with the building

owner, what measures need to be taken according to the EN 12015 and EN 12016

Standardfor lifts, escalators andpassengersconveyors.

PRÉCAUTIONS TO TAKE.

1.

The power supply arriva1LI, L2, L3

and Earth

(YellowIGreen)

must al1 pass through

the same cable.

2. The power link between the

MBISI

VECTOR

drive and the motor

(II, 12, 13 +

Earth)

must go through the same cable. In order to reduce disturbances a

screened

cable must be used,

(min.

3m50

-

type LIYYCY)

even if the motor cable is

mechanicallyprotected by a tube or metaltrunkway. This screening should consist of at

least one flat cable, the greater the number of flat cables the greater the efficiency of

the screening. The cable should be supple for ease of installation in the machine room

and should complywith EN81 standards.

To be completely efficient the screening must be connected at the

same time

to the

controller metal casing and to the motor metal housing.

In order to reduce any coupling effects, it is advisable to maximise the distance

between the motor cable and the three phase power supply cable, both inside and

..

-

outside the controller ; for the same reason, you~shouldkeep the cables carrying high

current as far apart from those carrying low current as possible. These two types of

cable should not be placed in the same trunkway, nor go through the controller casing

via the same hole.

MB191

VECTOR

Site

manual

page

IO

ELECTROMAGNETIC COMPATlBlLlTY PRECAUTIONS

(314)

At not time should the screening cable replace the yellow-green earthing cable.

:

In order to ensure the electromagnetic compatibility, it may be necessary to use to connect to the

motor, a metal stuffing box with a screening contact allowing an efficient electrical link between the

,flatscreening cable and the metal housing (seefigure below).

If the motor terminal box is isolated, then a metal stuff box is of course useless. The screening

cable should be linked in the shortest way to the motor earth terminal block.

Conventional connection

:

Controller

:

Motor

:

YellowlGreen

earthing

cable

lin

Note:

Keep the rnotor cable as far apart frorn the power cable

Note

The cables should only be separated frorn the screening

as possible, inside as well as outside the controller. once insidethe terminal box.

Connection using stuff-box

:

SCREENING

TERMINAL

CURVED

SEAL

FLAT

CABLE

BOX

WALL

3.

The other links between the

MB191

VECTOR

drive and the motor,

i.e. the brake

(+BR

and

-BR),

the motor thermistor

(OV, STH)

can run together but kept at least

10 cm

from

the power cables.

EXAMPLE

:

MOTOR

SCREENED

CABLE

LI,

L2,

L3

+

EARTH

11,12,13

AND

EARTH

+

SCREENING

-

SUPPLY

CONTROLLER

:O

crnEin

Li,

NEUTRAL

MOTOR

'THERMISTOR

BRAKE

I

HAN'GING

CABLE

SHAFT

WlRlNG

Check of course that the power supply arriva1does not

to the MB191 VECTOR drive and motor link. flow close

MB191

VECTOR

Site manual page

Il

USE OF DIFFERENTALCIRCUIT BREAKER

WlTH AUTINOR FREQUENCY DRIVES

(414)

First of al1 as a reminder

:

The low voltage directive explicitly states that electrical lift installations are excluded relating from

its field of application and so the standards relaring to electrical installations only applies as for as

the input

terminais

of the main lift installation switch (cf

EN

81

§

13.1-1.2)

;

Nevertheless the safety of al1 people must be ensured, and so to do this, we rely as much as

possible on the detail of

C

15-100 taking into account the imperatives concerning lifts.

The standard

C

15-100

§

532.2.1.3 states that

:

«

Les dispositifs de protection

à

courant différentiel-résiduel doivent être choisis et les circuits

électriques divisés de telle manière que tout courant de fuite

à

la terre susceptible de circuler durant le

fonctionnement normal des appareils ne puisse provoquer la coupure intempestive du dispositif.

))

AUTINOR frequency drives have a normal current leakage of 60 mA when the car is stopped or empty

and around 300 mA when loaded. We therefor recornmend the motor be supplied through a differen,tial

circuit breakerwith a differential current

(=

«

sensitivity

»)

16,

=

500 mA.

What is more,

C

15-100 states that for electrical installations cabled conform to the TT diagrams

(installations powered by the public electricity network), people should be protected against indirect

contacts by differential residual current circuit breaker which implies the following of the relation ship

which links the circuit breaker differential current 16, to the maximum conventional voltage of the

U,

contact and of the earthing socket resistance

:

16,

*

RA

I

UL

(NF

C

15-100

§

532.2.4.2)

Protection may be ensured by using a differential circuit breaker with a sensibility of 500 mA,

provided the building's earthing socket resistance is maximum 100 R for a lift installation, whose

maximum conventional voltage of the

UL

contact is 50

V.

It is up to the owner to supply the electrician

with the resistance value of this earthing socket, so that the electrician may ensure that the differential

sensitivity ensures the correct protection against indirect contact.

If the earthing socket resistance exceeds 100 RI the electrician may use an

S

type differential

circuit breaker with a differential current of 300 mA, which will ensure protection against indirect contact

for an earthing socket resistance of up to 167R. You should nevertheless ensure that a

«

full load

))

movement does not break the circuit at the wrong moment.

MB191

VECTOR

Site manual page

12

MINIMUM CONNECTIONS NECESSARY

FOR INITIAL MOVEMENT

(115)

INCREMENTAL ENCODER

STEGMAN HENGSTLER

RED

+24

RED

OV BLUE BLACK

STATE OF

CA1 WHITE WHITE

THE SAFETY LANE

THE

3

LED

(6,8,10)

CBI

Pl

NK GREEN NEED TO BE

Cut the wires which are not used.

BEFORE THE LlFT

Screening cable do not connect.

WlLL MOVE

Wires CA1 and CBI should be crossed

in dependance of your configuration.

To be installed

inthe safety lane

KA1

6

13

Il

1

CONTROLLER

TERMINAL RAIL

1

lncremental

encoder

STEGMAN

~REQUENCY

DRIVE

TERMINAL

RAI^

Iltevice

d

bridging

of

the

sâfety

meesures

of

doors

Figure

2

Minimumconnectionsnecessary for initial n~ovement

MB191

VECTOR Site manual page

13

MINIMUM CONNECTIONS NECESS

FOR INITIAL MOVEMENT

(215)

During the construction phase, you can temporarily use the OV, GMand GD inputs on the

KM12connector for running up and down respectively.

CONNECT

AS

FOLLOWS

:

(see

figure 2

on page

12

for where to make these connections)

Connect the thermistor andlor the motor safety thermo-contact between the

@

STHand OVtermnals on the

KM11

connector.

@

Temporarilv bridge OVand INSon the KC23 connector.

The "up" and "down" push buttons on the inspection box on the car roof to the

@

GM, GDand OVtermnalson the KM12connector.

@

The safety circuits

1s

6,

8

and 10onthe electromechanicalterminalrail.

The traction motor to II,12,13 on the electromechanical terminal rail and the

@

EARTH to the earth collecting bar, as well as the brake power supply

+BR

&

-BR

O

The power supply to LI,L2, L3and Earthto the earth collectingbar.

WARNING

:

DO

NOT CONNECTTHE LI,

L2,

L3

POWERSUPPLY TO

11,12,13

OR YOU RlSK DAMAGINGTHE TRANSISTORS.

CONNECT POINTS

a,

0,

@

FOLLOWINGTHE ELECTROMAGNETIC

COMPATlBlLlTY RECOMMENDATIONSAS SHOWN ON PAGE

10.

Temporarily bridge CS1 and OV on KA13 and possibly CS2 and OV on KA16

@

(when there are

2

door operators).

Connect the four wires on the incremental encoder to the KC22(Bottom)

connector onthe VECOI board.

MB191

VECTOR

Site

manual

page

14

POWER-UP FOR INITIAL MOVEMENT

(315)

1

Switch on-the power

:

I

-

The LEDsshowing the transistors are green.

CUT THE SAFETY LANE

Pleasesee page

17

for the description of how to use the frequency drive

parameterldiagnosticcommunication device

1

Checkingthe transistor control

:

1

1)At address 041, write

55

THE LEDS BECOME RED.

2)

At address 041, write 00

1

'

011

TEST

<

O0

!1

RECUP

x2

XI

Y2

Y1

22

ZI

THE LEDS BECOME GREENAGAIN.

RECUP

x2

XI

Y2

Y1

22

z1

MB191

VECTOR Site

manual

page

15

VVER4.JP FOR

INITIAL

MOVEME

ITO

checkthe capacitor voltage

:

CUT THE SAFENLANE

!

To check the VECIO current measuringdevice

:

Check at addresses 12A and 12Ethat the value is between 500 and 524. If the value are

not coherent, check the connection of the

K8

connector of the

VECOI

board.

To check the incrementalencoder connection

:

I

Check at address

116

on the parameterldiagnostic communication device (see page

64)

that the number of impulses

increases

as you turn the rotor in the

direction

corresponding to

up,

and

decreases

inthe

direction

corresponding to

down.

Turn the

rotor

gently

by hand.

Ifthe number of impulses changes in the wrong direction, inverse the

CA1

and

CBI

wires on

the

KC22(bottom)

connector of the

VECOl

board.

1

Checkthat the parametersare coherent.(see page

48)

:

RECONNECTTHE SAFETY LANE

!

Try an up movementand then adown movement, and check that the liftstarts off in

the requireddirection.

1

Possible faults

:

The system might come upwith one or more of the following fault codes

:

17

:

Phase

failure

or

inversion

of the controller.

102

:

Gap

betweenthe

advised

and

realspeed

of more than

15%

in

SlowSpeed.

100

:

Motor

over-intensity.

+

Cross

two of the motor phases.

+

Check that the encoder is

wired correctly.

62

:

003

tape head

fault.

MBI91

VECTOR

Site manual page

16

POWER-UP FOR

INITIAL

MOVEMENT

(515)

MB191

VECTOR Site

manual

page

17

UENCY DRIVE PARAME

COMMUNICATION

This chapter contains information which will allow you to adapt the

V.F.

equipment to

the specific conditions of the lift onwhich it is installed.

This adaptation is controlled by parameters, which you can modify according to your needs

using the removable parameter1diagnostic communication device as described below inthe

paragraph

Accessing the parameters.

The parameters are memorised in a particular type of chip called an

EEPROM

1

(or

E2PROM) which

keeps the information even when the equipment is switched

off.

Each parameter is linked to an

abridçied name

and an

address

which corresponds

to the position at which it is memorised in the EEPROM chip.

Accessincl the

ara met ers

As mentioned above, you can see and modify the parameters using the

parameterldiagnostic communication tool

;

this consists of a 16 character

LCD

display with

four push buttons, which is connected to the

VECOI

board by a standard MalelFemale Sub-

D

9

pt cable.

'UNITS

'TENS

1

EEPROM

stands

for

Electrically Erasable Programable Read Only Memory.

TO MODIFY THE VALUES

-

L~~

VALIDATE THE DATA

RESET TO ZERO

MB191

VECTOR

Site manual page

18

TO

ACCESS

THE PARAMETERS AND THE INPUT-OUTPUT INFORMATION

O

Power-up the equipment, the display shows

:

MODIF. CLEAR VALID.

m

Eachtime you press

1

the value shown will increase by

1.

Eachtime you press

10

the value shown will increase by

10.

Eachtime you press

100

the value shown will increase by

100.

Eachtime you press

1000

the value shown will increase by

1000.

Choosincr the lanciuacie

O

The parameterldiagnostic communication device is preset to the language of the

destination country. There are four options which appear at address

027

as follows

:

FRANCE, ENGLISH, DEUTSCH, ESPAGNOL.

Press twice button

10,

Press both

MODlF

buttons Press button

1

and choose the

then

7

times button

1,

at the same ,tirne required language.

for address

027

1

[

027

Country FRANCE

11

II

MDF Country FRANCE

11

I[

MDF Country ENOLISH

II

MODIF. CLEAR VALID.

Register the required language by pressing both

VALlD

buttons at the same time

Country ENGLISH

11

MODIF. CLEAR VAI-ID.

0000

..

\

The language in our example is

English

MB191VECTOR Site manual page 19

Other example

:

VIEWING

THE INCREMENTAL ENCODER IMPULSES

[SEE

PAGE

15).

Resetthe display to address 000

by pressing ,the

CLEAR

buttons

simultaneously

MODIF. CLEAR VALID.

The value displayed at address

II

6

increases when the rotor turns

inthe

upwards

direction

MODIF. CLEAR VALID.

m

Display address

11

6 using

buttons 100,10and

1

MODIF. CLEAR VALID.

The value displayed at address

116

decreases when the rotor turns

inthe

downwards

direction

MODIF. CLEAR VALID.

m

TRANSFER

OF THE SETTINGS INCLUDEDINTHE

VVVF

TOWARD THE DIAGNOSTIC TOOL.

Press the

2

end buttons to make Validate by pressing the Pressthe

2

end buttons

«

READ PARAMETERS

))

«

VALID

))

buttons to return to normal mode

appear.

.

...

.

Transfert

1-1

READ

PARAMETERS

[REI\DIII~]

MODIF. CLEAR VALID. MODIF. CLEAR VALID. MODIF. CLEAR VALID.

TRANSFER

OF THE SETTINGS INCLUDED IN THE DIAGNOSTIC TOOL TOWARD THE

VVVF.

Press the

2

end buttons, Display Validate by pressingthe Press the

2

end buttons to

you read,

«

WRlTE PARAMETERS

))

«

VALID

»

button returnto normal mode

«

READ PARAMETERS

))

usingbutton

1

.....

Transfer

[RE*OPIR*METWS]

[[[]

[j]

[ml

1000 100 10

1

1000 100 10 1 1000 100 10

1

1000 100 10 1

MODIF. CLEAR VALID.

~-~-~-$Jx

1

MODIF. CLEAR VALID.

TO

REMIND YOURSELF OF THE ADDRESS

If you forget the address you are changing, or the previous value

shown, just press both

MODIF

buttons.

MODIF. CLEAR VALID.

MB191

VECTOR

Site manual page

20

TO

CHANGE THE PARAMETERS IN DECIMAL MODE

After selecting the required language (see previous page) you can access the parameters and

change them

if

required.

Resetthe display by pressing To change the V2 speed for Press both

both CLEAR buttons example, display address 004 MODlF buttons

at the same time by pressing button 1 at the same time

MODIF. CLEAR VALID.

Press button 10

5

times to obtain

the desired speed

MODIF. CLEAR VALID.

Registerthe new speed by

pressing both VALlD buttons at

the same time

MODIF. CLEAR VALID.

5x

MODIF. CLEAR VALID.

0jO-Q

TO

CHANGE THE PARAMETERS IN SEGMENT MODE

You can access the options using segments and change them if so desired.

SegO

:

IG,

Segl

:

NOBAND,

Seg2

:

BATTERY,

Seg3

:

MLI,

Seg4

:

RETSEC,

Seg5

:

APPDIR,

Seg6

:

D65",

Seg7

:

ML220V

Reset the display by pressing Displayaddress OOE Press both MODlF buttons

both CLEAR buttons by pressing button 1 at the same ,tirne

at the same time

MODIF. CLEAR VALID.

Press button 10 Press button 1

to obtain the required segment to activate segment

5.

example

:

Direct approach.

1

MODIF. CLEAR VALID.

5x

Registerthe new data inthe

memory by pressing both VALlD

buttons at the same time.

MODIF. CLEAR VALID.

Table of contents