Scantronic

Specications

Standards and Compliance

The installer must remove or adjust any compliance labelling if a

non-compliant configuration is selected.

Intrusion compliance: EN 50131-1:2007+A2:2017; EN 50131-3:2009;

EN 50131-6:2017+A1:2021; EN 50131-10:2014; EN 50136-2:2013;

BS8243:2010; PD6662:2017

Security grade: Grade 2.

Environmental class: Class II.

Protection: IP40, IK06.

Security

Access codes: 4-digit, giving 10,000 combinations. 6-digit, giving

1,000,000 combinations.

Code blocking: Blocked for 90 secs after 4 incorrect codes in series.

Proximity tag differs: 4,294,967,296.

General

Relative Humidity: 0 to 93%, non-condensing.

Operating temp. range: -10°C to +55°C.

Dimensions: 239mm (h) x 250mm (w) x 87mm (d).

Weight: 2.8kg (without battery).

Case material: Steel.

Electrical

This product complies with the requirements of EN50131-6Type A

power supply at Grade 2 and environmental class II.

Mains power supply: 230Vac + 10%/-15%, 200mA max, 50Hz.

Control unit internal mains fuse: T250mA.

Control unit power supply: 13.7Vdc, 1.0A max of which 180mA is

reserved for battery recharge and 820mA to power the system.

Control unit PCB current consumption: 40mA quiescent; 70mA max

(in alarm) excluding external devices and battery charging.

Standby battery: 12V, 7Ah, sealed lead acid. Min standby time:12

hrs. (see “Step 2: Check standby battery capacity”). Max recharge

time: 72 hrs.

12V aux: 600mA max*

12V bus: 400mA max*

12V to plug-by communicator: 400mA max*

*Maximum current before triggering over-current protection.

Output voltage range: 12V outputs are 9.5Vdc to 13.8Vdc.

Max p-to-p ripple voltage: 0.5V.

Low-battery fault at: <12V.

Aux power output fault at: <9V.

OP1-3: Open collector transistor, 500mA max.

Plug-by outputs: Open collector transistor, 50mA max.

Loudspeaker: 12Vdc, 280mA max. Min impedance 16 Ohm.

The information, recommendations, descriptions and safety notations in this document are

based on Eaton Corporation’s (“Eaton”) experience and judgment and may not cover all

contingencies. If further information is required, an Eaton sales office should be consulted.

Sale of the product shown in this literature is subject to the terms and conditions outlined

in appropriate Eaton selling policies or other contractual agreement between Eaton and the

purchaser.

THERE ARE NO UNDERSTANDINGS, AGREEMENTS, WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY, OTHERTHAN THOSE SPECIFICALLY SET OUT IN ANY EXISTING

CONTRACT BETWEEN THE PARTIES. ANY SUCH CONTRACT STATES THE ENTIRE

OBLIGATION OF EATON. THE CONTENTS OFTHIS DOCUMENT SHALL NOT BECOME PART

OF OR MODIFY ANY CONTRACT BETWEEN THE PARTIES.

In no event will Eaton be responsible to the purchaser or user in contract, in tort (including

negligence), strict liability or other-wise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage or loss of use of

equipment, plant or power system, cost of capital, loss of power, additional expenses in

the use of existing power facilities, or claims against the purchaser or user by its customers

resulting from the use of the information, recommendations and descriptions contained

herein. The information contained in this manual is subject to change without notice.

© 2022 Eaton

Eaton, Security House, Vantage Point Business Village, Mitcheldean, GL17 0SZ.

www.myscantronic.com

Product Support (UK) Tel: +44 (0) 1594 541978 available 08:30 to 17:00 Monday to Friday.

i-on10 Control Unit

Installation Instructions

The i-on10 is a 10-zone grade-2-compliant control unit.The i-on10

provides a reliable, easy-to-install, wired solution for domestic and

small commercial applications.

Key features

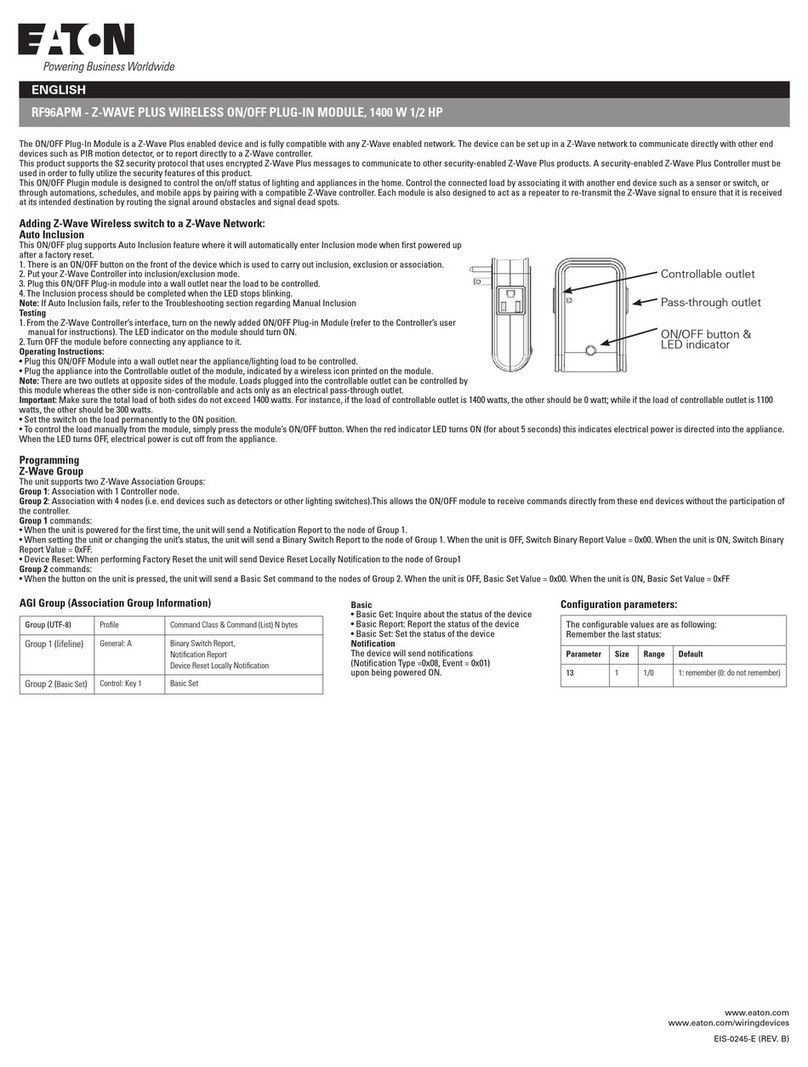

•Supports up to 10 wired zones, all provided on-board.

•Compatible with a range of wired detectors, including PIR sensors

and door contacts.

•Supports up to four keypads connected to the system bus.

•Grade 2 compliant.

•Support for one full-set level and up to three part-set levels.

•Configurable through a keypad.

•On-board connections for wired siren/strobe unit.

•On-board open-collector output to operate an external auxiliary

device.

•Plug-by communicator port with 8 outputs to communicate with

an alarms-receiving centre (requires MISC-COMPACK12 and a

suitable standalone communicator, such as 0840UK-21).

•Metal case, fitted with a 1A power supply and space for a 12Vdc

7Ah backup battery.

•Back and lid tamper switches.

•Support for up to 10 users.

Safety Information

This product must be installed by qualified service personnel.

WARNING: BEFORE INSTALLING THIS EQUIPMENT, ENSURE THAT

THE MAINS SUPPLY FORTHE CONTROL UNIT IS DISCONNECTED

AND ISOLATED. All electrical connections must be carried out by a

qualified electrician and comply with current local regulations.

WARNING: When connected to the mains with power applied, mains

voltages are present on the shrouded heads of the terminal screws

of the mains connector (Figure 4).

WARNING: The mains cable to the control unit must use a double-

pole isolation device in accordance with EN 62368-1.

WARNING: Good practice requires that documentation is not stored

within the enclosure.

Caution: If you need to handle the PCB in the control unit, take

standard precautions to prevent damage by static electricity.

Installing the control unit

Step 1: Choose a location for the control unit

The control unit must be located:

•Within the protected area (but not in an entry or exit zone).

•Out of sight of potential intruders.

•Upright (battery at the bottom) on a wall or other flat surface (to

discourage tamper attempts from the rear).

Step 2: Check standby battery capacity

Check that the battery is able to power the system for at least 12

hours during a mains failure, including two periods of 15 minutes in

alarm. This is the minimum period for grade 2 compliance.

To do this, you will need to calculate the total current drawn

from the battery during a mains failure. Please refer to the

i-on10

Configuration Guide

for worked examples.

Step 3: Install cabling

Note the following (refer to the

i-on10 Configuration Guide

for

guidance):

•Normally, standard 7/0.2 un-screened alarm cable is suitable for

wiring to keypads and wired siren/strobe units.

•Screened cable may be needed if the cable runs near to sources

of electromagnetic interference.

•Keep cables to keypads separate from any other wiring.

•You can connect keypads using a daisy-chain (serial) or star

(parallel) configuration.

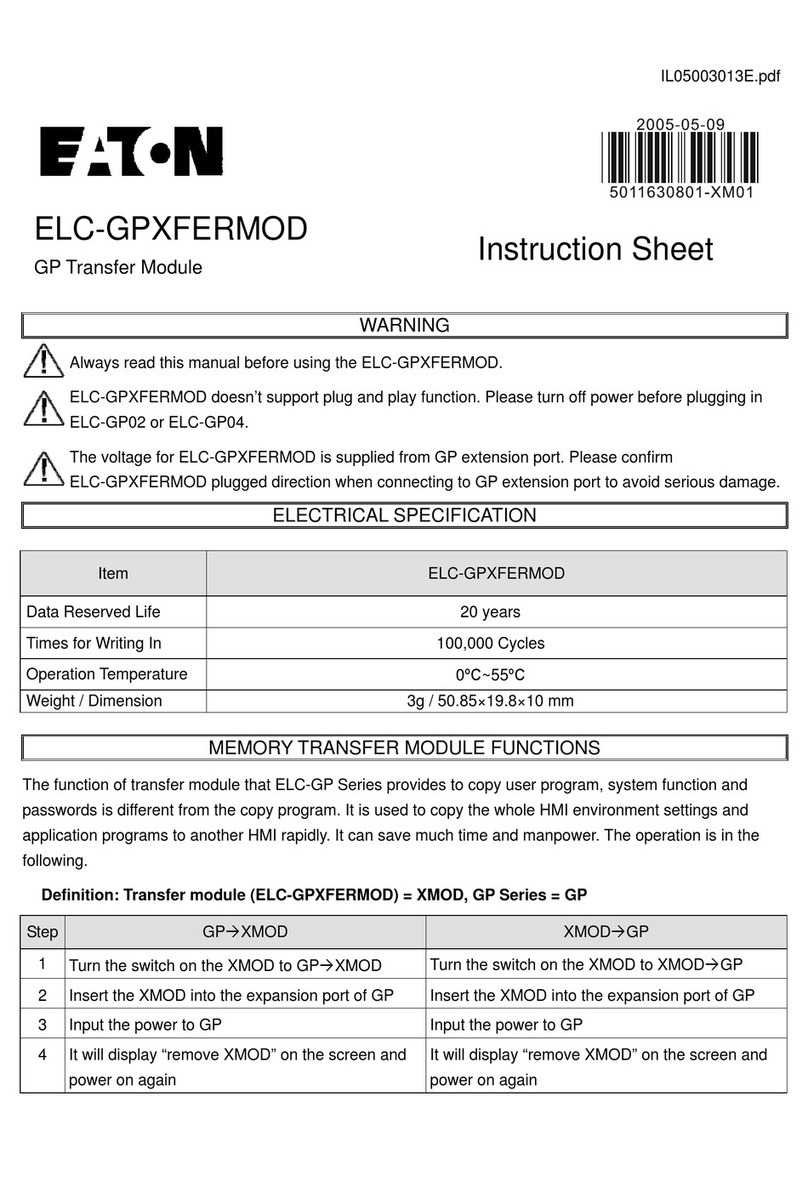

•Cables must enter the control unit using the dedicated cable-entry

holes (Figure 1).

•The maximum length of the cable to keypads depends on a

number of factors, including the number of keypads and whether

daisy-chain or star connections are used.

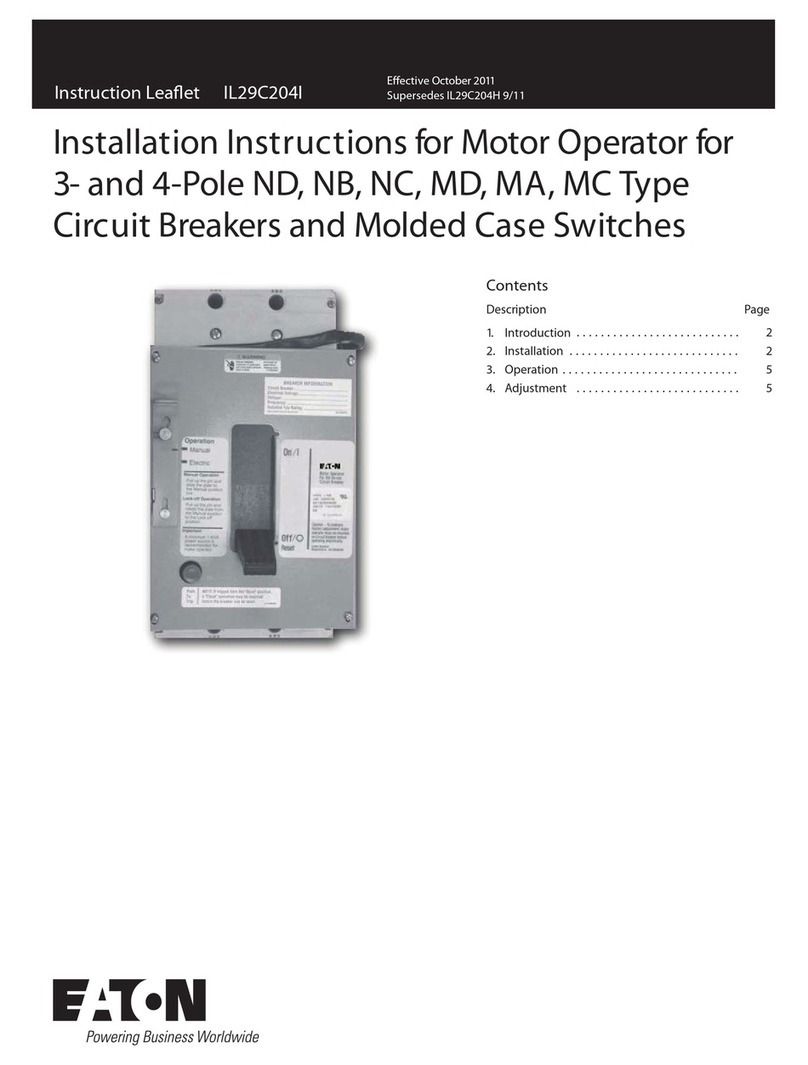

Step 4: Remove the lid of the control unit

Release the two screws on the front of the lid, then lift it off.

Step 5: Mount the control unit

Mount the control unit in the orientation shown in Figure 1 using the

three fixing holes and minimum 40mm long No8 (4mm) screws. Use

only the designated cable-entry holes.

L N

Mains cable

entry

Signal cable

entry

Mains

terminals

Fixing holes

Signal cable entry

Figure 1. Fixing holes and cable entries

Part number 14199588

Issue 2 24/01/22