Sit 849 Sigma MOD-S Technical manual

9.957.113 C00

ONLY FOR VERSIONS WITH VENT DIAMETER LARGHER THAN 0.56 mm

SIT code: 0.xxx.xxx

849 Sigma MOD-S

USE AND INSTALLATION INSTRUCTIONS

Read the instructions before use. This control must be installed in accordance with the rules in force.

2

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

1

3

7

7

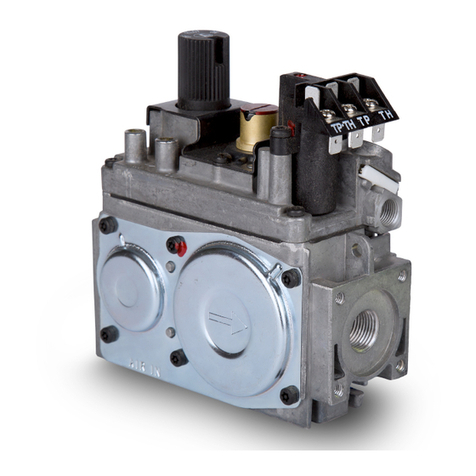

Fig. 1

4

6

2

5

3

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

MAIN FEATURES

•

Inlet filter (FL)

•

Inlet and outlet pressure test points with “captured” screws (Pin, Pout)

•

Servo pressure regulator (PR)

•

Current controlled modulating device (MD)

•

Gas flow sensor (SENS)

DESCRIPTION

See Fig. 1:

1. Inlet pressure test point (Pin)

2. Outlet pressure test point (Pout)

3. Modulating device terminals

4. Gas flow sensor terminals

5. Gas inlet with protective dust cover

6. Gas outlet with protective dust cover

7. Valve mounting holes

GAS

INLET

FLI

EV1

RP

EV2

MAIN

BURNER

PILOT

BURNER

FLP

FLO

PA

GAS

INLET

FL PR

PILO

T

BURNER

FLP

PA

MD

Pin

RESTRICTOR

GAS

OUTLET

SENS

Pout

Multifunctional gas control with a pressure regulator, a current controlled modulating device and a

gas flow sensor. The location for gas orifice (restrictor) is on the outlet of the multifunctional control.

The control is designed for use in domestic gas appliances using 2nd and 3rd gas families.

The designed lifetime* of this product is 500 000 cycles or 10 years (based on date code)

according to the standard EN 126 and the table on designed lifetime as stated in the Afecor

document, see http://www.afecor.org/news.html.

This lifetime is based on the use of the control in accordance with the appliance manufacturer’s

instructions.

Regular inspection of the control by authorized personnel in accordance with guidelines of the

appliance manufacturer is required.

After reaching the designed lifetime the product has to be replaced by authorized personnel.

*The warranty as opposed to the designed lifetime is described in the delivery terms.

4

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

TECHNICAL DATA

The technical data specified below refers to the European standards EN 126 “Multifunctional

controls for gas-burning appliances”.

Gas families 2nd, 3rd

Maximum inlet pressure 60 mbar

Ambient temperature range 0 to 60 °C

Storage temperature range -30 to 70 °C

Torsion and bending resistance Group 2

Maximum Humidity 95% RH at 40 °C

Assembly position All positions except upside down

Inlet gas connection Suitable for nut compliant with male G3/4 B ISO 228

Outlet gas connection Suitable for nut compliant with male G3/4 B ISO 228

Pressure test point ∅9 mm

Pressure regulating function

This is obtained by means of the servo regulator type with pressure compensation connection.

Pressure regulator Class B

Minimum gas flow 0.03 m3/h for 2nd family gas (G20)

Capacity @ 5 mbar pressure drop More than 1.6 m3/h (G20)

Modulating function

The pressure Pint is function of the modulator dc current. The reference of the pressure regulator is

the pressure at GAS OUTLET, internally connected.

Therefore the differential pressure across the gas orifice DP (= Pint – GAS OUTLET) is function of

the modulator current, see graph below.

α=0

α

α=π/2

Response time Less than 2 seconds

Maximum modulator voltage @20°C [V]10

Modulator modulator current @20°C [mA]40

Modulator resistance @20°C [W] 176 ± 6%

Offset [mbar] , see Fig. below 4.35 ( cosa - 1)

5

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

0

2

4

6

8

10

12

14

16

Modulator current [mA]

∆P [mbar]

Modulating characteristic with vertical modulator axis (α=0)

a

a=0

OFFSET

Gas Flow Sensor diagram

Output sensor [reading as decimal fixed point].

0

3000

6000

9000

12000

15000

18000

0100 200 300 400 500 600

MASS FLOW [Nl/h]

OUTPUT VALUE

G31

G271

G21

G20

Gas Flow Sensor

Supply voltage 3.3 Vdc

Output I2C protocol

6

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

INSTALLATION

849 Sigma MOD-S conforms to current safety standards. Installation on appliances must

nevertheless be checked with respect to the specific installation requirements for the appliance.

All the installation and adjustment operations must be carried out exclusively by qualified

personnel and on the basis of the specific characteristics of the user appliance and following the

instructions given in this booklet. All other operations are absolutely forbidden.

The control is not suitable for outdoor operation.

WARNING

CONDENSATION, FORMATION OF ICE AND INGRESS OF WATER ON

THE GAS VALVE ARE NOT PERMITTED.

WARNING

849 SIGMA MOD-S MUST BE USED SO THAT THERE CAN BE NO

GAS DEMAND IF THERE IS NO AIR FLOW.

IMPORTANT

Do not tamper with sealed parts

Do not remove labels

Only remove dust caps when installing (dust caps do not guarantee

sealing)

Do not exceed recommended torques

Use only the specified spanner grips shows in Fig.3 when making the

connections

Turn off gas supply before starting installation

WARNING

DO NOT SLACKEN ASSEMBLY SCREWS

WARNING

AVOID BLOWS (KNOCKS, FALLS ETC.)

WARNING

ENSURE THAT THE GAS FLOWS IN THE DIRECTION SHOWN BY

THE ARROW ON THE VALVE BODY

WARNING

DO NOT IMMERSE IN WATER OR SUBJECT THE MULTIFUNCTIONAL

GAS CONTROL TO TEMPERATURES EXCEEDING 70°C

WARNING

IF A SINGLE VALVE FALLS, DO NOT USE FOR PERFORMANCE AND

SAFETY REASONS

7

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

WARNING

DO NOT SUBJECT THE VALVE TO BENDING IN EXCESS OF 35 NM

AND TORQUE IN EXCESS OF 25 NM

WARNING

IN CASE OF OVERPRESSURE OF THE INPUT GAS ON THE VALVE

GREATER THAN 1 BAR, REPLACE THE VALVE.

WARNING

DO NOT OPEN, INTERFERE WITH OR MODIFY THE VALVE.

WARNING

IN GENERAL, USE NEW GASKETS AFTER REMOVING AND PUTTING

BACK OF ANY PARTS.

Gas restrictor fitting

See the figures below and follow the sequence (a) - (b). Insert completely the restrictor into the

outlet gas connection. Make sure that the restrictor does not interfere with the reference pressure

opening located inside the gas outlet, see the detail in the enlarged picture below.

(a)

(b)

Restrictor

Reference pressure opening

Restrictor

8

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

Gas inlet Gas outlet

Pipe

Connection with gasket

Locking ring

Gasket

Pipe

Connection with gasket

Locking ring

Gasket

Inlet and outlet gas connections with gasket

Use gas pipes with a suitable flat annular surface to allow the use of a sealing gasket, see Fig 2.

In particular for outlet connection, make sure that the gasket does not interfere with

the fitted restrictor and make sure that the surface of the gasket does not obstruct the

space beetwen the restrictor and the outlet pipe, see enlarged view in Fig.2.

The locking ring thread shall comply with ISO 228.

Ensure the gasket is suitable for the application.

Apply the proper torque to the locking ring, according to the washer characteristics, in order to

ensure the seal.

Fastening torque: maximum 50 Nm

minimum 30 Nm

WARNING

DO NOT OVER-TIGHTEN THE LOCKING RING. COUNTERBALANCE

THE TORQUE (SEE EXAMPLE IN FIG. 3).

Fig. 3

Fig. 2

Restrictor Gasket

41 mm

9

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

Electrical connections

All electrical connections must be made in accordance with current electrical standards. Check

that the voltages given to the modulator and to the sensor are correct. Disconnect the power

supply before starting installation. Check that all connections are made properly

The modulator is supplied with a male contact Molex compatible, suitable for female Molex series

70066 connector.

The gas flow sensor is supplied with a male contact Molex compatible, suitable for female Molex

series 87369 connector.

Check that the polarity of the connections are made properly as shown in Fig. 4.

Make the connections as specified in the technical instructions for the automatic burner control

used and/or in the specific standards for the appliance.

Wiring diagram

The connection diagram is given in Fig. 4.

1

2

3

4

EV1

EV2

MD

Fig.4

WARNING

CONDENSATION, FORMATION OF ICE AND INGRESS OF WATER ON

THE COIL TERMINALS ARE NOT PERMITTED.

CLK

V+

GND

DATA

10

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

SETTINGS AND ADJUSTMENTS

There are not any adjustments in this multifunctional control. Check inlet and intermediate

pressure using the pressure test points provided. To open the pressure test points use a 4.9 mm

screwdriver for slot-head screws. After setting, carefully seal test points ensuring gas soundness.

Recommended torque: 1.0 Nm.

At the end of all checking operations, check electrical insulation, gas seals and

the safety of the appliance. Finally ensure that the burner operates properly at

the minimum and maximum power of the appliance.

IMPORTANT

11

849 Sigma mOD-S USE aND iNSTaLLaTiON iNSTRUCTiONS

DIMENSIONAL DRAWING OF THE MULTIFUNCTIONAL GAS CONTROL

Table of contents

Other Sit Control Unit manuals