AUTOFLAME MK8 EGA EVO Manual

M

d

A

m

t

Mk8

an

E.G.A.

Se

t

-

Up

Trim

Gui

d

e

Mk8

尾气

分析仪设置

和调节指南

Mk8

E.G.A. Set-Up

and

Trim

Guide

Mk8 尾气分析仪设置和调节指南

Issued

by 发布公司:

AUTOFLAME

ENGINEERING

LTD

AUTOFLAME 工程有限公司

Unit 1-2,

Concorde Business

C

entre

Airport Industrial

Estate,

WirelessRoad

Biggin

Hill, Kent TN16

3YN

Tel:

+44 (0)845 872

2000

电话:

+44 (0)845 872

2000

Fax: +44 (0)845 872

2010

传真:+44 (0)845 872

2010

Email: [email protected]

电子邮件:

Website:

http://www.autoflame.com/

网站:

http://www.autoflame.com/

Registered

Holder 注册持有人:

Company 公司:

Department 部门:

This

manual and all the information

contained

herein

is copyright

of

Autoflame

Engineering Ltd.

It may not be

copied

in the whole or part without

the

consent

of the Managing

Director.

Autoflame工程有限公司拥有本手册的所有版权。在未经Autoflame公司常务董事同意的情况

下,本手册内容不得被整体或部分引用。

Autoflame

Engineering Ltd’s policy is

one of

continuous

improvement in

both

design

and manufacture. We therefore reserve the right to

a

m

end

specifications

and/or data without prior

notice.

All details

contained

in

this

manual are

correct

at the time of going to print.

Autoflame工程有限公司致力于不断提升Autoflame产品的设计和制造,我们保留修订本手册

规范/数据的权利,恕不另行通知。本手册内容于付印时准确无误。

Important

Notes

重要说明

A knowledge of

combustion

related

procedures

and

commissioning is essential

before

embarking work on any of the M.M./E.G.A.

systems. This

is for safety reasons and

effective

use

of the

M.M./

E.G.A. system.

Hands on training

is

required. For details on

schedules

and

fees

relating to group training

courses

and individual

instruction,

please

contact

the Autoflame

Engineering Ltd. offices

at the

address listed

on the front.

为了安全有效地使用控制模块/EGA 系统,控制模块/EGA 系统的操作员必须具有与燃烧相关的流程

知识和调试知识。我们要求操作员参加实践培训,请按首页所述地址联系上 Autoflame 办公室详细

了解团体培训课程和个别辅导的时间和费用。

Short Form -

General

Terms

and

Conditions

一般条款

A full statement of our

business terms

and

conditions

are printed on the reverse of

all

invoices.

A copyof

these can

be

issued

upon application, if requested in

writing.

所有发票背面均都印有我方商业条款全文。客户可书面申请获取我公司的商业条款文件。

The

System

equipment

and

control

concepts

referred to

in

this

Manual

MUST

beinstalled,

commissioned

and applied by

personnel skilled

in the various

technical disciplines

that

are inherent to the Autoflame

product

range, i.e.

combustion, electrical

and control.

仅有专业人员才能安装、调试、使用本手册所提及的系统设备和控制原理。他们必须精通 Autoflame

产品所涉及的燃烧、电气和控制等技术学科。

The

sale of Autoflame’s

systems

and equipment referred to in

this

Manual

assume

that

the dealer,

purchaser

and installer has the

necessary skills

at

his disposal.

i.e. A high

degree of

combustion

engineering experience, and a thorough understanding of the

local electri

c

al

codes

of

practice concerning boilers, burners

and their ancillary systems

and equipment.

经销商、采购商和安装人员必须具有丰富的燃烧工程从业经验、全面了解当地涉及锅炉、燃烧器和辅

助系统/设备相关的电气行业规范方能使用本手册提及的 Autoflame 系统和设备。

Autoflame’s warranty from point of sale is two years on all

electronic systems

and

components.

Autoflame 保修条款: 对所有电子系统和部件实行两年售后保修。

One year on all

mechanical systems, components

and sensors.

对所有机械系统、部件和传感器实行一年售后保修。

The

warranty

assumes

that all equipment supplied will be used for the purpose that

it was intended and in

strict compliance

with our

technical

recommendations.

Auto

-

flame’s warranty and guarantee

is

limited

strictly

to

product

build quality, and design.

Excluded

absolutely are any

claims

arising from

misapplication, incorrect

installation

and/or

incorrect

commissioning.

保修前提: 所有设备均按预期使用目的使用并严格遵守我方提供的的技术建议。Autoflame 产品保修

条款仅适用于产品制造质量问题和设计问题。根据保修条款,Autoflame 不接受因误操作、误安装和/

或调试导致的任何索赔请求。

Contents 目录

1

INTRODUCTION

前言

.................................................................................. 1

1.1

Overview and

Benefi

ts

.

概述与优点

.. ........................................................................

1

1.1.1

Features and

Benefits

.

特点与优点

. .......................................................................

1

1.1.2

System

Operation

系统运行

..........................................................................

1

1.1.3 Mk8

E.G.A. vs

Mk7

E.G.A.

Mk8 和Mk7 尾气分析仪

......................................................

2

1.2

3-Parameter Trim

3参数调节

..... ................................................................................................

2

1.3 Continuous Emissions

Monitoring

System

持续排放检测系统

.... ...............................................

3

2 WIRING AND

CO

MP

ONENTS

.

接线和主件

....................... ...... ...... ............... 4

2.1

Flying Lead Wiring

Diagram

.

飞线接线图

.............................................

4

2.2

Electrical

S

c

he

matics

.

电气原理图

............................................. ................................................

6

2.2.1

Interconnection between E.G.A. and

Mk7

M.M.

...........................................................

6

尾气分析仪和 Mk7 控制模块的互连

2.2.2

Interconnection between E.G.A. and

Mini Mk8 M.M.

Module

....... .................................

7

尾气分析仪和 Mk8 微型控制模块的互连

2.2.3

Interconnection between Stand-Alone

Mk8

E.G.A. and

Mk7

D.T.I.

............

8

单机 Mk8 尾气分析仪和 Mk7OTI 的互连

2.2.4

Interconnection between

Mk7 M.M., Mk8

E.G.A. and

Mk7

D.T.I.

.......................

9

Mk7 控制模块、Mk8 尾气分析仪和 Mk7 数据传输接口的互连

2.3

Components

组件

......... ....................................................................................

10

2.3.1

Inside View

内视图

. .......................................................................................

10

2.3.2

E.G.A. Connections.

尾气分析仪的连接

...............................................................

11

2.4

Cell Characteristics

感应器特点

.. ......................................................................

12

2.4.1 O2

Cell..

O2感应器

............................................... ........ ........ ........ ........ ......................

12

2.4.2

CO,

NO, NO2

and

SO2

Cells

.

CO,

NO, NO2

和

SO2感应器

...... ....................................

13

2.4.3

CO2

Sens

or

..

CO

2

传感器

......... ............................................. .........................................

13

3.

SET-

UP

..

设置

.

..................................................................................................14

3.1

E.G.A. Set-Up

尾气分析仪的设置

.........................................................................................

14

3.1.1

Sampling Screen

采样屏幕

............................................................................................

14

3.1.2 Mk8

E.G.A. Settings

.

Mk8 尾气分析仪的设置

...................................................

16

3.1.3

Cell Status

S

c

r

een

.

感应器状态屏幕

.................................................................

17

3.1.4

Fault

History

故障历史

.....................................................................................................

18

3.1.5

Factory Settings Screen

..

出厂设置屏幕

................................................

20

3.1.6

4-20mA

Set-u

p

.

4-20mA

设置

............................................................

21

3.1.7

Operating Mode Set-up.

运行模式设置

..............................................................

22

3.1.8

Time

and Date .

时间和日期

..............................................................

23

3.1.9

Change

Password

.

更改密码

..... ....................................................................................

24

3.2

CEMS Set-Up

CEMS 设置

........ .............................................................................

25

3.2.1

Fuel

Selection.

燃料选择

......... .........................................................................

25

3.2.2

Fuel

Flow Source

燃料流量源

....... ..............................................................................

27

3.2.3

Unit Measurement

设备测量

......... ............................................................................

28

3.3

CEMS

Data Screens..

CEMS

数据屏幕

....... ............................................................................

29

3.4

CEMS

Energy Audits .

CEMS 能源检查

............. ...................................................................

33

3.5

Trim

Settings..

调节设置

................ .............................................................................

35

3.5.1

Relevant

Mk7 M.M.

Opti

on

s

............ ....................................................................

35

Mk7 控制模块相关选项

3.5.2

Relevant

Mk7 M.M.

Parame

ters

......... ......................................................................

38

Mk7 控制模块相关参数

3.5.3

Relevant

Mini Mk8 M.M.

Op

tions

......... ..........................................................................

41

Mk8 微型控制模块相关选项

3.5.4

Relevant

Mini Mk8 M.M.

Parameters...... ....................................................................

44

Mk8 微型控制模块相关参数

3.5.5

Commissioning

Procedure.

调试流程

.... .........................................................................

46

3.6 Mk8

E.G.A.

T

r

im

........... ..................................................................................

47

Mk8 尾气分析仪的调节

3.6.1

Trim

Operation

调节操作

........ ..............................................................................

47

3.6.2

Quick Commission

Mk7

M.M.

... .............................................................................

49

快速调试 Mk7 控制模块

3.6.3

Quick Commission

Mini Mk8

M.M.

... ......................................................................

50

快速调试 Mk8 微型控制模块

3.6.4

Trim Timing

Operation .... ............................................................................

51

调节定时操作

3.6.5

Graphical Trim

Operation .. ...................................................................................

52

图形调节操作

3.6.6

Channel

5

Trim

....... ...................................................................................

53

通道 5的调节

3.6.7

Combustion Efficiency Calculations

.... ................................................................

53

燃烧效率的计算

3.7

Combustion

Limits

燃烧限值

................... .....................................................................................54

3.7.1

Overview

of

Combustion Limits

燃烧限值概述

...............................................................

54

3.7.2

Standard

Limits

标准限值

........... ........................................................................

54

3.7.3

Absolute

Lim

i

t

s

.

绝对限值

........ .....................................................................

54

3.7.4

Combustion Limits Control

F

uncti

on

s

..... .............................................................

54

燃烧限值控制功能

3.7.5 O2

Limits Example

氧气限值示例

....... ......................................................................

55

3.7.6 NO

Limits

Exam

ple

...... .....................................................................

56

一氧化氮限值示例

3.7.7

CO L i m i t

Exa

m

p l e

.......................................

57

一氧化碳限值示例

3.7.8

Temperature Limits

Exam

p

l

e

温度限值示例

....... .............................................................

58

3 DIMENSIONS AND

EQUIPMEN

T

尺寸和设备

.. .................... 59

4.1 Mk8

E.G.A. Dimensions.. ..................................................................

59

Mk8 尾气分析仪尺寸

4.2

Technical Specifications

技术规范

......... .................................................................

60

4.3

Sampling Probe

采样探头

............. ................................................................

61

4.3.1

Installation and Maintenance .

安装和维护

.. ................................................................

61

4.3.2

Sampling Probe Assembly

.

采样探头总成

.... .................................................................

62

4.3.3

Sampling Probe Internal Filter

...... ...............................................................

63

采样探头内部过滤器

4.3.4

Sampling Probe Maintenance . ................................................................

64

采样探头的维护

4.3.5

Servicing E.G.A. Sampling Probe

. .............................................................

64

尾气分析仪采样探头的维护

4.4

Ancillary Equipment.

辅助设备

...... ...........................................................

65

4.4.1

External Particulate

F

ilter

.

外部微粒过滤器

......... ..........................................................

65

4.4.2 Air

Inlet Filter

.

进气过滤器

.............................................................................................

66

4.4.3

Chilled Environmental

Encl

o

s

ure.

冷却环境保护罩

..................................... ...................

67

4.4.4

Pre-Heat

Air

Sensor

预热空气传感器

................ ................ ................ ...........................

68

5.

ERROR CHECKING

AND

SELF-DIAGNOSTICS

错误检查和自诊断

......................... 69

5.1

E.G.A.

Faul

ts

.

尾气分析仪故障

.............................................................................................

69

5.2

Troubles

hoo

t

i

n

g

故障排除

.......................................................................................................

70

5.2.1

Ambient Conditions

环境条件

............. .......................................................................

70

5.2.2

Fuses

保险丝

....................................... .......................................................................

70

5.2.3 O2

Reading .

氧气读数

...................... .........................................................................

70

5.3 Mk8

E.G.A. Faults

Mk8 尾气分析仪故障

........ .............................................

71

5.3.1

Trim

Delay

调节延迟

......................... ........................................................

73

5.3.2

Assembly

of

Dry Filter

干滤器的组装

........ .............................................................

73

5.4

E.G.A. Best

Pr

actice

............. ........................................................

74

尾气分析仪的最佳应用

5.4.1

Servicing the E.G.A.............. .............................................................

75

尾气分析仪的维护

5.4.2

Shipping the

E.G.

A.

......... ................................................................

75

尾气分析仪的运输

6

STANDARDS

标准

.........................................................................................

76

1

Introducti

on

前言

29.05.2015

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

Page

1

1

INTRODUCTION

前言

1.1 Overview and Benefits

概述与优点

1.1.1

Features

and

Bene

fits

特点与优点

The

Mk8

Exhaust

Gas Analyser (E.G.A.)

monitors

the

emissions

in the flue produced from the

burner/boiler

system. The

E.G.A. can improve

combustion,

increase efficiency, reduce fuel

consumption and improve safety through its

3

parameter trim function and combustionsafety

li

mits.

Mk8 尾气分析仪用于监视燃烧器和锅炉系统产生的烟道尾气。尾气分析仪能够改善燃烧、提高

效率、减少燃料消耗并通过 3参数调节功能和燃烧安全限制提高安全性。

1.

Stand-Alone: When

in

stand-alone mode, the E.G.A. can

be

used without

a

Micro-Modulation

(M.M.)

module

to

monitor the combustion gases. The

M.M.

trim function

and

the combust

i

on

safety limits

are not

activated

in

this stand-alone mode

of

operation. The emissions levels

can

be accessed via the full colour E.G.A. touch

screen.

单机运行:在单机模式下,尾气分析仪在无微型控制模块的情况下可以用于监视燃烧的

烟气。在单机运行模式下不会激活控制模块调节功能和燃烧安全限制。排放等级可以通

过全彩色尾气分析仪触摸屏访问。

2. With M.M.: When

interfaced

with an M.M., the E.G.A. can monitor

emissions

or the 3-

parameter combustion

trim and safety limits can be

activated. The emissions

levels are

monitored

by

the E.G.A.

and

the

M.M.

makes small adjustments

to

the

air

damper

to

trim

the

online exhaust gas data back

to

the commissioned values. The E.G.A. information is

accessible

through the

full

colour E.G.A. touch screen, the Data Transfer Interface module (D.T.I.),

or 6 x

4-20mA signals.

带控制模块:尾气分析仪在连接控制模块后可以监视排放,3参数燃烧调节功能和安全

限制可以被激活。排放等级可以通过尾气分析仪进行监视,控制模块对空气挡板进行微

调,使在线排气数据返回至调试的数据。尾气分析仪信息可以通过全彩色尾气分析仪触

摸屏、数据传输接口模块或 6 x4-20mA 信号进行访问。

The main benefits

of

the E.G.A. include the

ability to

monitor the exhaust gases

and bring

them

to the

safe commissioned levels. Setting

the

combustion limits

on the M.M. in

conjunction

with the E.G.A.

prevents unsafe combustion scenarios, reducing the fuel consumed

inbadcombustion.

尾气分析仪的主要优点包括监视排气并使其保持安全调试水平。在控制模块和尾气分析仪上设

置燃烧限值可以防止不安全的燃烧情况、减少在不良燃烧中的燃料消耗。

1.1.2

System

Operation

系统运行

The

Mk8

E.G.A. samples

the

combustion gases

via the

stack mounted sampling

probe

(p

urchased

separately

from the

analyser). The exhaust gases

are drawn from the

stack

by a pump

mounted

internally within the analyser.

Only

the supplied sample tubing should

be

used between the sampling

probe and

analyser. The internal diameter

of

the sampling tube is 3mm;

if a large

diameter tubing is

used the sample gas remains resident

in

the tubing

for a

longer period. The E.G.A.

will

then not be

able

to

respond

in

time

to

combustion changes, resulting

in

incorrect operation

of

the trim

function.

Mk8 尾气分析仪通过在排气管上安装的采样探头(需单独购买)对燃烧烟气进行采样。废气通

1

Introducti

on

前言

Page

2

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

29.05.2015

过安装在尾气分析仪内部的泵从排气管中抽出。在采样探头和尾气分析仪之间仅可使用提供的

采样管。采样管的内径为 3mm,如果使用大尺寸采样管,采样气体会在采样管中停留较长的

时间。这样尾气分析仪就无法及时对燃烧的变化做出响应,导致无法正确使用调节功能。

Once the exhaust gases have entered the E.G.A. the chiller block reduces their temperature and

drie

s

the

sample

to

remove

the

condensation

from the

gases

prior to

entering

the

cells. The condensate

accumulated

in

the chiller unit is drained every

4

minutes when running,

and

every

10

minutes

when

the E.G.A. is

in

idle mode, automatically through the drain

solenoid.

废气进入尾气分析仪后,冷却器组将降低其温度,在其进入设备前通过去除烟气中的冷凝水将

样本干燥。运行时在冷却器组中积累的冷凝水每隔 4分钟排出一次,当尾气分析仪处于空闲模

拟时每隔 10分钟排出一次,冷凝水将通过排放电磁阀自动排出。

The exhaust gas is then filtered through

the dry filter,

which

i

s

a fine filter

used

to

remove

any

d

u

s

t

particles carried over from the cooling process.

If

the burner is firing

on

heavy

or dirty oil, an external

particulate filter must

be

used

to

remove the excess

dirt

particles.

On

leaving the filter, the exhaust

gas

pressure is checked

again to

ensure

that a

vacuum is maintained

prior to

entering

the

pump

and on

exiting the pump, the pressure produced

by

the pump is checked. Both these pressure sensors

modulate

the

flow

rate

of

the sample into the E.G.A.

for

consistent operation. Once the exhaust gases have

been

conditioned, they

are

ready

for an

accurate sampling

by

the cells. After the gases have been sampled

by all

the cells, the remaining sample is pumped out

of

the E.G.A. from the clear tubing

at

the

bottom

of

the E.G.A.

casing.

然后废气通过干燥过滤器进行过滤,干燥过滤器是一种细过滤器,用于排出冷却过程中携带的

各种粉尘颗粒。燃烧器在重油或脏油情况下燃烧时则必须使用外部微粒过滤器,用于排除过多

的粉尘颗粒。废气在离开过滤器后将对其压力进行再次检查,确保在其进入泵前保持真空,废

气在离开泵时将对泵产生的压力进行检查。压力传感器用于调节进入尾气分析仪的样本流量以

确保操作一致。废气经过设备调节后则可以进行准确的采样,废气进行采样后剩余的样本将从

尾气分析仪外壳底部的干净管道中排出。

Note:

The E.G.A. needs

to

vent

to

atmosphere

via

the drain solenoid

on

the bottom; this is also

where

the E.G.A. performs its

air

calibrations. Care should

be

taken

to

ensure the outlet is

not

restricted

or

that contamination from exhaust gas

occurs.

注:尾气分析仪需要通过底部的排放电磁阀将废气排放到大气中,此时尾气分析仪需要执行空

气校准操作。应注意出口没有任何堵塞且废气不会造成污染。

1

Introducti

on

前言

29.05.2015

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

Page

3

1.1.3 Mk8

E.G.A. vs

Mk7

E.

G.A.

Mk8 和Mk7 尾气分析仪

The

Mk8

E.G.A. has been developed

to

building

on

the technology developed

in

the

Mk7

E.G.A.

Th

e

new features and changes

are:

Mk8 尾气分析仪的开发是在 Mk7 尾气分析仪开发技术的基础上进行,包括以下新功能和变化:

2

Years Continuous Emissions

Monitoring

System (CEMS) included as

standard

标配 2年连续排放监测系统。

Single PCB

board

单个 PCB 板

New flying

leads

新型飞线

New software

updater

新型软件更新器

More accurate

sampling

更多准确的采样

Longer cell

life

更长的设备寿命

CEMS included as

standard

标配连续排放监测系统

Cells contain calibration code and serial number

in

PCB

memory

设备校准码和序列号储存在 PCB 存储器中

New

air

inlet filter

construction

新型进气过滤器结构

Self-calibration

(optional)

自校准(可选)

1.2 3-Parameter Trim

3参数调节

The 3-parameter

trim

function

can be

enabled when

the Mk8

E.G.A. is used

in

conjunction

with an

M.M.

module

to

manage

the

combustion.

When the E.G.A.

detects

any

differences

in the online

exhaust gas readings

to

the original commissioned values, the trim function

will

make small

correction

s

to the air

damper

(and

channel

5 if

optioned

for trim), to bring

those

online

values

back to the

commissioned readings. The trim function controls the combustion

of

the burner

by

adding

air (air rich)

or

taking

away air

(fuel rich) from the commissioned

air

positions

to

keep the volume

of O2, CO2 and

CO close

to

their commissioned values without compromising safety. The

air

rich and fuel rich limits

are

set

by adding trim data

when

commis

s

ioning

the

burner

or

through single

point

change

for ‘quick

commission.’ This

trim data

is translated

into a

combustion map, which shows

how the

burner

reacts

when air

is

added or

removed

from the

combustion process

during

commis

s

ioning.

The

Autoflam

e

system continually

monitor

s

3

parameters

O2, CO2 and CO to

create the safest

and

most efficient

way

of

trimming the combustion

process.

当Mk8 尾气分析仪和控制模块一同用于管理燃烧时可以启用 3参数调节功能。当尾气分析仪检

测到在线废气读数和原调节数间存在差异时,调节功能将对空气挡板(可以选择通道 5进行调

节)进行微调,使在线数值与调节的读数保持一致。调节功能可以通过增加空气(富氧)或从

调试空气中排出空气(富油)控制燃烧,使氧气、二氧化碳和一氧化碳的含量接近其调试值而

不影响安全性。当调试燃烧器时或通过单点改变进行快速调试时,富氧和富油限值可以通过增

加调节数据进行设置。调节数据被转换成燃烧图,燃烧图将显示添加空气或在燃烧过程中排出

空气时的燃烧器反应。Autoflame 系统可以持续监视氧气、二氧化碳和一氧化碳 3个参数,使

调节燃烧过程更加安全有效。

Ingress

of

tramp

air

through

an

ill-fitting

boiler or

flue section

will

distort the

O2

reading

and

show

an

1

Introducti

on

前言

Page

4

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

29.05.2015

increase

in

this value. This results

in

the E.G.A. reading the tramp

air

influence

in

the sample rather

than

just the actual combustion

gases.

通过不匹配锅炉或烟道段进入的空气将改变氧气读数并显示数值增加,这会影响尾气分析仪在

样本中的读数,不会显示实际的燃烧气体。

Single parameter

O2 trim

systems

would

see

both of

these conditions

as rich

(excess

air)

com

b

ustion

and start

to

trim back on the

air by

closing the

air

damper. In reality this trim process is not trimming

the

combustion gases

at

this point,

but

is

in fact

trimming

the

exhaust gases

with

the excess

O2.

This

can

potentially

lead to the

formation

of

excessive amounts

of CO but

more importantly this

can lead to

incomplete combustionwith dangerous

consequences.

单参数氧气调节系统可以检测到富氧(过多空气)燃烧的条件,通过关闭空气挡板调节空气。

事实上,调节过程并不是在该点对燃烧气体进行调节,而是调节过多氧气中的废气。这样可能

导致过多一氧化碳的形成,更重要的是可能导致燃烧不完全的危险后果。

Similarly, single parameter

CO2 trim

systems

would

interpret

of air as lower CO2

levels

in the flue,

inflicting similar dangerous conditions

in

the

boiler.

同时,单参数二氧化碳调节系统将检测到烟道空气中存在含量低二氧化碳,使锅炉出现类似的

危险。

Another benefit

of

the

3

parameter trim is that the E.G.A. is continually measuring the formation

of CO

compared

to

its commissioned value.

A

higher

CO

reading can

be

contributed

to both lean and rich

combustion.

A

lack

of air will

produce incomplete combustion

and

the formation

of CO.

Also,

exces

s

air

around the flame envelope can chill the flame edge causing incomplete combustion and higher

CO

levels.

3参数调节的另一个优点是尾气分析仪可以根据调试值持续测量一氧化碳的形成。较高的一氧

化碳读数可能是因不完全燃烧和过度燃烧造成。缺少空气将产生燃烧不完全并形成一氧化碳。

同理,火焰周围有过多的空气可能冷却火焰边缘,导致不完全燃烧和较高的一氧化碳含量。

By referencing

all 3

parameters against mapped combustion performance the burner can

be trimmed

back

to

the original

c

o

mmis

s

ioned

values whilst maintaining the highest degree

of safety.

通过参考反应燃烧性能的这 3个参数可以将燃烧器调节至原始调试值,同时保持最高程度的安

全性。

When the

trim function

adds air to bring back the

combustion

to the

commissioned values,

as the

burner

modulates

to a new

position,

the

deviation

in air

damper movement is

added to each air

position. In this way, optimum combustion is maintained during modulation, through carry forward

trim.

当调节功能增加空气使燃烧与调试值保持一致时,由于燃烧器调节到一个新位置,空气挡板移

动的偏差被加入各空气位置。这样在调节过程中通过调节可以保持最佳燃烧。

As a

safety feature,

as the air

is

being taken away, the fuel to air ratio will return back to the

commissioned positions when

the

burner modulates,

for every 10

degrees

of fuel valve

movement.

Once this new position is held the system

will

determine whether the

air

damper should

be

closing. This

ensures safe combustion

atall

times without any

compromise.

至于安全功能,由于空气一直被排出,燃烧器进行调节时油气比将返回至调试位置,燃料阀将

移动 10 度。一旦新位置固定时,系统将确定是否关闭空气挡板。这样可以始终确保安全燃烧。

1

Introducti

on

前言

29.05.2015

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

Page

5

1.3

Continuous Emissions

Monitoring System

持续排放检测系统

The

Mk8

E.G.A.

now

has the CEMS function included

as

standard, logging the exhaust gas

and fuel

data

for up to 2

years. This data

include

s

the gas readings, flue temperature, calculated efficiency

and

fuel

consumption.

Mk8 尾气分析仪目前标配持续排放检测系统功能,可以记录两年的废气和燃料数据。该数据包

括燃气读数、燃料温度、计算效率和燃料消耗。

When using

a

standalone

Mk8

E.G.A.

a

direct connection as shown

in

section

2.2.3 will

be required

to

view and

log

up

to 2

years

of

data on the

Mk7

D.T.I. The

D.

T

.

I

.

will

need

to

be

s

et

-

u

p

as

‘

E

.

G

.

A

.

d

ir

e

c

t

’

through the ‘Edit Boiler’ screen and the E.G.A. setup

for

standalone operation (E.G.A.

selects

fuel).

使用单机 Mk8 尾气分析仪时,需要进行 2.2.3 节显示的直接连接并记录 Mk7 数据传输接口上

的数据。在‘编辑锅炉’屏幕上和尾气分析仪(EGA)单机操作中(EGA 选择燃料)需要将数据

传输接口设成‘EGA direct EGA 直接’。

Using

the

E.G.A.

in

conjunction

with the Mk7 M.M.

module

and

D.T.I,

a data link will be required

between the

M.M.

and E.G.A. and from the E.G.A.

to

the D.T.I. (see section

2.2.4).

The D.T.I.

will need

to

be setupas ‘E.G.A. Direct’

not

‘E.G.A. through

M.M.’

使用安装 Mk7 控制模块和数据传输接口的尾气分析仪时,控制模块和尾气分析仪以及尾气分析

仪至数据传输接口(见 2.2.4 章节)间需要有数据连接。数据传输接口需设为‘E.G.A.

DirectEGA 直接’而非‘E.G.A. through M.M EGA 通过控制模块’。

For multiple M.M.s, each with the E.G.A.s, refer

to

both sections

2.2.3

and

2.2.4.

There

will

need

to be

data cable

connected

as a daisy chain

between

the

E.G.A.s

and

D.T.I.,

a data cable daisy chain

between the M.M.s and D.T.I., and

data

cable links between each

M.M.

and its corresponding

E.G.A.

使用多个控制模块时,每个模块都需要连接尾气分析仪,见 2.2.3 和2.2.4 章节。尾气分析仪和

数据传输接口间要有菊花链连接的数据电缆,控制模块和数据传输接口间有菊花链连接的数据

电缆,每个控制模块和对应的尾气分析仪间有数据电缆连接。

Page

6

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

29.05.2015

2

Wiring and

Com

p

onents

接线和组件

2

2.1

WIRING AND

C

OMPON

E

NTS

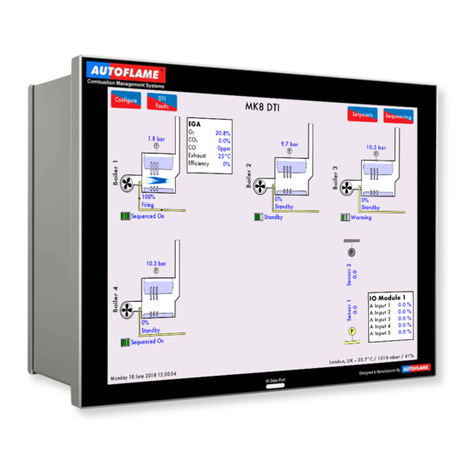

接线和组件

Flying

LeadWiring

Diagr

a

m

飞线接线图

Data

Connector 数据连接器

Figure

2.1.i

Data Connector

–

Insert PinMating

View

图2.1.i 数据连接器-插针匹配图

1

4-20 mA Output Channel

(

1+

)

4-20 mA

输出通道(

1+

)

2

4-20 mA Output Channel

(2+)

4-20 mA

输出通道(

2+

)

3

4-20 mA Output Channel

(3+)

4-20 mA

输出通道

(3+)

4

4-20 mA Output Channel

(4+)

4-20 mA

输出通道

(4+)

5

4-20 mA Output Channel

(5+)

4-20 mA

输出通道

(5+)

6

4-20 mA Output Channel

(6+)

4-20 mA

输出通道

(6+)

7

4-20 mA Output Common

(-)

4-20 mA

输出命令(-)

8

Fuel

1

Select

Input

燃料

1

选择输入

9

Fuel

2

Select

Input

燃料

2

选择输入

10

Fuel

3

Select

Input

燃料

3

选择输入

11

Fuel 4

Select

Input

燃料

4

选择输入

12

Fuel Select Input

com

m

o

n

燃料选择输入命令

13

MM

Comms

(-

)

控制模块通信(

-

)

14

MM

Comms

(+)

控制模块通信(

+

)

15

DTI Comms

(

-

) 数据传输接口通信

16

DTI Comms

(+)数据传输接口通信

17

4-20mA Input

(

-

)

4-20mA

输入

18

4-20mA Input

(+)

4-20mA

输入

19

Not Connected 未连接

Note: Fuel Select Inputs

in

standalone mode

are low

voltage. To select

a

fuel, put

a

link

on

the ‘Fuel X

Select Input’

to

the Fuel Select Input Common e.g.

to

select fuel

1,

link pin

8 to pin 12 to

select fuel

1 in

standalone

mode.

注:在单机模式下燃料选择输入为低电压。选择燃料时将‘燃料 X选择输入’连接至燃料选择输入

命令,例如:选择燃料 1时,在单机模式下将针 8连接至针 12。

29.05.2015

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

Page

7

2

Wiring and Components

接线和组件

Mains Connector

电源连接器

Figure

2.1.ii

Mains Connector

–

Insert PinMating

View

图

2.1.ii

电源连接器

-

插针匹配图

Pin

Number

针号

Assigned

function

分配的功能

1

Live

火线

2

Live

for

HSL

HSL 火线

3

Earth

for

HSL

HSL 地线

4

Neutral

for

HSL

HSL 零线

5

Neutral

中性

6

Earth

接地

Auxiliary

Connector 辅助连接器

Figure

2.1.iii

Auxiliary Connector

–

Insert Pin Mating

View

图2.1.iii 辅助连接器-

插针匹配图

Pin

Number

针号

Assigned

function

分配的功能

1

External Drain

(0V

)

外部排放(0V)

2

3

4

5

External Drain

(+24V)

外部排放(+24V)

6

Page

8

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

29.05.2015

2

Wiring and

Com

p

onents

接线和组件

2.2

Electrical

Schematics

电气原理图

2.2.1

Interconnectionbetween

E.G.A.

and

Mk7

M.M.

尾气分析仪和

Mk7

控制模块的互连

-

29.05.2015

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

Page

9

2

Wiring and Components

接线和组件

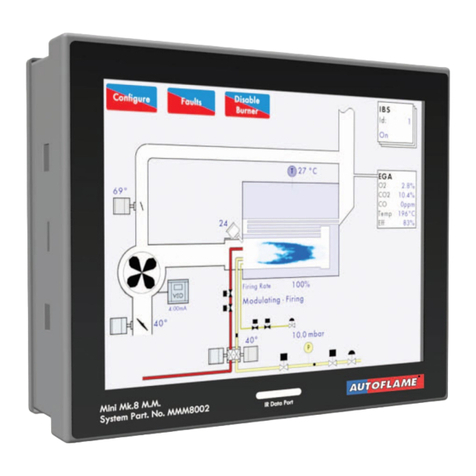

2.2.2

Interconnectionbetween

E.G.A

.

and

MiniMk8

M.M.

Module

尾气分析仪和

Mk8

微型控制模块的互连

Page

10

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

29.05.2015

2

Wiring and

Com

p

onents

接线和组件

2.2.3

Interconnectionbetween

Stand-Alone

Mk8

E.G.A.

and

Mk7

O.T.I.

单机 Mk8 尾气分析仪和 Mk7OTI 的互连

ENL

MAINS SUPPLY ENL 主电源

NOTE: 注

○

s -

EARTHING

SCREW

ON CONNECTOR 连接器接地螺丝

Th

e

contro

l

phases to each EGA module

&

OTI

un

i

t

must

be the

some

.

The 10

must

be set for

011

EGAs

connected directly to

the

OT

I.

各尾气分析仪模块和数据传输接口单元的控制相必须相同。

ID必须设为 EGA 直接连接 DTI。

29.05.2015

Mk8

E.G.A. Set-Up and Trim

Guide Mk8 尾气分析仪设置和调节指南

Page

11

2 Wiring and

Components

接线和组件

2.2.4

Interconnectionbetween

Mk7

M.M

,

.

Mk8

E.G.A

.

and

Mk7

D.T I.

Mk7 控制模块、Mk8 尾气分析仪和 Mk7 数据传输接口的互连

-

2

Wiring and

Com

p

onents

接线和组件

Mk8 E.G.A.Set-Up and

Trim

Guide

Mk8 尾气分析仪设置和调节指南

Page

10

29.05.2015

2.3

2.3.1

Components 组件

Inside

Vie

w

内视图

Figure 2.3.1.i Inside

View

图

2.3.1.i

内视图

1.

Particulate

F

ilt

er

微粒过滤器

2.

Chiller

Block 冷却器组

3.

Pinch

Valve 夹管阀

4.

Drain

Solenoid 排放电磁阀

5. NO Cell NO 感应器

6.

CO

Cell CO 感应器

7. O2 Cell O2 感应器

8. CO2 Cell CO2感应器

9.

CR

BatteryCR 蓄电池

10.

Software Update

Jumpe

r

s

软件更新跳线

11.

Cell Pump

组件泵

12.

E.G.A.

Fan 尾气分析仪风机

Other manuals for MK8 EGA EVO

3

Table of contents

Other AUTOFLAME Measuring Instrument manuals