AUTOFLAME Mini Mk8 M.M. User manual

Mini Mk8 M.M.

Installation &

Commissioning Guide

Mini Mk8 MM

Installation and Commissioning Guide

Issued by:

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: [email protected]

Website: http://www.autoflame.com/

Registered Holder:

Company:

Department:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both

design and manufacture. We therefore reserve the right to amend

specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential

before embarking work on any of the M.M./E.G.A. systems. This is for safety reasons

and effective use of the M.M./ E.G.A. system. Hands on training is required. For

details on schedules and fees relating to group training courses and individual

instruction, please contact the Autoflame Engineering Ltd. offices at the address listed

on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be

installed, commissioned and applied by personnel skilled in the various technical

disciplines that are inherent to the Autoflame product range, i.e. combustion, electrical

and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that

the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high

degree of combustion engineering experience, and a thorough understanding of the

local electrical codes of practice concerning boilers, burners and their ancillary

systems and equipment.

Autoflame’s warranty from point of sale is two years on all electronic systems and

components.

One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that it

was intended and in strict compliance with our technical recommendations.

Autoflame’s warranty and guarantee is limited strictly to product build quality, and

design. Excluded absolutely are any claims arising from misapplication, incorrect

installation and/or incorrect commissioning.

CONTENT

1DIMENSIONS AND WIRING .................................................................................. 1

1.1 Mini Mk8 MM .........................................................................................................................1

1.1.1 Fixing Holes and Dimensions...........................................................................................2

1.2 Wiring Schematic.....................................................................................................................3

1.3 Electrical Specifications ...........................................................................................................4

1.3.1 Classifications ..................................................................................................................4

1.3.2 Inputs and Outputs...........................................................................................................4

1.3.3 Cable Specifications ........................................................................................................5

1.3.4 Terminals Description.......................................................................................................5

1.4 Connection Between Mini Mk8 MM and Mk8 EGA................................................................8

1.5 Connection Between Mini Mk8 MM and Mk7 DTI..................................................................9

1.6 Sequencing Connection Diagram ......................................................................................... 10

2OPTIONS AND PARAMETERS ............................................................................... 11

2.1 Options................................................................................................................................. 11

2.2 Parameters............................................................................................................................ 33

3COMMISSIONING FUEL-AIR CURVE ..................................................................... 42

3.1 Overview.............................................................................................................................. 42

3.1.1 Commissioning Procedure............................................................................................. 42

3.2 Installation Checks ................................................................................................................ 43

3.2.1 Commissioning Checks.................................................................................................. 43

3.2.2 Operational Checks...................................................................................................... 43

3.2.3 Installation Precautions ................................................................................................. 43

3.2.4 Maintenance and Servicing.......................................................................................... 43

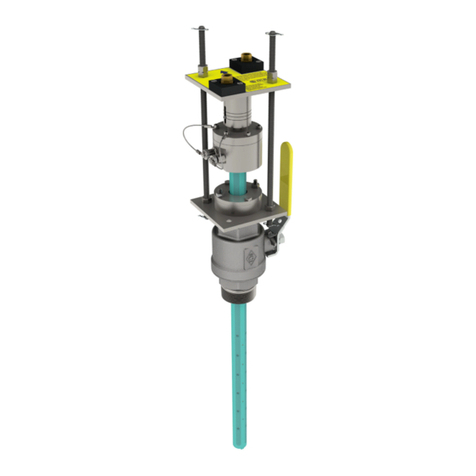

3.3 Servomotors.......................................................................................................................... 44

3.3.1 Adjusting the Servomotor Potentiometer....................................................................... 44

3.3.2 Servomotor Feedback Voltage..................................................................................... 45

3.3.3 Servomotors – Direction Change.................................................................................. 46

3.3.4 Servomotors with Autoflame Valves ............................................................................. 47

3.4 Commissioning Fuel and Air Positions................................................................................... 48

3.4.1 Starting Commissioning ................................................................................................ 49

3.4.2 Enter CLOSE Position.................................................................................................... 50

3.4.3 Enter OPEN Position ..................................................................................................... 51

3.4.4 Enter START Position..................................................................................................... 52

3.4.5 Phase Hold.................................................................................................................... 53

3.4.6 Add Trim Data During Commissioning.......................................................................... 54

3.4.7 Commissioning VSD...................................................................................................... 56

3.4.8 Set GOLDEN START Position........................................................................................ 57

3.4.9 Set FGR START Position ................................................................................................ 59

3.4.10 Set HIGH Position ......................................................................................................... 61

3.4.11 Set INTER Position......................................................................................................... 62

3.4.12 Set INTER or START Position......................................................................................... 63

3.4.13 Save Commission.......................................................................................................... 64

3.5 Fuel Flow Commissioning...................................................................................................... 65

3.5.1 Calorific Fuel Data........................................................................................................ 68

3.5.2 Conversion Factor for Imperial Gas Flow Meters ......................................................... 69

3.5.3 Correction Factor for Burners Significantly Above Sea Level ....................................... 69

3.5.4 Gas Volume Conversion Factors................................................................................... 70

3.6 Gas/ Air Pressure Commission ............................................................................................. 72

3.7 Single Point Change ............................................................................................................. 73

3.8 Online Changes.................................................................................................................... 78

3.9 General Operation............................................................................................................... 79

3.9.1 Calibrating the Actual Value......................................................................................... 79

3.9.2 External Modulation..................................................................................................... 79

3.9.3 Additional Functions ..................................................................................................... 80

4REMOTE CONTROL .............................................................................................. 81

4.1 Modbus Settings ................................................................................................................... 81

4.2 Configuration........................................................................................................................ 82

4.3 Modbus Addresses............................................................................................................... 83

5ERRORS AND LOCKOUTS .................................................................................... 88

5.1 Errors .................................................................................................................................... 88

5.2 Burner Lockouts .................................................................................................................... 91

5.3 EGA Errors ........................................................................................................................... 95

5.4 Troubleshooting and Further Information ............................................................................. 97

5.4.1 UV Shutter Faults .......................................................................................................... 97

5.4.2 UV Problems................................................................................................................. 97

5.4.3 Snubbers....................................................................................................................... 97

5.4.4 Channel Positioning Error ............................................................................................. 98

5.4.5 Input Fault..................................................................................................................... 98

5.4.7 Setting Conflicts ............................................................................................................ 99

5.4.8 Forced Commission..................................................................................................... 101

6STANDARDS ..................................................................................................... 103

1 Dimensions and Wiring

12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 1

1 DIMENSIONS AND WIRING

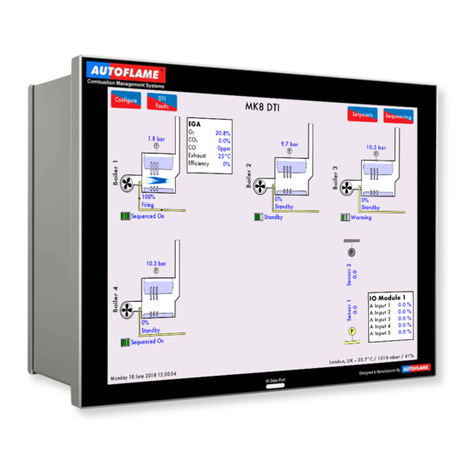

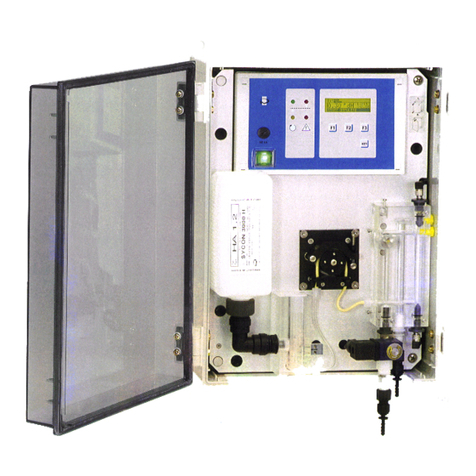

1.1 Mini Mk8 MM

1 Dimensions and Wiring

Page 2 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019

1.1.1 Fixing Holes and Dimensions

1 Dimensions and Wiring

12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 3

1.2 Wiring Schematic

Fuse

Terminals Protected

5A

Mains voltage output terminals 57 – 63

2A

Low voltage terminals and switched neutral outputs

1 Dimensions and Wiring

Page 4 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019

1.3 Electrical Specifications

1.3.1 Classifications

Classification according to EN298

Mains Supply:

230V, +10%/-15%}

47-63 Hz, unit max. consumption 140W

120V, +10%/-15%}

Climate:

Min. Temperature

0

O

C (32

O

F)

Recommended Temperature

Less than 40

O

C (104

O

F)

Max. Temperature

60

O

C (140

O

F)

Humidity

0 to 90% non-condensing

Storage:

Temperature

-20 to 85

O

C (-4 to 185

O

F)

Protection Rating:

The unit is designed to be panel mounted in any orientation and the front facia is

IP65, NEMA4. The back of the unit is IP20, NEMA1.

1.3.2 Inputs and Outputs

Inputs and Outputs

230V Unit:

Outputs

Terminal

57

250mA

Must be connected through contactor

Max Load 5A

58

250mA

Must be connected through contactor

59

1A

0.6 power factor

60

1A

0.6 power factor

61

1A

0.6 power factor

62

1A

0.6 power factor

63

1A

0.6 power factor

78

100mA

To drive relay only – switched neutral

79

100mA

To drive relay/lamp only – switched neutral

120V Unit:

Outputs

Terminal

57

250mA

Must be connected through contactor

Max Load 5A

58

250mA

Must be connected through contactor

59

2A

0.6 power factor

60

2A

0.6 power factor

61

2A

0.6 power factor

62

2A

0.6 power factor

63

2A

0.6 power factor

78

100mA

To drive relay only – switched neutral

79

100mA

To drive relay/lamp only – switched neutral

Note:

•The high and low voltage connections are not safe to touch. Protection against electric shock is

provided by correct installation. CAUTION – ELECTRIC SHOCK HAZARD.

•Control voltage cabling should be maximum 10m, screened (if not screened then less than 1m,

however servomotors can be unscreened up to 10m).

•Any cabling over 10m must have additional surge protection.

•Low voltage cables should be screened cable as specified in section 1.3.3.

•The burner ‘High Limit Stat’ must be a manual reset type.

•There is a lid (back plate) fitted onto the back of the Mini Mk8 MM with a Warning label to

prevent any unauthorised fuse replacements.

1 Dimensions and Wiring

12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 5

1.3.3 Cable Specifications

Low Voltage

The screened cable used for low voltage wiring from the MM to the servomotors, detectors and

variable speed drive must conform to the following specification:

U.V. cable length should not exceed 25m; all other screened cable should not exceed 50m.

16/0.2mm PVC insulated overall braid, screened, PVC sheathed.

Sixteen wires per core

Diameter of wires in each core 0.2mm

Rated at 440V AC rms at 1600Hz

DEF 61-12 current rating per core 2.5A

Maximum operating temperature 70oC (158oF)

Nominal conductor area 0.5sq mm per core

Nominal insulation radial thickness on core 0.45mm

Nominal conductor diameter per core 0.93mm

Nominal core resistance at 20oC. 40.1Ω/1000m

Nominal overall diameter per core 1.83mm

Fill factor of braid screen 0.7

Equivalent imperial conductor sizes 14/0.0076

Use the number of cores suitable for the application. A universal part numbering system appears to

have been adopted for this type of cable as follows:

16-2-2C 2 Core

16-2-3C 3 Core

16-2-4C 4 Core

16-2-6C 6 Core

16-2-8C 8 Core

(5 Core not readily available)

Note: If using 4 Core cable and interference is detected, use 2 sets of 2 Core.

Data Cable

Data cable must be used for communication connections between MMs for sequencing applications as

well as between MMs to EGAs, MMs to a DTI and DTI to BMS systems.

Communication cable should not exceed 1km.

Types of data cable that can be used:

1 Beldon 9501 for 2-core shielded cable (1 twisted pair)

2 Beldon 9502 for 4-core shielded cable (2 twisted pairs)

3 STC OS1P24

Samples are available upon request. Low voltage and data cable can be ordered directly from

Autoflame Engineering, please contact Autoflame Sales Department.

When using a VSD, please review the manufacturer’s guidelines on installations to prevent EMC

including the recommendations for reactors and filters.

1 Dimensions and Wiring

Page 6 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019

1.3.4 Terminals Description

S

All terminals marked S are internally connected provided for connections to the various

screened cables.

1

Current Input, 0-20mA/ 4-20mA. For channel 4 only. Can be connected to the current output

of a VSD or tachometer system or 4-20mA servomotor feedback

2

Voltage Input, 0-10V. For channel 4 only. Can be connected to the voltage output of a VSD

or tachometer system

3

0V common for Terminals 1 or 2

10

Current Output, 0-20mA/ 4-20mA. For channel 4 only. Can be connected to the current

input of a VSD or tachometer system or 4-20mA servomotor feedback

11

Voltage Output, 0-10V. For channel 4 only. Can be connected to the voltage input of a VSD

or tachometer system

12

0V common for Terminals 10 or 11

21, 22

Connections to an Autoflame self-check UV sensor

25, 26

Communications port connections to an Exhaust Gas Analyser (EGA)

27, 28

Communications port connections for DTI and/or IBS, or Modbus

29, 30

Digital communications connections to an Autoflame IR scanner (MM70017), Autoflame air

pressure sensor and/or Autoflame gas pressure sensor

37

0V supply to an Autoflame temperature or pressure detector or 0-10V external modulation

input

38

Signal input from an Autoflame temperature or pressure detector or 0-10V external

modulation input

39

12V supply to an Autoflame pressure detector

40

0V supply to channel 1 and channel 2 servomotors

41

+12V supply to channel 1 and channel 2 servomotors

42

Signal from channel 1 servomotor, indicating position

43

Signal from channel 2 servomotor, indicating position

44

Signal from channel 3 servomotor, indicating position

46

0V Supply to channel 3 servomotor

47

+12V Supply to channel 3 servomotor

48, 49

+15V connections to an Autoflame IR scanner (MM70017), Autoflame air pressure sensor

and/or Autoflame gas pressure sensor

50, 51

Connections to an Autoflame UV sensor

1 Dimensions and Wiring

12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 7

64

Connections to a flame rod

53

Mains voltage input – burner on/off signal, running interlock circuit

54

Mains voltage input – air proving switch

55

Mains voltage input - proving circuits, e.g. gas valve proof of closure

57

Mains voltage output – call for heat

58

Mains voltage output – burner motor

59

Mains voltage output – start/pilot valve

60

Mains voltage output – main fuel valve 1

61

Mains voltage output – main fuel valve 2

62

Mains voltage output – vent valve

63

Mains voltage output – ignition transformer

66

Mains supply – earth

67

Main supply – neutral

68

Mains supply – live/hot

69

Mains voltage output, power to servomotors and/or stepdown transformer

70

Switched neutral – drives channel 1 servomotor clockwise

71

Switched neutral – drives channel 1 servomotor counter clockwise

72

Switched neutral – drives channel 2 servomotor clockwise

73

Switched neutral – drives channel 2 servomotor counter clockwise

74

Switched neutral – drives channel 3 servomotor clockwise

75

Switched neutral – drives channel 3 servomotor counter clockwise

78

Switched neutral –2-port valve for IBS operation

79

Switched neutral – alarm output for MM lockout/MM error/EGA error

80

Start position interlock/ night setback input/ reduced setpoint input

81

Purge interlock/ low flame hold input/ purge pressure proving

82

Warming stat/ valve proving mains input

89

Mains voltage input – selects fuel 1 curve

90

Mains voltage input – selects fuel 2 curve

1 Dimensions and Wiring

Page 8 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019

1.4 Connection Between Mini Mk8 MM and Mk8 EGA EVO

1 Dimensions and Wiring

12.04.2019 Mini Mk8 MM Installation and Commissioning Guide Page 9

1.5 Connection Between Mini Mk8 MM and Mk8 DTI

1 Dimensions and Wiring

Page 10 Mini Mk8 MM Installation and Commissioning Guide 12.04.2019

1.6 Sequencing Connection Diagram

Other manuals for Mini Mk8 M.M.

2

This manual suits for next models

1

Table of contents

Other AUTOFLAME Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Vixen Horns

Vixen Horns VXA7240 installation guide

SellEton Scales

SellEton Scales SL-918 user manual

Hioki

Hioki HiTESTER 3415-02 instruction manual

Maxwell Digital Multimeters

Maxwell Digital Multimeters 25601 user manual

Vega

Vega INFO-1 operating manual

Precision Digital Corporation

Precision Digital Corporation PD6060 instruction manual