AUTOFLAME Mk7 User manual

M

S

e

M

k7

D

e

t-Up

G

D

.T.I.

G

uide

Mk7 D.T.I.

Set-Up Guide

Issued by:

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: [email protected]

Website: http://www.autoflame.com/

Registered Holder:

Company:

Department:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both

design and manufacture. We therefore reserve the right to amend

specifications and/pr data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before

embarking work on any of the M.M./E.G.A. systems. This is for safety reasons and

effective use of the M.M./ E.G.A. system. Hands on training is required. For details on

schedules and fees relating to group training courses and individual instruction, please

contact the Autoflame Engineering Ltd. offices at the address listed on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that

are inherent to the Autoflame product range, i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that

the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high

degree of combustion engineering experience, and a thorough understanding of the

local electrical codes of practice concerning boilers, burners and their ancillary systems

and equipment.

Autoflame’s warranty from point of sale is two years on all electronic systems and

components.

One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that

it was intended and in strict compliance with our technical recommendations. Auto-

flame’s warranty and guarantee is limited strictly to product build quality, and design.

Excluded absolutely are any claims arising from misapplication, incorrect installation

and/or incorrect commissioning.

Contents

1MK7 DATA TRANSFER INTERFACE MODULE ............................................................. 1

1 Overview of the Mk7 D.T.I. .........................................................................................................1

1.1.1 Introduction to the Mk7 D.T.I...........................................................................................1

1.1.2 Information Available from Mk7 D.T.I. ............................................................................1

1.2 Fixing Holes and Dimensions...................................................................................................4

2SET-UP AND CONNECTIONS .................................................................................... 5

2.1 Wiring......................................................................................................................................5

2.1.1 Mk7 D.T.I. Wiring Diagram .............................................................................................5

2.1.2 System Schematic ............................................................................................................6

2.1.3 M.M. Modules Connection ..............................................................................................7

2.1.4 Mk7 M.M. and Mk8 E.G.A. with Mk7 D.T.I. ...................................................................8

2.2 Mk7 D.T.I. Set-Up ....................................................................................................................9

2.2.1 Mk7 M.M. Options and Parameters................................................................................9

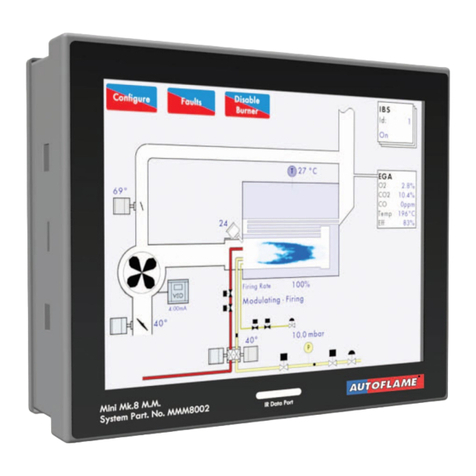

2.2.2 Mini Mk8 M.M. Options and Parameters..................................................................... 12

2.2.3 Configuring the Boiler Room......................................................................................... 15

2.2.4 D.T.I. Setup ................................................................................................................... 22

2.2.5 Deleting Boilers and I/O Modules................................................................................ 25

2.2.6 Network Set-Up ............................................................................................................ 30

2.3 Mk7 D.T.I. Connections ........................................................................................................ 32

2.3.1 PC Connection .............................................................................................................. 32

2.3.2 Network Connection..................................................................................................... 33

2.3.3 Pinging the D.T.I............................................................................................................ 34

2.3.4 RS422 Connection........................................................................................................ 35

3ANALOGUE AND DIGITAL INPUTS/OUTPUTS ........................................................ 36

3.1 Mk7 Universal Input/ Output Module .................................................................................. 36

3.1.1 Introduction................................................................................................................... 36

3.1.2 Wiring and Dimensions................................................................................................. 37

3.1.3 Set-Up I/O Modules on Mk7 D.T.I. .............................................................................. 39

4MODBUS............................................................................................................... 48

4.1 M.M.

Read Addresses .......................................................................................................... 48

4.2 E.G.A. Read Addresses ........................................................................................................ 56

4.3 Input/ Output Modules Read Addresses .............................................................................. 58

4.4 Read/Write Addresses ......................................................................................................... 61

4.4.1 M.M. Read/Write Addresses ....................................................................................... 61

4.4.2 Analogue and Digital I/O Read/Write Addresses ....................................................... 61

4.5 Information, Errors and Lockouts .......................................................................................... 62

4.5.1 Digital Inputs (1x Reference) ........................................................................................ 62

4.5.2 Analogue Inputs (3x References) ................................................................................. 63

4.5.3 Error and Lockout Codes .............................................................................................. 64

4.5.4 Water Level .................................................................................................................. 68

5INTERACTING WITH THE MK7 D.T.I. ....................................................................... 69

5.1 Burner Information................................................................................................................ 69

5.2 M.M. Display Screen............................................................................................................ 71

5.3 Fault Logs.............................................................................................................................. 74

5.4 M.M. I.B.S Screen................................................................................................................. 75

5.5 Display Logs ......................................................................................................................... 76

5.6 E.G.A. Display Screen .......................................................................................................... 78

5.7 I.B.S Information ................................................................................................................... 79

1 Mk7 Data Transfer Interface Module

10.08.2015 Mk7 D.T.I. Set-Up Guide Page 1

1 MK7 DATA TRANSFER INTERFACE MODULE

1 Overview of the Mk7 D.T.I.

1.1.1 Introduction to the Mk7 D.T.I.

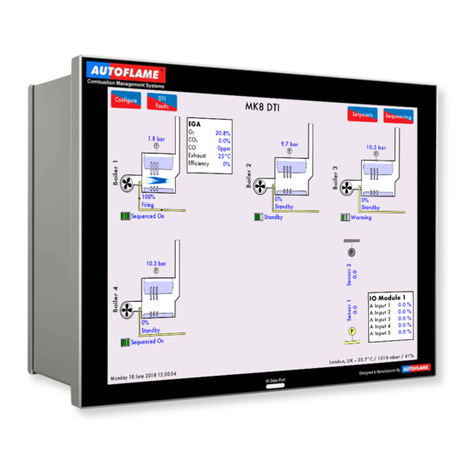

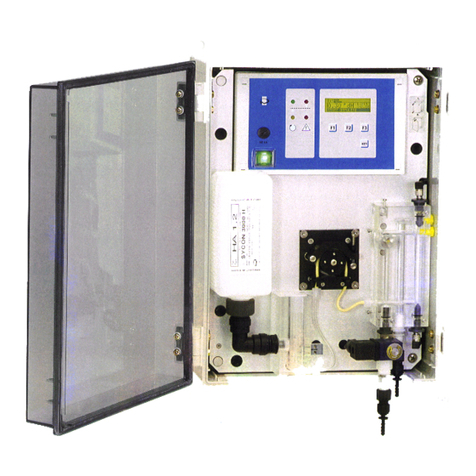

The Autoflame Data Transfer Interface (D.T.I.) is the gateway for communications between the M.M.

and E.G.A. range of products. All of the M.M. operational data, of up to ten M.Ms in one location, can

be collected by the D.T.I. The information gathered is available for transmission to an external source

via RS422 and Ethernet data links. The data gathered by the Mk7 D.T.I. can be collected and viewed

using the included CEMS Audit software, which allows data collection over a Local Area Network

(LAN), or over the internet.

Up to a maximum of ten M.M. modules, can be connected to one D.T.I. module. This can be a

combination of Mk7 M.M. modules and Mini Mk8 M.M. modules. It is also possible to receive data

from up to 10 E.G.A.s for emissions data. To accommodate the status information from other plant

related equipment, the D.T.I. can communicate with up to ten Mk6 Analogue and ten Mk6 Digital

Input/ Output Modules, or ten Mk7 Universal Input/ Output modules. The information gathered by the

D.T.I. from each system is then available for transmission to the Building Management System or

Energy Management System (BMS or EMS). This is done through the RS422 link or Ethernet to send

data via Modbus communications. Typical remote B.M.S. information and operational facilities are

subject to the particular site and management system requirements.

The Autoflame network operates using a two core screened cable and features dedicated data ports

for RS422 and Ethernet connections. The Mk7 D.T.I. poles each item on the network periodically,

storing up-to-date information every 2 seconds. The D.T.I. then outputs to defined Modbus addresses,

which are then available to third party systems like a B.M.S. The 10.4” touch-screen displays the

operational status of the D.T.I.’s communications, with corresponding error conditions in the event of a

communication failure.

1.1.2 Information Available from Mk7 D.T.I.

The Mk7 D.T.I. displays information from the Mk7 M.M., Mini Mk8 M.M., Mk8 E.G.A., and the Water

Level control. Remote on/off control of the burners can also be achieved as well as the adjustment of

the temperature or pressure setpoints and the sequence order. Through the D.T.I. touch screen, CEMS

Audit software and via Modbus, the following information is available:

Mk7 D.T.I. Input Values

Enable/disable burner

Change individual required setpoint

Change global required setpoint

Select lead boiler

Shuffle sequencing (not Modbus)

Set load index (firing rate)

Label and control input/outputs (not Modbus)

Mk7 M.M.

Actual boiler temperature (deg. C/F) or pressure (Bar/PSI)

Required setpoint i.e. required boiler temperature (deg. C/F) or pressure (Bar/PSI)

Burner on/off status

Burner firing rate (%)

Fuel selected

Burner rating

1 Mk7 Data Transfer Interface Module

Page 2 Mk7 D.T.I. Set-Up Guide 10.08.2015

Fuel flow metering values

Load detector type (temperature/pressure)

16 lockout and error history with date and conditions

Auto/hand/low flame hold operation

Number of channels used

Channe1, 2, 3, 4, 7, servomotor angle

Channel 5, 6 output and input signals to VFD with feedback history

Burner firing status phase (off, standby, purge, ignition, firing etc.)

Lead/lag boiler status

Sequence order

Sequence status (on, standby warming, off)

Enabled/disabled status

Total hours run

Number of start-ups per fuel

Online and commissioned gas/ oil pressure

Online and commissioned air pressure

UV scanner signal history

Mk8 E.G.A.

E.G.A. operation optioned

Standalone/M.M. operation

Flue gas O2present value

Flue gas CO2present value

Flue gas CO present value

Flue gas NO present value

Flue gas NO2present value (if optioned)

Flue gas SO2present value (if optioned)

Flue gas O2commissioned value

Flue gas CO2commissioned value

Flue gas CO commissioned value

Flue gas NO commissioned value

Flue gas NO2commissioned value (if optioned)

Flue gas SO2commissioned value (if optioned)

Flue gas exhaust temperature

Ambient temperature

Flue gas delta temperature

E.G.A. errors

Chiller condition

Current emissions by weight and volume (O2, CO2, CO, NO, SO3, H2O, N2, Total)

Totalised emissions by weight and volume (O2, CO2, CO, NO, SO3, H2O, N2, Total)

Heat input, heat loss and net useful heat

Net efficiency, gross efficiency and delta temperature

Fuel flow rates, instantaneous and totalised for up to 2 years

Fuel consumption, fuel costs instantaneous and totalise for up 2 years

1 Mk7 Data Transfer Interface Module

10.08.2015 Mk7 D.T.I. Set-Up Guide Page 3

Mini Mk 8 M.M.

Actual boiler temperature (deg. C/F) or pressure (Bar/PSI)

Required setpoint i.e. required boiler temperature (deg. C/F) or pressure (Bar/PSI)

Burner on/off status

Burner firing rate (%)

Fuel selected

Burner rating

Fuel flow metering values

Load detector type (temperature/pressure)

16 lockout and error history with date and conditions

Auto/hand/low flame hold operation

Number of channels used

Channe1, 2, 3 servomotor angle

Channel 4 output and input signals to VFD with feedback history

Burner firing status phase (off, standby, purge, ignition, firing etc.)

Lead/lag boiler status

Sequence order

Sequence status (on, standby warming, off)

Enabled/disabled status

Total hours run

Number of start-ups per fuel

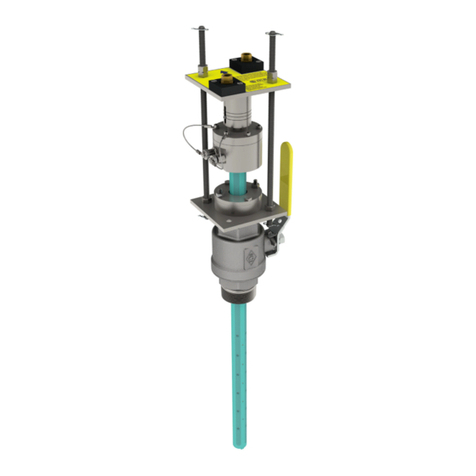

Water Level Control

Actual water level signal value for probe 1 and 2

Average water level signal of probes

Commissioned end of probe position

Commissioned 2nd low position

Commissioned 1st low position

Commissioned 1st low pre-alarm position

Commissioned control point position

Commissioned pump on/ pump off positions

Commissioned high water pre-alarm position

Commissioned high water position

15 First out annunciation inputs status

Instantaneous and totalised steam flow metering

Feedwater temperature

Feedwater valve position

Feedwater pump status

Feedwater VSD output

Steam temperature and pressure

Top blow down status and operation

TDS actual value

TDS valve position

TDS target value

16 Water level/ Expansion alarms conditions and date

Bottom blowdown operation

1 Mk7 Data Transfer Interface Module

Page 4 Mk7 D.T.I. Set-Up Guide 10.08.2015

1.2 Fixing Holes and Dimensions

2 Set-Up and Connections

10.08.2015 Mk7 D.T.I. Set-Up Guide Page 5

2 SET-UP AND CONNECTIONS

2.1 Wiring

2.1.1 Mk7 D.T.I. Wiring Diagram

Figure 2.1.1.i Mk7 D.T.I. Wiring Diagram

Electrical Specifications:

Max power for the Mk7 D.T.I. power supply is 184W.

Figure 2.1.1.ii Mk7 D.T.I. Board

2 Set-Up and Connections

Page 6 Mk7 D.T.I. Set-Up Guide 10.08.2015

2.1.2 System Schematic

2 Set-Up and Connections

10.08.2015 Mk7 D.T.I. Set-Up Guide Page 7

2.1.3 M.M. Modules Connection

2 Set-Up and Connections

Page 8 Mk7 D.T.I. Set-Up Guide 10.08.2015

2.1.4 Mk7 M.M. and Mk8 E.G.A. with Mk7 D.T.I.

2 Set-Up and Connections

10.08.2015 Mk7 D.T.I. Set-Up Guide Page 9

2.2 Mk7 D.T.I. Set-Up

2.2.1 Mk7 M.M. Options and Parameters

To get the Mk7 D.T.I. to communicate with the Mk7 M.M., the right communication settings need to be

set on the Mk7 M.M. The following options and parameters need to be set.

2 Set-Up and Connections

Page 10 Mk7 D.T.I. Set-Up Guide 10.08.2015

Option No.

Factory Setting

Option Value

Description

3 0 DTI Comms Mode

0 Mk6 DTI - 9600bps

1 Mk7 DTI - 19200bps

16 0 Lead/Lag (IBS) and DTI: A lead boiler can be selected by connecting a line voltage to terminal 88 on

the appropriate MM. Only 1 MM may be selected as lead boiler at a time, or the sequencing will

not operate. The lead boiler can be selected via the DTI. However, for this to be effective all the MM

units on the system must have Terminal 88 volt free. Line voltage on Terminal 88 overrides the DTI

command.

0 No sequencing - MM units still communicate and can be seen on the DTI.

1 Sequencing enabled - MM units will respond to sequencing commands. Lead boiler is selected by a line

voltage on terminal 88.

2 Setpoint & enable/disable commands accepted from DTI.

3 Both 1 and 2.

Note

:

Accurate fuel flow metering must be entered for sequencing to operate. An RS485 data cable

(Belden 9501) must be connected between each MM unit (see section 2.17.3.4 for correct connection).

30 50 DTI Required Setpoint Minimum Limit: If the system is being used with a DTI a maximum and

minimum limit for the required setpoint must be set. If a value is received from the DTI that is outside

these limits, it will be ignored and the system uses its previous required setpoint. Practical range is

limited to range of sensor selected.

5 - 9990 If Centigrade, Fahrenheit or PSI units effective.

0.5 - 999.0 If Bar units effective.

31 100 DTI Required Setpoint Maximum Limit:

5 - 9990 If Centigrade, Fahrenheit or PSI units effective.

0.5 - 999.0 If Bar units effective.

33 1 MM Identification: The identification number must be set on all MM Units in the boiler house. If

not, then problems will occur with sequencing/twin burner and with the DTI communications. Each

unit must have a different identification number.

34 5 Rating of Burner:

1 - 999 See Option 77 for units.

77 0 Burner rating units: Display purposes only for fuel flow metering.

0 KW x 100 /hr

1 Kg x 100 /hr

2 MW /hr

3 Btu x 100 /hr

4 Hp x 100 /hr

5 lbs x 100 /hr

6 Btu x 1000 /hr

7 Hp x 10 /hr

8 lbs x 1000 /hr

9 Btu x 1000 000 /hr

2 Set-Up and Connections

10.08.2015 Mk7 D.T.I. Set-Up Guide Page 11

Parameter No.

Factory Setting

Option Value

Description

57 0 0 - 10 Sequencing: Highest MM ID. This parameter speeds up communications between MM's

when sequening.

101 0 Shuffle sequencing:

0 Disabled

1 Sequence order changed from DTI.

2 Set-Up and Connections

Page 12 Mk7 D.T.I. Set-Up Guide 10.08.2015

2.2.2 Mini Mk8 M.M. Options and Parameters

To get the Mk7 D.T.I. to communicate with the Mini Mk8 M.M., the right communication settings need

to be set on the Mini Mk8 M.M. The following options and parameters need to be set.

Other manuals for Mk7

3

Table of contents

Other AUTOFLAME Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Vixen Horns

Vixen Horns VXA7240 installation guide

SellEton Scales

SellEton Scales SL-918 user manual

Hioki

Hioki HiTESTER 3415-02 instruction manual

Maxwell Digital Multimeters

Maxwell Digital Multimeters 25601 user manual

Vega

Vega INFO-1 operating manual

Precision Digital Corporation

Precision Digital Corporation PD6060 instruction manual