AUTOFLAME MK8 EGA EVO Manual

Mk8 EGA

Set-Up and Trim Guide

Mk8 EGA Set-Up and Trim Guide

Issued by:

AUTOFLAME ENGINEERING LTD

Unit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

Tel: +44 (0)845 872 2000

Fax: +44 (0)845 872 2010

Email: [email protected]

Website: http://www.autoflame.com/

Registered Holder:

Company:

Department:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

the consent of the Managing Director.

Autoflame Engineering Ltd’s policy is one of continuous improvement in both

design and manufacture. We therefore reserve the right to amend

specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Important Notes

A knowledge of combustion related procedures and commissioning is essential before

embarking work on any of the M.M./E.G.A. systems. This is for safety reasons and

effective use of the M.M./ E.G.A. system. Hands on training is required. For details on

schedules and fees relating to group training courses and individual instruction, please

contact the Autoflame Engineering Ltd. offices at the address listed on the front.

Short Form - General Terms and Conditions

A full statement of our business terms and conditions are printed on the reverse of all

invoices. A copy of these can be issued upon application, if requested in writing.

The System equipment and control concepts referred to in this Manual MUST be installed,

commissioned and applied by personnel skilled in the various technical disciplines that

are inherent to the Autoflame product range, i.e. combustion, electrical and control.

The sale of Autoflame’s systems and equipment referred to in this Manual assume that

the dealer, purchaser and installer has the necessary skills at his disposal. i.e. A high

degree of combustion engineering experience, and a thorough understanding of the

local electrical codes of practice concerning boilers, burners and their ancillary systems

and equipment.

Autoflame’s warranty from point of sale is two years on all electronic systems and

components.

One year on all mechanical systems, components and sensors.

The warranty assumes that all equipment supplied will be used for the purpose that

it was intended and in strict compliance with our technical recommendations. Auto-

flame’s warranty and guarantee is limited strictly to product build quality, and design.

Excluded absolutely are any claims arising from misapplication, incorrect installation

and/or incorrect commissioning.

Contents

1INTRODUCTION ......................................................................................... 1

1.1 Overview and Benefits.............................................................................................................1

1.1.1 Features and Benefits.......................................................................................................1

1.1.2 System Operation............................................................................................................1

1.2 3-Parameter Trim .....................................................................................................................2

1.3 Continuous Emissions Monitoring System ................................................................................3

2WIRING AND COMPONENTS...................................................................... 4

2.1 Flying Lead Wiring Diagram....................................................................................................4

2.2 Electrical Schematics................................................................................................................6

2.2.1 Interconnection between EGA and Mk8 MM..................................................................6

2.2.2 Interconnection between EGA and Mini Mk8 MM Module ............................................7

2.2.3 Interconnection between Stand-Alone Mk8 EGA and Mk7 DTI ......................................8

2.2.4 Interconnection between Mk8 MM, Mk8 EGA and Mk7 DTI..........................................9

2.3 Components.......................................................................................................................... 10

2.3.1 Inside View ................................................................................................................... 10

2.3.2 EGA Connections.......................................................................................................... 11

2.4 Cell Characteristics ............................................................................................................... 12

2.4.1 O2Cell .......................................................................................................................... 12

2.4.2 CO, NO, NO2and SO2Cells........................................................................................ 13

2.4.3 CO2 Sensor................................................................................................................. 13

3SET-UP...................................................................................................... 14

3.1 EGA Set-Up .......................................................................................................................... 14

3.1.1 Sampling Screen........................................................................................................... 14

3.1.2 Mk8 EGA Settings ........................................................................................................ 16

3.1.3 Cell Status Screen ......................................................................................................... 17

3.1.4 Fault History.................................................................................................................. 18

3.1.5 Factory Settings Screen ................................................................................................ 20

3.1.6 4-20mA Set-up.............................................................................................................. 21

3.1.7 Operating Mode Set-up................................................................................................ 22

3.1.8 Time and Date .............................................................................................................. 23

3.1.9 Change Password......................................................................................................... 24

3.2 CEMS Set-Up ........................................................................................................................ 25

3.2.1 Fuel Selection................................................................................................................ 25

3.2.2 Fuel Flow Source .......................................................................................................... 27

3.2.3 Unit Measurement ........................................................................................................ 28

3.3 CEMS Data Screens.............................................................................................................. 29

3.4 CEMS Energy Audits ............................................................................................................ 33

3.5 Trim Settings.......................................................................................................................... 35

3.5.1 Commissioning Procedure............................................................................................. 36

3.6 Mk8 EGA Trim...................................................................................................................... 37

3.6.1 Trim Operation ............................................................................................................. 37

3.6.2 Trim Timing Operation .................................................................................................. 40

3.6.3 Trim Correction Calculation .......................................................................................... 41

Example........................................................................................................................................ 41

3.6.4 Channel 5 Trim ............................................................................................................. 43

3.6.5 Combustion Efficiency Calculations .............................................................................. 43

3.7 Combustion Limits ................................................................................................................. 44

3.7.1 Overview of Combustion Limits..................................................................................... 44

3.7.2 Standard Limits ............................................................................................................. 44

3.7.3 Absolute Limits .............................................................................................................. 44

3.7.4 Combustion Limits Control Functions............................................................................. 44

3.7.5 O2Limits Example ......................................................................................................... 45

3.7.6 NO Limits Example ....................................................................................................... 46

3.7.7 CO Limit Example ......................................................................................................... 47

3.7.8 Temperature Limits Example ......................................................................................... 48

4DIMENSIONS AND EQUIPMENT................................................................ 49

4.1 Mk8 EGA Dimensions........................................................................................................... 49

4.2 Technical Specifications ........................................................................................................ 50

4.3 Sampling Probe .................................................................................................................... 51

4.3.1 Installation and Maintenance ....................................................................................... 51

4.3.2 Sampling Probe Assembly ............................................................................................ 52

4.3.3 Sampling Probe Internal Filter ...................................................................................... 53

4.3.4 Sampling Probe Maintenance ...................................................................................... 54

4.3.5 Servicing EGA Sampling Probe .................................................................................... 54

4.4 Ancillary Equipment.............................................................................................................. 55

4.4.1 External Particulate Filter .............................................................................................. 55

4.4.2 Air Inlet Filter ................................................................................................................ 56

4.4.3 Chilled Environmental Enclosure................................................................................... 57

4.4.4 Pre-Heat Air Sensor ...................................................................................................... 58

5ERROR CHECKING AND SELF-DIAGNOSTICS .............................................. 59

5.1 EGA Faults............................................................................................................................ 59

5.2 Troubleshooting .................................................................................................................... 60

5.2.1 Ambient Conditions ...................................................................................................... 60

5.2.2 Fuses............................................................................................................................. 60

5.2.3 O2Reading ................................................................................................................... 60

5.3 Mk8 EGA Faults ................................................................................................................... 61

5.3.1 Trim Delay .................................................................................................................... 63

5.3.2 Assembly of Dry Filter................................................................................................... 63

5.4 EGA Best Practice ................................................................................................................. 64

5.4.1 Servicing the EGA......................................................................................................... 65

5.4.2 Shipping the EGA ......................................................................................................... 65

6STANDARDS............................................................................................. 66

1 Introduction

12.04.2016 Mk8 EGA Set-Up and Trim Guide Page 1

1 INTRODUCTION

1.1 Overview and Benefits

1.1.1 Features and Benefits

The Mk8 Exhaust Gas Analyser (EGA) monitors the emissions in the flue produced from the

burner/boiler system. The EGA can improve combustion, increase efficiency, reduce fuel consumption

and improve safety through its 3 parameter trim function and combustion safety limits.

1. Stand-Alone: When in stand-alone mode, the EGA can be used without a Micro-Modulation

(MM) module to monitor the combustion gases. The MM trim function and the combustion

safety limits are not activated in this stand-alone mode of operation. The emissions levels can

be accessed via the full colour EGA touch screen.

2. With MM: When interfaced with an MM, the EGA can monitor emissions or the 3-parameter

combustion trim and safety limits can be activated. The emissions levels are monitored by the

EGA and the MM makes small adjustments to the air damper to trim the online exhaust gas

data back to the commissioned values. The EGA information is accessible through the full

colour EGA touch screen, the Data Transfer Interface module (DTI), or 6 x 4-20mA signals.

The main benefits of the EGA include the ability to monitor the exhaust gases and bring them to the

safe commissioned levels. Setting the combustion limits on the MM in conjunction with the EGA

prevents unsafe combustion scenarios, reducing the fuel consumed in bad combustion.

1.1.2 System Operation

The Mk8 EGA samples the combustion gases via the stack mounted sampling probe (purchased

separately from the analyser). The exhaust gases are drawn from the stack by a pump mounted

internally within the analyser. Only the supplied sample tubing should be used between the sampling

probe and analyser. The internal diameter of the sampling tube is 3mm; if a large diameter tubing is

used the sample gas remains resident in the tubing for a longer period. The EGA will then not be able

to respond in time to combustion changes, resulting in incorrect operation of the trim function.

Once the exhaust gases have entered the EGA the chiller block reduces their temperature and dries the

sample to remove the condensation from the gases prior to entering the cells. The condensate

accumulated in the chiller unit is drained every 4 minutes when running, and every 10 minutes when

the EGA is in idle mode, automatically through the drain solenoid.

The exhaust gas is then filtered through the dry filter, which is a fine filter used to remove any dust

particles carried over from the cooling process. If the burner is firing on heavy or dirty oil, an external

particulate filter must be used to remove the excess dirt particles. On leaving the filter, the exhaust gas

pressure is checked again to ensure that a vacuum is maintained prior to entering the pump and on

exiting the pump, the pressure produced by the pump is checked. Both these pressure sensors modulate

the flow rate of the sample into the EGA for consistent operation. Once the exhaust gases have been

conditioned, they are ready for an accurate sampling by the cells. After the gases have been sampled

by all the cells, the remaining sample is pumped out of the EGA from the clear tubing at the bottom of

the EGA casing.

Note: The EGA needs to vent to atmosphere via the drain solenoid on the bottom; this is also where

the EGA performs its air calibrations. Care should be taken to ensure the outlet is not restricted or that

contamination from exhaust gas occurs.

1 Introduction

Page 2 Mk8 EGA Set-Up and Trim Guide 12.04.2016

1.2 3-Parameter Trim

The 3-parameter trim function can be enabled when the Mk8 EGA is used in conjunction with an MM

module to manage the combustion. When the EGA detects any differences in the online exhaust gas

readings to the original commissioned values, the trim function will make small corrections to the air

damper (and channel 5 if optioned for trim), to bring those online values back to the commissioned

readings. The trim function controls the combustion of the burner by adding air (air rich) or taking

away air (fuel rich) from the commissioned air positions to keep the volume of O2, CO2and CO close to

their commissioned values without compromising safety. The air rich and fuel rich limits are set by

adding trim data when commissioning the burner or through single point change for ‘quick

commission.’ This trim data is translated into a combustion map, which shows how the burner reacts

when air is added or removed from the combustion process during commissioning. The Autoflame

system continually monitors 3 parameters O2, CO2and CO to create the safest and most efficient way

of trimming the combustion process.

Ingress of tramp air through an ill-fitting boiler or flue section will distort the O2reading and show an

increase in this value. This results in the EGA reading the tramp air influence in the sample rather than

just the actual combustion gases.

Single parameter O2trim systems would see both of these conditions as rich (excess air) combustion

and start to trim back on the air by closing the air damper. In reality this trim process is not trimming the

combustion gases at this point, but is in fact trimming the exhaust gases with the excess O2. This can

potentially lead to the formation of excessive amounts of CO but more importantly this can lead to

incomplete combustion with dangerous consequences.

Similarly, single parameter CO2trim systems would interpret of air as lower CO2levels in the flue,

inflicting similar dangerous conditions in the boiler.

Another benefit of the 3 parameter trim is that the EGA is continually measuring the formation of CO

compared to its commissioned value. A higher CO reading can be contributed to both lean and rich

combustion. A lack of air will produce incomplete combustion and the formation of CO. Also, excess

air around the flame envelope can chill the flame edge causing incomplete combustion and higher CO

levels.

By referencing all 3 parameters against mapped combustion performance the burner can be trimmed

back to the original commissioned values whilst maintaining the highest degree of safety.

When the trim function adds air to bring back the combustion to the commissioned values, as the

burner modulates to a new position, the deviation in air damper movement is added to each air

position. In this way, optimum combustion is maintained during modulation, through carry forward trim.

As a safety feature, as the air is being taken away, the fuel to air ratio will return back to the

commissioned positions when the burner modulates, for every 10 degrees of fuel valve movement.

Once this new position is held the system will determine whether the air damper should be closing. This

ensures safe combustion at all times without any compromise.

1 Introduction

12.04.2016 Mk8 EGA Set-Up and Trim Guide Page 3

1.3 Continuous Emissions Monitoring System

The Mk8 EGA now has the CEMS function included as standard, logging the exhaust gas and fuel data

for up to 2 years. This data includes the gas readings, flue temperature, calculated efficiency and fuel

consumption.

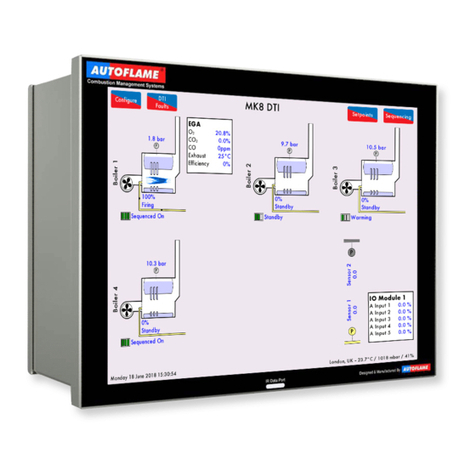

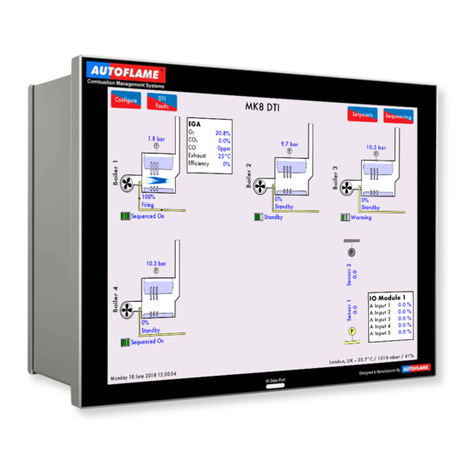

When using a standalone Mk8 EGA a direct connection as shown in section 2.2.3 will be required to

view and log up to 2 years of data on the Mk7 DTI The DTI will need to be set-up as ‘EGA direct’

through the ‘Edit Boiler’ screen and the EGA setup for standalone operation (EGA selects fuel).

Using the EGA in conjunction with the MM module and D.T.I, a data link will be required between the

MM and EGA and from the EGA to the DTI (see section 2.2.4). The DTI will need to be setup as ‘EGA

Direct’ not ‘EGA through MM’

For multiple MMs, each with the EGAs, refer to both sections 2.2.3 and 2.2.4. There will need to be

data cable connected as a daisy chain between the EGAs and DTI, a data cable daisy chain between

the MMs and DTI, and data cable links between each MM and its corresponding EGA.

2 Wiring and Components

Page 4 Mk8 EGA Set-Up and Trim Guide 12.04.2016

2 WIRING AND COMPONENTS

2.1 Flying Lead Wiring Diagram

Data Connector

Figure 2.1.i Data Connector – Insert Pin Mating View

Pin Number Assigned function

1 4-20 mA Output Channel (1+)

2 4-20 mA Output Channel (2+)

3 4-20 mA Output Channel (3+)

4 4-20 mA Output Channel (4+)

5 4-20 mA Output Channel (5+)

6 4-20 mA Output Channel (6+)

7 4-20 mA Output Common (-)

8 Fuel 1 Select Input

9 Fuel 2 Select Input

10 Fuel 3 Select Input

11 Fuel 4 Select Input

12 Fuel Select Input common

13 MM Comms (-)

14 MM Comms (+)

15 DTI Comms (-)

16 DTI Comms (+)

17 4-20mA Input (-)

18 4-20mA Input (+)

19 Not Connected

Note: The data cable should be screened at the MM/DTI end and connected all the way to the EGA

plug; the screen from the flying lead provided should be connected to the data cables that connect to

the MM/DTI.

Note: Fuel Select Inputs in standalone mode are low voltage. To select a fuel, put a link on the ‘Fuel X

Select Input’ to the Fuel Select Input Common e.g. to select fuel 1, link pin 8 to pin 12 to select fuel 1 in

standalone mode.

2 Wiring and Components

12.04.2016 Mk8 EGA Set-Up and Trim Guide Page 5

Mains Connector

Figure 2.1.ii Mains Connector – Insert Pin Mating View

Pin Number Assigned function

1 Live

2 Live for HSL

3 Earth for HSL

4 Neutral for HSL

5 Neutral

6 Earth

Auxiliary Connector

Figure 2.1.iii Auxiliary Connector – Insert Pin Mating View

Pin Number Assigned function

1 External Drain (0V)

2

3

4

5 External Drain (+24V)

6

2 Wiring and Components

Page 6 Mk8 EGA Set-Up and Trim Guide 12.04.2016

2.2 Electrical Schematics

2.2.1 Interconnection between EGA and Mk8 MM

2 Wiring and Components

12.04.2016 Mk8 EGA Set-Up and Trim Guide Page 7

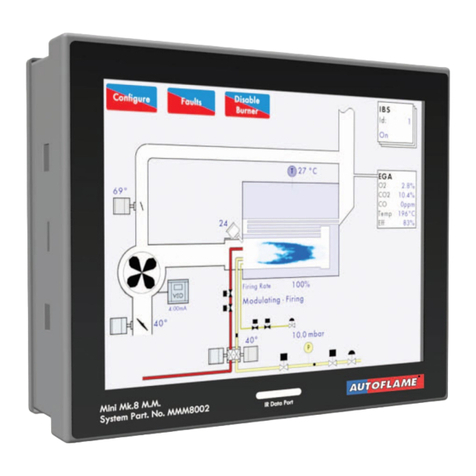

2.2.2 Interconnection between EGA and Mini Mk8 MM Module

2 Wiring and Components

Page 8 Mk8 EGA Set-Up and Trim Guide 12.04.2016

2.2.3 Interconnection between Stand-Alone Mk8 EGA and Mk7 DTI

2 Wiring and Components

12.04.2016 Mk8 EGA Set-Up and Trim Guide Page 9

2.2.4 Interconnection between Mk8 MM, Mk8 EGA and Mk7 DTI

2 Wiring and Components

Page 10 Mk8 EGA Set-Up and Trim Guide 12.04.2016

2.3 Components

2.3.1 Inside View

Figure 2.3.1.i Inside View

1. Particulate Filter

2. Chiller Block

3. Pinch Valve

4. Drain Solenoid

5. NO Cell

6. CO Cell

7. O

2

Cell

8. CO

2

Cell

9. CR Battery

10. Software Update Jumpers

11. Cell Pump

12. EGA Fan

Other manuals for MK8 EGA EVO

3

Table of contents

Other AUTOFLAME Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Aqua Medic

Aqua Medic Marin Control Digital Operation manual

Delta OHM

Delta OHM HD21ABE manual

Unit

Unit UT2658 operating manual

Check-line

Check-line TI-CMXDL operating manual

Centech

Centech 97389 Set up and operating instructions

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. KEW SNAP 2431 instruction manual