AUTOFLAME MK8 EGA EVO User manual

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 1

Mk8 EGA EVO

Set-Up Guide

尾气分析仪

设置指南

1 Installation and Wiring

Page 2 Mk8 EGA Evo Set-Up Guide 20.03.2017

EGA Set-Up Guide

尾气分析仪设置指南

Issued b

AUTOFLAME ENGINEERING LTDUnit 1-2, Concorde Business Centre

Airport Industrial Estate, Wireless Road

Biggin Hill, Kent TN16 3YN

发布公司:

AUTOFLAME 工程有限公司

Tel

电话

: +44 (0)845 872 2000

Fax 传真: +44 (0)845 872 2010

Website 网站: www.autoflame.com

Registered Holder 所有人:

Company 公司:

Department 部门:

This manual and all the information contained herein is copyright of

Autoflame Engineering Ltd. It may not be copied in the whole or part without

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 3

the consent of the Managing Director.

Autoflame工程有限公司拥有本手册的所有版权。在未经 Autoflame公司总经理

同意的情况下,本手册内容不得被整体或部分引用。

Autoflame Engineering Ltd’s policy is one of continuous improvement in

both design and manufacture. We therefore reserve the right to amend

specifications and/or data without prior notice. All details contained in this

manual are correct at the time of going to print.

Autoflame工程有限公司致力于不断提升 Autoflame产品的设计和制造,我们保

留随时修订本手册的权利,所有本手册中提及的详细数据在印刷时为最新版。

1 Installation and Wiring

Page 4 Mk8 EGA Evo Set-Up Guide 20.03.2017

Important

Notes

重要说明

A knowledge of

combustion

related

procedures

and

commissioning

is

essential

before embarking work on any of the M.M./E.G.A.

systems. This

is for safety

reasons and effective

use

of the

M.M./

E.G.A. system.

Hands on training

is

required. For details on

schedules

and

fees

relating to group training

courses

and individual

instruction,

please

contact

the Autoflame

Engineering Ltd. offices

at the

address listed

on the front.

为了安全有效地使用控制模块/EGA 系统,控制模块/EGA 系统的操作员必须具有与燃

烧相关的流程知识和调试知识。我们要求操作员参加实践培训,请按首页所述地址联

系Autoflame 办公室以详细了解团体培训课程和个别辅导的时间与费用。

Short Form -

General

Terms

and

Conditions

一般条款

A full statement of our

business terms

and

conditions

are printed on the reverse

of all

invoices.

Acopyof

these can

be

issued

upon application, if requested in

writing.

所有发票背面均印有我方商业条款全文。客户可通过书面申请的形式获取我公司的商

业条款文件。

The System

equipment

and

control concepts

referred to

in this

Manual

MUST

be

installed,

commissioned

and applied by

personnel

skilledin the various

technical

disciplines

that are inherent to the Autoflame

product

range, i.e.

combustion,

electrical

and control.

本手册所提及的系统设备和控制原理须由精通 Autoflame 产品燃烧、电气和控制等技

术的专业人员进行安装、调试和使用。

The

sale of Autoflame’s

systems

and equipment referred to in

this

Manual

assume

that the dealer,

purchaser

and installer has the

necessary skills

at his

disposal.

i.e. A high degree of

combustion

engineering experience, and a

thorough understanding of the

local electri

c

al

codes

of

practice concerning

boilers, burners

and their ancillary systems and equipment.

经销商、采购商和安装人员必须具有丰富的相关工作经验、全面了解当地锅炉、燃烧

器和辅助系统及设备相关的电气行业规范方能使用本手册提及的 Autoflame 系统和设

备。

Autoflame’s warranty from point of sale is two years on all

electronic systems

and components.

Autoflame 保修条款: 对所有电子系统和部件实行两年售后保修。

One year on all

mechanical systems, components

and sensors.

对所有机械系统、部件和传感器实行一年售后保修。

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 5

The

warranty

assumes

that all equipment supplied will be used for the

purpose that it was intended and in

strict compliance

with our

technical

recommendations.

Auto

-

flame’s warranty and guarantee

is

limited

strictly

to

product

build quality, and design.

Excluded

absolutely are any

claims

arising

from

misapplication, incorrect

installation and/or

incorrect

commissioning.

保修条件: 所有设备均按照预期使用目的使用,并严格遵守我方提供的技术建议。

Autoflame 产品保修条款仅适用于产品制造质量问题和设计问题。根据保修条款,

Autoflame 不接受因误操作、误安装和/或误调试导致的任何索赔请求。

1 Installation and Wiring

Page 6 Mk8 EGA Evo Set-Up Guide 20.03.2017

Contents 目录 .........................................................................................6

1INSTALLATION AND WIRING 安装和连接 ...................................................................9

1.1EGA 尾气分析仪 .....................................................................................................9

1.1.1 Inside View 内视图.........................................................................................10

1.2 Fixing Holes and Dimensions 固定孔和尺寸..........................................................11

1.3 Technical Specifications 技术规范 ........................................................................12

1.4 Flying Lead Wiring 飞线接线图..............................................................................13

1.4.1 EGA Connections 尾气分析仪连接.................................................................13

1.4.2 Flying Leads 飞线 ..........................................................................................14

1.5 Installing Sampling Probe and EGA 安装采样探头和尾气分析仪...........................15

1.5.1 Sampling Probe Dimensions 采样探头尺寸....................................................16

1.5.2 Sampling Probe –Internal Layout 采样探头内部结构.....................................18

1.5.3 Assembly of Dry Filter 干滤器的组装..............................................................19

1.5.4 Sampling Probe Installation 采样探头的安装..................................................20

1.5.5 EGA Installation 尾气分析仪的安装................................................................22

1.5.6 Cable Specification 电缆规范 .........................................................................24

1.6 Wiring Schematics 接线示意图..............................................................................26

1.6.1 Connection between EGA and Mk8 MM 尾气分析仪和 Mk8 控制模块的连接.....26

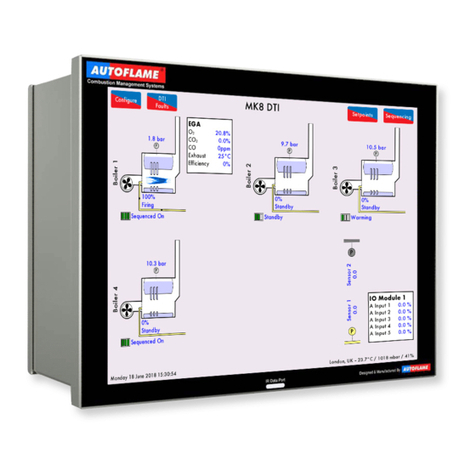

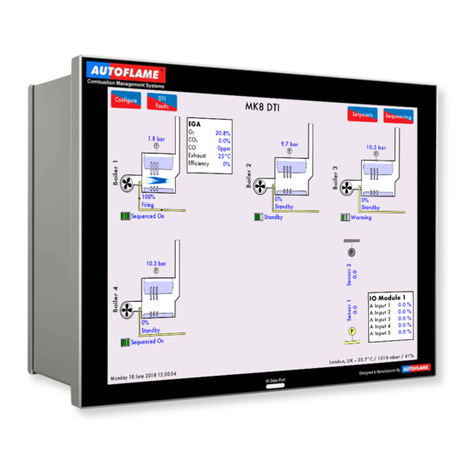

1.6.2 Connection between EGA, MM and DTI..........................................................27

尾气分析仪、控制模块和数据传输接口的连接..............................................................27

1.6.3 Connection between EGA and DTI 尾气分析仪和数据传输接口的连接 ..........28

1.7 Ancillary Parts 辅助部件........................................................................................29

1.7.1 Air Inlet Filter 进气过滤器...............................................................................29

1.7.2 External Particulate Filter 外部微粒过滤器 .....................................................30

1.7.3 Chilled Environmental Enclosure 冷冻环境保护罩..........................................31

1.7.4 Pre-Heated Air Sensor 预热空气传感器 .........................................................33

2COMMISSIONING EGA 调试尾气分析仪.....................................................................35

2.1 Operating Modes 运行模式 ...................................................................................35

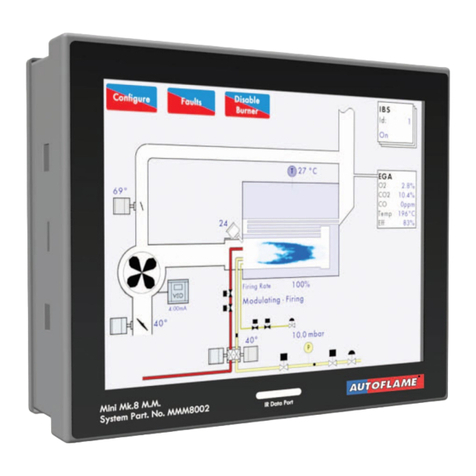

2.1.1 EGA through MM 通过控制模块调试尾气分析仪 ...........................................35

2.1.2 Standalone EGA 单机运行尾气分析仪 ..........................................................37

2.2 EGA Settings 尾气分析仪的设置 ...........................................................................38

2.2.1 Commission Mode Settings 调试模式设置 .....................................................41

2.2.2 Fuel Setup Settings 燃料设置 ........................................................................51

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 7

2.2.3 Analogue Setup Settings模拟设置.................................................................60

2.3 Commissioning MM with EGA 用尾气分析仪调试控制模块 ...................................68

2.4 Calibration Schedule 校准安排..............................................................................70

2.5 Resetting Data 重置数据.......................................................................................73

2.5.1 Reset Cells to Factory Calibration 重置感应器至出厂设置..............................73

2.5.2 Reset Run Times 重置运行时间.....................................................................73

2.5.3 Reset Other Data 重置其他数据.....................................................................74

3SYSTEM CONFIGURATION 系统设置 ........................................................................ 75

3.1 Language 语言......................................................................................................75

3.2 Set Clock 设置时钟 ...............................................................................................76

3.3 Online Changes 在线修改 .....................................................................................77

3.3.1 Settings 设置..................................................................................................77

3.3.2 Fuel Setup 燃料设置 ......................................................................................77

3.3.3 Calibration Schedule 校准安排.......................................................................78

3.4 Run Times 运行时间 .............................................................................................78

3.5 Diagnostics 故障诊断 ............................................................................................80

3.6 System Log 系统日志............................................................................................82

3.7 Manual 用户手册...................................................................................................83

3.8 Cell Information 感应器信息 ..................................................................................84

3.8.1 O2Cell Characteristics 氧气感应器的特点......................................................86

3.8.2 CO, NO, NO2and SO2Cell Charaacteristics CO、NO、NO2和SO2感应器的特

点................................................................................................................................. 88

3.8.3 CO2 Sensor CO2传感器 ................................................................................90

3.9 Calibrate Now 开始校准 ........................................................................................90

4EGA OPERATION 尾气分析仪的操作..........................................................................91

4.1 Sampling Screen Icons 采样屏幕图标...................................................................91

4.1.1 Temperature 温度 .........................................................................................92

4.1.2 Emissions 排放 ..............................................................................................94

4.1.3 Pressure 压力 ................................................................................................96

4.1.4 Fuel Flow 燃料流量........................................................................................98

4.1.5 Faults 故障.....................................................................................................99

4.2 EGA Overview 尾气分析仪概述...........................................................................101

4.2.1 Features and Benefits 特点和优点 ...............................................................101

4.2.2 System Operation 系统运行 .........................................................................101

1 Installation and Wiring

Page 8 Mk8 EGA Evo Set-Up Guide 20.03.2017

4.2.3 Overview of 3-Parameter Trim 3 参数调节概述 ............................................103

4.3 EGA Trim Function 尾气分析仪的调节功能 ......................................................... 105

4.3.1 Trim Operation 调节操作..............................................................................105

4.3.2 Important of Measuring 3-Parameters 3参数测量的重要性.......................... 106

4.3.3 Trim Correction Calculation 调试校正值的计算 ............................................108

4.3.4 Trim Timing Operation 调节定时操作 ..........................................................111

4.3.5 Channel 5 Trim (Mk8 MM Only) 通道 5的调节(仅用于 Mk8 控制模块)....111

4.3.6 Trim Delay 调节延迟 ...................................................................................112

4.4 Combustion Efficiency Calculations 燃烧效率的计算...........................................113

4.5 Combustion Limits 燃烧限值 ...............................................................................114

4.5.1 O2Combustion Limits 氧气燃烧限值 ............................................................116

4.5.2 NO Combustion Limits 一氧化氮燃烧限值....................................................117

4.5.3 CO Combustion Limits 一氧化碳燃烧限值....................................................118

4.5.4 Temperature Limits 温度限值....................................................................... 119

5SERVICING AND TROUBLESHOOTING 维护和故障排除........................................ 120

5.1 Servicing 维护.....................................................................................................120

5.1.1 Sampling Probe Maintenance 采样探头的维护 ............................................120

5.1.2 Servicing EGA Sampling Probe 尾气分析仪采样探头的维护 ........................122

5.2 Shipping 运输......................................................................................................124

5.3 Fault Codes 故障代码 .........................................................................................125

5.3.1 General Troubleshooting 一般故障排除 .......................................................128

5.3.2 Faults on MM 控制模块故障.........................................................................129

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 9

1 INSTALLATION AND WIRING 安装和连接

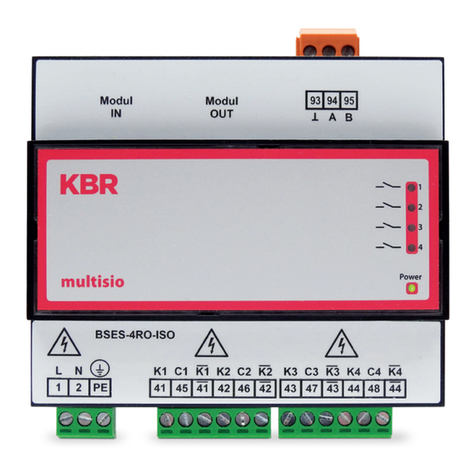

1.1 EGA 尾气分析仪

1 Installation and Wiring

Page 10 Mk8 EGA Evo Set-Up Guide 20.03.2017

1.1.1 Inside View 内视图

Figure 1.1.1.i Inside view

图

1.1.1.i

内视图

1. Dry filter 干滤器

2. Chiller block 冷却器组

3. Pinch valve 夹管阀

4. Drain solenoid 排放电磁阀

5. NO2cell (optional) NO2感应器(可选)

6. SO2 cell (optional) SO2感应器(可选)

7. NO cell NO 感应器

8. O2cell O2感应器

9. CO cell CO 感应器

10. CO2cell CO2感应器

11. Battery 电池

12. Pump 组件泵

13. Fan 风机

1

4

2

3

9

5

6

7

8

10

11

12

13

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 11

1.2 Fixing Holes and Dimensions 固定孔和尺寸

Drawing No. 7976

图纸编号:7976

1 Installation and Wiring

Page 12 Mk8 EGA Evo Set-Up Guide 20.03.2017

1.3 Technical Specifications 技术规范

Electrical Supply

电源

230/110V (minimum 100V, maximum 240V)

50/60 Hz

Power Rating

功率额定值

160W

Max Power Consumption

最大功率消耗

225W

Fuse Rating

保险丝额定值

4A

Environmental Rating

环境额定值

IP20, NEMA 1

Internal Temperature

内部温度

5 –40°C (40 –104°F)

K Type Thermocouple

K型热电偶

0 –400°C (32 –752°F)

Sampling

TubingEnvironment

Temperature

采样管环境温度

Maximum 60°C (140°F)

最大 60°C (140°F)

Pump Flow

泵流量

600ml/min

Heating Sampling Line

加热采样线

Requires separate power supply.

需要独立电源。

Power consumption will depend on application and length.

功率消耗取决于应用场所和持续时间。

Fuse rating on EGA for HSL is 20A.

用于加热采样线的尾气分析仪保险丝额定值是 20A。

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 13

1.4 Flying Lead Wiring 飞线接线图

1.4.1 EGA Connections 尾气分析仪连接

1. Pre-heated air sensor connection 预热空气传感器连接

2. Exhaust temperature thermocouple connection 排气温度热电偶连接

3. Sampling line connection 采样线连接

4. Mains flying leading connection 电源飞线连接

5. Data flying leading connection 数据飞线连接

6. Auxiliary flying lead connection 辅助飞线连接

Drawing No. 9058 图纸编号:9058

1

2

3

6

5

4

1 Installation and Wiring

Page 14 Mk8 EGA Evo Set-Up Guide 20.03.2017

1.4.2 Flying Leads 飞线

Mains Flying Lead 电源飞线

Figure 1.4.2.i Mains

图

1.4.2.i

电源飞线

(Insert Pin Mating View)

(插针匹配图)

Pin 针号

Description 说明

1

Live 火线

2

Live for HSL*

加热采样线火线

3

Earth for HSL

加热采样线地线

4

Neutral for HSL

加热采样线零线

5

Neutral 零线

6

Earth 地线

*Note: If a Heated Sample Line (HSL) is fitted,

then a separate power supply is required.

*注:如已安装加热采样线,则需要一个独立电源。

Data Flying Lead 数据飞线

Figure 1.4.2.ii Data

图

1.4.2.ii

数据飞线

(Insert Pin Mating View)

(插针匹配图)

Pin

针号

Description

说明

1

Channel 1 4-20mA Output (+)

4-20mA 通道 1输出(+)

2

Channel 2 4-20mA Output (+)

4-20mA 通道 2输出(+)

3

Channel 3 4-20mA Output (+)

4-20mA 通道 3输出(+)

4

Channel 4 4-20mA Output (+)

4-20mA 通道 4输出(+)

5

Channel 5 4-20mA Output (+)

4-20mA 通道 5输出(+)

6

Channel 6 4-20mA Output (+)

4-20mA 通道 6输出(+)

7

Common for 4-20mA Outputs (-)

4-20mA 输出命令(-)

8

Fuel 1 Select Input

燃料 1选择输出

9

Fuel 2 Select Input

燃料 2选择输出

10

Fuel 3 Select Input

燃料 3选择输出

11

Fuel 4 Select Input

燃料 4选择输出

12

Common for Fuel Select Input

燃料选择输入命令

13

MM Comms (-)

控制模块通信(-)

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 15

14

MM Comms (+)

控制模块通信(+)

15

DTI Comms (-)

数据传输接口通信(-)

16

DTI Comms (+)

数据传输接口通信(+)

17

Common for Fuel Flow 4-20mA Input (-)

4-20mA 燃料流量输入命令(-)

18

Fuel Flow 4-20mA Input (+)

4-20mA 燃料流量输入(+)

19

Unused

未使用

*Note: For standalone mode, a fuel select must be

connected to pin 12 Common for Fuel Select

Input.

注:在单机模式下,燃料选择必须连接针 12 燃料

选择输入命令。

Auxiliary Flying Lead 辅助飞线

Figure 1.4.2.iii Auxiliary

图

1.4.2.iii

辅助飞线

(Insert Pin Mating View)

(插针匹配图)

Pin 针号

Description 说明

1

External Drain (0V)*

外部排放(0V)*

2

Unused

未使用

3

Unused

未使用

4

Unused

未使用

5

External Drain (24V)

外部排放(24V)

6

Unused

未使用

*Note: If an external particulate filter is fitted, then

the 24V DC power supply required for the external

drain, comes from the EGA.

* 注:如已安装外部颗粒过滤器,则外部排放所需

的24V 直流电源来自尾气分析仪。

1.5 Installing Sampling Probe and EGA 安装采样探头和尾气分析仪

The sampling probe must be purchased separately to the EGA and is supplied with the

sampling tube for the exhaust gases and the thermocouple. The sampling tube and

thermocouple is available in the below standard lengths, however if a different length is

required, please contact Autoflame.

采样探头必须和尾气分析仪分开购买,采样探头配备了用于排气采样的采样管和热电偶。采样

管和热电偶的标准长度见下表,如需不同长度,请联系 Autoflame。

Sampling Probe

采样探头

Sampling Tube and Thermocouple Length

采样管和热电偶长度

MM10033

3m (10ft)

1 Installation and Wiring

Page 16 Mk8 EGA Evo Set-Up Guide 20.03.2017

MM10033/5

5m (16ft)

MM10033/10

10m (33ft)

The EGA should be checked before installing it on site. It is advisory that EGA remains

upright during any tests and checks. Thereafter the E.G.A should be turned off for a period

(couple of hours), and turned back on again to drain out any excess moisture remaining in

the EGA.

安装尾气分析仪前必须对其进行检查。在测试和检查期间建议使尾气分析仪保持直立状态,随

后应将尾气分析仪关闭一段时间(数小时),然后再次开启使其排出内部剩余的水分。

1.5.1 Sampling Probe Dimensions 采样探头尺寸

1. Internal filter 内部过滤器

2. Set screw 2mm (5/64”) 固定螺丝 2mm (5/64”)

3. Threaded probe socket 1.5” BSP/ NPT 螺纹探头插座 1.5” BSP/ NPT

4. Exhaust temperature thermocouple slot 排气温度热电偶槽

5. Set screw 2mm (5/64”) 固定螺丝 2mm (5/64”)

6. Sampling line hole 采样线孔

Figure 1.5.1.i Sampling Probe Assembly

图

1.5.1.i

采样探头总成

1

2

3

4

5

6

Drawing No. 9058

图纸编号:9058

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 17

Figure 1.5.1.ii Sampling Probe Dimensions

图

1.5.1.ii

采样探头尺寸

1 Installation and Wiring

Page 18 Mk8 EGA Evo Set-Up Guide 20.03.2017

1.5.2 Sampling Probe –Internal Layout 采样探头内部结构

Figure 1.5.2.i Sampling Probe Internal Layout

图

1.5.2.i

采样探头内部结构

1 Installation and Wiring

20.03.2017 Mk8 EGA Evo Set-Up Guide Page 19

1.5.3 Assembly of Dry Filter 干滤器的组装

If pump faults are occurring on the EGA it is advised to check the dry filter in the EGA and

check for any blockages and make sure that the filter material has not become saturated.

如尾气分析仪上的泵发生故障,我们建议检查尾气分析仪内的干滤器以及是否堵塞,确保过滤

材料未饱和。

N.B. FREE SPACE MUST BE LEFT AT BOTTOM TO STOP ANY PREMATURE BLOCKAGE

THE SAMPLE IN & OUT PIPES MUST BE CONNECTED CORRECTLY OR BLOCKAGE WILL OCCUR

WITHIN A FEW HOURS.

注意底部必须留有自由空间以防止过早堵塞。必须正确连接样本进出口管,否则在几

小时内就会发生堵塞。

This filter is specifically used as a dry filter to remove and dust particulate before the dry gas

passed into the cells. The filter is carefully packed as a complete replacement part and

should be repacked or the filter material changed in the field, as the filter is critically

calibrated for a specific pressure drop. The filter should always be dry, if any carryover of

liquid or moisture is sent in the filter, please isolate the EGA and contact Autoflame

Technical Support.

该过滤器专门用作干滤器,用于在干燃气进入感应器前清除灰尘微粒。干滤器作为完整的替换

件经过仔细包装,在现场需要重新包装或更换过滤材料,因为该过滤器是按特定的压降进行校

准。干滤器应始终保持干燥,如果过滤器内出现液体或水份,请隔离尾气分析仪并联系

Autoflame 技术支持。

1 Installation and Wiring

Page 20 Mk8 EGA Evo Set-Up Guide 20.03.2017

1.5.4 Sampling Probe Installation 采样探头的安装

The sampling probe must be installed as per the below guide to prevent any blockages in

the line and incorrect operation.

采样探头必须根据以下规定安装,以防采样线内堵塞和错误运行。

1. Install a 1.5” BSP socket on the flue where the sampling probe is to be positioned.

在烟道内安装一个 1.5” BSP 插座使采样探头定位。

a. If using the Autoflame draft control system, the sampling probe should be

positioned after the stack damper and air pressure sensor.

如使用 Autoflame 通风控制系统,则采样探头应在固定排气管挡板和空气压力

传感器后定位。

b. If using a single EGA on a twin furnace, the sampling probe should be

positioned after the individual flues are combined into one stack.

如在一个双炉上使用一个尾气分析仪,则采样探头应在烟道连接排气管后定

位。

c. If an economiser is fitted to the flue, the sampling probe should be positioned

before the economiser.

如在烟道内安装节能器,则采样探头应在固定节能器前定位。

2. Mount the sampling probe at an angle of approximately 45Ointo the stack. This will

allow any condensate in the sample to flow down to the EGA rather causing

blockages in the sampling line. A build-up of condensation in the EGA could result in

a pump failure. 将采样探头按 45 度角安装在排气管中。这样样本中的冷凝水将不会流

入尾气分析仪而导致采样线堵塞,累积在尾气分析仪内的冷凝水可导致泵故障。

3. Mount the main body of the sampling probe as far in as possible; adjustment is made

by loosening the grub screws in the flats of the 1.5” BSP bush supplied on the probe.

在尽可能远的位置安装采样探头主体,松开探头上 1.5” BSP 衬套固定螺丝可以进行调

节。

Notes 备注

Keep the thermocouple and blue sampling tube away from hot surfaces.

使热电偶和蓝色采样管远离热表面。

The thermocouple should be positioned away from high voltage cabling.

使热电偶远离高压线。

Ensure that the thermocouple and sampling tube run from the sampling probe to the

EGA with no coils or loops.

确保热电偶和采样管从采样探头至尾气分析仪之间没有盘绕或卷线现象。

The sampling probe must be positioned without air leaks as this will result in incorrect

readings on all cells.

采样探头必须正确定位而无空气泄露,因为这将导致所有传感器读数不准确。

If the thermocouple is run in conduit from the sampling probe to the EGA, this must

be earthed.

如热电偶在采样探头至尾气分析仪的管道内运行,则热电偶必须接地。

Other manuals for MK8 EGA EVO

3

Table of contents

Languages:

Other AUTOFLAME Measuring Instrument manuals