AUTOFLAME Mk7 User manual

M

Mk7

D.T.I.

Set-Up

Guide

Mk7

数据传输接口设置指南

Mk7

D.T.I.

Set-Up

Guide

Mk7

数据传输

接口设置指南

Issued

by 发布公司:

AUTOFLAME

ENGINEERING

LTD

AUTOFLAME 工程有限公司

Unit 1-2,

Concorde Business

C

entre

Airport Industrial

Estate,

WirelessRoad

Biggin

Hill, Kent TN16

3YN

Tel:

+44 (0)845 872

2000

电话:

+44 (0)845 872

2000

Fax: +44 (0)845 872

2010

传真:+44 (0)845 872

2010

Email: [email protected]

电子邮件:

Website:

http://www.autoflame.com/

网站:

http://www.autoflame.com/

Registered

Holder 注册持有人:

Company 公司:

Department 部门:

This

manual and all the information

contained

herein

is copyright

of

Autoflame

Engineering Ltd.

It may not be

copied

in the whole or part without

the

consent

of the Managing

Director.

Autoflame工程有限公司拥有本手册的所有版权。在未经Autoflame公司常务董事同意的情况

下,本手册内容不得被整体或部分引用。

Autoflame

Engineering Ltd’s policy is

one of

continuous

improvement in

both

design

and manufacture. We therefore reserve the right to

a

m

end

specifications

and/pr data without prior

notice.

All details

contained

in

this

manual are

correct

at the time of going to print.

Autoflame工程有限公司致力于不断提升Autoflame产品的设计和制造,我们保留修订本手册

规范/数据的权利,恕不另行通知。本手册内容于付印时准确无误。

Important

Notes

重要说明

A knowledge of

combustion

related

procedures

and

commissioning is essential

before

embarking work on any of the M.M./E.G.A.

systems. This

is for safety reasons and

effective

use

of the

M.M./

E.G.A. system.

Hands on training

is

required. For details on

schedules

and

fees

relating to group training

courses

and individual

instruction,

please

contact

the Autoflame

Engineering Ltd. offices

at the

address listed

on the front.

为了安全有效地使用控制模块/EGA系统,控制模块/EGA系统的操作员必须具有与燃烧相关的流程知

识和调试知识。我们要求操作员参加实践培训,请按首页所述地址联系上Autoflame办公室详细了解

团体培训课程和个别辅导的时间和费用。

Short Form -

General

Terms

and

Conditions

一般条款

A full statement of our

business terms

and

conditions

are printed on the reverse of

all

invoices.

A copyof

these can

be

issued

upon application, if requested in

writing.

所有发票背面均都印有我方商业条款全文。客户可书面申请获取我公司的商业条款文件。

The

System

equipment

and

control

concepts

referred to

in

this

Manual

MUST

beinstalled,

commissioned

and applied by

personnel skilled

in the various

technical disciplines

that

are inherent to the Autoflame

product

range, i.e.

combustion, electrical

and control.

仅有专业人员才能安装、调试、使用本手册所提及的系统设备和控制原理。他们必须精通 Autoflame

产品所涉及的燃烧、电气和控制等技术学科。

The

sale of Autoflame’s

systems

and equipment referred to in

this

Manual

assume

that

the dealer,

purchaser

and installer has the

necessary skills

at

his disposal.

i.e. A high

degree of

combustion

engineering experience, and a thorough understanding of the

local electri

c

al

codes

of

practice concerning boilers, burners

and their ancillary systems

and equipment.

经销商、采购商和安装人员必须具有丰富的燃烧工程从业经验、全面了解当地涉及锅炉、燃烧器和辅

助系统/设备相关的电气行业规范方能使用本手册提及的 Autoflame 系统和设备。

Autoflame’s warranty from point of sale is two years on all

electronic systems

and

components.

Autoflame保修条款: 对所有电子系统和部件实行两年售后保修;

One year on all

mechanical systems, components

and sensors.

对所有机械系统、部件和传感器实行一年售后保修。

The

warranty

assumes

that all equipment supplied will be used for the purpose that

it was intended and in

strict compliance

with our

technical

recommendations.

Auto

-

flame’s warranty and guarantee

is

limited

strictly

to

product

build quality, and design.

Excluded

absolutely are any

claims

arising from

misapplication, incorrect

installation

and/or

incorrect

commissioning.

保修前提: 所有设备均按预期使用目的使用并严格遵守我方提供的的技术建议。Autoflame 产品保修条

款仅适用于产品制造质量问题和设计问题。根据保修条款,Autoflame 不接受因误操作、误安装和/或

调试导致的任何索赔请求。

Contents 目录

1MK7

DATA TRANSFER

I

N

TE

RFACE

MODULE

.

Mk7 数据传输接口模块

. ........ ........... ... ....

1

1

Overview

of

the

Mk7

D.T.I.

Mk7 数据传输接口概述

..... ... ... .... ... ... ... ................

1

1.1.1

Introduction

to

the

Mk7

D.

T.I.

Mk7 数据传输接口简介

.. ... ... ... ...... .... .... ..... ... ... ... ........

1

1.1.2

Information Available from

Mk7

D.T.I.

Mk7 数据传输接口信息

... ... ... .... .... .......

1

1.2

Fixing Holes and

Dimens

ions

.

固定孔和尺寸

....... .... .... .... .... .... .... ..... ... ... ... .........................

4

2

SET-UP

AND

CONNECTIONS

.

设置和连接

................................................................

5

2.1

Wiri

ng

接线

................................................... ... ... .... .... .... ....... ........................

5

2.1.1 Mk7

D.T.I. Wiring

Diag

ram

Mk7 数据传输接口接线图

... ... ... ... ........

5

2.1.2

System Schematic

系统原理图

...... .... .... .... .... .... .... ... ... ... ... .............

6

2.1.3 M.M.

Module

s

Connection

控制模块的连接

. .... .... . .... .... ....... .... .... ..... ... ... ... ...............

7

2.1.4 Mk7 M.M.

and

Mk8

E.G.A. with

Mk7

D.T.I

... .... .... .... .... .... .... .... .... .... .... ... ... ...............

8

MK7 控制模块和带 Mk7 数据传输接口的 Mk8 尾气分析仪

2.2 Mk7

D.T.I. Set-Up

.

Mk7 数据传输接口的设置

.. .... .... .... .... .... .... ..............

9

2.2.1 Mk7 M.M.

Option

s

and

Pa

rame

ters

..

Mk7 控制模块选项和参数

.... .... .... .... .... .... .... .... ...

9

2.2.2 Mini Mk8 M.M.

Options and Parameters

Mk8 微型控制模块选项和参数

. .. ......

12

2.2.3

Configuring the Boiler Room

配置锅炉房

. ... ... ... ... ... .... ... ... .... ... ... .......

15

2.2.4

D.T.I. Setup

数据传输接口的设置

. ... ... .... .... .... ....... ... ... ... ... ....

22

2.2.5

Deleting Boilers and

I/O

Modules.

删除锅炉和输入输出模块

. . .... .... .... ..... .....

25

2.2.6

Network

Set-Up

...

网络设置

...... .... .... .... .... ............ ... ... ... ...............

30

2.3 Mk7

D.T.I. Connections

...

Mk7 数据传输接口的连接

. ... ... ... ... .... .... .... .... ......

32

2.3.1

PC Connection

..

PC 连接

..... .... . ... ... ... ...... .... ......... ... ... ... ..................

32

2.3.2

Network Connection...

网 络 连 接

...... ........ ... ... ...........................

33

2.3.3

Pinging the D.T.I...

Pinging 数据传输接口

.... .... .... .... .... .... ........ ... ... ...........

34

2.3.4

RS422 Connection....

RS422 的连接

.... ... .... .... .... .... .... .... ........ ... ... ... .......................

35

3

ANALOGUE

AND

D

I

G

I

T

A

L

INPUTS/OUTPUTS

.

模 拟 和 数 字 输入 输 出

............

36

3.1 Mk7

Universal

Input/

Output

Mo

du

le

....

Mk7 通用输入输出模块

.....................................

36

3.1.1

Introduction..

简介

..................................................................

36

3.1.2

Wiring and Dimensions...

接线盒尺寸

..............................................

37

3.1.3

Set-Up

I/O

Module

s

on

Mk7

D.T.I.

..

设置 Mk7DTI 上的输入输出模块

...

39

4

MODBUS.

..............................................................................

..........................

48

4.1 M.M.

Read

A

ddre

sses

.

控制模块读取地址

.................... ... ... ....................

48

4.2

E.G.A. Read Addresses

.

尾气分析仪读取地址

.. .... .... .... ... ... ..................

56

4.3 Input/

Output Modules Read Addresses

.

输入输出模块读取地址

.. . .... .... .... .... ...... ... ........

58

4.4

Read/Write

Addresses

.

读取/写入地址

.. ... .... .... .... . ... ... ... ... ...... ... ... ..........

61

4.4.1 M.M.

Read/Write

Addresses

.

控制模块读取/写入地址

. ... ... ... ... .... .... .......

61

4.4.2

Analogue and Digital

I/O

Read/Write

Addresse

s

模拟和数字输入输出读取/写入地址

.

61

4.5

Information, Errors and

Lo

ckouts

信息、错误和锁定

.. ... ... ............ ....... .............

62

4.5.1

Digital Inputs

(1x

Reference)

.

数字输入(1x参考值)

.... ... ... ... ... ....... ........................

62

4.5.2

Analogue Inputs

(3x

References)

模拟输入(3x 参考值)

... .... ... ... ...... ..............

63

4.5.3

Error and Lockout

C

odes

.

错误和锁定代码

........... ....... ... ... ... ... ....... ....................

64

4.5.4

Water Level

.

水位

................. .... .... ... ... ... ... .... .................. ....... ....... .............................

68

5

INTERACTING

WITH

THE

MK7

D.T

.I

.

.

Mk7 数据传输接口的相互作用

......

69

5.1

Burner

Information.

燃烧器信息

................... ........................ ....... ....... ........................

69

5.2 M.M.

Display

Screen

控制模块显示屏幕

..... .... .............. ....... ....... ..........................

71

5.3

Fault Logs.

故 障日志

................ .... .... ...................... ....... ..................

74

5.4 M.M.

I.B.S

Screen.

控制模块 IBS 屏幕

............. ....... ....... ............................

75

5.5

Display Logs

显示日志

............. . ...... .... .... .... .... ............... ....... .....................

76

5.6

E.G.A. Display Screen

尾气分析仪显示屏幕

.. .... ... ... ... ... .... .... .... .... ..... ....... .......................

78

5.7

I.B.S

Information

IBS 信息

..................... .... . ... ... ...... .... .... ................... ....... ....... ........

79

...

1

Mk7

Data TransferInterfáce

Module Mk7

数据传输接口模块

Page

.4

Mk7 D

.T.I.

Set-Up

Guide Mk7

数据传输接口设置指南

10.08.2015

1 MK7

DATA TRANSFER INTERFACE

MODULE

MK7 数据传输接口模块

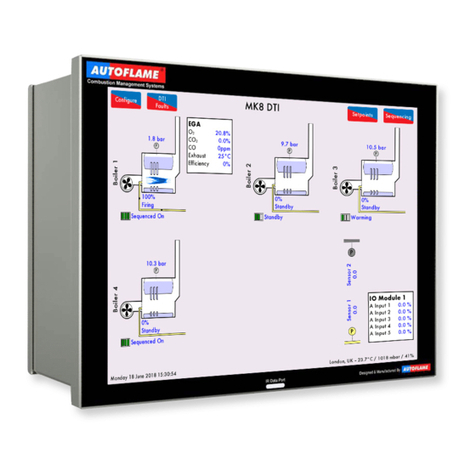

1 Overview of the Mk7 D.T.I.

Mk7 数据传输接口概述

1.1.1

Introduction

to the Mk7 D.T.I.

Mk7 数据传输接口简介

The Autoflame Data Transfer Interface (D.T.I.) is

the

gateway

for

commun

i

cat

i

o

n

s

between

the M.M.

and E.G.A. range

of

products.

All of

the

M.M.

operational data,

of

up

to

ten M.Ms

in

one location,

can

be

collected

by

the D.T.I. The information gathered is available

for

transmission

to an

external

source

via

RS422

and

Ethernet data links. The data gathered

by

the

Mk7

D.T.I. can

be

collected and

viewed

using

the

included CEMS

Audit

software, which allows

data

collection

over a

Local

Area Network

(LAN),

or

over the

internet.

Autoflame 数据传输接口是控制模块和尾气分析仪间的通信网关间的通信网关。由于一个位置

可以有 10 个控制模块,因此控制模块的所有运行数据都可以通过数据传输接口控制,收集的

信息将通过 RS422 和以太网数据链路传输至外部源。Mk7 数据传输接口收集的数据可以用

CEMS Audit 软件收集、查看,CEMS Audit 软件允许通过局域网或互联网进行数据收集。

Up to a

maximum

of ten M.M.

modules,

can be

connected

to one

D.T.I. module. This

can be a

combination

of Mk7 M.M.

modules

and Mini Mk8 M.M.

modules.

It

is also

pos

s

ible

to

receive

data

from up to 10

E.G.A.s

for

emissions

data.

To accommodate

the

status information

from other plant

related

equipment,

the

D.T.I.

can

communicate

with up to ten Mk6

Analogue

and ten Mk6 Digital

Input/

Output Modules,

or

ten

Mk7

Universal

Input/

Output modules. The information gathered

by the

D.

T

.

I

.

from

each

system

i

s

then available for

transmission

to the

Building Management System

or

Energy Management System (BMS

or

EMS). This is done through the RS422

link or

Ethernet

to send

data via

Modbus communications. Typical remote B.M.S. information

and

operational facilities

are

subject

to

the particular site

and management system

requirements.

一个数据传输接口模块最多可以连接 10 个控制模块,该数据接口模块可以是 Mk7 控制模块和

Mk8 微型控制模块的组合,同时也可以从 10 个尾气分析仪模块接收尾气数据。为适应其他工

厂相关设备的状态信息。该数据传输接口可以与 10 个Mk6 模拟模块和 10 个Mk6 数字输入输

出模块或 10 个Mk7 通用输入输出模块进行通信。数据传输接口从各系统接收的信息可以传输

至楼宇管理系统或能源管理系统,传输将通过 RS422 链路或以太网利用 Modbus 通信完成数

据传输。典型的远程楼宇管理系统信息和运行设施需要满足特定站点和管理系统的要求。

The Autoflame network operates using

a two

core screened cable

and

features dedicated

data ports

for

RS422

and

Ethernet connections. The

Mk7

D.T.I. poles

each item on the

network

periodically,

storing up-to-date information every

2

seconds. The D.T.I. then outputs

to

defined Modbus

a

ddresses,

which

are then available to third party

systems

like a

B.M.S. The

10.4”

touch-screen displays

the

operational status

of

the D.T.I.’s communications, with corresponding

error

conditions

in

the event

of a

communication

failure.

Autoflame 网络使用一个双芯屏蔽电缆运行,配有 RS422 和以太网连接的专用数据接口。Mk7

数据传输接口定期在网络上轮询各项目,每两秒储存一次更新信息。然后数据传输接口输出至

指定的 Modbus 地址,Modbus 地址则分配给第三方系统如楼宇管理系统。10.4”触摸屏用于显

示数据传输接口的通信运行状态,出现通信故障时将提供相应的错误条件。

1.1.2 Information Available from Mk7 D.T.I.

Mk7 数据传输接口信息

The

Mk7

D.T.I. displays information from the

Mk7 M.M., Mini Mk8 M.M., Mk8

E.G.A., and the

Water

Level control. Remote

on/off

control

of

the burners can also

be

achieved as

well

as the adjustment

of

the temperature

or

pressure setpoints

and

the sequence order. Through the D.T.I. touch screen, CEMS

1

Mk7

Data TransferInterfáce

Module Mk7

数据传输接口模块

Page

.4

Mk7 D

.T.I.

Set-Up

Guide Mk7

数据传输接口设置指南

10.08.2015

Audit software and via Modbus, the following information is

available:

Mk7 数据传输接口显示 Mk7 控制模块、Mk8 微型控制模块、Mk8 尾气分析仪和水位控制信

息。燃烧器可以进行远程开启/关闭控制,同时还可以远程调节温度或压力设定值和排列顺序。

通过数据传输接口触摸屏、CEMS Audit 软件和 Modbus 可以显示以下信息:

Mk7

D.T.I. Input Values

Mk7

数据传输接口输入值

Enable/disable burner

启用

/

禁用燃烧器

Change individual required setpoint

更改单个需要的设定值

Change global required setpoint

更改全局需要的设定值

Selectlead

boiler

选择主锅炉

Shuffle sequencing (not

M

o

dbus)

重新排序(非 Modbus)

Set load index (firing

rate)

设置负荷指标(燃烧率)

Label

and control input/outputs (not Modbus)

标志并控制输入输出(非 Modbus)

Mk7 M.M.

Mk7 控制模块

Actual boiler temperature (deg. C/F)

or

pressure

(Bar/PSI)

锅炉实际温度(C/F)或压力(Bar/PSI)

Required setpoint i.e. required boiler temperature (deg. C/F)

or

pressure

(Bar/PSI)

所需设定值如所需锅炉温度(C/F)或压力(Bar/PSI)

Burner

on/off

status

燃烧器启停状态

Burner firing rate

(%)

燃烧器燃烧率(%)

Fuel selected

选定的燃油

Burner

rating

燃烧器额定值

Fuelflow metering

values

燃油流量计量值

Load detector type

(temperature/pressure)

负荷检测器类型(温度/压力)

16

lockout and error history with date and

conditions

16 个锁定和错误历史,带数据和条件

Auto/hand/low

flame hold

operation

自动/手动/低火焰保持操作

Number

of

channels

used

使用的通道数量

Channe1,

2, 3, 4, 7,

servomotor

angle

通道 1,2,3,4,7 伺服电机角度

Channel

5, 6

output and input signals

to

VFDwith feedback

history

通道 5,6 至VFD的输入输出信号,带反馈历史。

Burner firing status phase (off, standby, purge, ignition, firing

etc.)

燃烧器燃烧状态阶段(关闭、待机、吹扫、点火、燃烧等)

Lead/lag boiler status

主从锅炉状态

Sequence

order

排序顺序

1

Mk7

Data TransferInterfáce

Module Mk7

数据传输接口模块

Page

.4

Mk7 D

.T.I.

Set-Up

Guide Mk7

数据传输接口设置指南

10.08.2015

Sequence status (on, standby warming,

off)

排序状态(开启、待机、警告、关闭)

Enabled/disabled status

启用/禁用状态

Total hours

run

总运行时间

Number

of

start-ups per

fuel

每次燃油启动次数

Online and commissioned

gas/ oil pressure

在线和调试的燃气/燃油压力

Online and commissioned

air pressure

在线和调试的空气压力

UV scannersignal

history

紫外线扫描仪信号历史

Mk8 E.G.A.

Mk8 尾气分析仪

E.G.A. operation

optioned

选定的尾气分析仪操作

Standalone/M.M.

operation

独立操作/控制模块操作

Flue gas

O2

present

value

油气中 O2现值

Flue gas

CO2

present

value

油气中 CO2现值

Flue gas CO present

value

油气中 CO 现值

Flue gas

NO

present

value

油气中 NO 现值

Flue gas

NO2

present value

(if optioned)

油气中 NO2现值(如选择)

Flue gas

SO2

present value

(if optioned)

油气中 SO2现值(如选择)

Flue gas

O2

commissioned

value

油气中 O2调试值

Flue gas

CO2

commissioned

value

油气中 CO2调试值

Flue gas CO commissioned

value

油气中 CO 调试值

Flue gas

NO

commissioned

value

油气中 NO 调试值

Flue gas

NO2

commissioned value

(if optioned)

油气中 NO2 调试值(如选择)

Flue gas

SO2

commissioned value

(if optioned)

油气中 SO2 调试值(如选择)

Flue gas exhaust

temperature

油气排气温度

Ambient

temperature

环境温度

Flue gas delta

temperature

油气 delta 温度

E.G.A.

errors

尾气分析仪故障

Chiller

condition

冷却器条件

Current emissions

byweight

and volume

(O2,

CO

2

, CO,

NO,

SO

3

, H

2

O,

N2, Total)

当前尾气重量和体积(O2,

CO

2

, CO,

NO,

SO

3

, H

2

O,

N2, 总计)

Totalised emissions

by

weight and volume

(O2,

CO

2

, CO,

NO,

SO

3

, H

2

O,

N2, Total)

1

Mk7

Data TransferInterfáce

Module Mk7

数据传输接口模块

Page

.4

Mk7 D

.T.I.

Set-Up

Guide Mk7

数据传输接口设置指南

10.08.2015

总尾气重量和体积(O2,

CO

2

, CO,

NO,

SO

3

, H

2

O,

N2,总计)

Heat input, heat loss and net useful

heat

热输入、热损失和净用热

Net efficiency, gross efficiency and delta

temperature

净效率、总效率和 delta温度

Fuelflow rates, instantaneo

u

s

and

total

i

s

e

d

for

up

to2 years

两年内燃油流量,瞬时和总计

Fuel consumption, fuel costs instantaneous and totalise

for

up

2 years

两年内燃油消耗、燃油费用,瞬时和总计

MiniMk 8 M.M. M

Mk8 微型控制模块

Actual boiler temperature (deg. C/F)

or

pressure

(Bar/PSI)

锅炉实际温度(C/F)或压力(Bar/PSI)

Required setpoint i.e. required boiler temperature (deg. C/F)

or

pressure

(Bar/PSI)

所需设定值如所需锅炉温度(C/F)或压力(Bar/PSI)

Burner

on/off

status

燃烧器启停状态

Burner firing rate

(%)

燃烧器燃烧率(%)

Fuel

selected

选定的燃油

Burner

rating

燃烧器额定值

Fuelflow metering

values

燃油流量计量值

Load detector type

(temperature/pressure)

负荷检测器类型(温度/压力)

16

lockout and error history with date and

conditions

16 个锁定和错误历史,带数据和条件

Auto/hand/low

flame hold

operation

自动/手动/低火焰保持操作

Number

of

channels

used

使用的通道数量

Channe1,

2, 3, 4, 7,

servomotor

angle

通道 1,2,3,4,7 伺服电机角度

Channel

5, 6

output and input signals

to

VFDwith feedback

history

通道 5,6 至VFD的输入输出信号,带反馈历史。

Burner firing status phase (off, standby, purge, ignition, firing

etc.)

燃烧器燃烧状态阶段(关闭、待机、吹扫、点火、燃烧等)

Lead/lag boiler status

主从锅炉状态

Sequence

order

排序顺序

Sequence status (on, standby warming,

off)

排序状态(开启、待机、警告、关闭)

Enabled/disabled status

启用/禁用状态

Total hours

run

总运行时间

Number

of

start-ups per

fuel

每次燃油启动次数

Water Level

Control

水位控制

Actual water level signal value

for

probe

1

and

2

探头 1和2实际水位信号值

1

Mk7

Data TransferInterfáce

Module Mk7

数据传输接口模块

Page

.4

Mk7 D

.T.I.

Set-Up

Guide Mk7

数据传输接口设置指南

10.08.2015

Average water level signal

of probes

探头的平均水位信号

Commissioned end

of

probe

position

探头位置的调试端

Commissioned

2nd lowposition

调试的第二低位

Commissioned 1

st

lowposition

调试的第一低位

Commissioned 1

st

low

pre-alarm

position

各报警位置的调试第一低位

Commissioned control point

position

调试控制点位置

Commissioned pump

on/

pump

offpositions

调试的泵启停位置

Commissioned high water pre-alarm

position

各报警位置的调试高水位

Commissioned high water

position

调试的高水位位置

15

Firstout annunciation inputs status

15 个点火控制器输入状态

Instantaneous and totalised steamflow

m

e

tering

瞬时和总计蒸汽流量计量

Feedwater

temperature

给水温度

Feedwater valve

position

给水阀位置

Feedwater pump status

给水泵状态

Feedwater VSD

output

给水 VSD 输出

Steam temperature and

pressure

蒸汽温度和压力

Top blow down status and

operation

顶吹状态及操作

TDSactual

value

TDS 实际位置

TDSvalve

position

TDS 阀位置

TDS target

value

TDS 目标值

16

Water

level/

Expansion alarms conditions and

date

16 个水位/扩展报警条件和日期

Bottom blowdown

operation

底部排污操作

1

Mk7

Data TransferInterfáce

Module Mk7

数据传输接口模块

Page

.4

Mk7 D

.T.I.

Set-Up

Guide Mk7

数据传输接口设置指南

10.08.2015

1.2

Fixing Holesand Dimensions

固定孔和尺寸

2

Set-Up

and Connections

设置和连接

10.08.2015

Mk7

D.T.I. Set-Up

GuideMk7 数据传输接口设置指南

Page

5

2

SET-UP

AND CONNECTIONS 设置和连接

2.1 Wiring 接线

2.1.1 Mk7 D.T.I.Wiring Diagram MK7 数据传输接口接线图

Figure 2.1.1.i

Mk7

D.T.I.

Wiring Diagram

图

2.

1.1.iMk7

数据传输接口接线图

Electrical

Spe

c

ific

atio

ns:

电气规范

Max

power

for

the

Mk7

D.T.I. power supply is

184W.

Mk7 数据传输接口电源的最大功率是 184W。

Figure

2.1.1.iiMk7

D.T.I.

Board

图

2.1.1.ii Mk7

数据传输接口板

2

Set-Up

and Connections

设置和连接

Mk7

D

.

T.

I.

Set-Up

GuideMk7

数据传输接口设置指南

10.08.2015

Page

6

2.1.2 System Schematic

系统原理图

2

Set-Up

and Connections

设置和连接

10.08.2015

Mk7

D.T.I. Set-Up

Guide Mk7 数据传输接口设置指南

Page

7

2.1.3 M.M. ModulesConnection

控制模块的连接

2

Set-Up

and Connections

设置和连接

Page

8

Mk7

D.T.I. Set-Up

Guide Mk7 数据传输接口设置指南

10.08.2015

2.1.4 Mk7 M.M. and Mk8

E.G.A.

with Mk7 D.T.I.

MK7 控制模块和带 Mk7 数据传输接口的 Mk8 尾气分析仪

2

Set-Up

and Connections

设置和连接

10.08.2015

Mk7

D.T.I. Set-Up

Guide Mk7 数据传输接口设置指南

Page

9

2.2 Mk7 D.T.I.Set-Up Mk7 数据传输接口的设置

2.2.1 Mk7 M.M.

Options

and Parameters Mk7 控制模块选项和参数

To get the

Mk7

D.T.I.

to

communicate with the

Mk7M.M.,

the right communication settings need

tobe

set on the

Mk7 M.M.

The

following options and parameters need

to

be set.

要使 Mk7 数据传输接口和 Mk7 控制模块保持通信,需要在 Mk7 控制模块上进行正确的通信设

置,需要设置以下选项和参数:

2

Set-Up

and Connections

设置和连接

Page

10

Mk7

D.T.I. Set-Up

Guide Mk7 数据传输接口设置指南

10.08.2015

3 0

DTI Comms

Mode

数据传输接口命令模式

0 Mk6

DTI -

9600bps Mk6 数据传输接口

-

9600bps

1 Mk7

DTI -

19200bps Mk7 数据传输接口

- -

19200bps

16 0 Lead/Lag

(IBS)

and

DTI:

A

lead boiler can

be

selected

by

connecting

a

line voltage

to

terminal

88 on

the appropriate

MM. Only1 MM

may

be

selected as lead boiler

at a

time,

or

the sequencing

will

not operate. The lead boiler can

be

selected

via

the DTI. However,

for

this

tobe

effective

all

the

MM

units on the system must have Terminal

88

volt free. Line voltage on Terminal

88

overrides the DTI

command.

主从(IBS)和数据传输接口:主锅炉可以通过连接线压至相应的控制模块终端 88 进行选

择。一次仅能选择 1个控制模块作为主锅炉,否则排序将不会运行。主锅炉可以通过数据传

输接口选择。因此,为使其生效,系统上的所有控制模块单元上的终端 88 都必须无电压。终

端88 上的线电压将取代数据传输接口命令。

0 No

sequencing

-

MM

units still communicate and can

be

seen on the

DTI.

无排序-控制模块单元仍然通信并可以在数据传输接口上看到。

1

Sequencing enabled

-

MM

units

will

respond

to

sequencing commands. Lead boiler is selected

by a line

voltage on terminal

88.

启用排序-控制模块单元将响应排序命令。主锅炉通过终端 88 上的线压选定。

2

Setpoint

&

enable/disable

commands accepted from

DTI.

可以通过数据传输接口接受设定值和启用/禁用命令。

3

Both

1

and

2. 1和2

Note:

Accurate fuel flow metering must

be

entered

for

sequencing

to

operate. An RS485

datacable

(Belden

9501)

must

be

connected between each

MM

unit (see section

2.17.3.4 for

correct

connection).

注:精确的燃油流量计量必须输入进行排序操作。

RS485

数据电缆(

Belden

9501

)必须连接每个控制模块单

元(见

2.17.3.4

节关于正确连接)。

30 50

DTI

Required Setpoint Minimum

Limit:

If

the system is being used with

a

DTI

a

maximum

and

minimum limit

for

the required setpoint must

be

set.

If a

value is received from the DTI that is

outside

these limits,

it will be

ignored and the system uses its previous required setpoint. Practical range is

limited

to

range

of

sensor

selected. 数据传输接口所需设定值的最小限值:如果系统用于一个

数据传输接口,则需要为所需设定值设定一个最大和最小限值。如果数据传输接口接收的数

值超过该限值,该数值将被忽略,系统将使用先前所需的设定值。实际范围受到所选传感器

范围的限制。

5

-

9990 If

Centigrade, Fahrenheit

or

PSI units

effective. 如是摄氏度,华氏度或 PSI 单位有效。

0.5

-

999.0 If

Bar units effective.

如巴单位有效。

31 100

DTI

Required Setpoint Maximum Limit: 数据传输接口所需设定值的最大限值

5

-

9990 If

Centigrade, Fahrenheit

or

PSI units

effective. 如是摄氏度,华氏度或 PSI 单位有效。

0.5

-

999.0 If

Bar units effective.

如巴单位有效

33 1 MM Identification:

The identification number must

be

set on

all MM

Units

in

the boiler house.

If

not, then problems

will

occur with sequencing/twin burner and with the

DTI communications. Each

unit must have

a

different identification

number.

控制模块标识:标识号必须在锅炉房内所有控制模块单元上设置,如未设置,则燃烧器测

序燃烧器和双燃烧器以及数据传输接口通信将出现问题。各单元必须有不同的标识号。

34 5 Rating of Burner: 燃烧器额定值

1

-

999

See Option

77 for

units.

关于单位见选项

77

77 0 Burner rating

units:

Display purposes only

for

fuel

flowmetering.

燃烧器额定值单位:仅显示燃油流量计量值

0 KW x 100

/hr

1

Kg

x 100

/hr

2 MW

/hr

3

Btu

x 100

/hr

4

Hp

x 100

/hr

5

lbs

x 100

/hr

6

Btu

x 1000

/hr

7

Hp

x 10

/hr

8

lbs

x 1000

/hr

9

Btu

x 1000 000

/hr

2

Set-Up

and Connections

设置和连接

10.08.2015

Mk7

D.T.I. Set-Up

Guide Mk7 数据传输接口设置指南

Page

11

57 0 0

-

10

Sequencing:

Highest

MM

ID. This

parameter speeds up communications between

MM's

when

sequening.

排序:最大控制模块 ID。排序时本参数将加快控制模块间的通信

101 0 Shufflesequencing: 改变排序

0 Disabled 禁用

1

Sequence order changed from

DTI.

排序顺序从数据传输接口改变

2

Set-Up

and Connections

设置和连接

Page

12

Mk7

D.T.I. Set-Up

Guide Mk7 数据传输接口设置指南

10.08.2015

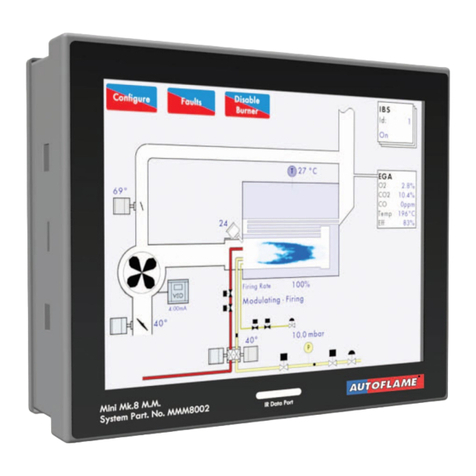

2.2.2 Mini Mk8 M.M. Option

s

and Parameters Mk8 微型控制模块选项和参数

To get the

Mk7

D.T.I.

to

communicate with the

Mini Mk8 M.M.,

the right communication settings

need

to

be seton the

MiniMk8M.M.

The

following options and parameters need

to

be set.

传输接口与 Mk8 微型控制模块保持通信,则需要在 Mk8 微型控制模块进行正确的通信设置。需

要设置以下选项和参数。

Other manuals for Mk7

3

Table of contents

Other AUTOFLAME Measuring Instrument manuals