AUTOK TC808 User manual

TENSION CONTROLLER

TC808

INSTRUCTION MANUAL

AUTOK

AUTOK

Table of Contents

Tension sensor

TC808

Tension controller

Magnetic powder brake

Typical installation of an unwind application

TENSION CONTROLLER TC808

1 Introduction ................................................................................. 1

2 Features ....................................................................................... 1

3 Order Code .................................................................................. 2

4 Installation ................................................................................... 2

5 Electrical Wiring .......................................................................... 3

6 Operator Interface ....................................................................... 6

7 Operation ..................................................................................... 7

8 Operation of Tension Control System .................................... 10

9 Tension Calibration .................................................................. 13

10 Use of Diameter Tension Control ........................................... 15

11 Taper Tension Control ............................................................. 17

12 Diameter-Output Program Tension Control .......................... 18

13 Digital Communication ........................................................... 20

Appendix A: ASCII Table .............................................................. 24

Appendix B: The Mounting of SUP Tension Sensor ................. 24

Technical Data .............................................................................. 25

AUTOK

WWW.CHINA-AUTOK.COM

1 Introduction

2 Features

1

TENSION CONTROLLER TC808

● Full digital circuit, easy tension calibration. ● Advanced PID control algorithm provide high

control precision.

● Universal tension sensor input:

● RS485/RS232 serial communications.

1. Micro-displacment based tension sensor

(signal: 200mV, power supply:5V) ● Tension transmission.

2. Strain gauge based tension sensor ● Automatic/Manual tension control.

(signal:20mV,power supply10V) ● Reel exchange function.

● Diameter tension control.

● Wild range switching power supply(85~264V).

● Taper tension control.

● Friendly user interface, easy to use.

● Program tension control, multi programs for ● More cost efficient.

various material tension control.

The TC808 Tension Controller is an application-specific controller designed to provide you with precise

control over winding and unwinding tension control applications for web and strand.

The tension controllers can be divided into manual, half-automatic and full automatic controller. According to

the different needs of customers, the TC808 tension controller can be configured as manual, half-automatic

or full-automatic tension controller.

For manual tension controller, the operator adjusts the actuation current of the powder clutch/brake manually

to get the desired tension control.

The half-automatic tension controller also known as diameter or opened-loop tension controller, the tension

controller calculates the reel radius automatically during winding or unwinding process, according to the

current reel radius and setting tension, the tension controller adjusts the output to get the constant tension

controls.

The full automatic tension controllers detect the web tension with tension sensor directly. According to the

difference between setting tension and measured tension and the build-in PID algorithm, the controller

adjusts the output automatically to get the precision constant tension control of the web.

AUTOK

WWW.CHINA-AUTOK.COM

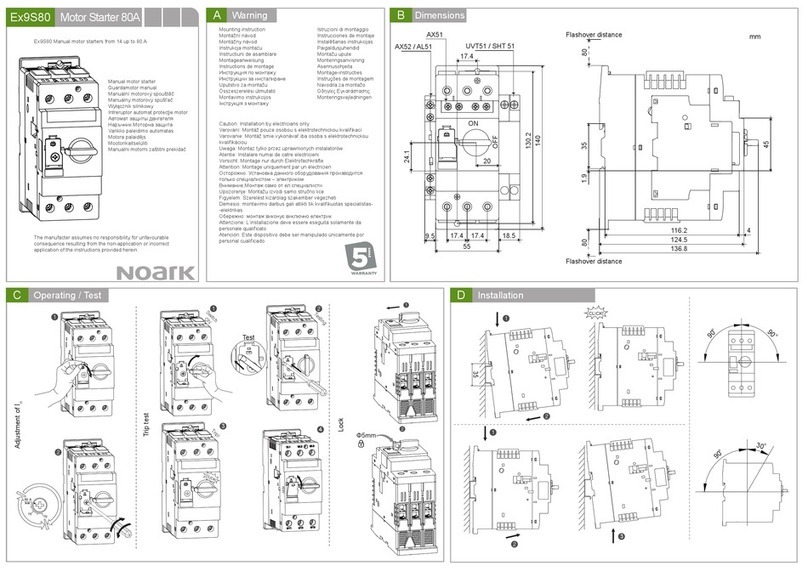

TC808 tension controller can be installed on floor, wall or panel.

MAN

AUT O

PAR PROG

OFF ON

POW ER

AUT O MAN

OUT B OUTA ALM C OM

OUT

PV

SV

TC808

TENSI ON CONTROL LER

OUT PUT

ON/ OFF

N

%

R

MON ITOR

SEL ECT

256

168

Installed on floor

172.5

Installed on wall

4-M4*12

Mounting screw

2~4 140

Installed on panel

4-M4

244 +3

-0.5

80+

-

0.5

Screw holes dimensions

for mounting on floor and wall

232

+

-

0.5

150+

-

0.5

Output

24V

Model Number

TC808

-

-

Comms

0

RS232

RS485

BS

Options

0

QP

Tension Controller

Comments

24V/4A

Drive powder clutch/brake

None

RS232

RS485

Tension transmission

None

Programmer/Controller

4 Installation

3 Order Code

Panel mounting cut-out dimensions

TENSION CONTROLLER TC808

2

AUTOK

AUTOK

WWW.CHINA-AUTOK.COM

MAN

AUTO

PAR PROG

OFF ON

POWER

AUTO MAN

OUTB OUTA ALM COM

OUT

PV

SV

TC808

TENSION CONTROLLER

OUT PUT

ON/ OFF

N

%

R

MONITO R

SELECT

245

228

16.5 140

147

154

60

60

5 Electrical Wiring

Notice

TENSION CONTROLLER TC808

Outline Dimensions

3

●

line.

● If the AC power supply is connected to the I/O terminals or DC supply terminals, the tension controller will

be burn out.

● Connect the tension sensor according to the wiring diagram, pay more attention to the wiring of tension

sensor if two tension sensors are connected otherwise the measurement value will be incorrect.

● When one tension sensor is used, make sure to short-circuit the unused tension signal terminals.

In order to avoid electrical noise to the input signal, the signal line should be seqarated from the power

AUTOK

AUTOK

WWW.CHINA-AUTOK.COM

RY

NB

PB

NA

PA

12V/2A

24V/4A

-5V

5V

Main reel pulse

Auxiliary power output

Communications

or

Tension transmission

Acceleration switch

Dot start

Start output select

Deceleration switch

Reel exchange

Output 2

4 ~ 20 mA

Zero tension

alarm output

Power supply

(160V~240 V AC)

24V

DI0

DIA

DIB

GND

MC6

MC5

MC4

MC3

MC2

MC1

MCC 0V

+6V

TRG

TR-

TR+

ZT

ZT

EAP

EAN

SA

Run/Stop

SN

{

}

}

}

}

}

250V 8A

PSL

PSN

REDL

GRL

WHL

GRR

WHR

BLKL

REDR

BLKR

Tension

sensor

(Left)

A/D

A/D

Terminals Layout

Terminal group 1 Terminal group 2

PSL PSN ZTC NA NB MCC MC2 MC4 MC6 DI0

+24V

GNDMC5

MC3

MC1PBPAZTZT DIB WHL BLKL BLKR WHR SA EAP TRG TR+

DIA GRL REDL REDR SN EAN +6V 0V TR-GRR

5.1 Wiring Diagram

Tension

sensor

(Right)

red

green

white

black

red

green

white

black

0 ~ 20 mA

Sync signal output

to Reel-A magnetic

powder clutch/brake

to Reel-B magnetic

powder clutch/brake

Reel-A pulse

Reel-B pulse

Power board

TENSION CONTROLLER TC808

4

AUTOK

WWW.CHINA-AUTOK.COM

5.2 Terminals Description

Terminal group 1

SN

1

2

3

4

5

6

7

8

9

10

11

12

13

Terminal

PSL, PSN

ZT, ZTC

PA NA,

PB, NB

MCC

MC1

MC2

MC3

MC4

MC5

MC6

+24V, GND

DI0

Specification Comments

input

output

output

output

input

input

input

input

input

input

input

input

output

85~264V AC, 50/60 Hz

I/O

Power supply

Zero tension alarm output(Automatic tension control mode)

Reel radius lower limit alarm output(Diameter tension

control mode)

Output for reel A powder clutch/brake, motor

Output for reel B powder clutch/brake, motor

Contact input common terminal

Run/stop

Reel exchange signal

Acceleration switch

Start output selection

Dot start signal input

Deceleration switch

Power supply of proximity switch or encoder

Main reel pulse inputMax Freq: 15K Hz

24V/4A or 90V/10A

24V/4A or 90V/10A

1

2

3

4

5

6

7

8

9

10

11

12

13

DIA

DIB

GRL

WHL

REDL

BLKL

GRR

WHR

REDR

BLKR

SA SN,

EAP,EAN

TR+,TR-,TRG

input

input

input

input

output

output

input

input

output

output

output

output

output

Max freq: 15K Hz Reel A pulse input

Reel B pulse input

Left tension sensor signal+

Left tension sensor signal-

Left tension sensor power supply+

Left tension sensor power supply-

Right tension sensor signal+

Right tension sensor signal-

Right tension sensor power supply+

Right tension sensor power supply-

Control signal output

Control signal output for E/P regulator

Serial communication or tension transmission

RS232/RS485

0~200mV or 0~20mV

14 +6V,0V output Auxiliary power supply

Max freq: 15K Hz

5V or 12V

0~200mV or 0~20mV

5V or 12V

0~20mA or 0~5V

0~20mA or 0~5V

SN Terminal Specification CommentsI/O

Terminal group 2

TENSION CONTROLLER TC808

5

AUTOK

WWW.CHINA-AUTOK.COM

DescriptionSN Item

6 Operator Interface

TENSION CONTROLLER TC808

6

PV Display Indicates the Process Value,

Parameter display

Indicates the Setting Value,

parameter value, alarm code

Tension SV displaying LED

Output power displaying LED

SN Item Description

SV Display

Reel radius displaying LED

N

%

R

Lower display selector

Automatic mode indicator

Manual mode indicator

AUTO

MAN

Manual/Automatic mode

switching key

Parameter scroll key

Raise key, increase value

Programming key

Lower key, decrease value

Power switch

ON/OFF

Power LED

Output power indicator

higher the output, brighter the

LED

Reel B output indicator

Reel A output indicator

Zero tension alarm indicator

Communication indicator

Output ON/OFF switch

Output ON/OFF LED

lit when output is ‘ON’

POWER

OUT

OUTB

OUTA

ALM

COM

PAR

PROG

MONITOR

SELECT

MAN

AUTO

OUTPUT

ON/OFF

1

3

2

4

5

6

7

8

9

10

11

12

PAR PROG

OFF ON

POWER

OUTB OUTA ALM COM

OUT

PV

SV

TC808

TENSION CONTROLLER

OUTPUT

ON/OFF

8

9

10

11

12

MAN

AUTO

AUTO MAN

N

%

R

MONITOR

SELECT

1

3

2

4

5

6

7

AUTOK

AUTOK

WWW.CHINA-AUTOK.COM

7 Operation

TENSION CONTROLLER TC808

7

There are two LED displays indicate the operating parameters.

The upper display(green) indicates the measured tension value(PV) when in base condition. On modifying a

parameter, the appropriate parameter appears.

The Lower display(red) indicates the setting tension value in the automatic mode. On modifying a parameter,

the appropriate value appears here. This display also indicates the output power, reel diameter in some

case.

When the controller is powered on, the upper display indicates the model code of the controller, and the

lower display indicates the software version.

3 seconds later, the upper display will indicates the measured tension(PV) while the lower display will

indicates the setting tension(SV).

The upper display will indicates the current measured reel radius when TC808 is configured as a 'Diameter

Tension Controllr' or a 'Diameter-Output program tension controller'.

The type of contents displayed on the lower display is changed every time the ‘Lower display selector’ key is

pressed. The type of contents displayed is indicated by the LED provided on the left side of the ‘Lower

display selector’ key.

When running in Diameter-Output program tension control mode and the indicator ‘N’ is lit, the lower display

will indicates the program number and segment number of the current running program. e.g. ‘L2.R3’ represent

Program 2 segment 3 is running.

Press Man/Auto key, automatic operation mode and manual operation mode can be changed conveniently.

When TC808 performs automatic operation, indicator ‘AUTO’ will be lit, if the setting tension is displaying on

the lower display at this time(LED ‘N’ is lit) press keys and to modify the setting tension. Adjustable

range: SP K~SP L.

When the controller performs manual operation, indicator ‘MAN’ will be lit, if output power is displaying on the

lower display at this time(LED ‘%’ is lit) the control output power can be modified by pressing and key.

Control output power can be turned ON and OFF by pressing ‘OUTPUT ON/OFF’ key. When indicator

‘OUTPUT ON/OFF’ is lit, output is ‘ON’ otherwise output is ‘OFF’, the output power becomes 0.

In automatic operation mode and when MC1 switch is turned on, indicator ‘OUTPUT ON/OFF’ will be lit;

when MC1 switch is turned off, indicator ‘OUTPUT ON/OFF’ will flash, at this time the output is permissive.

The green LED ‘OUT’ indicates the current control output level, higher the output power level, brighter the

LED. The LED will be turned off when the output becomes 0.

LED ‘OUTA’ indicates the output status of Reel-A, it is lit when Reel-A output is ON.

LED ‘OUTB’ indicates the output status of Reel-B, it is lit when Reel-B output is ON.

When measured tension is lower than ‘zero tension alarm value’(Code AL0), zero tension alarm indicator

‘ALM’ will be lit and at the same time relay ZT is ‘ON’, generate a alarm signal. Zero tension alarm don’t act

in Run/Stop and reel exchange progress.

The indicator 'COM' flashed when the TC808 is in active communication with a host computer.

▲ ▼

▲ ▼

7.1 Display & Basic Operation

AUTOK

WWW.CHINA-AUTOK.COM

Specific tension contol systems need specific software configurations. TC808 must be configured porperly in

order to perform the correct control funtion.

How to enter software configuration menu:

1) Press PAR key and hold for 3 seconds to enter the first level menu(i.e. operation parameter list);

2) Press PAR key to scroll the parameter to LOC and set its value to

3) Press PAR key, the first parameter appears on the upper display, at the same time the lower display will

display the value of this parameter. The values can be modified by pressing keys ▲ and ▼ . After

modification, press the PAR key, the next parameter appears, at the same time, the modified data has been

saved in the memory.

If the last parameter is displayed or there is no key operation within 16 seconds, the controller will return

back to the PV/SV display status.

After configuration, set the configuration password(code LOC) to data other than 808 in order to protect the

parameter values from being inadvertent modification.

808(the initial password);

TENSION CONTROLLER TC808

8

Mnemonic

AL0

TON

POFF

TOFF

PROP

INT.T

PDOT

DB

PCHA

REL.C

TCHA

STOP

( ,NC

(DEC

LOC

PON

SN

4

5

6

7

8

9

10

13

11

14

12

15

16

17

18

19

Parameter

Zero tension alarm value

Start output value

Start time

Stop output value

Stop time

Proportional band

Integral time

Dot start output

Dead band

Reel exchange output

Dead band ratio

Reel exchange time

Reel exchange brake time

Acceleration coefficient

Deceleration coefficient

Configuration password

Adjustable Range

0.0~999.9 Kg

0~100.0%

1~30.0 seconds

0~100.0%

1~30.0 seconds

0.1~999.9 Kg

1~100 seconds

1~100%

0.1~999.9Kg

1~100%

0.01~1.00

1~30.0 seconds

1~30.0 seconds

0.01~0.99

1.00~1.99

0~9999

Comments

Only alarms while running

when MC4 & MCC are shorted, start output value is PON

The smaller the PROP the faster response

The greater the PROP, the slower response

,

The smaller the INT.T, the faster response

The greater the INT.T, the slower response

set to 808 to enter the configuration menu

Operation Parameter List

F0

3 Start frequency 1~50 Hz If main reel freq. F > F0, system starts

If main reel freq. F < F0, system stops

7.2 Modifying the Operation Parameter

7.3 Software Configuration

R0

1 Initial reel radius 0~1000mm

TH,N

2 Material thickness 0.00~3.00mm

When the controller is in the PV/SV displaying status, press PAR key and hold for 3 seconds reveals the first

parameter. The parameter value can either be modified with the or key, or left unmodified. Press PAR

key again, the next parameter and its current value appears, the modified data has been saved.

or there’s no key operation within 16 seconds, the menu times out

automatically.

▲ ▼

If the last parameter is displayed

In dead band, the smaller REL.C, the smaller

proportional gain, this made the system more

stable but slower response.

AUTOK

WWW.CHINA-AUTOK.COM

SN

1

2

3

5

6

7

8

9

14

10

11

12

13

15

16

17

18

19

20

21

23

24

27

28

Mnemonic Parameter Adjustable Range Comments

SP K

SP L

K PL

0FST

SN

ADDR

BAVD

FVNC

(AL(

(TRL

T 1

K, R

LO R

N1

N2

R1

TT

RAL

((

RVN

0P2

PL-2

F,L

(AL

Tension setpoint high limit

Tension setpoint low limit

Max output power

Input/calibration offset

Display units of input signal

Instrument address

Baud rate

Control Function

Reel radius calculation

Control algorithm

Taper ratio

Reel radius high limit

Reel radius low limit

P revolution

(main reel)

ulses/

Pulses/revolution

(Reel-A or Reel-B)

Main reel radius

Reel pulses/calculation

( calculation radius)

Reel radius lower limit alarm value

Powder brake rated torque

Wind mode

OVT2 output mode

2nd output value

Input filter

Tension calibration

Measurement Range

Measurement Range

0.0~100.0%

-9.99~10.00

TC

.TC

00~99

2400, 4800 9600 19.2, ,

AVTO

D ,A

PR1

PR2

P,D

R SP

RO

P 9

0.01~1.00

1~999 mm

1~999 mm

1~300

1~300

20~500mm

10~3000

1~999mm

1~600NM

VTVN

TVN

AVTO

KAND

0.01~99.99

P 1

P2

without tenths’ precision

with tenths’ precision

Automatic tension control

Diameter tension control

Thickness adding up caculation

Ratio calculation

Appears if (TRL = R SP

or FVNC = D,A

When pulses equal to TT, do a reel

radius calculation.

zero tension calibration

full-scale tension calibration

appears if 0P2 KAND=

same with main output OP1

Manual setting

unwinding(reel radius decrement)

winding(reel radius increment)

Appears if FVNC = D ,A

Appears if (TRL = R SP

0.0~100.0%

PID control

Taper tension control

Program tension control

22 OVT2 Output 2 0-20

4-20

0~20 mA

4~20 mA

25 ACT Control action REV

DIR

reverse control

direct control

26 SYNT Synchronous Run/Stop NO

YES

Disable

Enable

TENSION CONTROLLER TC808

9

Software Configuration Paramter List

always > SP L

always < SP K

4SN.N Tension sensor selection

L-SN

R-SN

L-R

select left tension sensor

select right tension sensor

select left & right tension sensors

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

10

Starting procedure: Before starting, TC808 will outputs PON to generate preparatory tension. When the

Run/Stop switch(MC1-MCC) is turned on and after a overflow of time set in start timer TON, the automatic

control will start. At this time, indicator ‘OUTPUT ON/OFF’ will be lit. See the figure above.

Stopping procedure: When the Run/Stop switch is turned off, the controller output stop power

until the stop timer times up. After that, controller outputs PON to generate preparatory tension. At this time, indicator

‘OUTPUT ON/OFF’ will be turned off. See the figure above.

When ‘Synchronous Run/Stop’ function is available(SYNT = YES), the run/stop operation is controlled by the frequency of

main reel but not the MC1 input. A proximity switch must be mounted on the main reel before using ‘Synchronous

Run/Stop’ function, the controller will monitor the running frequency of main reel.

When the Run/Stop switch is turned on and main reel freq. is greater than start freq. F0, system starts, indicator

‘OUTPUT ON/OFF’ will be lit.

When the Run/Stop switch is turned on and main reel freq. is smaller than start freq. F0, system stops, the indicator

‘OUT’ ON/OFF will flash.

In full automatic tension control systems, generally short-circuit MC1 and MCC, the system will run/stop according to the

main reel’s frequency automatically. TC808 don’t act run/stop operation during reel exchange process.

Note that when the controller was configured as Diameter Tension Controller(FVNC = D,A), the start timer TON must be

long enough allowed the controller to have enough time to calculate out the reel radius otherwise the controller will

perform incorrectly.

POFF instantly

The system start output selection is controlled by the start output selection switch(MC4-MCC). When the switch is turned

on, start output is PON saved in controller memory. When the switch is turned off, the start output is the output when

system stops.

8.1 Run/Stop

Speed

Control output

OFF

ON

Stop timer

Automatic control output

Start timer

Stop output(POFF)

Start output(PON) Start output(PON)

t

t

0

0

MC1 input

TON TOFF

8 Operation of Tension Control System

The run/stop operation of TC808 tension controller is controlled by MC1 and MCC. Connect a switch across

the terminal MC1 and MCC, the switch is called Run/Stop switch of the tension system.

8.2 Start output Selection

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

11

During system testing or new materials feeding, the “dot start” function is necessary.

This function is controlled by the dot start switch(MC5-MCC, see the wiring diagram please)

ON

OFF OFF

ON

dot start time

Speed

Start output

0

0t

t

MC5 input

8.3 System Acceleration/Deceleration

8.4 Dot Start

dot start time

Start output Start output

Stop output Stop output

dot start control output dot start control output

The tension control system acceleration is controlled by the MC3-MCC).

When the system needs to accelerate, turn on the acceleration switch, the controller enters open-looped control mode, at

this time, the control output equals the current output times [,NC. After acceleration, turn the switch OFF, the system

returns to automatic tension control mode.

Acceleration Switch(

The tension control system deceleration is controlled by the Deceleration Switch(MC6-MCC).

When the system needs to decelerate, turn on the deceleration switch, the controller enters open-looped control mode,

at this time, the control output equals the current output times [DEC. After deceleration, turn the switch OFF, the system

returns to automatic tension control mode.

Note that TC808 don’t act the Acceleration/Deceleration command during reel exchange, system halting, or system

starting process.

Acceleration

Deceleration

Before starting dot start operation, let the system stop(turn the Run/Stop switch off) and the controller outputs PON to

generate the preparatory tension. When the dot start switch is turned on, TC808 outputs PDOT made the system start

running. The controller will maintain the output PDOT while the dot start switch is ON.

Once the dot start switch is turned off, the controller outputs the ‘stop output’ POFF instantly to decrease the running

speed and the stop timer TOFF starts. After the stop timer TOFF times up, the controller outputs PON to generate the

preparatory tension, system halts. Awaiting for the next dot start operation.

Note that TC808 don’t act the dot start command during reel exchange, system halting, or system starting process.

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

12

Reel A Reel A

Reel B Reel B

Reel A output

Reel B output

+12V Auxiliary

power output

MC2 input

Reel exchange

0

Reel exchange output

t

8.5 Reel exchange

Exchange of winding reel

Control output Control outputBrake output

Brake output Brake outputControl output

Exchange of unwinding reel

In the two-reel operation, the reel exchange is controlled by the ‘reel exchange’ switch(MC2-MCC). This

function is applicable when material on reel is over or full.

When the switch is turned on, reel A is active.

When the switch is turned off, reel B is active.

When the wind mode(code: RVN) was configured as unwinding(VTVN), suppose that the reel exchange switch

is off, reel A is active. At this time, if change the switch from OFF to ON, the control output exchanges to reel

B and the controller enters open-looped control mode. The control output is preset to PCHA. When the r

times up, the automatic control starts. At the same time, +12V auxiliary power is

applied to reel A in ‘reel exchange brake time’(Code STOP) preset to brake reel A. For exchanging from reel B

to reel A, reverse above process. See the figure below.

eel

exchange timer TCHA

When the wind mode(code: RVN) was configured as winding(TVN), suppose that the reel exchange switch is

off, reel A is active. At this time, if change the switch from OFF to ON, the auxiliary power supply(+12V) will

be applied to reel B and when ‘reel exchange brake time’(Code STOP) times up, the control output exchanges

to reel B and the controller enters open-looped control mode. The control output is preset to PCHA. When the

r times up, the automatic control starts. For exchanging from reel B to reel A,

reverse above process.

eel exchange timer TCHA

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

13

Input signal calibration

Tension sensor

+24V

ZTC

PSL PSN

ZT MC1

NBNA

ZT PA

MCC

PB MC5MC3

MC2 MC4

GND

MC6 DI0

JP11

EANREDL

DIB

DIA GRL

WHL

GRR

REDR

BLKL BLKR WHR

SN

SA

J8 -5V

GND

TRG

EAP

+6V

TR+

0V TR-

JP8

JP7

Tension sensor

Suspend weight

9 Tension Calibration

9.1 Jumpers setup

Jumpers setup

Jumpers holding zone

TC808 accepts various tension sensor inputs:

1. Using micro-displacment based tension sensor(signal: 200mV, power supply: 5V)

Please short jumpers JP7, JP8 and JP11, jump J8 to GND to get 5V output.

2. Using strain gauge based tension sensor(signal: 20mV, power supply: 10V)

Please open jumpers JP7, JP8 and JP11, jump J8 to -5V to get 10V output.

The tension controller must be calibrated after

installation, and only the proper calibrated

controller can get the desirable measurement

precision.

Connect the tension sensor according to the

wiring diagram, pay more attention to the wiring

of tension sensor otherwise the measured

value will be incorrect.

● When two tension sensor is used, set parameter SN.N to L-R, connect the two sensors.

● When the left tension sensor is used, set parameter SN.N to L-SN, connect the tension sensor to REDL,

BLKL, GRL, WHL terminals.

● When the right tension sensor is used, set parameter SN.N to R-SN, connect the tension sensor to REDR,

BLKR, GRR, WHR terminals.

When use one tension sensor, make sure to short-circuit the unused tension signal terminals.

Stretch a string in the

center of the roller.

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

14

(AL

----

(AL

P2

P2

45.0

P2

50.0

50.0

NO

50.0

YES

P2

P2

Display

(AL

----

Step

1

2

3

4

5

6

Button Operation

Load weight of 50Kg on the tension sensor, press PAR key until

(AL appears in the upper display

Press ▼ key, P2 appears in lower display

Press PAR key, the number in the lower display will be the value

after adjustment assigned to injected input signal

Press ▲ and ▼ key to adjust the number in the lower display until

it corresponds to the value represented by the injected signal

Press PAR key

Press ▲ key to affirm

7Press PAR key, P2 appears in the upper and lower display at

the same time

8 5 seconds later, the scaling of the 2nd point is completed

(Suppose that the max load of the tension sensor is 50.0Kg in this example)

(AL

----

(AL

P1

P1

15.0

P1

0.0

0.0

NO

0.0

YES

P1

P1

Display

(AL

----

Step

1

2

3

4

5

6

Button Operation

Turn on the power switch, add no weight on the tension sensor,

press PAR key until (AL appears in the upper display

Press ▲ key, P1 appears in the lower display

Press PAR key, the number in the lower display will be the value after

adjustment assigned to the injected input signal

Press ▲ and ▼ key to adjust the number in the lower display until it

corresponds to the represented by the injected signal

Press PAR key

Press ▲ key to affirm

7Press PAR key, P1 appears in the upper and lower display at the same

time

8 5 seconds later, the scaling of the 1st point is completed

9.2 Zero Tension Calibration(P1)

9.2 Full Scale Tension Calibration(P2)

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

15

10 Use of Diameter Tension Control

10.1 Introduction

10.2 Thickness Adding up Reel Radius Calculation

In some special tension control system, it it not convenient for tension sensor mounting or there’s no need of

high precision of tension control. In these conditions, TC808 could be configured as diameter tension

controller.

To run TC808 as diameter tension controller, configure parameter ‘Control Function’(Code FVNC) as D,A.

The highlight feature of diameter tension control is that there’s no need of tension sensor and the mounting is

easy, and this mode is applicable for taper tension control too. Ideas for printing, package machines and

material cutting machines, etc.

TC808 monitors the pulses generated by main reel and material reel, the CPU calculates the reel radius,

according to radius, setting tension, powder brake rated torque [[, TC808 adjusts the output to control the

web tension.

There are two reel radius calculation methods: Thickness adding up and ratio method.

TC808 Tension Controller

Rx

R1

material thickness

TH,N

Diameter Tension Control(Unwinding)

powder brake

proximity

switch

proximity

switch

When using this method detecting the reel radius, material thickness TH,N, initial reel radius R0(Press PROG key to reset

R0) and reel pulses/r N2 must be set properly.

The TC808 counts the pulses generated by the proximity switch mounted on material reel, according to the total pulses N

and the initial reel radius, calculate the current reel radius according to the following formula:

R=R0±T*N/n (Winding: +,unwinding: -)

R:Current reel radius R0:Initial reel radius T:Material thickness N: Total pulses n: Reel pulses/r

TT: reel pulses/calculation, when pulses equal to TT, do a reel radius calculation. This parameter effect the reel radius

calculation precision and the measurement interval, the smaller TT, the higher precision and response.

Parameter ‘wind mode’(code RVN) effect the radius calculation: If RVN = TVN, radius increases; If RVN = VTVN, radius

decreases. When the system is in stop mode(the run/stop switch MC1-MCC is turned off) or manual operation mode,

press PROG key, measured radius will reset to initial radius R0. The measured radius will reset to initial radius R0

automatically during reel exchange process.

In order to get the correct

reel radius calculation, the

parameters related must be

set properly.

Pay more attention to the

mounting and response

speed of proximity switch

and encoder.

main reel

material reel

ZOETIC

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

16

10.3 Reel Radius CalculationRatio

10.4 The Principle of Diameter Tension Control

When using this method to calculate the reel radius ,the following parameter must be set properly:

N1 — main reel pulses/r

N2 — material reel pulses/r

R1 — main reel radius

TC808 monitor the pulses generated by main reel and material reel, and according to the setting parameter to calculate

the reel radius. This method neither care the material thickness nor the winding or unwinding parameters.

When the system is in stop mode(the run/stop switch MC1-MCC is turned off) or manual operation mode, press PROG

key, measured radius will reset to initial radius R0.

TT: reel pulses/calculation, when pulses equal to TT, do a reel radius calculation. This parameter effect the reel radius

calculation precision and the measurement interval, the greater TT, the higher precision but the measurement interval

becomes longer.

When the material reel runs at a constant speed, the the tension torque F*Rx equals the brake torque generated by the

powder brake. So, to keep the tension F a constant in the unwinding tension system, a way is to calculate the current

reel radius Rx and adjust the output to the powder brake.

Output X=F*Rx/CC(%)

F — Setting tension, unit: N

Rx — material reel radius, unit: m

CC — powder brake rated torque, unit: N*M

e.g. there’s a powder brake whose rated torque is 40 N*M, setting tension is 50 N, material reel radius is 300mm = 0.3m.

the output X=50*0.3/40=37.5%

As the above formula shows, TC808 adjusts the output according to reel radius, the output is proportional to the reel

radius and setting tension.

Note that when the controller is running in the manual operation mode, if there’s a modification to output X, the controller

will adjust the target tension F according to the formula above automatically.

AUTOK

WWW.CHINA-AUTOK.COM

F ---------- Current target tension(kgf)

F0 ------- Setting tension(kgf)

r --------- Current diameter(mm)

x

r --------- Minimum diameter(mm)

0

t1 -------- Taper ratio

F=F0

(

1-t1rx

((

(

1-r0

r0

rx

0.2

t1=0.25

t1=0.0

t1=0.5

t1=0.75

t1=1.0

1098

7

6

5

4

3

21

0.4

0.6

0.8

1.0 F0(Setting Tension)

F(Target Tension)

11 Taper Tension Control

Set ‘Control algorithm’(Code [TRL) to RSP,

In winding tension control systems, to prevent the material from winding too tight or too loose on the reel,

TC808 may be setting as Taper Tension Controller. This control as to increase/decrease the working

tension depending on the change in winding diameter, in which the tension is controlled in accordance with

the preset pattern, to suit the change in winding diameter.

The greater the taper ratio t1, the greater the change of tension when reel radius increases. If t1=0, TC808

performs constant tension control. See the figure below.

TC808 is configured as Taper Tension Controller.

While TC808 is working in taper tension control mode and the lower display is indicating the setting tension,

press PAR key, current target tension F appears in the lower display.

When [TRL = P,D, TC808 is configured as constant tension controller which is idea for unwinding tension

controls.

TENSION CONTROLLER TC808

17

AUTOK

WWW.CHINA-AUTOK.COM

TENSION CONTROLLER TC808

R6 R5 R4 R3 R2 R1

L1

L2

L3

L4

L5

L6

Reel Radius(mm)

Output(%)

Diameter-Output Program

12 Diameter-Output Program Tension Control

12.1 Introduction

Diameter-Output program(curve) contains up to 6 points, each point is a diameter-output coordinate, the

setting of reel radius must satisfy the following condition: R1 > R2 > R3 > R4 > R5 > R6

PR.N : Program number, TC808 may store multi programs, from 1 to 10.

R1 : Material reel radius, adjustable range: END; 1~999mm.

Note that if the radius is setting as END, the following parameters are not available.

L1~L6 : Output power, adjustable range: 0~100.0%.

The diameter-output program tension control is a special application of diameter tension control. According

to the presetting programs and the change of reel diameter, TC808 increase/decrease the output power to

achieve tension control purpose. In this mode, parameter (( needn’t setting.

12.2 Program Parameters

12.3 Program Parameters Access

First, (TRL must be configured as PRO9. When the controller is in the PV/SV displaying status, press PROG

key and hold for about 3 seconds, the first program parameter appears in the upper display. The value

associated with this parameter is shown in the lower display. At this time, use ▲ and ▼ key to modify the

parameter's value. Then, press PAR key, the next parameter appears. The modification has been saved in

the memory.

If there’s no key operations within 16 seconds, the display returns to the base condition.

18

AUTOK

WWW.CHINA-AUTOK.COM

Table of contents

Other AUTOK Controllers manuals

Popular Controllers manuals by other brands

Texas Instruments

Texas Instruments TMS320DM646x user guide

Festo

Festo VPPM operating instructions

Mitsubishi Electric

Mitsubishi Electric Central Controller G-50A installation manual

Danfoss

Danfoss EKC 312 user manual

Panduit

Panduit Atlona AT-DISP-CTRL user manual

IAI

IAI ROBO Cylinder RCP2 Series operating manual

Manitowoc

Manitowoc E-0400 installation instructions

Eurapo

Eurapo OMNIBUS 360 MAINTENANCE and Operation manual

Mitsubishi Electric

Mitsubishi Electric Melservo-J5 MR-J5 Series user manual

Vortice

Vortice C 1.5 Instruction booklet

Horizont

Horizont scout N2 operating instructions

Angst+Pfister

Angst+Pfister PFLOW5001 Series manual