EVCOS.p.A.|EV8338|Instructionsheetver.2.0|Code1048338E203|Page3of4|PT50/20

8. Touch the INTERACTIVE 1 key or the INTERACTIVE 2 key within

15 s to set the value.

9. Touch the INTERACTIVE 3 key (or take no action for 15 s).

10. Touch the INTERACTIVE 1 key or the INTERACTIVE 2 key to se-

lect “Day”.

11. Touch the INTERACTIVE 3 key: the display will show the day in

yellow.

12. Touch the INTERACTIVE 1 key or the INTERACTIVE 2 key within

15 s to set the value.

13. Touch the INTERACTIVE 3 key (or take no action for 15 s).

14. Touch the INTERACTIVE 4 key to exit the procedure (or take no

action for 60 s).

8.3 Restoring factory settings (default)

N.B.

Check that the factory settings are appropriate; see the section CONFIGURATION PA-

RAMETERS.

Make sure that the device is switched off.

1. Touch the INTERACTIVE 4 key: the display will show the “Con-

figuration” menu.

2. Touch the INTERACTIVE 1 key or the INTERACTIVE 2 key to se-

lect “Service”.

3. Touch the INTERACTIVE 3 key: the display will show “Password”

in yellow.

4. Touch the INTERACTIVE 1 key or the INTERACTIVE 2 key within

15 s to set “149”.

5. Touch the INTERACTIVE 3 key: the display will show the “Ser-

vice” menu.

6. Touch the INTERACTIVE 1 key or the INTERACTIVE 2 key to se-

lect “Restore default”.

7. Touch the INTERACTIVE 3 key for 3 s: the display will show a

tick.

8. Touch the INTERACTIVE 4 key to exit the procedure beforehand

(the reset will not be carried out).

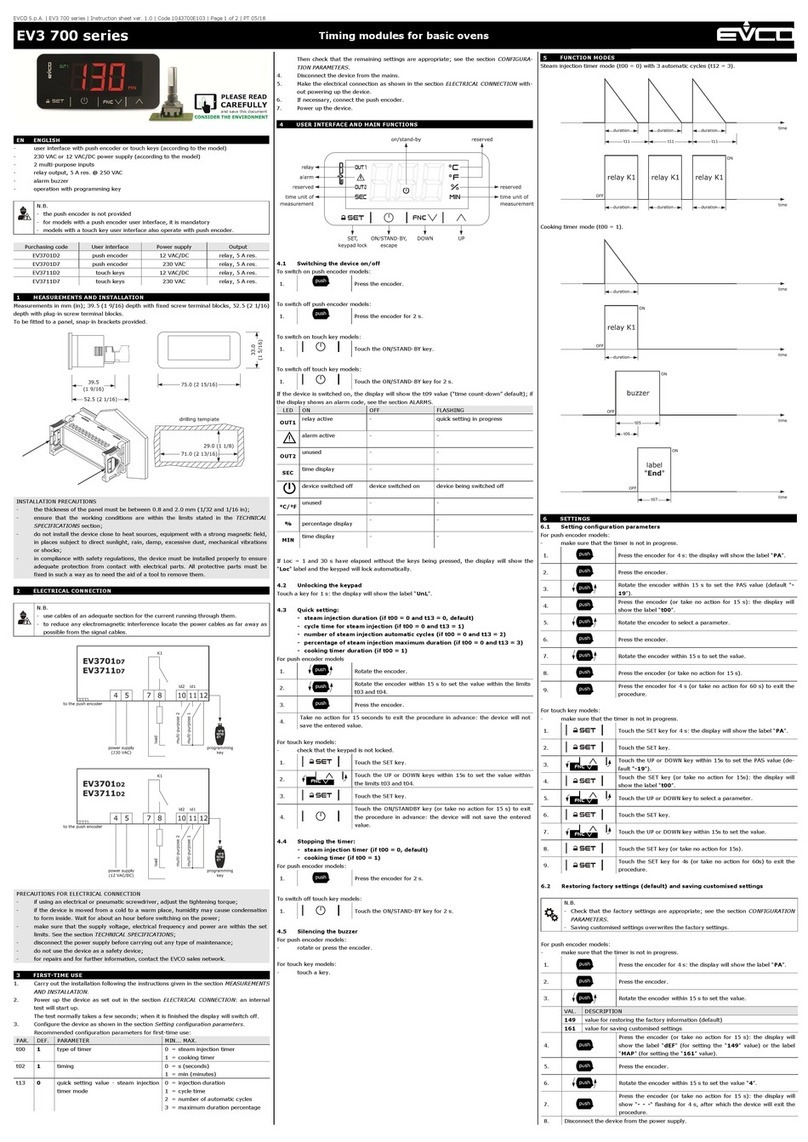

9 CONFIGURATION PARAMETERS

NO.

PAR. DEF. ANALOGUE INPUTS MIN... MAX.

1

P0

0

type of probe

0 = J 1 = K

2 = Pt 100 2-wire

2 P1 0 unit of measurement 0 = °C 1 = °F

3

P3

1

type of steam injection

0 = disabled

1 = manual and automatic

(with t8, t9 and t10)

4

P4

0

configurable input function

0 = disabled

1 = floor probe

2 = multi-purpose input 3

5 CA1 0 chamber probe offset -25... 25 °C/°F

6 CA2 0 floor probe offset -25... 25 °C/°F

NO.

PAR. DEF. REGULATION MIN... MAX.

7

r0

5

chamber setpoint differential

1... 99 °C/°F

effective if r10 = 0

8 r1 0 minimum chamber setpoint 0 °C/°F... r2

9 r2 300 maximum chamber setpoint r1... 999 °C/°F

10

r3

130

chamber setpoint default in

phase configuration r1... r2

11

r4

10

chamber setpoint in pre-heating

mode (relative to working set-

point phase 1 cooking cycle)

-199... 199 °C/°F

working setpoint phase 1

cooking cycle + r4

12

r8

80

cycle time for chamber and floor

heaters on 1... 999 s

if r10 > 0, cycle time PI

13

r10

0

proportional band

0... 99 °C/°F

0 = on-off control

14

r11

0

integral action time

0... 999 s

0 = P control

15

r14

180

delay between two chamber

heater switch-ons 1... 240 s

16

r15

10

minimum time chamber heaters

on/off 1... 240 s

NO.

PAR. DEF. GENERAL SETTINGS MIN... MAX.

17

c0

15

time buzzer on from end of

cooking cycle -1... 120 s

-1 = until silencing

18

c1

0

activate buzzer for 1 s at end of

cooking phase 0 = no 1 = yes

19

c2

60

keyboard inactivity time to

switch off the device from week-

ly programmed switch-on activa-

tion

0... 240 min

0 = disabled

20

c3

10

high chamber temperature

threshold for locked display (rel-

ative to chamber setpoint)

0... 99 °C/°F

chamber setpoint + c3

0 = disabled

21

c4

10

low chamber temperature

threshold for locked display (rel-

ative to chamber setpoint)

0... 99 °C/°F

chamber setpoint - c4

0 = disabled

22

c5

1

enable weekly programmed

switch-on 0 = no 1 = yes

23 c10 10 duration of controller cleaning 1... 120 s

24

c11

0

status chamber and fan heaters

at end of cooking cycle 0 = off

1 = with last settings

25

c12

0

cooking timer start-up with door

opening/closing

0 = if device status is "PRE-

HEATING" or "READY"

1 = if device status is

"READY"

26

c13

0

door opening function at end of

cooking cycle

0 = disabled

1 = start up cooking cycle

2 = start up cooking timer

NO.

PAR. DEF. STEAM INJECTION MIN... MAX.

27

t1

30

delay steam injection from start-

up of cooking cycle phase 0... 600 s

28

t2

100

chamber temperature for inhibit-

ing automatic steam injection

cycles

0... 999 °C/°F

29

t3

0

fan off time from end of steam

injection (fan off in steam injec-

tion)

-1... 120 s

-1 = injection inhibited if fan

off, pending until fan on

and fan off at end of in-

jection

0 = disabled

30

t4

1

activate automatic steam injec-

tion cycles at start-up of cooking

cycle

0 = no 1 = yes

31

t5

0

steam injection inhibited and

pending until chamber heaters

switched on and chamber heat-

ers switched off at end of injec-

tion

0 = no 1 = yes

32

t6

0

inhibition steam injection if vent

is open 0 = no 1 = yes

33

t7

2

time available with quick setting

of automatic steam injection cy-

cles

0 = injection time on

1 = injection time on and

injection time off

2 = injection time on, injec-

tion time off and num-

ber of automatic cycles

3 = injection time on and

number of automatic

cycles

34

t8

steam injection default time on

with quick setting 1... 99 s

35

t9

10

steam injection default time off

with quick setting

1... 999 s

if t7 = 1 or 2, injection time

off

36

t10

3

number of automatic steam in-

jection cycles default

-1... 20

-1 = until generator is

switched off

if t7 = 0 or 1, number of au-

tomatic cycles

NO.

PAR. DEF. FAN MIN... MAX.

37

F0

1

type of fan

0 = on/off, single speed

mode

1 = on/off, single speed

mode and with inver-

sion of the fan direction

2 = on/off, two-speed mode

and with inversion of

the fan direction

3 = modulating with PWM

driving signal and with

inversion of the fan di-

rection, for EVCO phase

cut speed regulator

4 = modulating with PWM

driving signal, with fre-

quency tracking and

with inversion of the fan

direction, for EVCO in-

verter speed regulator

(with F4, F5 and F6, du-

ty = 50%)

38

F1

15

fan off time for inversion of di-

rection 1... 600 s

39

F2

120

fan on time for every fan direc-

tion 1... 600 s

40

F3

1

chamber heaters off if fan off for

inversion of direction 0 = no 1 = yes

41

F4

50

if F0 = 3, minimum value fan

speed; if F0 = 4, minimum fre-

quency fan speed

if F0 = 3, 0... 100 %

if F0 = 4, 0... 100 Hz

42

F5

100

if F0 = 3, maximum value fan

speed; if F0 = 4, maximum fre-

quency fan speed

if F0 = 3, 0... 100 %

if F0 = 4, 0... 100 Hz

43 F6 5 fan start-up duration 0... 10 s

NO.

PAR. DEF. ALARMS MIN... MAX.

44

A0

10

temperature alarm switch-off

differential 1... 99 °C/°F

45 A1 0 high temperature alarm thresh-

old 0... 500 °C/°F

46

A2

0

high temperature alarm delay

and delay after modifying set-

point

0... 240 min

47

A3

0

type of high temperature alarm

0 = disabled

1 = absolute

2 = relative to setpoint

48

A4

70

high operating temperature

alarm threshold 0... 88 °C/175 °F

0 = disabled

49

A5

240

power failure duration due to in-

terruption of cooking cycle 0... 240 min

0 = disabled

NO.

PAR. DEF. DIGITAL INPUTS MIN... MAX.

50

i0

0

multi-purpose input 1 activation

0 = with contact closed

1 = with contact open

51

i1

1

multi-purpose input 1 function

0 = disabled

1 = suction hood on, fan off

(door open alarm)

2 = steam injection off,

chamber heaters off,

fan off, suction hood on

(door open alarm)

3 = steam injection off,

chamber heaters off,

fan off (door open

alarm)

4 = chamber heaters off

(thermal switch alarm)

5 = fan off (thermal switch

alarm)

6 = electronics compart-

ment fan on, remaining

outputs off (general

thermal switch alarm)

7 = switches device on/off

8 = manual steam injection

52

i2

0

door open alarm delay and

thermal switch alarm delay from

multi-purpose input 1

0... 120 s

53

i3

0

multi-purpose input 2 activation

0 = with contact closed

1 = with contact open

54 i4 6 multi-purpose input 2 function as i1

55

i5

0

door open alarm delay and

thermal switch alarm delay from

multi-purpose input 2

0... 120 s

56

i6

0

multi-purpose input 3 activation

0 = with contact closed

1 = with contact open

57 i7 6 multi-purpose input 3 function as i1

58

i8

0

door open alarm delay and

thermal switch alarm delay from

multi-purpose input 3

0... 120 s

NO.

PAR. DEF. DIGITAL OUTPUTS MIN... MAX.

59

u0

0

opening vent

0 = with contact closed

1 = with contact open

60

u1

10

time vent open from end of

cooking cycle

0... 600 s

-1 = open until closed by

pressing key

61

u2

10

time suction hood on

0... 999 s

0 = switch on/off by press-

ing key

62

u3

0

chamber light on when device is

switched on 0 = yes 1 = no

63

u4

0

chamber light off when device is

switched off 0 = yes 1 = no

64

u6

60

operating temperature threshold

when electronics compartment

fans on and device off

20... 65 °C/65... 150 °F

fans always on with device

on and device sensor in

alarm mode

65 u7 10 u6 differential 1... 99 °C/°F

66

u8

0

activate chamber light flashing

for 10 s at end of cooking cycle 0 = no 1 = yes

67

u9

0

venting configuration

0 = solenoid valve on/off

1 = motorised solenoid

valve

68

u10

120

duration of venting stoppage

from end of short pulse for

opening and from end of long

pulse for closing motorised vent-

ing solenoid valve

0... 600 ds

69

u11

10

duration short pulse for closing

motorised venting solenoid valve

0... 600 ds

70

u12

30

duration long pulse for opening

motorised venting solenoid valve

0... 600 ds

71

u13

0

floor setpoint

-999... 999 °C/°F

-999... 0 °C/°F = u13 +

chamber setpoint

1... 999 °C/°F = u13

72 u14 0 open vent with door opening 0 = no 1 = yes

73

u15

0

venting status with device

switched off 0 = closed

1 = open

74

u1c

8

K1 output configuration

0 = disabled

1 = chamber heaters

2 = fan rotation right

3 = fan rotation left

4 = fan high/low speed

5 = chamber light

6 = steam injection

7 = venting

8 = suction hood

9 = electronics compart-

ment fan

10= on/stand-by

11= sound

12= economy

13= floor heaters

75 u2c 6 K2 output configuration like u1c

76 u3c 9 K3 output configuration like u1c

77 u4c 5 K4 output configuration like u1c

78 u5c 1 K5 output configuration like u1c

79 u6c 12 K6 output configuration like u1c

80

u7c

3

K7 output configuration

like u1c

if F0 = 3 or 4, K7 output

configuration = fan enabling

81

u8c

2

K8 output configuration

like u1c

if F0 = 3 or 4, K8 output

configuration = NO contact is

reverse, NC contact is run

NO.

PAR. DEF. MODBUS MIN... MAX.

82 LA 247 MODBUS address 1... 247

83

Lb

3

MODBUS baud rate

0 = 2,400 baud

1 = 4,800 baud

2 = 9,600 baud

3 = 19,200 baud

N. PAR. DEF. SICUREZZE MIN... MAX.

84 PA1 426 level 1 password -99... 999

85 PA2 824 level 2 password -99... 999

N. PAR. DEF. DATA-LOGGING EVLINK MIN... MAX.

89

bLE

1

serial port configuration for con-

nectivity

0 = free

1 = forced for EVconnect or

EPoCA

2-99= EPoCA local network

address

87 rE0 15 data-logger sampling interval 0... 240 min

88 rE1 1 recorded temperature 0 = none 1 = all

10 ALARMS

LABEL RESET TO CORRECT

Chamber probe automatic - check P0

Floor probe automatic - check integrity of the probe

- check electrical connection

Board probe automatic check operating temperature

time flashing manual set time and day of the week

Chamber high temp. automatic check A1 and A3

Controller high temp. automatic check A4

Door automatic check i0, i1, i3 and i4

Power failure

manual

- touch a key

- check A5

- check electrical connection

Thermal switch manual check i0, i1, i3 and i4

11 TECHNICAL SPECIFICATIONS

Purpose of the control device: function controller.

Construction of the control device: built-in electronic device.

Housing: black, self-extinguishing.

Category of heat and fire resistance: D.

Measurements:

76.4 x 148.4 x 77.0 mm (3 x 5 13/16 x 3

in).

Mounting methods for the control device:

to be fitted to a panel, screwed-in brackets

provided.

Degree of protection provided by the casing: IP65 (front).

Connection method:

plug-in screw terminal

blocks for wires up to

2.5 mm²

Pico-Blade connector

female Micro USB

connector.

Maximum permitted length for connection cables:

power supply: 10 m (32.8 ft) analogue inputs: 10 m (32.8 ft)

digital inputs: 10 m (32.8 ft) digital outputs: 10 m (32.8 ft)

Operating temperature: from 0 to 60 °C (from 32 to 140 °F).

Storage temperature: from -25 to 70 °C (from -13 to 158 °F).

Operating humidity:

relative humidity without condensate from

10 to 90%.

Pollution status of the control device: 3.

Compliance:

RoHS 2011/65/EC

WEEE 2012/19/EU

REACH (EC) Regula-

tion no. 1907/2006

EMC 2014/30/EU LVD 2014/35/EU.

Power supply:

115... 230 VAC (+10 % -15 %), 50/60 Hz

(±3 Hz), max. in EV8338J9

24 VAC (+10 % -15 %), 50/60 Hz (±3 Hz),

max. in EV8338J4

Earthing methods for the control device: none.

Rated impulse-withstand voltage: 2.5 KV.

Over-voltage category: II.

Software class and structure: A.

Clock: built-in secondary lithium battery.

Clock drift: ≤ 60 s/month at 25 °C (77 °F).

Clock battery autonomy in the absence of a

power supply: > 24 h at 25 °C (77 °F).

Clock battery charging time:

24 h (the battery is charged by the power

supply of the device).

Analogue inputs:

1 for J/K thermocouples or Pt 100 2-wire

probes (chamber probe).

J thermocouples:

Measurement field: from 0 to 700 °C (from 32 to 999 °F).

Resolution: 1 °C (1 °F).

K thermocouples:

Measurement field: from 0 to 999 °C (from 32 to 999 °F).

Resolution: 1 °C (1 °F).

Pt 100 probes:

Measurement field: from 0 to 650 °C (from 32 to 999 °F).

Resolution: 1 °C (1 °F).

Digital inputs:

2 dry contact (multi-purpose 1 and multi-

purpose 2).

Dry contact: Type of contact: 3.3 V, 1 mA

Protection: none.

Other inputs:

can be configured for analogue input (floor probe) or digital

input (multi-purpose input 3).

Analogue outputs:

1 for PWM signal (for EVCO speed regula-

tor).

Digital outputs:

8 with electro-mechanical relay (K1...K8

relays).

The maximum overall current permit-

ted for loads is 15 A.

K1 relay: SPST, 16 A res. @ 250 VAC

K2...K7 relay: SPST, 8 A res. @ 250 VAC.