MODULEX CONTROLLER OPERATION

The basic procedures for navigating through the Main Menus, Sub-Menus and functions are described

in paragraph 3.1 The items and functions included in each Main Menu and Sub-Menu are briefly

described in paragraphs 3.2 through 3.7.

3.1 BASIC MENU PROCESSING PROCEDURE

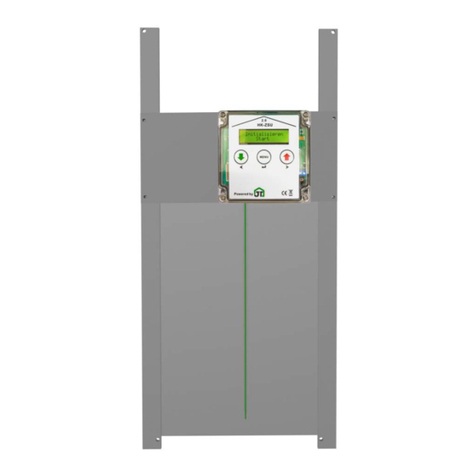

In order to change or view displayed settings, the display cover must first be opened. When opened,

the Controller automatically takes you to the display and indicator area.

The basic menu processing procedure is accomplished using the Rotary Knob and the Program Key

shown in Figure 2-2. Following initial startup and one-time entry of the required INSTALLATION menu

items (see paragraph 3.8), perform the following steps to access, view and/or change menu items:

NOTE

The following menu processing steps assume that all required (one-time)

INSTALLATION menu items have already been entered. It should be

noted that whenever the unit is powered down and then powered up

again, the INSTALLATION menu will reappear. When this occurs, the

INSTALLATION menu items DO NOT need to be reentered. Normally,

after entry of the required initial INSTALLATION menu entries, turning

the Rotary Knob clockwise will automatically advance the Controller to

the DISPLAY menu group. All items in this group are “Read Only” and

cannot be changed.

1.

When the ON/OFF switch on the front of the boiler is turned ON and the swing-down hinged panel

is opened, INSTALLATION will be displayed. This is the initial INSTALLATION menu and it is

assumed that all entries have already been made.

2.

Turn the Rotary Knob clockwise until the display advances to the DISPLAY menu. The dial on the

clock face will rotate one revolution counterclockwise and then go off. The display will then show

INSTALLATION, which is the first sub-menu in the DISPLAY menu group

3.

To view functions included in the INSTALLATION sub-menu, press the Program Key (Item B in

Figure 2-2). If desired, turn the Rotary Knob to scroll through the functions in the INSTALLATION

sub-menu. As previously mentioned, these display functions are read-only and cannot be

changed. Once you reach the end of the sub-menu, RETURN will appear in the display.

4.

To exit this sub-menu and advance to the next sub-menu in the DISPLAY menu, press the

Program Key. INSTALLATION will again be displayed. Turn the Rotary Knob clockwise until the

next sub-menu is displayed.

5.

Repeat steps 2, 3 and 4 to view the remaining main menus and their associated sub-menus. The

remaining main menus are: USER, TIME PROGRAM, EXPERT, EXPERT HS (Not Applicable to

Modulex), and GENERAL.

NOTE

Except for the items included in the DISPLAY Menu and sub-menus, all

other Menu groups and sub-menus contain Read-Write items which can

be viewed or, changed. Also, turning the Rotary Knob counterclockwise,

instead of clockwise will scroll through menu items in reverse order.

6.

When in the USER, TIME PROGRAM, EXPERT, or GENERAL Main Menu, virtually all sub-menu

items can be changed if the desired value or condition is not displayed.

7.

Turn the Rotary Knob clockwise to display the next menu item in the group.