Parvalux Electric Motors Ltd. SC 50/15 Controller Hardware Reference 1817 Operation

Operation List of figures

List of tables

4.0 5.0

5.0

4.1 Operation

The «SC 50/15» can operate in two modes:

•Closed loop speed control compares the actual speed signal with the applied set value. In case of deviation, the speed is dynamically readjusted.

•Open loop speed control feeds the motor with a voltage proportional to the applied speed set value. Changes in load are compensated using the IxR methodology.

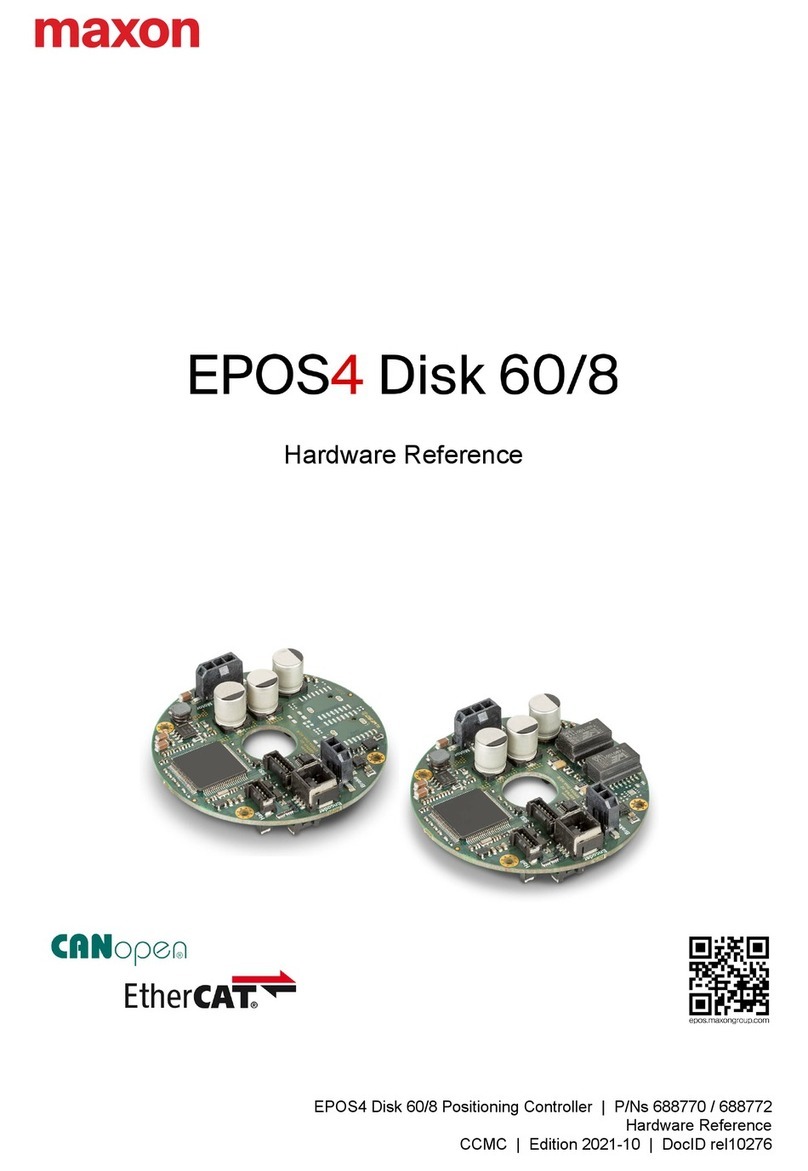

The below graphs (→Figure 4-21) illustrate the relationship between the speed set value input and the controlled/ commanded motor parameters with no load connected

to the motor.

The DIP switches #1, #2, and #3 (see →Table 3-27 on page 13) define the main components of your application—the type of motor, the control mode, and the speed set

value’s source.

Motor speed rpm

Set value speed

5V

100%

0

0

nmin

0

nmax

Closed loop speed control

Motor voltage V

Set value speed

5V

100%

0

0

0

0.98 x Vcc

Open loop speed control

Figure 4-21 Operation modes – closed loop speed control vs. open loop speed control

Important: DIP switch settings during «closed loop speed control»

In control mode «closed loop speed control» (DIP switch #2 “OFF”), the configurations «PMDC motor» (DIP switch #1 “ON”) and «Hall sensor only» (DIP switches #4…#6

“OFF”) are not valid and the controller will report an error.

In «open loop speed control», the SC 50/15 operates as a voltage controller

A «Speed Set Value» of 0 (zero) VDC is equal to a motor voltage of 0 (zero) VDC and thus a speed of 0 (zero) rpm or standstill. Independent of the position of DIP switch #8

(see →Table 3-29 on page 14), the maximum speed is given by the SC 50/15’s supply voltage and the motor’s speed constant.

In case of abnormal motor behavior: Changing the Hall sensor polarity using DIP switch #7

The Hall sensor polarity cannot be determined from the outside nor can it be retrieved from the motor’s datasheet.

If, after the completed controller setup procedure, the motor is not running as expected—for example if the motor speed is fluctuating or if the motor speed is not changing

in line with the speed set value input—the Hall sensor polarity might not be according to the standard configuration. If the case, set DIP switch #7 (see →Table 3-27 on page

13) to “ON” to invert the Hall sensor polarity.

How to setup the controller

1. For closed loop speed control: Use the DIP switch #3 to select the input source of the speed set value—either analog input AnIN1 or potentiometer P1.

The set value range (0…+5.0 VDC, respectively 0%…100% PWM) is equal to a motor speed range as selected with DIP switch #8 (in correlation with DIP switches #4

through #6). The set value changes in linear fashion.

For open loop speed control:

Use the DIP switch #3 to select the input source of the speed set value—either analog input AnIN1 or potentiometer P1.

The set value range (0 … +5.0 VDC, respectively 0% … 100% PWM) is equal to a motor voltage range of 0 VDC … 0.98 x VCC. The maximum speed is determined by the

controller’s supply voltage and the motor’s speed constant and is independent on the DIP switches #4 through #8 positions. The set value changes in linear fashion.

2. If you are using the analog input AnIN1 to set the «Speed Set Value», the potentiometer P1 will adjust the speed ramp (in the range of 5 s … 20 ms) in linear fashion.

3. Adjust the potentiometer P2 to the required limiting values of Icont (in the range of 1 … 15 A) and Imax (in the range of 2 … 30 A). Both ranges are adjusted at the same time,

the limiting values change in linear fashion.

Important: The limiting value Icont should be below the motor’s nominal current (max. continuous current, refer to the →motor data sheet).

4. Slowly increase the potentiometer P3 to the required gain. The SC 50/15 will thereby use this value for thermal motor protection according to the I2t method and will

limit the output current to Icont if necessary.

Important: If the motor starts to rattle, vibrate, or making noises, the set gain is too high. If so the case, turn the potentiometer P3 in CCW direction to lower

the gain.

Figure number Description Page number

Figure 2-1 Dimensional drawing [mm] 04

Figure 2-2 Derating of output current 05

Figure 2-3 Power dissipation and efciency 05

Figure 3-4 Fixation points 06

Figure 3-5 Connectors 07

Figure 3-6 Power supply and motor connector X1 07

Figure 3-7 Hall sensor connector X2 08

Figure 3-8 H1 input circuit (analogously valid for H2 and H3) 09

Figure 3-9 I/O connector X3 09

Figure 3-10 DigIN1 input circuit (analogously valid for DigIN2 and DigIN3) 10

Figure 3-11 DigOUT1 output circuit 10

Figure 3-12 AnIN1 input circuit 11

Figure 3-13 Encoder connector X4 11

Figure 3-14 Ch A differential input circuit (analogously valid for Ch B) 12

Figure 3-15 Ch A single-ended input circuit (analogously valid for Ch B) 13

Figure 3-16 DIP switch and potentiometers - location 13

Figure 3-17 DIP switch - default factory setting 13

Figure 3-18 Potentiometers 14

Figure 3-19 LEDs - location 15

Figure 3-20 Main wiring diagram 16

Figure 4-21 Operation modes - closed loop speed control vs. open loop speed control 17

Table number Description Page number

Table 1-1 Notation used 02

Table 1-2 Abbreviations and acronyms used 02

Table 1-3 Symbols and signs 02

Table 2-4 Technical data 04 / 05

Table 2-5 Limitations 05

Table 2-6 Standards 05

Table 3-7 Recommended tools 06

Table 3-8 Power supply and motor connector X1 - specications 07

Table 3-9 Power supply and motor connector X1 - pin assignment for PMDC motor 07

Table 3-10 Power supply and motor connector X1 - pin assignment for BLDC motor 07

Table 3-11 Power supply requirements 08

Table 3-12 Hall sensor connector X2 - specications 08

Table 3-13 Hall sensor connector X2 - pin assignment 08

Table 3-14 Hall sensor - specications 09

Table 3-15 I/O connector X3 - specications 09

Table 3-16 I/O connector X3 - pin assignment 09

Table 3-17 Digital inputs 1 ... 3 - specications 10

Table 3-18 Digital input - functionality 10

Table 3-19 Digital output 1 - specications 10

Table 3-20 Digital output - functionality 10

Table 3-21 Analog input 1 - specications 11

Table 3-22 Analog input 1 (PWM) - specications 11

Table 3-23 Encoder connector X4 - specications 11

Table 3-24 Encoder connector X4 - pin assignment 12

Table 3-25 Differential encoder - specications 12

Table 3-26 Single-ended encoder - specications 12

Table 3-27 DIP switch settings - functionality 13

Table 3-28 DIP switch settings - speed sensor setting and encoder resolution 14

Table 3-29 DIP switch settings - speed range setting 14

Table 3-30 Potentiometers - functionality 14

Table 3-31 LEDs - interpretation of condition 15