Linkam Scientific Instruments RH95 User manual

RH95 Humidity Controller

Linkam Scientific Instruments

USER GUIDE

1.1.1

2©2017 Linkam Scientific InstrumentsLtd.

v1.1.1

Table of Contents

...................................................................................................................................................................3Introduction

...................................................................................................................................................................4ImportantNotices

....................................................................................................................................................................................................4Warranty ....................................................................................................................................................................................................4Technical Support

....................................................................................................................................................................................................4Feedback

...................................................................................................................................................................5SafetyInformation

....................................................................................................................................................................................................5Important notice

....................................................................................................................................................................................................5Requirements for safe use

....................................................................................................................................................................................................5Caution Labelsand Indicators

....................................................................................................................................................................................................5Equipment Maintenance

...................................................................................................................................................................6Informations de sécurité

....................................................................................................................................................................................................6Note importante

....................................................................................................................................................................................................6Exigences en matière de sécurité d'utilisation

....................................................................................................................................................................................................6Étiquettes d' avertissement et indicateurs

....................................................................................................................................................................................................6Entretien de l'appareil

...................................................................................................................................................................7SystemOverview

....................................................................................................................................................................................................8Connecting your RH95 Controller

.............................................................................................................................................................................................. 8

Back Panel Connections

........................................................................................................................................................................... 8

USB Connector

........................................................................................................................................................................... 8

RS232 Connector

........................................................................................................................................................................... 8

Humidity sensor connector

........................................................................................................................................................................... 8

Power socket........................................................................................................................................................................... 8

Transit Screw Holder

........................................................................................................................................................................... 8

Air Inlet Connector

.............................................................................................................................................................................................. 9

Connecting the RH95 to the humidity chamber

.............................................................................................................................................................................................. 10

Connecting the RH95 to a Linkam Heating Stage

...................................................................................................................................................................12Usingthe RH95Controller

....................................................................................................................................................................................................12Filling the water bottle

....................................................................................................................................................................................................14Desiccant conditioning

....................................................................................................................................................................................................14Setting the humidity level

....................................................................................................................................................................................................15RH95 settings and configuration

.............................................................................................................................................................................................. 15

RH95 status

.............................................................................................................................................................................................. 15

Humidity sensor details

....................................................................................................................................................................................................15Touchscreen Calibration

...................................................................................................................................................................16Validatingthe humidityreading

...................................................................................................................................................................19Declaration of Conformity

...................................................................................................................................................................20Technical Specifications

©2017 Linkam Scientific InstrumentsLtd.

3

v1.1.1

Introduction

Thankyou forpurchasingyourLinkam equipment, please take a momenttoread this manual before settingup the equipment.

Ifyou have purchased control software,please install the software first.

See your software manual forfurtherinstallationinstructions.

©2017 Linkam Scientific InstrumentsLtd.

4v1.1.1

ImportantNotices

Please register your products by goingto www.linkam.co.ukandclickingon the activate warrantylink.Youwill needtoregister yourequipment with

us to:

Activate yourwarrantyandtechnical support.

Access the online setup videos.

Warranty

This equipmenthas a warrantyagainst defects inmaterial and workmanship for a periodof12months fromthe date ofshipping. Linkamwill either

repairorreplace products that prove to be defective. Forwarrantyservice orrepair,this product must be returned to Linkam ora designated

service facility.

The warrantyshall notapplyto defects resultingfrominterfacing, unauthorized modificationormisuse,operationoutside ofthe environmental

specifications for the product, orimpropersite preparation ormaintenance.

Technical Support

Anytechnical questions orqueries should be addressedtothe Technical SupportDepartment at the address shown belowand on the backofthis

manual.

Tel:+44(0)1737 363 476

Email:support@linkam.co.uk

Feedback

Your feedbackwill be greatlyappreciated,please email us directlyinfo@linkam.co.uk

©2017 Linkam Scientific InstrumentsLtd.

5

v1.1.1

SafetyInformation

Important notice

Please check that your Linkamequipment has not beendamagedduringtransport.

Ifthere is any evidence ofexternal damage toanyofthe electrical items:-

do not connect power to the power supply or the RH95 unit.

ContactLinkamScientificInstruments Ltd ortheirappointeddistributorimmediately.Yourwarrantymaybe impaired ifLinkamis not informedof

any transport damage within 7 workingdays ofdelivery.

Requirements for safe use

1. Read all ofthis guide before usingthe equipment.Save these instructions forlater use.

2. Followall warnings andinstructions markedon anyofyourLinkamequipment,orcontainedwithinthe manuals.

3. To prevent electric shock, do not remove the cover ofthe equipment.

4. Never use the equipment ifany ofthe cables, includingthe powercord,have beendamaged. Donot allow any heavyobjects torest on the

powercord. Never lay the power cordonthe floor.

5. Do not obstruct any ventilation holes. Do not attempttoinsertanythingintothese openings. Provide adequate ventilation ofat least

75mmall around the equipment.

6. The mains cord setis the overall disconnect and must remainaccessible.

7. Ifthe equipment is used in a manner not specifiedbythe manufacturer, the protectionprovided bythe equipment may be impaired.

8. Do not expose the equipmenttowater. Ifforany reason it gets wet,thenremove the power cord fromthe powersupplyandcontactLinkam

Scientific Technical Support.

9. The equipment is not intended to be used outdoors.

10. Eachproduct is equippedwitha 3-wire grounded(earth)powerplugor a free-end3 wire power cord. The plugonlyfits into a grounded-type

outlet. The free-endpower cordshould be connected to a correctlygrounded 3-wire poweroutlet. Donot defeat the purpose ofthe

grounded (earth)type plug.

Free -endpowercords are colourcoded as follows:-

Colour Function

Brown Live

Blue Neutral

Green/Yellow Earth(Ground)

11. The power cord must be an appropriatelyrated and approved cord-set forthe country it is beingusedin.

12. Onlyuse an appropriatelyrated powersupply, that is approved forthe country it is beingusedin.

13. Ifanyproblems occurthen remove the powercordfrom the power supply and contact Linkam Scientific Technical Support.

14. NOattempt should be made torepair or modifythe equipment in any way. Any servicingshouldbe carriedoutby qualifiedservice

personnel. Do notremove the coverfrom the equipment unless the powercord has been removed fromthe mains outlet.

15. After servicingthe safe state ofthe equipmentmust be checked.

Caution Labelsand Indicators

This safetysymbol is seenonthe RH95instrumentratinglabel and warns theuser:

·

Do notmake or remove anyconnections while the unit is poweredon.

·

Do notremove the cover.

·

Servicingshould onlybe done byqualifiedservice personnel.

Equipment Maintenance

The equipment does not require anyregular maintenance. ContactLinkam should you require anymaintenance.

Before cleaningthe case or front panel ofthe equipment, remove power fromthe unit.Use a small quantityofisopropyl alcohol (IPA)on a soft cloth

and gentlywipe the surface.

©2017 Linkam Scientific InstrumentsLtd.

6v1.1.1

Informations de sécurité

Note importante

Veuillezvérifierque votre appareil Linkam n'a pas été endommagé pendant le transport.

S'il présente une trace quelconque d'endommagement aux éléments électriques:

ne pas brancher l'alimentation à l'alimentation ou à l'unité RH95

ContactezLinkamScientific Instruments Ltd ouson distributeurdésigné immédiatement. Votre garantie pourraitêtre réduite si Linkam n'est pas

informée de toutdommage causé par le transportdans les 7ouvrables suivantla livraison.

Exigences en matière de sécurité d'utilisation

1. Lisezce guide intégralement avantd'utiliser l'appareil. Conservezces instructions pourunusage ultérieur.

2. Suiveztoutes les mises engarde etinstructions marquées surtoutepièce devotre appareil, oufigurant dans les manuels.

3. Pourprévenirl'électrocution,n'enlevezpas le couvercle de l'appareil.

4. N'utilisezjamais l'appareil silecordond'alimentation a été endommagé.Ne laissez pas d'objets lourds appuyés sur le cordon

d'alimentation. Ne posezjamais le cordon d'alimentationsur le sol.

5. Le secteur cordon est la déconnexion globale et doitresteraccessible.

6. Si l'équipement est utilisé d'une manière nonspécifiée parle fabricant,la protection fournie parl'équipement peutêtre altérée.

7. N'obstruezaucundes orifices deventilation. N'essayezpas d'insérerquoi que ce soit dans ces ouvertures.Prévoyezunespace de

ventilationadéquat d'au moins 75autourde l'appareil.

8. N'exposezpas l'appareil à l'eau. Si pourune quelconque raison l'appareil est mouillé,retirezle cordond'alimentationde la prise de courant

et contactezle support technique de Linkam.

9. L'appareil n'est pas destiné à un usage à l'extérieur.

10. Chaque produitest équipé d'une fiche d'alimentationmise à la terre oud'un cordon d'alimentationavec 3 fils à extrémité libre. La fiche ne

s'insère que dans une prise de courant mise à la terre. Le cordond'alimentationà extrémités libres doitêtre raccordé à une prise de

courant à 3fils correctement mise à la terre.N'empêchezpas le fonctionnement de la fiche mise à la terre.

Les cordons d'alimentation à extrémité libre suivent les codes couleursuivants:

Couleur Fonction

Marron conducteurde phase

Bleu conducteurneutre

Vert/jaune mise à la terre

11. Le cordon d'alimentationdoitêtre constitué d'unensemble de câbles répondant aux caractéristiques nominales etapprouvé dans le pays

d'utilisation.

12. Utilisezuniquementune alimentation nominale appropriée, qui est approuvé pourle pays, il est utilisé po.

13. Si un problème survient, débranchezle cordond'alimentationde la prise de courant et contactezle support technique de Linkam.

14. Aucune tentative ne devrait être faitpour réparer ou de modifierl'équipement enaucune façon. Toute réparationdoit être effectuée parun

personnel qualifié .Ne pas retirerle couvercle de l'appareil, saufle cordond'alimentation a été retiré de la prise secteur.

15. Après l'entretiende l'étatde sécurité de l'équipement doit être vérifiée.

Étiquettes d' avertissement et indicateurs

Ce symbole de sécurité est visible surl'instrument étiquette signalétique RH95 et avertit l'utilisateur:

·

N'effectuezoun'enlevezaucunraccordement quand l'appareil est sous tension.

·

N'enlevezpas le couvercle.

·

L'entretiendoitêtre effectué exclusivementpardupersonnel qualifié.

Entretien de l'appareil

L'appareil ne nécessite pas d'entretienrégulier. ContactezLinkam si vous souhaitezprocéder à unentretien.

Avant de nettoyerle boîtier ou le panneau avantde l'appareil, débranchezle cordonsecteur de la prise de courant.Utilisezune petite quantité

d'alcool ispropylique (IPA)surun chiffon douxet frottezdélicatement la surface.

©2017 Linkam Scientific InstrumentsLtd.

7

v1.1.1

SystemOverview

The RH95 system contains the followingcomponents:

1. RH95 Controller

2. RH95 power adaptor

3. Mains lead

4. Humiditysensorandcable forhumiditychamber

5. Humiditychamber

6. Humiditychambertool

7. RHwater bottle

8. Humiditydata RS232 cable (onlyincluded when a T95 controller is supplied)

9. Screwdriver

10. USBType Atomicro Bcable forfirmware upgrades

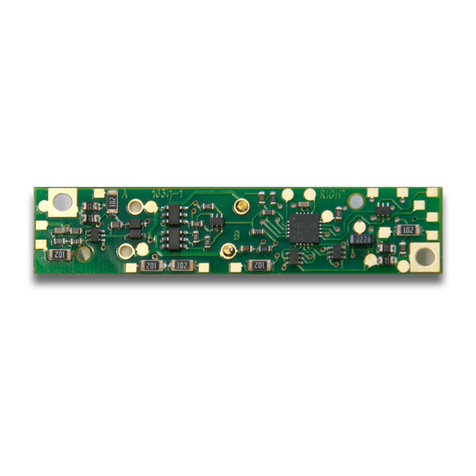

IMPORTANTNOTE:The humiditysensor(4)issusceptible todamage fromelectrostatic discharge. Please observe proper ESDhandlingprecautionswhen

handlingthe humiditysensororsensorcable assembly

©2017 Linkam Scientific InstrumentsLtd.

8v1.1.1

Connecting your RH95 Controller

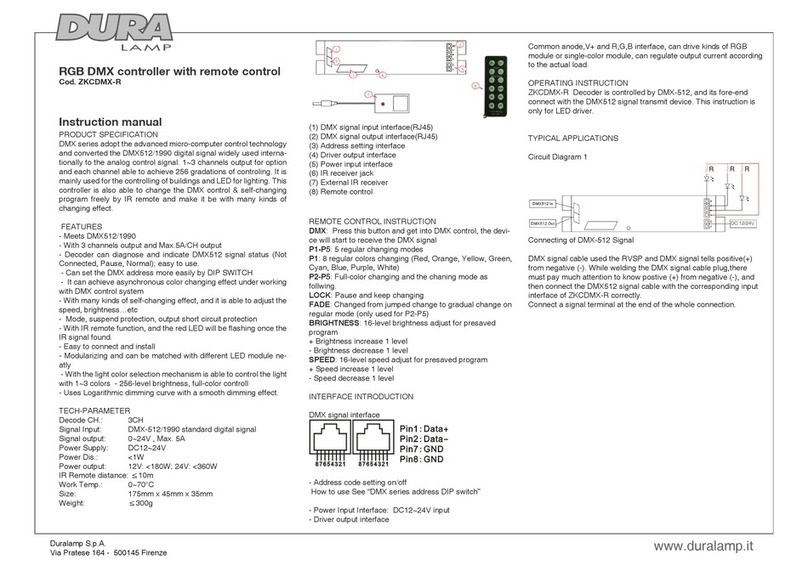

This sectiondescribes the connections on the backpanel ofthe RH95 humiditycontrollerand their purpose.

BackPanel Connections

Warning:To avoid anydamage to the RH95, switch the unitoffbefore connectingor disconnectinganyconnection.

1: MicroUSBconnector(currentlyused forfirmware upgrade only).

2: RS232 Connector

3: HumiditySensorConnector

4: Power socket

5: Transitscrewholder

6: AirInletconnector

USBConnector

At presentthis is onlyused forupdatingthe firmware in the RH95.

RS232 Connector

The RS232 connectoris intended to allow the RH95controllerto be connected to a Linkamcontrollerusingthe humiditydata RS232 cable.

Humiditysensorconnector

The humiditysensorconnectoris usedtoconnect the RH95 to the humiditysensorcable.

Powersocket

For connection to the power supply provided with the RH95 unit.

Note:DONOTconnect the powertransformertothe RH95 while the transformerispoweredon. Firstconnectthe transformer tothe RH95,andthen

connect the mainspowerto the transformer.

TransitScrewHolder

The transit screwholdershouldbe used to hold the transit screws,whichholdthe internal pump secure duringshipping.These are foundonthe

underside ofthe controller and should be removed before use. Rememberto re-secure the pumpwiththese transitscrewsbefore shipping.

AirInletConnector

This is the portthat supplies airto theRH95 controllerforhumidification/drying.Blockingaccess to this port will prevent theRH95 fromfunctioning.

Important Note:Onlysuitable for use with gasatatmospheric pressure.DONOTflowpressurizedgasinto thisport.

©2017 Linkam Scientific InstrumentsLtd.

9

v1.1.1

Connectingthe RH95 tothe humiditychamber

YourRH95 systemincludes a small humiditychamberthat can be usedto testyoursamples at ambient temperature.Toconnectthe RH95

controller to the supplied humiditychamberfollowthe below procedure:

Note:This chamberis alsousedwhenvalidatingthe humidity reading.

IMPORTANTNOTICE:The humiditysensor isextremelysensitive tocontaminants-DONOTtouch the exposedchipor allowanythingto come into

contact with it. These sensorscannot be repairedifbrokenor contaminated, and are notcovered bywarranty.

1. Carefully remove the capprotectingthe humidity sensor.Donot touch the exposed chip on the humiditysensor.

2. Remove the lid ofthe humiditychamberusingthe providedtool, as shown:

3. Screw the sensorinto the chamber,beingvery careful not to damage the fragile sensor.

4. Connect the 9 pinconnectorfor the sensortothe port onthe backofthe RH95 marked 'HumiditySensor'

©2017 Linkam Scientific InstrumentsLtd.

10 v1.1.1

5. Connect the humiditytube fromthe front ofthe RH95 to the port on the humiditychamberopposite the sensor,as shown:

Note:Do not connect the humiditytube tothe same side ofthe chamber as the sensor,as this will affect the readings.

6. Replace the lidofthe humidity chamber.You are nowreadyto control the humidity in the chamber.

Connectingthe RH95 to aLinkam HeatingStage

Ifyou have purchased a Linkamheatingstage with humiditycapabilityto gowithyourRH95 controller,follow these instructions to connect it:

IMPORTANTNOTICE:The humiditysensor isextremelysensitive tocontaminants-DONOTtouch the exposedchipor allowanythingto come into

contact with it. These sensorscannot be repairedifbrokenor contaminated, and are notcovered bywarranty.

1. Carefully remove the capprotectingthe humidity sensor.

2. Screw the humiditysensorintothe provided threadedhole in the Linkam heatingstage,beingverycareful not to touch the sensor.

3. Connect the 9 pinconnectorfor the sensortothe port onthe backofthe RH95 marked 'HumiditySensor'

©2017 Linkam Scientific InstrumentsLtd.

11

v1.1.1

4. Connect the humiditytube fromthe front ofthe RH95 to the port on the Linkam stage,as shown:

5. Insert the gas valve insert into the gas valve on the opposingside ofthe stage tothe humidity feed.

6. You are nowreadytocontrol the humidityofyourLinkam stage.

©2017 Linkam Scientific InstrumentsLtd.

12 v1.1.1

Usingthe RH95Controller

This sectiondescribes the operation ofthe RH95 control unit.

Filling the water bottle

Before the RH95can control the humidityofyoursample chamber, the water bottle must be filled.Itis important that onlydistilledwateris used in

the HumidityGenerator.

Step1:

Make sure the controlleris powered downandthat the transit screws have beenremovedfromthe base ofthe unit. Store these screws in the

providedholes on the backpanel ofthe unit.

Step2:

Unscrewthe bottle lid assemblyandremove from the bottle,beingcareful not todamage the heatingelement.

Step3:

Halffill the bottle to the level indicatedandcarefully re-attachthe lid assembly. Do not fill the bottle past the maximumlevel indicator.

©2017 Linkam Scientific InstrumentsLtd.

13

v1.1.1

Step4:

Remove the magnetic front panel ofthe RH95

Step5:

Slide the bottle into the RH95 and tighten the lockingscrewuntil it is just tight.Donot overtightenthe screw.

Step6:

Replace the magnetic front panel ofthe RH95

Important Note:Before shippingthe RH95, the water bottle should be removed from the unit, drained and placed into the space provided inthe

packaging.The RH95 shouldnot be shippedwiththe waterbottle fitted.

©2017 Linkam Scientific InstrumentsLtd.

14 v1.1.1

Desiccant conditioning

When the RH95 has not beenusedinsome time, the desiccant inthe controllerwill needdryingoutbefore use. Itis advised toperformthis

procedure whenthe goods are initiallyreceived.

Tapthe buttonand the followingscreen will appear:

tap the 'set'time display and a keypad screen will appear:

Enter the time required inhours,minutes andseconds and press enter, then push the start button to begin the conditioning.

NOTE:The suggesteddryingtime is 1:00:00 hour.

Setting the humidity level

Tap onthe humidityvalue onthe LCD displayofthe RH95 controller. This will bringupa number pad.Enter a humidity value ofbetween 10-90%and

press Ent.Press Ctoclearthe last digit.

Press the (start)button to begin controllingthe humidityinyourchamber.

©2017 Linkam Scientific InstrumentsLtd.

15

v1.1.1

RH95 settings and configuration

To checkthe serial numbers and firmware information forthe humidity controllerand attachedsensor,tap the button atthe top ofthe screen,

and the followingscreen will appear:

RH95 status

Tapthe buttonin the settings screen to see a graphical displayofthe current status ofthe RH95, as below:

Tap the 'X'buttontoreturntothe previous screen.

Humiditysensordetails

The buttonaccesses the humiditysensorinformation. This includes the chambertype it is designed forandthe serial number ofthe sensor.

Touchscreen Calibration

Ifthe touchscreen interface on the RH95 is not respondingcorrectlytotouch input,it may need to be re-calibrated. In order to do this, please follow

this procedure:

1. Power down the RH95 Controller.

2. Place a fingeronthe touchscreenandholdit there

3. While continuingto hold a finger on the screen, power the RH95 back on, you shouldsee the below screen:

(youcan now remove the finger fromthe screen)

4. Touch the blue dotinthe centre ofeachsmallwhite square. Once all 4 corners have been touched the RH95 will start normally.

NOTE:Use a biroorstylus tocomplete this operation, touches with a finger maynot be sufficientlyaccurate.

©2017 Linkam Scientific InstrumentsLtd.

16 v1.1.1

Validatingthe humidityreading

Ifyou have purchased an optional Rotroniccalibrationstandard with your RH95 unit, you can use these to validate the humidity readingofyour

RH95.

Youshould have received the followingpackage:

This will containsome textile pads and five ampoules ofcalibration salts. The RH%will dependupon whichkit was ordered. Theyare available in RH

values of10%,35%,65%and80%.

These standards consist ofsalts which will alter the humidityofa small enclosedspace toa specific RHvalue,byeither absorbingor releasing

moisture into the air. The humidityreadings canbe affected by several factors,so the environmentmust be controlledwhenusingthese validation

standards:

·

Roomtemperature must be 23°C+/-2°C.

·

The humiditystandard must be atthe same temperature as the humiditysensor. A1 degree difference in temperature cancause anerrorof

up to6%RH

·

There mustbe no draughts in the calibration room

·

Do notexpose the calibration chamber to directsunlightwhile in use

·

Do notexpose the calibration salts todirect sunlight atany time.

Usage directions

Note:It is recommended thatyouwearsafetygoggles while performingthis validationprocedure.

1. Remove the lid ofthe supplied humiditychamberand place one ofthe textile pads inthe recess.

Note:do not touchthe textile pad with bare hands,as this cancause contaminationand inaccurate readings.Wearsterile gloves, oruse a clean

pairofpliers or tweezers to loadthe pad.

©2017 Linkam Scientific InstrumentsLtd.

17

v1.1.1

2. Holdthe ampoule ofthe selected humiditystandardat the neckand bringthe entire contents intothe further,lower partofthe ampoule by

swingingor lightlytappingagainst the glass.

3. Breakthe ampoule at the marked place and emptyitcompletely onthe centerofthe textile padwhile tappingitlightlytomake sure all of

the liquidis soakedintothe pad.

Note:wrapthe topofthe ampoule with tissue paper to containanyglass fragments.

4. Screw the humiditysensorintothe chamber.

Note:Be careful duringthis step to make sure the RH sensordoes not come into contact with the soaked pad. The salts will damage the sensorifit

comes intocontact with them.

©2017 Linkam Scientific InstrumentsLtd.

18 v1.1.1

5. Replace the lidofthe humidity chamber and place the caps on the white plastic airports.

6. Allowthe chambertoreach humidityequilibrium (see table below)andswitch the RH95 uniton. You can nowcompare the humidityreading

ofthe RH95 with the expectedhumidity value ofthe calibration standard used to validate the accuracyofthe RH95.

Time to reach equilibrium

RH%ofhumiditystandard

45 minutes

10%, 35%, 65%

60 minutes

80%

Note:After everycalibrationthe textile pad must be renewed and the chamber washed out with waterandwell dried. Thoroughlywash yourhands

to remove anytraces ofthe calibration salts.

©2017 Linkam Scientific InstrumentsLtd.

19

v1.1.1

Declaration of Conformity

ManufacturersName: Linkam Scientific Instruments Ltd

ManufacturersAddress: 8 Epsom Downs Metro Centre

Waterfield

Tadworth

Surrey

KT20 5LR

UK

Declaresthat the productsasoriginallydelivered:

Product Name: RH95 Controller

has been found to complywiththe followingapplicable EuropeanDirectives, and carries the CEmarkingaccordingly:

EMCDirective 2014/30/EUusingproduct standard EN61326-1:2013

LowVoltage Directive 2014/35/EUusingproduct standard EN61010-1:2010

RoHS2 Directive 2011/65/EU

and also carriesthe additional certification:

EMC: FCC CFR 47 Part 15B:2014

Safety: IEC61010-1:2010/EN61010-1:2010/UL60950-1:2012/CAN/CSAno.61010-1-12

Date: 14thApril 2016

R&DManager: PeterGrocutt

©2017 Linkam Scientific InstrumentsLtd.

20 v1.1.1

Technical Specifications

RH95 Controller

Dimensions: 250 x 270 x 140 (mm)

Weight: 4.5Kg(excludingcables and powersupply)

OperatingEnvironment: 5~40°C, 80% relative humidityat 31°C decreasinglinearlyto50%at 40°C(without condensation)

Supplyvoltage: 24Vdc

Maxcurrent: 3A

Display Resolution: 128 X 64 pixels

DisplaySize: 2.3 inch

UserInterface: Touchscreen

RH Sensor: Digital capacitive sensor

RHRange: 10 to 90%

RHResolution: 0.1%resolution

RHAccuracy: 1.8%

RHStability: 0.5%

SetPoint Resolution: 0.1%

USBInterface

MicroUSB Type B connector: Currently onlyusedforfirmware updates.

PowerSupply

SupplyVoltage: 24Vdc

MinimumSupplyCurrent: 3A

Connector: 4 pinMini DIN

Note—onlyuse anearth referencedpowersupplywith this equipment

Table of contents

Other Linkam Scientific Instruments Controllers manuals