Automatic Products 310 Instruction and safety manual

75 WEST PLATO BOULEVARD • ST. PAUL, MINNESOTA 55107-2095

AUTOMATIC PRODUCTS international, ltd.

OPERATING SYSTEM &

SERVICE MANUAL

MODEL 310 CONTROL MODULE

MODEL 320 MERCHANDISER

PLEASE DONOT

REMOVE MANUAL

FROM MACHINE

APi 320 V4.59

general index

Table of Contents

Sections 1 & 2

Section 3

Quick Set Up Guide

Table of Contents

Section 4

Advance Set Up and Operations Guide

Section 5

Parts

Section 6

Trouble Shooting

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

HOW TO USE THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

STANDARD FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.01

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.01

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.02

TOWER INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.04

OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.05

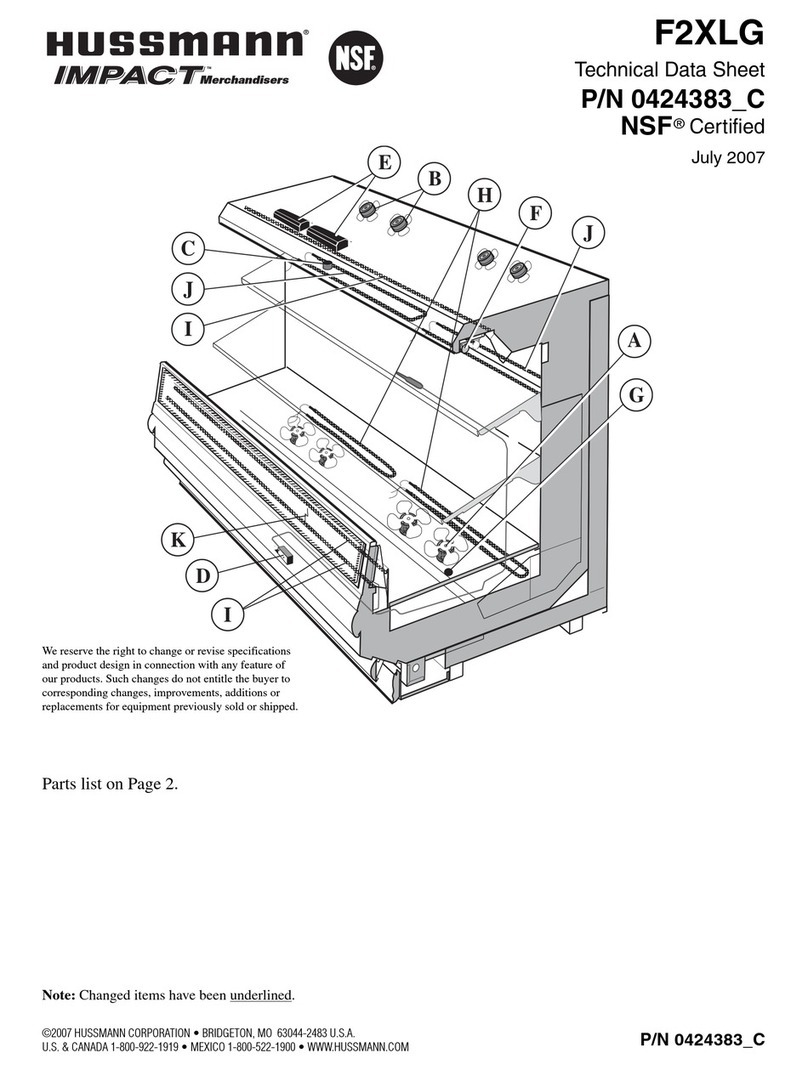

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.01

Tower Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.01

Lighting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.01

Main Product Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.01

Conveyer Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.01

Removal of Product Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.01

Delivery Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.01

Heated Glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.01

DEX/UCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.01

Printer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.01

Coin Mechs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.02

Bill Validators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.02

Debit Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.02

The Chime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.02

Interlock Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.02

Temperature Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.03

The Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.03

Refrigeration Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.03

Defrost Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.04

Vend Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.05

Cabinet and Shelf Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.05

Selection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.07

MasterMenu Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.08

LogiCenter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.09

Food Driver Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.09

The Front Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.09

To achieve the most trouble-free operation from your APi 320 series Merchandiser, it is recommended that this service

manual be thoroughly read and the instructions followed pertaining to installation, servicing and maintaining of the unit.

Should you have questions pertaining to this manual or the vendor, please contact your APi distributor or write directly to:

Technical Service Dept.

Automatic Products int. ltd.

75 West Plato Blvd.

St. Paul, MN. 55107 USA

651-224-4391

651-602-3558 (fax)

©1999 Automatic Products international, ltd

table of contents

WARRANTY

ii

Automatic Products international ltd. (APi) expressly warrants these automatic merchandisers (the "Unit"),

manufactured by it, to be free under normal use and service from defects in material or workmanship for a

period of two (2) years from the date of delivery of this Unit to the original purchaser. This warranty extends

only to the original purchaser of the Unit.The exclusive remedy for this warranty is limited to the repair or

replacement, at APi's sole option, of any part or parts of the Unit that are returned to APi or to the

authorized dealer or distributor of APi from whom the unit was purchased with all transportation charges

prepaid, and which, on APi's examination, shall, conclusively appear to have been defective. This warranty

does not:

a. extend to any Unit, or part thereof, that was subjected to misuse, neglect, or accident by other

than APi after its delivery to the original purchaser;

b. extend to any Unit, or part thereof, that was modified, altered, incorrectly wired or improperly

installed by anyone other than APi or used in violation of the instructions provided by APi;

c. extend to a Unit which has been repaired or altered by anyone other than APi or authorized

dealer/distributor;

d. extend to a Unit which has had the serial number removed, defaced or otherwise altered;

e. extend to plastic or glass windows, lamps, fluorescent tubes and water contact parts;

f. extend to any unit used outdoors

g. extend to accessories used with the Unit that were manufactured by some person or entity

other than APi.

APi DISCLAIMS ALL OTHER WARRANTIES OF ANY KIND AS TO THE UNIT AND ALL WARRANTIES

OF ANY KIND AS TO ANY ACCESSORIES. THIS DISCLAIMER OF WARRANTIES INCLUDES ANY

EXPRESS WARRANTIES OTHER THAN THE LIMITEDWARRANTY PROVIDED ABOVE AS TO THE

UNIT AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE AS TO THE UNIT AND ANY ACCESSORIES. UNDER NO CIRCUMSTANCES SHALL APi BE

RESPONSIBLE FOR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES, LOSSES OR

EXPENSES ARISING FROM OR IN CONNECTION WITH THE USE OF, OR THE INABILITY TO USE,

THE GOODS FOR ANY PURPOSE WHATSOEVER. No representative of APi or any other person is

authorized to assume for APi, or agree to on the behalf of APi, any other liability or warranty in connection

with the sale of this Unit.

APi reserves the right to make any changes or improvements in its products without notice and without

obligation, and without being required to make corresponding changes or improvements in Unit theretofore

manufactured or sold.

75 West Plato Boulevard

St. Paul, MN 55107

iii

introduction

The APi 120/320 features the MasterVend Control System and MasterMenu system which provide a user friendly menu

to setup and configure the machine. The simple operation and built in flexibility of this system allows each user to

customize the menu system to their preference. The system can be configured to display service and operational mode

messages in any of six different languages and support up to 110 selections. Robust testing capability as well as

extensive diagnostics and error reporting facilities are built in to provide ease of maintenance.

The APi 320 Series machine is designed to be used as a refrigerated or frozen, pre-packaged food merchandiser.

Changing the machine between refrigerated and frozen is accomplished by choosing between food or frozen on the

LogiCenter (LCB) board. In addition there is a default setting (jumper) on the Food Driver Board (FDB) to ensure that if

the FDB should loose communications with the LCB, the refrigeration unit will maintain the temperature of the default

setting, refrigerated or frozen. All APi 320 series machines are companion machines and are dependent upon a Control

module or 120 series snack merchandiser to control the machine.

The Control module is a cabinet that mounts to the right side of the API 320.The Control module contains a power

supply, LogiCenter board (LCB), selection keypad, coin mech and any other peripherals. The Control module is capable

of supporting up to two machines. When two machines are attached to one Control module, each machine has the

capability of being set up independently as a food or frozen.The APi 120 Series snack machine is capable of supporting

one 320 Series merchandiser.

HOW TO USE THIS MANUAL

This manual is divided into six basic parts:

1. Unpacking and Installation.

2. Components.

3. Quick set up Guide.

4. Advanced set up and Operating system.

5. Parts.

6. Troubleshooting.

◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆

WATCH THROUGHOUT THE MANUAL FOR THIS

SPECIAL ◆DIAMOND MARK.THIS INDICATES A

POINT OF SPECIAL INFORMATION OR A HINT

THAT WILL ASSIST YOU IN SETTING UP,

OPERATING OR TROUBLESHOOTING THE

MACHINE.

◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆◆

CAUTION: Certain procedures in both the operating section and the service

section require that voltage be on in the machine. Only trained personnel should

perform this function. Exercise extreme caution while performing these

procedures. These procedures will be marked with the lightening bolt symbol as

it appears at left.

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

CAUTION: Certain procedures in both the operating section and the service

section requires a qualified trained technician to perform the particular task at

hand.These procedures will be marked with the exclamation symbol as it appears

at left.

iv

STANDARDFEATURES

■Up to 80 selections.

■Multi drop buss capabilities.

■Extensive diagnostics capabilities.

■Friendly text based interface.

■Configuration upload and download capabilities.

■User programmable function keys.

■Flexible spiral spacing for large products.

■Eight point star drive motor.

■Four security levels.

■Six languages.

■Machine reset capability.

■Real time clock.

■Personal computer interface.

■Printer interface.

■Chime.

PRICING

■Global pricing by machine or by shelf.

■Extensive discounting capabilities.

■Shutdown capabilities.

■Combo vends.

■Product codes.

■Programmable spiral count.

■

Upload and download capabilities for pricing and set up.

■Programmable maximum payout.

■Extensive accountability, including all discounts and

free vends.

SCROLLING DISPLAY

■User friendly scrolling display to help with the

selection process and provide customer feedback.

■User programmable point of sale and

■Operational messages.

■20 character display.

OPTIONS

■Point of sale window.

■Delivery bin cushion.

■Base kit.

■Lexan window.

■MasterMenu™ online software.

■Transportable memory unit.

NOISE LEVEL:

Operates at less than 70 dB(A)

ACCEPTABLE AMBIENT OPERATING TEMPERATURE

RANGE

All equipment manufactured by Automatic Products

intl. Ltd. is designed to work properly in a temperature

range of 10˚C to 38˚C (50˚F to 100˚F) in still air (75% R.H.

non-condensing).The machine is being stored in a

temperature range of -18˚C to 68˚C (0˚F to 155˚F).

features of the APi 320 food/frozen merchandiser

Height 72”/ 183 cm 72”/ 183 cm 72” / 183 cm 72” / 183 cm

Width 10.25”/ 26cm 10.25” / 26cm 10.25” / 26cm 10.25” / 26cm

Depth 33.33” / 84 cm 33.33” / 84 cm 33.33”/ 84 cm 33.33”/ 84 cm

Voltage (AC) 120V 230V 120V 230V

Hertz 60Hz 50Hz 60Hz 50Hz

Standby Amperes 0.7A .35A 1.7A .8A

Running Amperes 1A .5A 16A 8A

Watts 120W 1440W 1920W 1840W

Refrigerant Type N/A N/A 404A 404A

Refrigerant Charge N/A N/A 27 oz / 76 Kg 27 oz / 76 Kg

High Side Test Pressure

N/A N/A 440 psi 440 psi

Low Side Test Pressure

N/A N/A 162 psi 162 psi

Shipping Weight 190 lbs / 86 kg 190 lbs / 86 k 800 lbs / 363 kg 800 lbs / 363 kg

SPECIFICATIONS 310

DOMESTIC

310

EXPORT

320

DOMESTIC

320

EXPORT

1.01

unpacking

The APi 320 Series is assembled and packed so that a

minimum amount of time is necessary for preparation to

install it on location. The following steps are

recommended to insure correct unpacking.

1. Shipping Damage: Thoroughly inspect the exterior of

the carton for damage which may have occurred

during shipment. Report any damage to delivering

carrier and follow their instructions.

2. Remove staples from lower edge and those at top of

carton, and slit carton vertically at the taped corner.

Open and remove carton. Remove the remainder of

the packing material. On machines shipped with lock

in place, the keys are taped inside the coin return.

3. Remove Vendor With A Fork Lift Truck:

Remove the carton from the vendor. From the front of

the vendor tip the vendor backward and run forks

under the cabinet.

4. Removing Vendor Without A Fork Lift Truck:

Remove the carton from the vendor. Break off the thin

piece of board behind the rear legs. From the front of

the machine tip the vendor back enough to clear the

lower legs from the holes in the front board. Push

the machine back off the base. Remove the pallet.

NOTE: Because the weight concentration is

toward the back of the cabinet, trucking and lifting

should be done from the back. CAUTION should

be taken when trucking from side .

5. On machines with lock in place, unlock, and turn

handle to open door. When no lock is furnished,

remove tape and turn handle. Swing door to its full

open position.

6. Remove all packing tape and paper from various

areas of machine and the shipping strap.

7. Warranty: The warranty card is attached to the cover

of this manual. It must be filled out in full and mailed

at once to insure coverage.

◆IMPORTANT: A set of anchoring brackets are sent

with each machine. The kit is located in the bottom of

the machine complete with instructions. It is

recommended that this kit be installed to prevent shifting

of the machine.

8. Air Deflector: Remove the air deflector from the

delivery bin. Loosen to four screws holding the screen

on the back of the machine, place the slotted holes in

the air deflector over the screws and push down,

re-tighten the screws.

CLEANING & MAINTENANCE

The 320 Series Merchandiser will do the best

merchandising job for you if it is kept clean.The amount of

cleaning your machine will require will vary from location

to location depending on the environment. We suggest

that a thorough cleaning be preformed at least twice a

year in a clean environment, in addition to this, light

cleaning that should be performed each service. The

display windows can be cleaned with any good glass

cleaner. The exterior and interior surfaces should be

cleaned with warm water and mild detergent (food grade).

Rinse thoroughly and dry all surfaces. Always use a clean

lintless disposable towel for cleaning.Their is an option

in the software to preform a manual defrost (see the

operating system section of this manual for instructions ).

The main product shelves can be best cleaned with the

spirals and product spacers removed. Refer to page 1.03

for removal of spirals and removal of the product spacers.

Clean the acceptor on the changer frequently as

accumulated dirt in this area can cause coins to hang or

not be accepted. Follow recommended cleaning

procedures as described by the manufacturer.

◆It Is extremely important that the air intake screen for

the refrigeration unit is cleaned weekly and that no

product is stored in this machine blocking this screen

or the condenser unit.This screen is located toward the

front and center of the machine floor.

1.02

Leveling the Machine on location is important for the

machine to function properly. The four leveling screws in

the legs are the means of leveling the machine. After

positioning the machine, level machine in front to rear and

right to left directions. After leveling, turn front right (lock

side) leveling screw in about one-half turn to drop this

corner slightly to make the door easier to close and lock.

Voltage and Polarity Check. It is important that this

machine is hooked up to the proper voltage and polarity.

Using a voltmeter, perform the following checks from the

illustration below.

◆NOTE: It is imperative that the machine is on it’s own

20 AMPERE SERVICE. Only the Control module may be

plugged into the same service.

NOTE: Should the readings be different from above,

have a certified electrician correct the problem.

For Health reasons it should be noted that cold

(refrigerated) or frozen vending machines are designed

for short term storage of already refrigerated or frozen

product. The definitions for cold and frozen machines are

as follows:

1. Cold is defined as 41°F (5°C) or lower for cold food.

All food in a Refrigerated machine must have a

product expiration date on the package. See your

product suppler for specifics on date codes and

expiration dates.

2. Slack is defined as a frozen machine set below 15°F

(-9°C) or lower for slacking precooked frozen food.

3. Frozen is defined as 0°F (-18°C) or lower for frozen

food. Items used in a frozen machine should have

frozen designated packaging.

When installing a machine, the machine should be

allowed to pull down to operating temperature before

loading product into the machine, approximately 1 hour

for a cold machine and 2 hours for a frozen machine.

See blue page 3.01 for instructions on setting temperature.

For more information on pull down times and health

control see page 2.03 of the components section of this

manual.

Loading Shelves. Open door to full open position, push

down on the two plastic lock levers on right and left side

panel by shelf to unlock shelf, holding lever down. Grasp

the shelf, under both front corners, lift front shelf slightly

and pull forward until shelf reaches its stop. The shelves

tilt down (do not drop) to make loading easier. Only one

product shelf should be in the loading position at a time.

When returning a shelf, be sure the shelf is in its full home

or vend position. Begin loading

with the top shelf. Move it to the loading position.The

height spacing for items is greatest in this shelf and the

tallest items should be placed there. Soft items, should

be placed in the lowest shelf, making the drop distance

as short as possible.

installation

CAUTION: THIS MACHINE IS DESIGNED

FOR INDOOR USAGE ONLY. ANY OTHER

USAGE MAY VOID THE MANUFACTURERS

WARRANTY.

CAUTION: THE FOLLOWING PROCEDURE

REQUIRES THAT THE MACHINE HAVE

POWER APPLIED AND A POTENTIAL

ELECTRICAL SHOCK HAZARD EXISTS.

1.03

IMPORTANT: Product must not be forced into the spiral

spaces but should fit freely. If the product is too tight, use

a larger pitch spiral. The bottom of the product should be

placed on top of the spiral wire that rests on the shelf

surface.

Vending Large Products

The 320 Series can be configured to use two spirals to

vend one product.The motor to be paired will be called

the left motor, and must be an even numbered motor. Any

even numbered motor may be paired.This motor must

always be paired to the odd numbered motor next in

sequence (i.e. motor “110” will always be paired with

motor “111” and “114” always with “115”). Only motors in

the same row of the machine can be paired. For more

information on Motor pairs see the operating system

section of this manual.

Adjusting the Stopping Position of the Spiral.

One primary difference that distinguishes the new motors

from previous motors is the presence of an eight sided

star at the drive hub of the motor. This permits the

stopping position of the spiral to be customized by the

operator to ensure the best possible delivery of product.

To change the stopping position of the spiral, remove the

spiral lock from the motor by pinching the shaft of the

spiral lock from the back side of the motor and pulling

forward on the front side of the spiral lock.The spiral lock

can be reinstalled in any of eight different positions by

turning the spiral lock to the position desired and pushing

the shaft of the spiral lock through the eight sided star at

the drive hub of the motor.

Removal of Spiral. Grasp the front of the spiral and turn

it clockwise for an even numbered selection and

counterclockwise for an odd numbered selection. Lift the

spiral up and off of the spiral lock. When replacing a spiral

attach it around the tab on the spiral lock and turn the

spiral to lock it in place. Be sure the front end of the spiral

is positioned properly. (see Figure 3). The spiral lock is

attached between the spiral retainer tabs. Give a light

forward pull on front of the spiral to check it is locked in

place.

Product Spacers

A product spacer is used to reduce the width of the

product area and can be used on any shelf . Spacers

should fit within 1/8” of the product but should not fit tight

against the product. There are four positions in each

column where these spacers can be placed. To install the

spacer, lift upward on the front of the spacer, align the lock

ear on the rear of the spacer with the slot on the rear of

the cabinet, push the spacer downward aligning the three

tabs on the lower edge of the spacer with the three sets

of slots on the shelf bottom. Pull the spacer forward to lock

in place.

Lock Product Shelves. After all the product has been

loaded be sure all shelves are returned to their vend

position behind the front roller guides.

Install Proper Price Tabs into price tab holder for each

selection in the main product area.

Quick Set up Guide. See page 3.01

installation

1.04

Control module Installation Instructions.

A. Remove the 3 hole plugs from the top, inside right

corner of the 320 cabinet. Once removed, remove the

foam insulation (pre cut) behind the holes.

B. Locate the front and rear lower support brackets on

the bottom right hand side of the 320 cabinet. (These

brackets have already been installed at the factory.)

There should be a 1/8” space opening between the

cabinet side and the mounting bracket, these

mounting brackets can be adjusted by loosening the

2 outside bolts from each of

the leg weld’s on the lock side of the cabinet.

C. Move the base of the Control module close to the 320

cabinet so the bottom left edge of the Control module

rests on the support bracket.Tip the Control module

to an upright position.

D. Install the upper mounting plate using the 1/4-20 kept

nuts provided. Install three in the refrigerated cabinet

and Three in the control module.

E. Put the insulation and plugs back into the 3 holes in

the refrigerated cabinet.

F. Locate the interconnect harness (communications

cable) coming out of the back of the 320 and route it

into the back of the Control module to the LogiCenter

board and plug into the P8 connector (MDB). When

using a MDB coin mech and/or bill validator these

peripherals must be plugged into the pig tail coming

off of the communications cable. The machine

attached to the Control module is considered Cabinet

1.

G. Level the Control module to the machine by adjusting

the leg levelers.

◆NOTE: Because the Control Module is top heavy

and unstable, always use two people when attaching

the it to the 320.

Using a Second Machine with a Control

module.

If a second machine is to be operated off of

the Control module, it should be placed to the right of the

Control module. The second machine is free standing and

does not physically attach to the Control module. Find the

interconnect harness coming out of the back of the

second machine and route it into the back side of the

Control module to the LogiCenter board and plug the

harness into the jumper coming out of the cabinet 1

interconnect harness. This machine is considered Cabinet

2.

◆NOTE:The second machine being run off of a

Control module MUST have it’s own 20 Ampere

service, It CAN NOT be plugged in on the same

circuit as Cabinet 1.

Connecting a 320 to a 120 Series Snack.

A 320 machine can also be driven of a 120

Series snack in lieu of a Control module. To

do this, locate the interconnect harness coming out of the

back side of the food cabinet and route it into the back

side of the snack (remove the triangular plate just above

the line cord) to the LogiCenter board and plug into the J8

connector.

This machine considered Cabinet 2. Only one 320 can be

operated off of a snack machine. NOTE:The 120 and 320

CAN be plugged into the same 20 Ampere service if

necessary.

installation

WARNING

TOP HEAVY EQUIPMENT

CAN CAUSE

PERSONAL INJURY.

USE 2 PEOPLE WHEN

ATTACHING 310 CONTROL

MODULE TO 320 MACHINE.

ONLY INSTALL THE

310 MODULE TO A

320 FOOD MACHINE.

NOTICE

COMMUNICATION CABLE INLET

COMMUNICATION CABLE FROM THE

320 FOOD MACHINE TO A 120 SERIES

SNACK MACHINE OR

310 CONTROL MODULE.

DISCONNECT CABLE (CONNECTIONS)

BEFORE MOVING MACHINES.

1.05

MasterMenu Online Software

MasterMenu Online software gives you the capability of

completely setting up any 120 Series Snack

merchandiser, 310 Control Module, 320 food

merchandiser, or 223 Hot beverage merchandiser on your

personal computer (PC).MasterMenu Online also has the

ability to load complete new logic board software revisions

to a machine. To load complete new software into a

machine the PC must be connected directly to the

machine logic board via a cable P/N 56800022 and the

DEX/UCS harness P/N 680509 . Software updates can be

sent to you via e-mail or as a file on a floppy disk.

MasterMenu Online Installation

Personal Computer Requirements

To install MasterMenu Online, you need:

■Personal or Multimedia computer with a 486 or

higher processor.

■Microsoft Windows 95 operating system or later.

■16 MB of Ram.

■5 MB of hard disk required.

■VGA or higher resolution video adapter.

■Microsoft Mouse or Compatible pointing device.

■3.5 inch floppy drive

CHIP

Two pieces are required to use CHIP, the touch memory

button (CHIP) and an Upload/download Harness that

allows Chip to communicate with the machine.

Touch Memory Button (Pn 17500003)

The Touch Memory Button (CHIP) can be used to

download to or upload from any 310 Control Module or

APi 20 Series machine. CHIP is capable of storing all

settable data from a machine, with the exception of the

time and date. Once CHIP is programed you can take it to

as many machines as you wish to upload the information

stored in CHIP.CHIP can be overwritten and reused as

many times as desired. CHIP is mounted on a key chain

holder. CHIP can be programed from a machine that is

already set up and then used to set up other machines

that are to be programed identically.

CHIP can also be programed from MasterMenu Online,

MasterMenu Online is a software program that allows you

to set up any 310 Control Module or 20 Series machine

on your personal computer (PC).This information can then

be stored by filename in you PC and is always accessible

for any changes you may want to make the machine in the

future, including pricing. To load CHIP from your PC

requires harness (Pn 17500004), included in this package.

Touch Memory Button (CHIP) and Upload/download

Harness (Pn 16800013)

The CHIP upload/download harness is attached to the

Logic Board (LCB) on J1 (upper right hand corner) and

the other end is mounted on the swing panel in a

depression just above the display, six of these harnesses

included in this package.

Chip Upload and Download Instructions.

1. Open Machine/Tower door, the display should

indicate “Enter for MasterMenu”.

2. Press Enter

3.

Press the > until the display indicates “Configuration”.

4. Press Enter

5. Press the > until the display indicates “Configuration

Load”.

6. Press Enter, the display should read

“MasterMenu Online”.

7. Press the + until the display indicates “Tmu

Upload” ( from Tmu to Lcb) or “Tmu Download”

(From board to Tmu).

8. Press Enter

9. The display will indicate “Awaiting Download” or

“Awaiting Upload”.

10. Press the memory button CHIP against the socket

and the display will indicate “Transfer in Progress”.

When the transfer is complete the display will prompt

“Transfer Complete”. If for any reason the transfer

was unsuccessful the display will prompt “Transfer

Error”.

Note: To Use MasterMenu Online or Chip the Software

on the Logic Board must Be at the Following Revision

or Higher: 3.5 Flash Memory and 3.0 Microprocessor

Echo Package

The Echo package contains the components necessary to

hook a voice synthesizer to any APi 20 series machine.

The voice synthesizer will Echo the display while in

service mode.

Base Kits

Base kits are available to make the vendor compatible

with other manufacturers.

Delivery Bin Cushion

A delivery bin cushion is available for use when vending

heavy items. This cushion is standard in the 320.

Lexan Window

A Lexan window is available as a direct replacement for

the outside tempered glass.

MasterMenu Online Software

MasterMenu Online software provides the means of

remotely configuring the AP 120/320 Series machines.

Conveyer Shelf

The is also a conveyor shelf available for the 320 Series

machine. This shelf is a direct replacement for a standard

shelf. It has a total of 4 columns and can be configured to

hold from 4 to 8 selections per column.

Control module Power Supply

optional equipment

2.01

The 115 VAC power cord from the wall outlet comes into

the machine and plugs into the back of the main junction

box located on the top center of the cabinet. The voltage

output to the board is 24 volts and 8 volts and is plugged

into Logic Center Board.

Lighting System

There are two fluorescent lamps in the APi 320 Series

machines. The lamps are located vertically on the inside

of the door along the edge of the outer glass which light

up the main product area. The starter is located on the

underside of the bottom lamp socket of each lamp. Each

lamp is covered by a plastic shield.

Main Product Shelves:

There are a maximum of five main product shelves per

machine. Each selection has its own motor mounted to

the back of the shelf. Every shelf has its own harness and

plug for connecting to the remainder of the circuit through

the cabinet receptacle, located in the rear right of the

cabinet. You also have the capability to adjust each shelf

1⁄2inch either up or down on any shelf. To do this the shelf

should be removed and the cabinet back harness

receptacle lowered or raised with the right & left shelf

tracks.

Note: When exchanging the shelves, you will not need

any parts but you will have to reprogram the machines for

prices and selections.

Removal of Product Shelf:

A. Lift up and push the lock levers toward the back of

cabinet.

B. Pull the shelf to its loading position.

C. Grasp shelf in front and rear center. Lift front of shelf

up above horizontal and pull shelf forward while lifting.

D. To install shelf, reverse above procedure.

Delivery Bin:

This is located below the display window on the door and

is mechanically operated. The linkage on the outside end

of the delivery bin may require occasional lubrication.

Should the door become difficult to operate, place a small

amount of grease on the arm tracks.

Removal of Delivery Bin:

A. Remove the screws from the sides of the

delivery bin.

These screws fasten into the lower door

brace and remove the two screws and

brackets at the

top of the delivery bin.

B. Grasp delivery bin on both sides and lift upand pull

back. Should the bin be tight, rock it by lifting on one

end, then the other.

Replacement of Delivery Bin:

A. Locate lip on front edge of delivery bin

over lower edge of opening in door and

behind trim. Press down

along lip to make sure it is fully engaged

between door and trim.

B. Install the four screws and two brackets, to secure bin

to door.

Heated Glass

The glass on the inner door is a double pane, heated,

thermal pane. There is a connector on the bottom right

hand side of the glass. The glass receives power for the

heater strip through this connector from the junction box.

DEX/UCS

The APi 310 supports DEX/UCS Communications

Protocol - NAMA Vending Industry Data Retrieval

Standard.The machine will automatically recognize the

DEX/UCS device when it is plugged into the control board

and will recognize when the device initiates the

communication protocol.The transmission/reception of

data to the device will then take place automatically.

Baffle Door

The baffle door is located above the delivery bin and

extends out from the bottom of the main product area.The

purpose of the baffle door is to seal the area between the

refrigerated cabinet and the delivery bin. Each time a

selection is made the baffle door is opened before the

product is delivered and is closed after the product has

been delivered.The baffle door is opened and closed by a

motor mounted toward the back left hand side of the

machine just above the compressor. The baffle door can

be re-opened one time after a vend by pressing the

coin return.

The Chime

The chime will sounded when the following events occur:

•Three times when an invalid key sequence is entered

from either the front panel or the MasterMenu™

Keypad.

• Three times when the customer enters an invalid key

sequence from the front panel.

• Five times when the customer has won a free vend

due to WINNER MODE.

• Five times when the customer attempts to purchase a

sold-out item as determined by spiral selection.

• A single time to indicate the acceptance of an action

by the control system.

Power Interlock Switch

The interlock switch is located on the bottom right corner

of the machine. When the door on the machine is open

the interlock breaks the power (hot and neutral) going into

the refrigerated cabinet control box. Power for the FDB

comes from the LCB via the interconnect harness and

this power is not interrupted by the interlock switch.

components

2.02

DEX/UCS

The APi 120 supports DEX/UCS Communications

Protocol - NAMA Vending Industry Data Retrieval

Standard. The machine will automatically recognize the

DEX/UCS device when it is plugged into the control board

and will recognize when the device initiates the

communication protocol.The transmission/reception of

data to the device will then take place automatically.

Printer Support

The machine is able to print to a 40 character wide printer

connected to the serial port.The communication is as

specified by the user in the Printer Setup Menu .The

machine uses only standard printer control codes to

maximize the number of possible supported printers. The

machine is able to print any of the following types of

information set by a menu item in the MIS Menu heading:

• MIS Data

• Machine Setup/Configuration Parameters

• Diagnostic Information

When an attempt is made to output data to the printer

without a printer connected, an error message will be

displayed indicating that the printer is not connected.

components

The 20 Series Machines Support the 24V Micromech, executive, and MDB protocols for Coin Mechs,

Validators and Card Readers.

NOTE: DO NOT ATTEMPT TO OPERATE TWO DIFFERENT PERIPHERALS

SIMULTANEOUSLY. FOR EXAPMLE: MDB WITH PULSE OR MICROMECH.

Peripherals in Column 1 and 2 can work together and columns 4 and 5 can

work together.

Micro Mech Pulse Validator Executive MDB Coin Mechanism MDB Bill

24V 15 pin 24V Validator

Mars TRC-6010XV VN2502-U5E 540 TRC-6510 VN2502-U5M

VN4010XV VN2512-U5E 560 TRC-6512 VN2512-U5M

VFM1-L2-U4C VN-4510

VFM3-L2-U4C

CoinCo 9302 LF BA32SA 9302-GX BA32SA**

USD-L701 BA32R USQ-G701 BA32R

USQ-L701 USO-G703

USQ-L701

Conlux USLX-001-01F USLZ-004-01F USLZ-004-01F

CCM 5 G

The APi 20 Series will automaticaly determine at power up which peripherals are connected and configure itself

accordingly.

2.03

components

Temperature Monitoring

To display the temperature of all food and/or frozen

cabinets in an installation depress and hold the “C” (for

temperatures to be displayed in Celsius) or “0” (for

temperatures to be displayed in Fahrenheit) button on the

front panel keypad. After three seconds, the temperatures

(in all refrigerated and frozen cabinets present in the

installation) will display for three (3) seconds and continue

to do so until the button is released.

The Refrigeration System

The refrigeration system is comprised of a 3/4 horse

compressor and is a hermetically sealed system (no

service ports).The refrigerant used in the refrigeration

system is 404a and the charge is 28 ounces. The

Compressor is turned on and off by a relay contained in

the refrigerated cabinet junction box.This relay is

energized by the Food Driver Board (FDB).The

temperature sensor is plugged into the P2 connection of

the FDB. The entire refrigeration assembly comes out in

one piece by removing the two screws (to the right of

the condenser) fastening the refrigeration assembly to the

cabinet bottom.

◆CAUTION: Because of the weight of the refrigeration

assembly it should be removed by two people.

Refrigeration Control

The refrigeration system in the APi 320 cabinets is

controlled by the Electronic control system (ECS)

according to the temperature range selected by the

operator in the MasterMenu system.The temperature

readings from the temperature sensor is accurate to 1ß F.

The temperature sensor data is monitored and the

readings averaged over time. The cabinet temperature is

checked once every 5 seconds. Using the Set

Temperatures menu item, the cabinets may be designated

as Ambient, Food, or Frozen.When a cabinet is

designated as Ambient, the Control System will not control

the temperature in that cabinet and the refrigeration

system in that cabinet will be disabled if it exists.

Temperature readings will still be available for cabinets

designated as Ambient.When a cabinet is designated as

Food or Frozen, the Control System will attempt to

maintain the temperature in the cabinet to within 3° F of

target temperatures specified in the Set Temperatures

menu item during normal operation (this is fixed at 36°F

(2°C) for Food and is settable from -15°F to +10°F (-26°C

to -12°C) for Frozen). To accomplish this, the refrigeration

unit will be turned on when the temperature exceeds the

appropriate target temperature by more than 3°F for 3

seconds during normal operation.The refrigeration unit

will then remain on until the temperature falls 3° below the

target temperature for 3 seconds.

Health Monitoring

The APi 120 and/or Control module allow for accurate

monitoring of all refrigerated and/or frozen cabinets in the

installation.This also allows for shutdown of each cabinet

individually by the machine without impact to the others.

When the machine shuts down a cabinet due to an out of

tolerance temperature, the light in that cabinet is turned

off, all selections in that cabinet disabled, and the display

updated to indicate “CABINET X OUT OF SERVICE”

(where “X” is “1” if the temperature sensor in Cabinet 1

detected the out of tolerance condition, or “2” if the

temperature sensor in Cabinet 2 detected the out of

tolerance condition). A temperature sensor is present in

each refrigerated and/or frozen cabinet.The Pull down

period describes the time elapsed between a cabinet

Power Up (Door Closed) and the point in time when the

cabinet temperature first reaches the target temperature.

Health processing is suspended during the Pull down

period. If the Pull down time period exceeds 75 minutes in

a Frozen cabinet or 30 minutes in a Food cabinet

however, vending will also be disabled in that cabinet for

health reasons. Vending will be allowed again after the

door to that cabinet has been opened and closed.The Pull

down period does not apply to the Ambient cabinets. If at

any time during normal operation after an initial Pull down

period, the temperature in a Frozen cabinet rises above

the set target temperature by 10° F for more than 15

continuous minutes of temperature readings, vending will

be prohibited in that cabinet. If at any time during normal

operation after the initial Power Up Pull down period, the

temperature in a Food cabinet rises above +45° F for

more than 5 continuous minutes of temperature readings,

vending will be prohibited in that cabinet.The cabinet

temperature control processing will remain unaffected by

this vending state. An error message will be recorded

indicating the Health Time-out occurred. Vending will be

allowed again after the door to that cabinet has been

opened and closed.

2.04

components

Defrost Processing

The refrigeration units in the 320 cabinets are defrosted

by the refrigeration control system at regularly scheduled

intervals based on the Defrost Interval, starting from the

Defrost Time selected in MasterMenu™ . A defrost cycle

will begin with the compressor and condenser fan turned

off and the defrost heater on.The heater will remain on

until the Defrost Thermal switch indicates that the

temperature of the air around the refrigeration coils has

reached the desired temperature. The compressor will

then be turned on two minutes later. Normal refrigeration

processing then resumes. A Defrost cycle will also occur

75 minutes after the door is closed in a Frozen cabinet or

45 minutes after the door is closed in a Food cabinet. If

the cabinet is a Food cabinet and the compressor has not

yet reached Pull down, the Defrost cycle will be delayed

until it reaches Pull down. Another Defrost Cycle will occur

either 6 or 8 hours later where 6 or 8 is the number of

hours specified in the Defrost Interval field of the Setup

Defrost Menu Item in MasterMenu™ . If a scheduled

defrost is to occur before 4 hours after the Power Up

defrost is complete, it will be delayed until 4 hours after

the Power Up defrost is complete. All subsequent

scheduled defrosts will occur at their normal times.

Manual Forced Defrost

Enter Master Menu, Configuration Menu, Setup Defrost menu item for specific cabinet, Press F2, compressor will turn off

and a defrost cycle will begin following the sequence above.

Normal Temperature Operation:

With temperature set at -15°F, the following three conditions indicate a correctly operating refrigeration unit:

1) Unit should reach that temperature within 1 hour.

2) After reaching that temperature, Compressor On cycle should not exceed 35 minutes.

3) During a defrost cycle, cabinet temperature should not rise above 0°F.

Current Readings: 120V Operation 230V Operation

Stand-by 1.5A ± .5A .75A ± .5A

Compressor On 12A ± 1A 7A ± .5A

Defrost Cycle 7A ± .5A 2.5A ± .5A

Defrost Heater

Resistance 23 ohms ± 3 85 ohms ± 6

30

45˚

8-12

2.05

components

Vend Motors

The vend motors used in the APi 320 machines have been specifically developed to operate with the APi MasterVend™

Control System and are different physically from previous motors. The motors are color coded, but one primary

difference that distinguishes the new motors from previous motors is the presence of an eight sided star at the drive hub

of the motor. This permits the stopping position of the spiral to be customized by the operator to ensure the best possible

delivery of product.The combinations of different colors on the motors and their hubs will help identify its function (see

figure 2.1).

Some of the motors used in the 120 & 320 will be of the fast trac style, with all electronics required to correctly operate

the motor contained inside the gear case or the motor housing and no external control board. Each of the motors used

with the MasterVend™ Control System will have two terminals. The two terminals continue to be used to identify the

shelf and column (selection) to be vended. In a cabinet that contains a Food Driver Board, their are left hand and right

hand motors, this permits odd and even motors to be paired and operate in counter rotating (similar to the current dual

spiral motor) and creates a very flexible means to vend items of many shapes and sizes. This is accomplished by

removing any motors between the two motors required to vend the properly and pairing the odd and even in the motor

pairs menu items.

Cabinet and Shelf Harnesses

The shelf and cabinet harnesses connectors are different than the snack motors, they have been changed to insure a

better connection.This change in addition to using a lower temperature grease in the motors, was made to insure the

motors would operate in colder temperatures.

360276

360275

2.06

components

SHELF WIRING DIAGRAM

Each motor requires two wires to operate correctly. These wires are: shelf common, and selection.

Each selection on a shelf has the same common shelf wire - all shelf harness use the wire #12 as a shelf common.This

corresponds to the selected shelf wire in the cabinet harness. The terminal for the shelf common in the harness is the

smallest of the two terminals.

Selection numbers are assigned from left to right, starting with selection 0. Each selection number corresponds to the

number of the wire for that selection.

Selection Wire Number

Shelf Common Number

8 Point Star Drive

Selection Number 0

through 9

Shelf Common

2.07

components

Selection System

The selection system used with the MasterVend™ Control System is different from all previous alpha-numeric systems

we have manufactured.The eleven digit selection panel (see figure 2.2) is located on the front control bezel and consists

of the numbers 0 through 9 and the letter C, which is defined as a clear button.The selection system used with the

MasterVend™ Control System is all numeric and uses three digits to identify all the selections. The first digit is used to

determine which cabinet is selected, the second digit determines the shelf selected, and the third digit, the selection on

that shelf. The left or first selection on each shelf is designated as selection 0, and on a ten select shelf the selection

numbers would be increase by one, so that the right hand selection will be selection 9.The numeric keys on the selector

panel can be used to enter numeric data any time it is required during setup or maintenance of the equipment.

Figure 2.2

2.08

components

MasterMenu™ Keypad

The MasterMenu™ keypad (pictured below) is located on the front of swing out panel directly below the selection

keypad. The MasterMenu™ keypad is only active when the door is open, so even in the event of vandalism to the

control bezel, no access to the control functions is permitted.The MasterMenu™ keypad consists of seven function

buttons, a *key, four coin payout buttons and the eight keys used to operate the MasterMenu™ functions. The entire

keypad becomes active once the machine door is opened.

Function Buttons

The seven function keys (F1-F7) are assigned to specific pre-determined menu headings, primarily for route service

personnel. See page 4.02 for specific menu heading for each of the function keys.

Pressing the *key before one of the function keys ¡through ¶are assigned to the second level of menu headings.

Coin Payout Buttons

The four coin payout buttons are used to pay coins out of an L+ or a standard US (dummy mech).The four coin payout

buttons are , , and .The four coin payout buttons may also be used to enter pricing

information while assigning prices. For example, to enter a price of $.65, pressing the key twice, the key

once and the key once, would result in .65 appearing on the display. See the price setting section for additional

information.

The skey is used for exiting the current menu without making any changes prior to commitment. Note: Closing the

main cabinet door will have the same effect as if the user pressed the skey and causes the machine to exit the

MasterMenu™ System and return to Operational Mode.

The ekey provides a dual purpose operation. It provides the a mechanism for entering a menu. It also provides a

means to commit insertions/modifications/deletions made in a menu item.

The +and -keys are used for incrementing and decrementing the available choices in a menu.

Note: Anywhere in this manual that the +or -keys are defined to sequence through numeric data, the front

panel may be used as an alternate input source.

The <and >keys have a dual purpose operation.They provide a means to select the menu heading immediately to

the left or right of the current menu heading.When inserting data within a menu , these keys also provide a means to

move the cursor from its current position to the position directly to its left or right.

The ykey is used to delete the character on the current cursor position, shifting all subsequent characters to the right

of that position left by one.

The fkey provides a mechanism to insert a character to the left of the current cursor position, shifting all characters

to the right of that position (including the current character) right by one.

Note: Depressing a function key will not cause you to enter the MasterMenu™ System.

F1

F3

F5

F7

F2

F4

F6

*

.05

.10

.25

1.00

ESC

INS

DEL

-+

ENTER

2.09

components

Control System and Boards

The MasterVend™ Control System consists of up to three different boards, depending on the configuration. All Model

120 and all Control modules consist of the LogicCenter board (LCB) and the display board. All 320 machines also

contain a Food Driver Board (FDB).

LogiCenter Board (LCB)

The LCB interfaces with the FDB (when used), display board, selector panel, MasterMenu keypad, coin mechs, bill

validators and all other peripherals. The LCB also stores all the programing and Mis information.In addition the LCB

supplies power to the FDB. (ESD sensitive)

Food Driver Board (FDB)

This board contains all the temperature monitoring functions for cabinet that it is contained in, and communicates with

the LCB via a 6 wire computer level interconnect harness. The FDB has three LEDs on it and the status of the FDB can

be determined by observing these LEDs. The three LEDs will give you the status of the communications between the

FDB and LCB, if the board is currently telling the refrigeration unit to run, and if the board is currently telling the machine

to go through a defrost cycle. (ESD sensitive)

The Food Driver Board is located on the front face of the Relay Box for the compressor assembly. This board controls the

function of all the refrigeration components along with providing the circuits for the vend motors and the baffle delivery

door. There are also two jumpers for default settings of this board.These jumpers are a set of three pins which will have

only two pins connected at any one time. The connection between the two pins is made by a small black cap, which

slides over the pins in use. The black caps are identical, and should not be removed from the board for any reason.The

two jumpers are the Cabinet selection jumper and the temperature control jumper.

Cabinet Selection Jumper

The position of this jumper identifies which cabinet is named CAB1 (Cabinet 1), or CAB2 (Cabinet 2).These are

abbreviated on the FDB board cover decal (pictured below) as C1 and C2 Cabinet 1 will contain the selections 110

through 157, and Cabinet 2 will contain the selections 210 through 257.All machines are shipped with this jumper

installed on CAB1.This jumper should be changed only if you are connecting a second cabinet to a 310 Control

Module or a 120 Snack.

Temperature Control Jumper

The second jumper on the board controls the default setting for the temperature in the event the FDB looses

communication with the LCB. This will hold the cabinet temperature at the setting indicated by the jumper. A jumper

set at “R”will hold the temperature at 36°F (2°C), and a jumper set at “F” will hold the temperature at -15°F (-26°C). If

you change the temperature in the SET TEMPS menu item, you must also change the position of the jumper to the

corresponding position.The position of this jumper can be verified through the hole in the board cover.

The Front Panel Display

The display is capable of displaying 20 alpha-numeric characters. The supported character set includes:

• Upper case alphabetic characters “A” through “Z”

• Numeric characters “0” through “9”

• Special characters: (, ), [, ], ., ‘, -, =, $, /, \, *, ^, +, , ,”, ?, _.

This manual suits for next models

1

Table of contents