AutomationDirect DL305 User manual

Errata Sheet

Page 1 of 1

Product Family:DL305

Manual Number D3-DCU-M

Revision and Date 1st Edition, Rev. A; June, 1998

Date: April 2018

This Errata Sheet contains corrections or changes

made after the publication of this manual.

Errata Sheet

Change to Page 15. Address Switch

The second sentence in the Address Switch section is incorrect. There is no BCD (Binary Coded Decimal) involved with the

addressing.

Instead of “The decimal address is set in BCD (Binary Coded Decimal) format with valid addresses from 1 to 90 decimal.” the

sentence should be:

“The decimal address is set from 1 to 90 decimal.”

Change to Page 19. Troubleshooting

For the “DIAG off” entry in the troubleshooting table, the cause listed is “DCU is defective”. Two other possible causes are a

defective CPU module or base.

111

Introduction

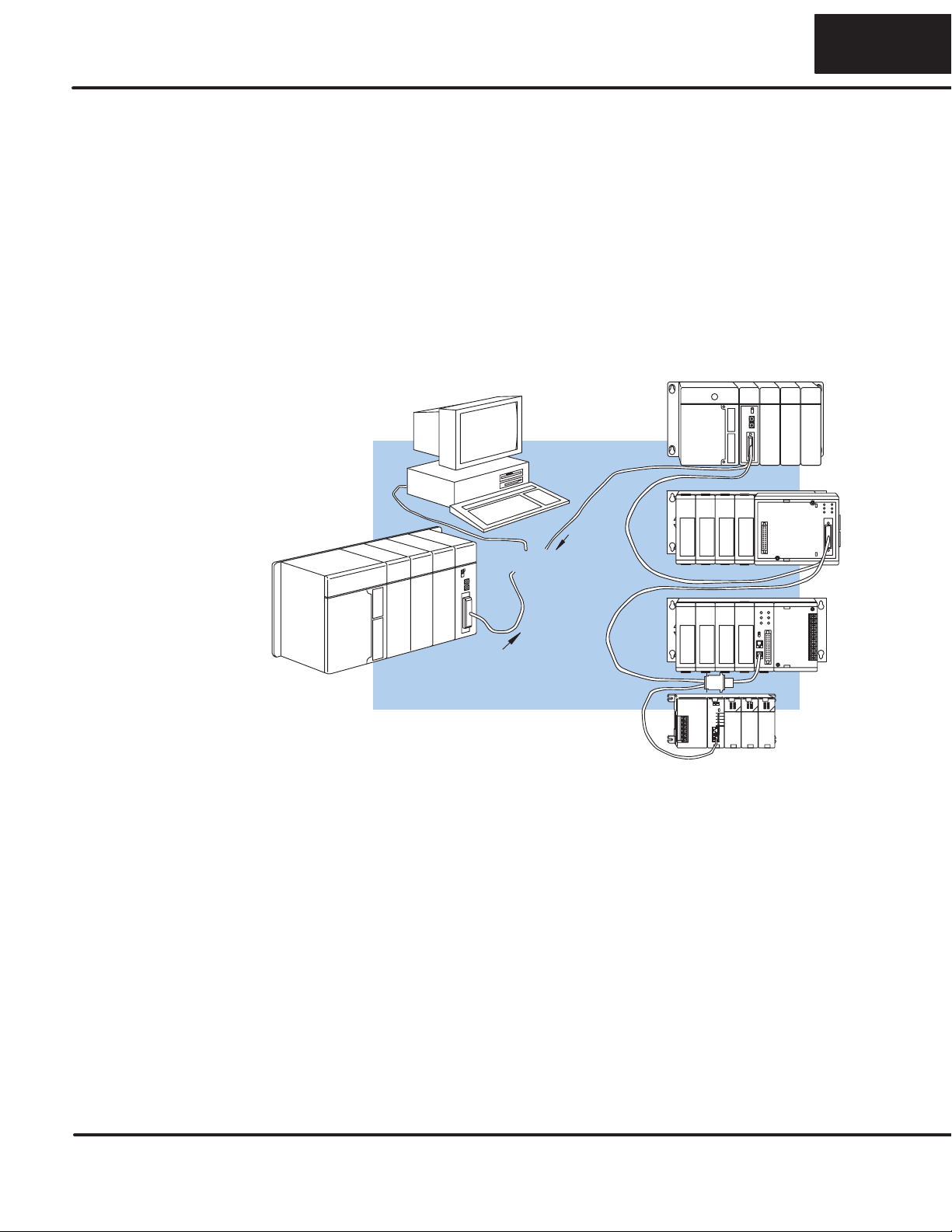

This manual is designed to allow you to quickly install your DL305 Data

Communications Unit (DCU). This is the only manual you will need if your are using

the DCU as an interface for the

Direct

SOFT programming package or, as a

communications port for an operator interface. If you plan on using the DCU as a

slave interface on a

Direct

NET network, you should read the

Direct

NET manual

first. The

Direct

NET manual provides detailed descriptions of the network

configuration and protocol that is necessary to control communications with the

DCUs.

The following diagram shows the major DCU components. The address selection

switches and the communication dipswitches are of special importance. Also, there

are two versions of the DCU RS232C and RS422. You can use RS232C/RS422

converters with these units, but it is generally easier to use the version that is best

suited for your application.

Online/Offline Switch

RS232C/RS422

Communication Port

DIP Switches for communications

and Protocol Parameters

Handheld Programmer

Connector

RUN

BATT

CPU

DATA

DIAG

PWR

On when PLC is in

Run Mode

On when PLC battery

needs replacing

On when a fatel error

has occured in the CPU.

On (flashing) when data is

being transmitted

On when internal diagnostic tests

have complete and passed.

On when base power is on. If an external

power supply is used, both base power

and the external supply must be provided

for this indicator to be on.

TheDL305 DataCommunications Unit(DCU) isa communicationsinterface forthe

DL305 family of Programmable Logic Controllers (PLCs). This module is primarily

used for two reasons.

SAs a general purpose communications port to connect a personal

computer or operator interface.

SAs a network interface to a

Direct

NET network.

The following pages provide an overview of these uses, along with the information

you need to connect the DCU.

Is this the right

manual for you?

DCU Hardware

Overview

DCU Uses

2

How can I use the DCU?

As a communication port, you can connect various devices, such as operator

interfaces or personal computers.

Since the DCU does not require any programming, you can simply set the DCU

communication parameters, connect the appropriate RS232C or RS422 cables,

and start programming or transferring data.

DL305 with DCU

As a General

Purpose

Communication

Port

333

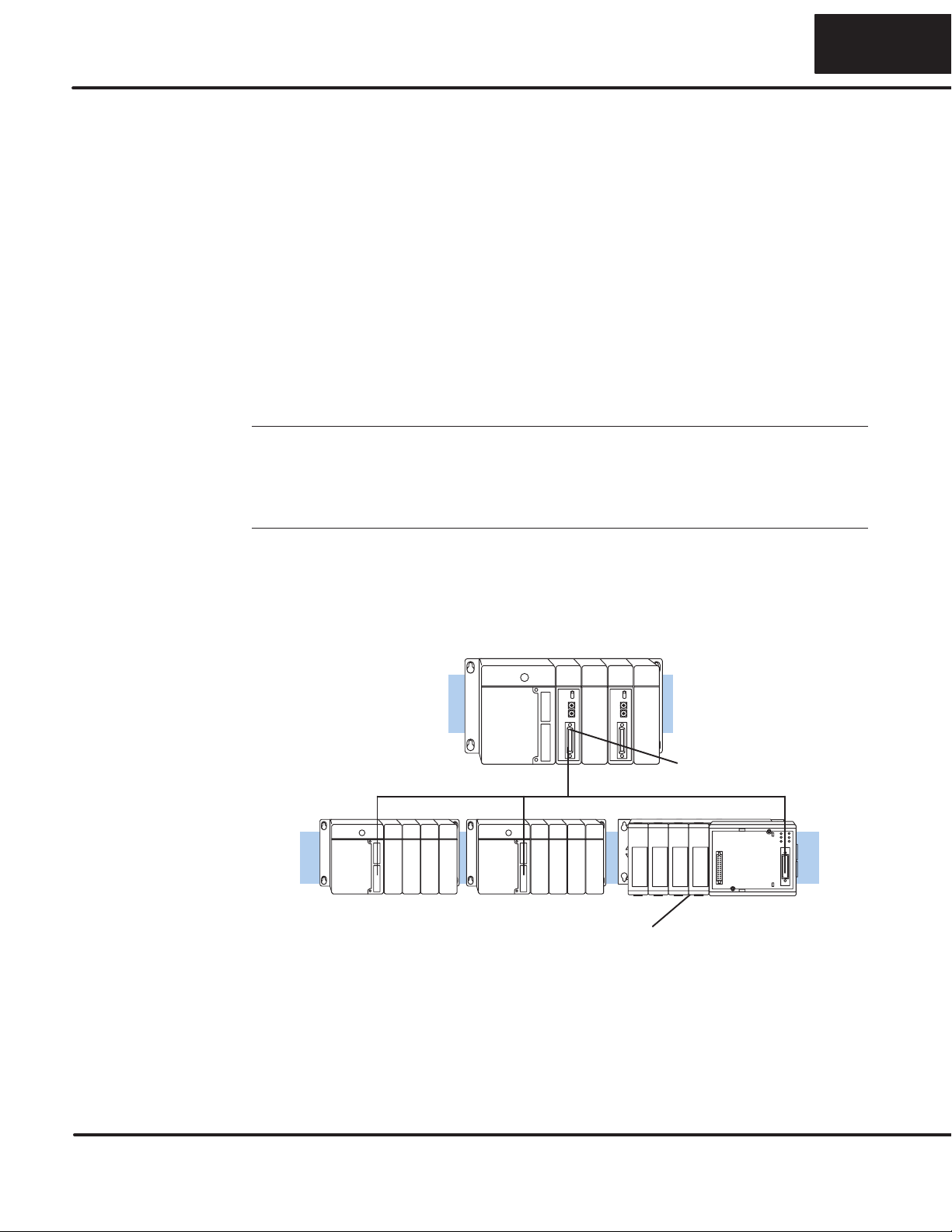

The DCU can be used as a network interface for applications that require data to be

shared between PLCs, or between PLCs and an intelligent device (such as a host

computer). The DCU easily connects to

Direct

NET. This network allows you to

upload or download virtually any type of system data including Timer/Counter data,

I/O information, and Register memory information.

As part of a PLC Network Slave — The DCU can only be used in a DL305 PLC

stationthatisservingasanetworkslavestation.Inthiscase,theDCU“listens”tothe

network for any messages that contain the DCU’s address. The DCU deciphers the

network commands, carries out the request to read or write data, and sends

confirmation and/or information to the master station.

Request

Direct

NET Slaves

Slaves respond to

the master’s request

Response

or

Direct

NET Masters

As a

Direct

NET

Interface

4

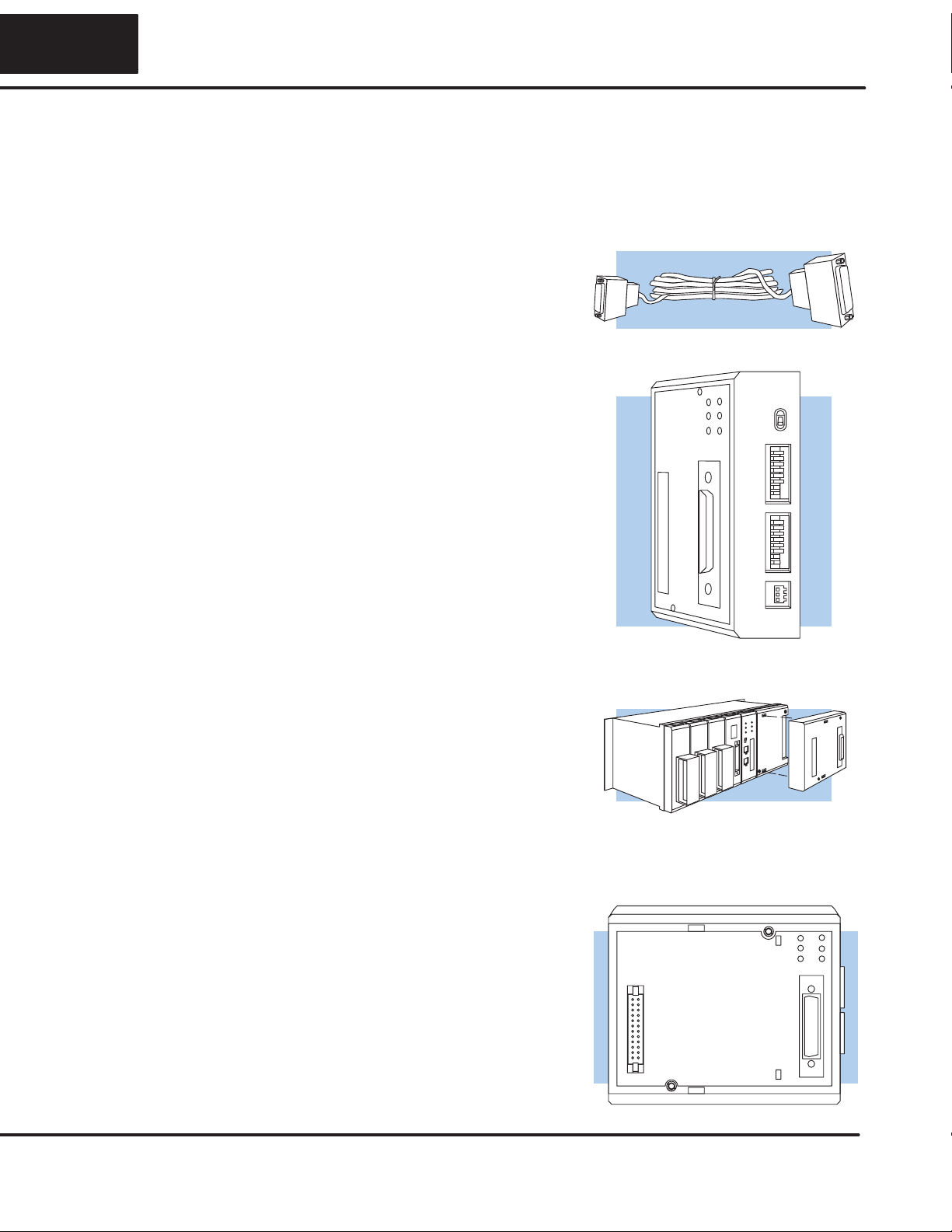

How can I connect the DCU? – Four Simple Steps

Complete the following steps to connect

the DCU.

STEP 1. Build the communication cable

that fits your needs.

STEP 2. Set the DCU switches. (Baud

rate, parity, etc.)

STEP 3. Install the DCU.

STEP 4. Verify correct operation.

Cable

Set the Switches

Install the DCU

Check the LEDs

555

Step 1: Build the communication cable

There are several considerations that help determine the type of cable needed for

your DCU application.

1. Will the DCU be physically connected in a point-to-point configuration or

multi-drop configuration?

2. What electrical specification is best for your application? RS232C or

RS422?

3. What is the cable schematic?

4. What are the relevant cable specifications?

5. What installation guidelines are necessary?

6. Do you just need a quick test cable?

The next few pages discuss these considerations in detail. If you already know the

type of cable that is needed, the cable schematics are included on pages 8 and 9.

Things to Consider

6

Depending on the version of DCU you have, you can use the DCU in either a

point-to-point or multi-drop configuration. A point-to-point connection only has two

stations, a master and a slave. Use the point-to-point configuration to connect a

personal computer, an operator interface, or an intelligent device to a single DCU.

You should also use this configuration when you want to connect a

Direct

NET

master station to a single

Direct

NET slave station.

Use the multi-drop configuration to connect one master to two or more slaves.

Point to Point

DL405 Master DL305 PLC Slave

DCM

DL305 with DCU

DCU

Consideration 1:

Physical

Configuration

777

ThereisaspecificmodelofDCUforbothRS232CandRS422communication.Your

application and configuration choice will help determine which electrical

specificationisbestforyou.Ifyouareusingmulti-drop,youshoulduseRS422.(You

can use RS232C/RS422 converters if necessary.) If you are using point-to-point,

you may have a choice between RS232C and RS422.

YoucanuseRS232Cifthecablelengthislessthan50feetandifthecablewillnotbe

subjected to induced electrical noise that is commonly found near welders, large

motors, or other devices that create large magnetic fields.

You should use RS422 for all other applications. RS422 allows longer cable

distances (up to 3300 feet) and provides higher noise immunity.

Direct

NET Slaves

Direct

NET

Masters

DCM

Multi-drop

or

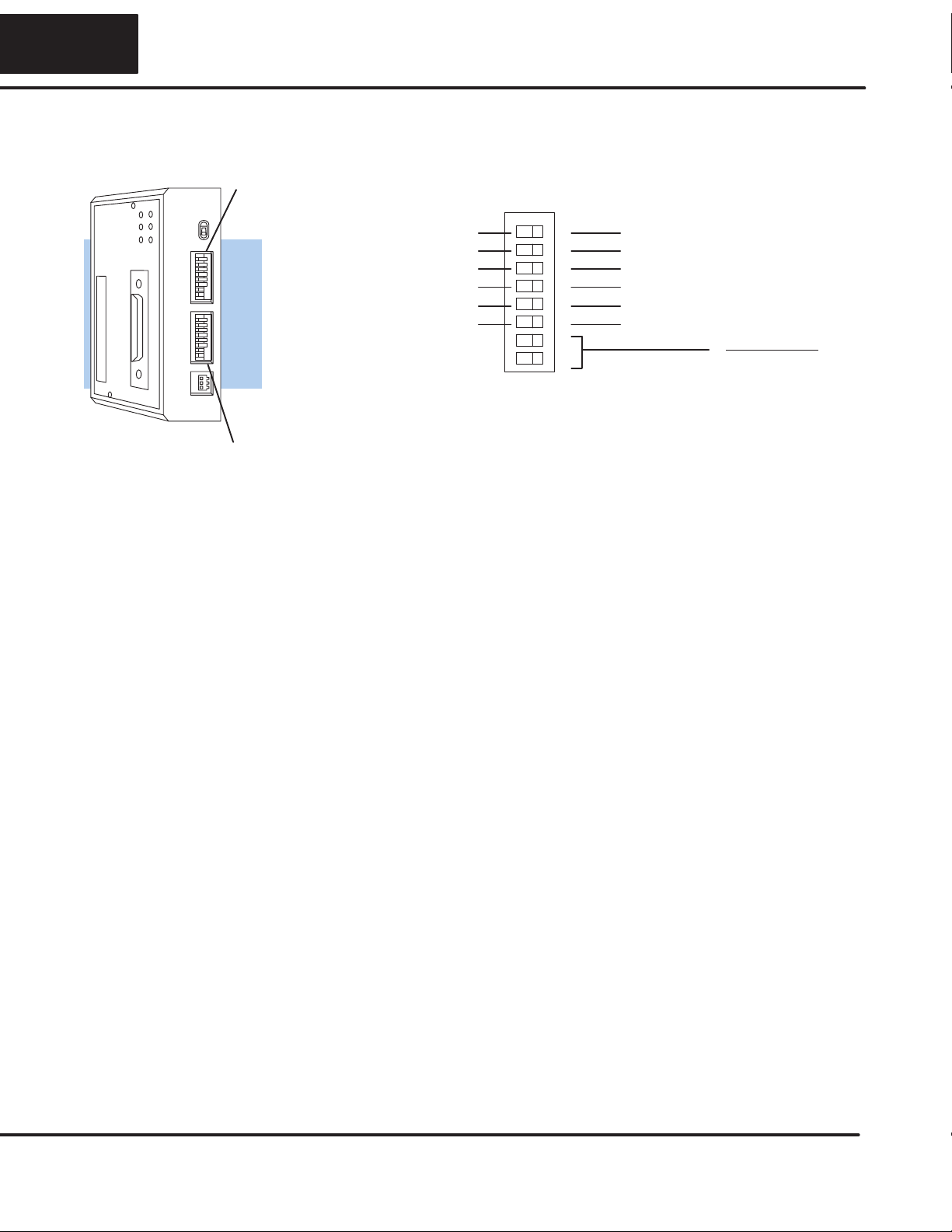

The following diagram shows the port pinouts for the two types of DCUs.

Pin Signal Definition

1 Not connected

2 Not connected

3 Not connected

4 Not connected

5 Not connected

6 Not connected

7 Logic ground 0V

8 Not connected

9 Not connected

10 RS422 RTS +

11 RS422 RTS –

12 RS422 CTS +

13 RS422 CTS –

Pin Signal Definition

14 RS422dataout+

15 RS422data out –

16 RS422 data in –

17 RS422 data in +

18 Not connected

19 Not connected

20 Not connected

21 Not connected

22 RS422data out+

23 RS422data out –

24 RS422data in –

25 RS422 data in +

Pin Signal Definition

1 Not connected

2 RS232C TXD

3 RS232C RXD

4 RS232C RTS

5 RS232C CTS

6 Not connected

7 Logic ground 0v

8 Not connected

9 Not connected

10 Not connected

11 Not connected

12 Not connected

13 Not connected

Pin Signal Definition

14 Not connected

15 Not connected

16 Not connected

17 Not connected

18 Not connected

19 Not connected

20 Not connected

21 Not connected

22 Not connected

23 Not connected

24 Not connected

25 Not connected

D3–232–DCU Port Pinouts

114

D3–422–DCU Port Pinouts

Consideration 2:

Electrical

Specification

RS232C or RS422

8

Thefollowingcableschematicsareappropriateformostapplications.Youmayhave

to combine some of these examples to design a cable that meets your exact

application requirements.

DL305 DCU

DL405 DCM

DL405 DCM to DCU (RS422)

DL405 DCM

2 TXD

3

4

5

RXD

RTS

CTS

3 RXD

2

4

5

TXD

RTS

CTS

AB

AB

7 GND 7 GND

2 TXD

3

5

1

4

RXD

GND

DCD

DTR

2 TXD

3

7

4

5

RXD

GND

RTS

CTS

6 DSR

7RTS

8 CTS

7 GND

10

11

12

13

+RTS

–RTS

+CTS

–CTS

7 GND

10

11

12

13

+RTS

–RTS

+CTS

–CTS

14 +OUT

15 –OUT 17 +IN

16 –IN

16 –IN 15 –OUT

17 +IN 14 +OUT

Personal Computer to DCU (RS232C)

DL405 DCM to DCU (RS232C)

AB

AB

DL305 DCU

DL305 DCU

Master

DL305

DCU

Slave

DL405

DCM

AB

Master

DL305

DCU

Slave

PC

AB

Master

DL305

DCU

Slave

DL405

DCM

3 RXD

2

7

4

5

TXD

GND

RTS

CTS

2 TXD

3

7

4

5

RXD

GND

RTS

CTS

6 DCD

8 DTR

20 DSR

AB

Master

DL305

DCU

Slave

PC

9–pin

Connector

25–pin

Connector

Consideration 3:

Cable Schematics

999

DL405

CPU Port

DL405

CPU Port

DL405

CPU Port

Multi-drop, DL405 DCM to DL305DCU and

DL405PLC Slaves (RS422)

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

7 GND

19

18

11

23

14

16

10

9

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

A

BCD

Master Slave Slave Slave

ABCD

Termination Resistors*

2 TXD

3

5

1

4

RXD

GND

DCD

DTR

3 RXD

2

7

20

25

TXD

GND

DTR

+5V

6 DSR

7RTS

8 CTS

7 GND

10

11

12

13

14

15

16

17

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

A

B

Termination Resistor*

RS422 Multi-drop requires termination resistors (see installation)

Multi-drop, PC to DL305DCU and DL405PLC

Slaves (RS422)

Termination Resistor*

DL405

DCM DL305

DCU DL305

DCU DL405

CPU Port

DL305

DCU DL305

DCU

DL405

DCM

Master Slave Slave Slave

ACDE

PC

DL305

DCU DL305

DCU

FA–UNICON Convertor

B

CDE

DL305

DCU DL305

DCU

7 GND

19

18

11

23

14

16

10

9

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

10

Although many types of cables may work for your application, we recommend you

use a cable that is constructed to offer a high degree of noise immunity. A cable

constructed equivalent to Belden 9855 should be sufficient. The following

specifications should be used as a guideline.

Structure Shielded, twisted-pair. . . . . . . . . . . . . . . . . . . . . . . (RS232C only uses two wires and a ground)

Conductor size 24 AWG or larger. . . . . . . . . . . . . . . . . .

Insulation Polyethylene. . . . . . . . . . . . . . . . . . . . . . .

Shield Copper braid or aluminum foil. . . . . . . . . . . . . . . . . . . . . . . . . .

Impedance 100W@ 1MHz. . . . . . . . . . . . . . . . . . . . . .

Capacitance 60pf / meter or less. . . . . . . . . . . . . . . . . . . .

Your company may have guidelines for cable installation. If so, you should check

those before you begin the installation. Here are some general things to consider.

SDon’t run cable next to larger motors, high current switches, or

transformers. This may cause noise problems.

SRoute the cable through an approved cable housing to minimize the risk

of accidental cable damage. Check local and national codes to choose

the correct method for your application.

SConsider redundant cabling if the application data is critical. This allows

you to quickly reconnect all stations while the primary cable is being

repaired.

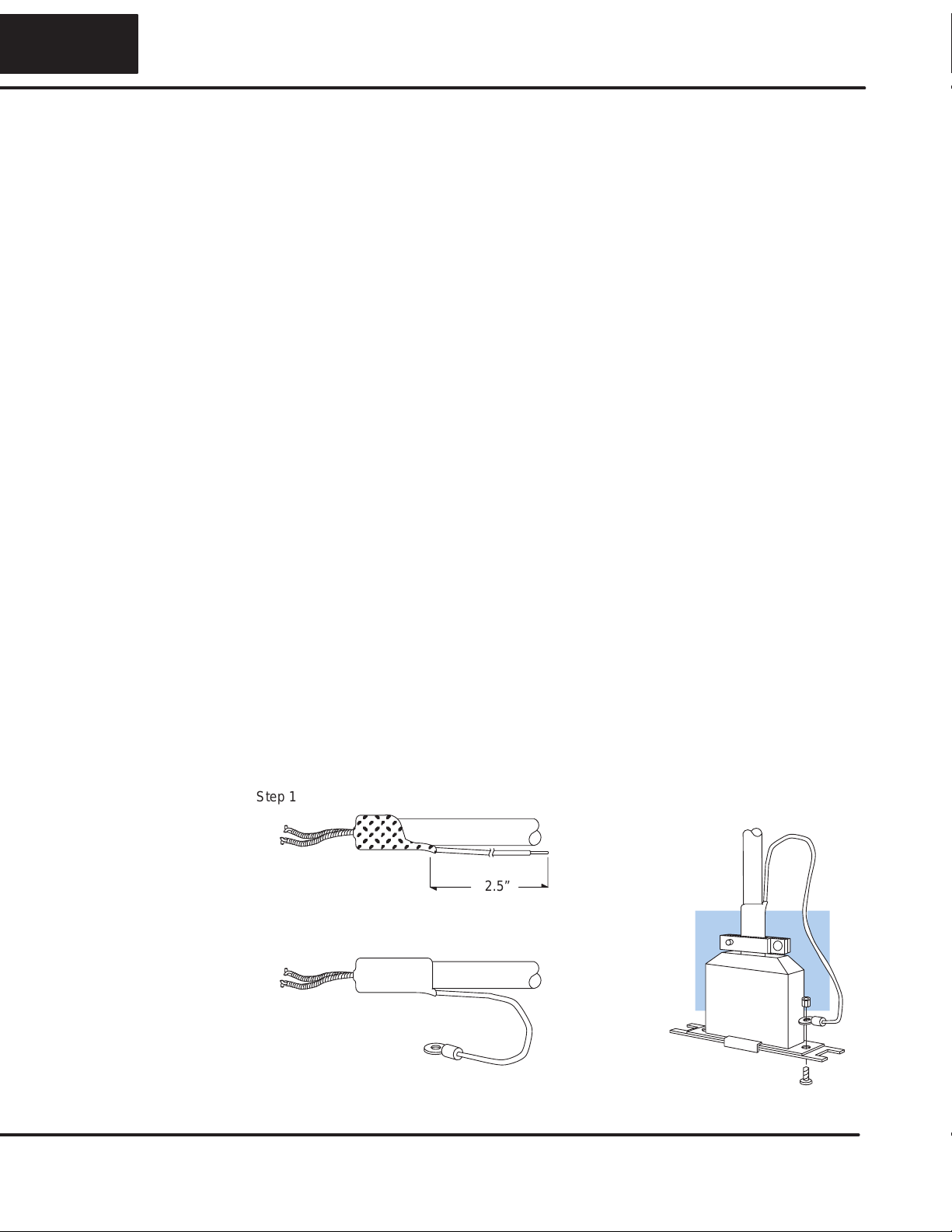

Cable Shield Grounding — It is important to ground the cable shield to minimize

the possibility of noise. The preferred method is to connect one end (preferably the

receiver end) of the cableshield to the connector housing.If noise problems arestill

present and you have a good earth ground for the cabinet, you should connect one

end of the shield to the cabinet earth ground.

Don’t

ground both ends of the shield

because this will create induced noise on the cable.

ÎÎÎÎÎ

ÎÎÎÎÎ

2.5”

Step 1: Strip back about 2.5” of the shield.

Step 2: Crimp a ring connector onto the shield.

Step 3: Secure the shield to the

connector shell.

Consideration 4:

Cable

Specifications

Consideration 5:

Installation

Guidelines

11 1111

Multi-drop Termination Resistors — It is important you add termination resistors

at each end of the RS422 line. This helps reduce data errors during data

transmission. You should select resistors that match the cable impedance. For

example,atypical22AWGsolidconductorcablewith4.5twistsperfoothasatypical

impedance of about 120W.

There are two ways to actually connect the resistors.

SLine-to-Line — this method balances the receive data lines (IN+ and

IN–) and requires one resistor at each end of the line. (The cable

diagrams we’ve provided show this method, but you can use either.)

SLine-to-Ground — this method also balances the receive data lines, but

common mode noise rejection is improved significantly. This method

requires two resistors at each end of the line. Also, since there are two

resistors, the sum total of both resistors should match the cable

impedance.

The following diagram illustrates the two options.

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

7 GND

19

18

11

23

14

16

10

9

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

Master

120 ohm

Resistor

Last Slave

120 ohm

Resistor

Slave

Line-to-Line Termination

7 GND

10

11

12

13

14

15

16

17

22

23

24

25

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

+OUT

–OUT

–IN

+IN

7 GND

19

18

11

23

14

16

10

9

+RTS

–RTS

+CTS

–CTS

+OUT

–OUT

–IN

+IN

Master

62 ohm

Resistors

Last SlaveSlave

62 ohm

Resistors

Line-to-Ground Termination

Terminate

at Master

Terminate

at Last Slave

12

PLC

Direct

offers a Universal Cable Kit (part number FA–CABKIT). This cable kit

allows you to connect various types of

Direct

LOGICproducts with an RS232C

cable in a matter of minutes. The kit consists cable (phone cable with male plugs

already attached) and several specially wired connectors. The special connectors

are a D-sub style with built-in female phone jacks. The kit includes a wide variety of

the special connectors so you can use one kit to easily connect products from the

different

Direct

LOGICfamily of products. To use the kit with the DCU, just follow

these steps.

1. Plug the appropriate D-sub connector onto the DCU.

2. Plug the appropriate D-sub connector onto the other device you are

connecting to the DCU.

3. Connect the 50 foot cable to the two D-sub connectors.

WARNING: This cable is suitable for quick testing situations and should not

be used in actual applications. This cable is not shielded and is highly

susceptible to electrical noise. Electrical noise can cause unpredictable

operation that may result in a risk of personal injury or damage to equipment.

Use the cable specifications described earlier in this manual to select a cable

suitable for actual applications.

9 Pin

Build A Test Cable In 30 Seconds

1. Attach Universal Cable Adapter to the DCU

2. Attach another Universal Cable Adapter to the

Device which will connect to the DCU

3. Attach the Universal Cable

Universal 9 pin

D–sub connector Universal 25 pin

D–sub connector

Consideration 6:

A Quick Test Cable

13 1313

Step 2: Set the DCU switches

The device(s) connected to the DCU will help you determine the appropriate switch

settings.

Ifyou’reconnectingtheDCUtoacomputeroroperatorinterface,justsettheDCUto

match those communication parameters. Check the documentation that came with

your computer or operator interface to determine the available communication

parameters.

You’ll need to know the following things.

SBaud rate

SParity settings

SProtocol

NOTE: Some operator interfaces support multiple protocols. Make sure your

operator interface uses one of the following protocols.

S

Direct

NET (DL330, DL340, D3–232–DCU, or D3–422–DCU)

SHostlink (TItor SimaticrTI325, –330, -335, 305–03DM, or 305–02DM)

The DCU can only be used as a slave station, so set the switches to match the

communications parameters for the master station.

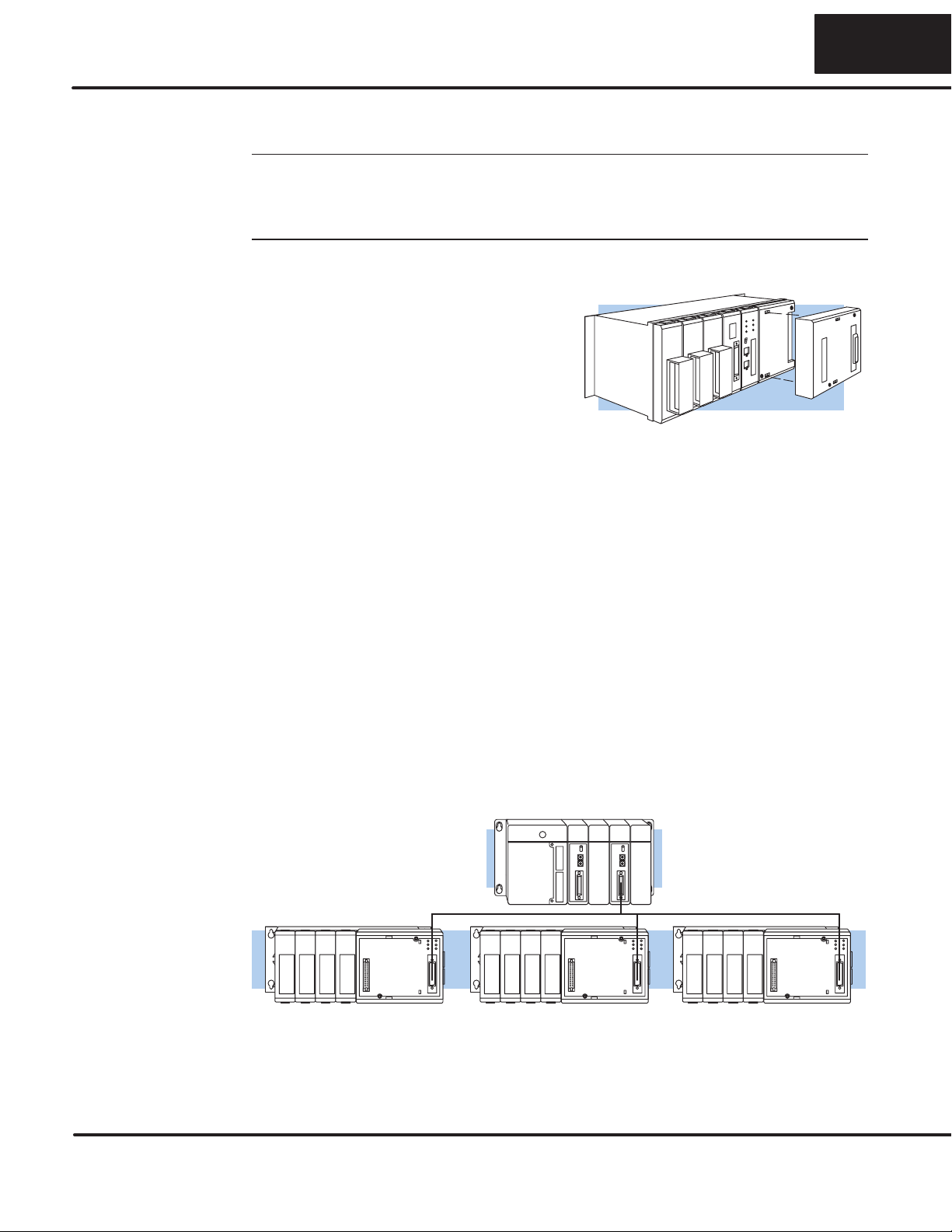

DL405 PLC Master - Slave Network

DCM as Master

DL305 DCU as Slave

Host Computer or

Operator Interface

Connection

Direct

NET Interface

Connection

14

There are two banks of switches located on the side of the DCU that are used to set

the communications and protocol parameters. The following diagram shows the

locations and setting options.

Baud 1 2

300 OFF OFF

1200 ON OFF

9600 OFF ON

19200 ON ON

Baud Rate

ODD Parity Switch Positions

Self Test NO Parity

Set to OFF

ON OFF

Block 11

2

3

4

5

6

7

8

10 ms Delay Time No Delay

PGM Mode at power up Run Mode at power up

Not Used Not used

ASCII Mode HEX Mode

Baud Rate: The first two positions on block 1 are used to set the baud rate for the

DCU. There are four baud rate selections available ranging from 300bps to

19.2Kbps.Allstationsmusthavethesamebaudratebeforethecommunicationswill

operate correctly. Usually, you should use the highest baud rate possible unless

noise problems appear. If noise problems appear, try reducing the baud rates.

Parity: Position 3 on block 1 selects between the two parity options, odd or none. If

you’re using all

Direct

LOGICequipment, you can use odd parity. Odd parity uses

eleven bits total (1 start bit, 8 data bits, 1 stop bit, and 1 parity bit.) Some devices

require no parity, which uses only 10 bits (1 start bit, 8 data bits, and 1 stop bit.)

Self-Test: Position 4 on block 1 selects the factory self-test and should always be

switched off. If the self-test is on, the DCU will not operate correctly.

Response Delay Time: Position 5 on block 1 sets the response delay time. This

sets how long the DCU will wait before it responds to each component of a

Direct

NETcommunicationrequest. Ifyou’re usingall

Direct

LOGICequipment, a

response delay is not required and you should turn off the switch.

The DCU may respond too quickly for some devices, such as telephone or radio

modems. If you encounter this problem, turn on the delay switch to provide a 10 ms

delay. If this still does not work, check your device manual to see if the device

requires more than a 10 ms delay.

Mode at Power-up: Position 6 on block 1 allows you to select the CPU operating

mode when system power is supplied. If the switch is turned on, the CPU

automatically enters Program mode when power is supplied. If the switch is off, the

CPU automatically enters Run mode when power is supplied.

ASCII/HEX Mode: Position8 onblock 1selects betweenASCII andHEX modesof

data representation. If you want the fastest communication possible, use HEX

mode.Thedifferenceisinthewaythedataisrepresented.Thesamedataistwiceas

longinASCII format,so ifthere’s moredata, ittakes longerto transfer. Ifyou havea

deviceonthenetworkthatrequiresASCIImode,thensettheswitchforASCIImode,

otherwise, use HEX mode.

DCU

Switch Settings

Block

1

Block

2

15 1515

As you examined the diagrams at the

beginningofthismanualyoumayhavenoticed

you can still connect a Handheld Programmer

even when there is a cable connected to the

DCU. There’s an Online/Offline switch on the

side of the unit that determines which

connection has control of the CPU.

In the Offline position, this switch logically

disconnects the DCU from the network (just as

if you pulled the cable from the 25-pin

connector.) Once this switch is moved to the

Offline position, the DCU will not communicate

with the network, and the Handheld

Programmer can communicate with the CPU.

If you move the switch to the Online position,

the DCU will communicate with the network,

but not until the master sends a request for

communication. This does not operate like the

reset switch on many personal computers.

NOTE: You cannot use the Handheld

Programmer if the switch is in the Online

position.

TheDCUstationaddressissetbythesecond

switch block, which is located on the side of

the unit. The decimal address is set in BCD

(Binary Coded Decimal) format with valid

addressesfrom1to90decimal.Forexample,

to set an address of 10, you should turn on

switches 4 and 2.

The addresses do not have to be sequential,

buteach stationmusthave auniqueaddress.

NOTE: The DCU address switch settings are

only read at power up. If you’ve want to

change the address and the DCU is already

up and running, you’ll have to cycle the

system power to initialize the change.

Block 2

1

2

3

4

5

6

7

864

32

16

8

4

2

(Binary Value)

1

Not used

ON OFF

Online / Offline

Switch

Address Switch

The highlighted

sentence is incorrect.

It should read: "The

decimal address is set

from 1 to 90 decimal.

16

Step 3: Install the DCU and start the communications

The DCU requires 500 mA of +5V base power. Make sure you will not exceed the

available base power budget by installing the DCU.

WARNING: Exceeding the base power budget may cause unpredictable

systemoperation that can result in personal injury or equipment damage.See

the DL305 User Manual for details on power budget calculations.

On the back of the DCU is a switch to select if it will receive power form the base

(INT–internal position)or froman externalpower source(EXT –externalposition).

If there appears to be a power budget problem, use the external power source

option. The DCU is shipped with a three pin pigtail which should be used to connect

theexternalpowersource.Thepigtailconnectstothebottomoutletonthesideofthe

DCU.

Green

(G)

Black

(OV)

Wh te

(5V)

PWR

EXT

INT Set

Sw tch

to reflect

power

source

If you use an external power supply, you must provide an external ground

connection for the DCU. The following diagram shows how the external power

sources are connected.

5V

Power

Supply +

-5V

Power

Supply +

-5V

Power

Supply +

-

RS422/422 Amp or

RS422/432 Convertor

To host or

Tw sted Pa r slave stat on

GND

Check the Power

Budget

17 1717

Use the following procedures to install the DCU.

WARNING: Always disconnect the system power before installing or

removing any system component. Also,

do not

install a DCU while the CPU is

in RUN mode. This may cause unpredictable operation which can result in a

risk of of electrical shock, personal injury, or equipment damage.

1. Set the power source switch, located

on the rear of the DCU, to the correct

position.

2. Carefully align the connector on the

rear of the DCU with the CPU

connector and gently push the DCU

ontotheCPU.(Iftheconnectorsarenot

aligned properly, you can bend the

connector pins.)

3. Secure the DCU to the system with the

two mounting screws.

Make sure you have all the cables connected and that all the network devices have

the same communication parameters (baud rate, parity, etc.)

Connect the cables and follow the procedures outlined in the documentation that

camewith yourhostcomputersoftwareor operatorinterface.You’ll haveto execute

your host or operator interface program before the communications can begin. For

example, if you’re using

Direct

SOFT, you can just specify the station address and

start working!

Sinceyou canonlyusetheDCU inaslave station,there hastobe anetworkmaster

that issues the communication requests. The PLC master station must contain an

RLL communications program . (See the

Direct

NET Manual or the DL405 User

Manualfordetails ontheRXandWXinstructions.) ThemasterstationCPUmustbe

in Run mode in order to execute the communications program. The slave station

CPUs do not absolutely have to be in Run mode because the DCU will still transfer

the data. Whether you put the slave stations in Run mode depends on your

application requirements.

Install the DCU

Connect the

Cables

If you’re using an

Operator Interface

or Computer...

If you’re using

Direct

NET...

18

Step 4: Verify that it’s working correctly

Check the DCU indicators to verify the DCU is operating correctly. The following

diagram shows the proper indicator conditions.

RUN

BATT

CPU

DATA

DIAG

PWR

On when PLC is in

Run Mode

On when PLC

battery needs

replacing

On when a fatel

error has occured in

the CPU.

On (flashing) when

data is being

transmitted

On when internal

diagnostic tests are

complete and have

passed.

On when base

power is on. If an

external power

supply is used, both

base power and the

external supply must

be provided for this

indicator to be on.

19 1919

Troubleshooting

If the DCU does not seem to be working correctly, check the following items.

1. Cable and connections. Incorrectly wired cables and loose connectors

cause the majority of problems. Verify you’ve selected the proper cable

configuration and check to see the cable is wired correctly.

2. Dipswitch settings. Make sure you’ve set the DCU to match the

communication parameters required by the master station (DL405 DCM,

operator interface or host computer).

3. Incorrectprotocol.Makesureyouroperatorinterfaceorpersonalcomputer

software can use the

Direct

NET, Hostlink/CCM2 protocol.

4. Communicationsprogram. Checkthecommunicationsprogram forerrors.

Consult the

Direct

NET Manual or the manuals that came with your host

computer software or operator interface for details.

The following table provides additional troubleshooting details.

Indicator Status Possible Cause Corrective Action

PWR off PLC power is disconnected

DCU is not connected to the CPU

properly

DCU external power source

(if used) is not connected

DCU is defective

Check the PLC source power.

Make sure the DCU is securely

fastened to the CPU and no

connector pins are bent.

Check the external power source.

Replace the DCU

DIAG off DCU is defective Replace the DCU

DATA does not flash during

communications Loose or incorrectly wired cable

Online / Offline switch is in the

Offline position

Communications program is not

correct

Check the cable connections and

pinouts.

Set the switch to Online.

Check the master

communications program. Verify

the address, amount of data, and

data type are correct.

For "DIAG off", two

other possible causes

are a defective CPU

module or base.

Other manuals for DL305

1

Table of contents

Popular Recording Equipment manuals by other brands

ADInstruments

ADInstruments PowerLab C Series owner's guide

Erica Synths

Erica Synths fusionbox user manual

National Instruments

National Instruments NI 9860 Getting started guide

Roland

Roland TR-707 owner's manual

Extron electronics

Extron electronics RGB 202 Rxi VTG user manual

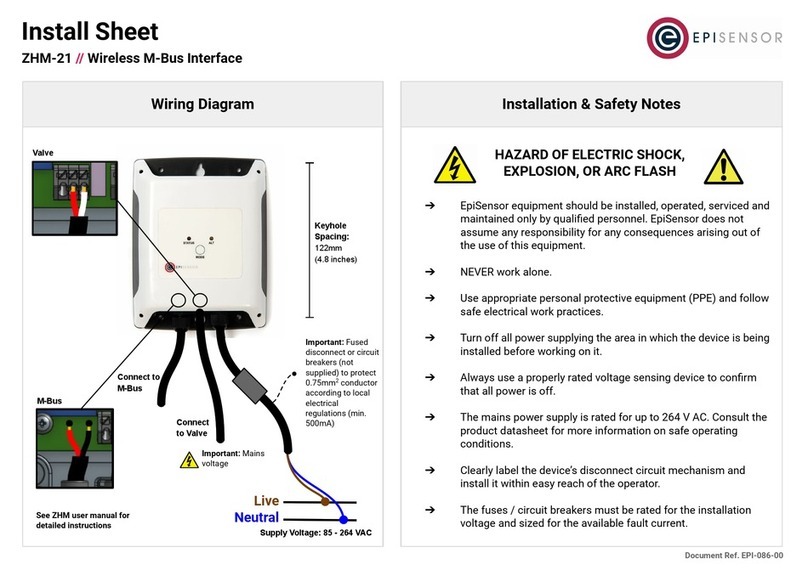

EpiSensor

EpiSensor ZHM-21 Install Sheet