Manual EIM 316/336 interface application for setup and conguration of MMIMyK

4DKRCC.PS.RQ0.C2.02 / 520H8422 © Danfoss A/S (AC-MCI/sw), 2014-03

5. Starting the

application

The MyK will startup in its Bios menu if no

application has previously been loaded. From

this menu it is possible to load the applications

that are stored on the MyK, either in its internal

or external memory. Please refer also to the

MMIMyK software download guide.

Select Application – Appl.Load, then select the

disc that the application is stored on, 0:/ (internal

memory) or 1:/ (SD/MMC card). Select the folder

containing the application and press the enter

button. The application should load automati-

cally and will startup after a few seconds.

The next time the MyK is powered, it will start the

application automatically. To enter the bios menu

again, press the Esc and enter buttons at the same

time, and keep them pressed for a few seconds,

until the MyK enters the bios menu. From here it is

possible to load another application.

6. Using the

application

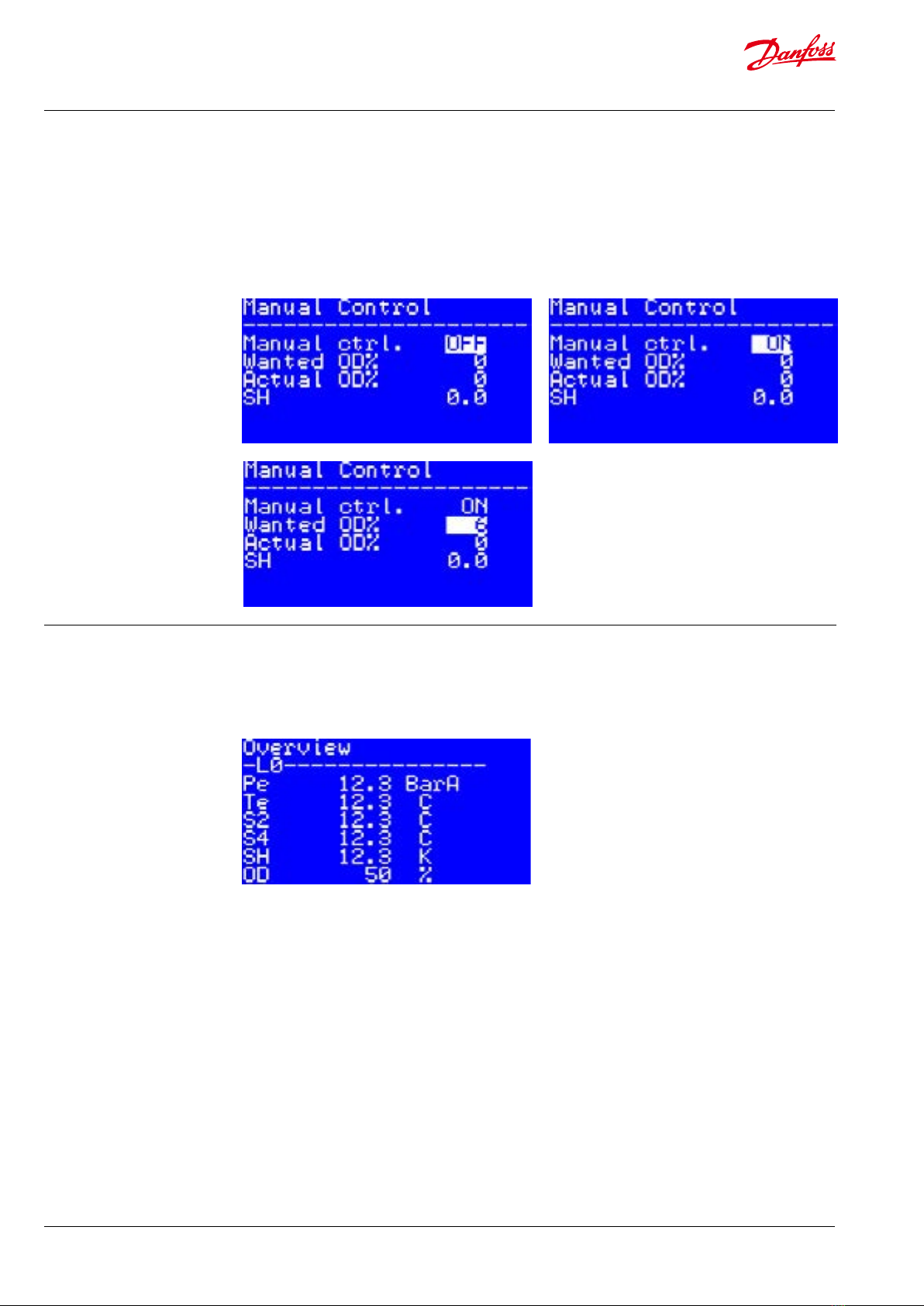

6.1 The main screen

The main screen shows the current superheat (SH)

and opening degree (OD) in large characters.

If the main switch is o, this will be shown with

the characters OFF in large characters in the

upper right corner. If the main switch is on, the

currently active superheat reference is shown in

the upper right corner instead.

If an alarm is present, this is indicated by the

word “ALARM” to the right of the opening

degree. If the unit is in manual control mode, this

is indicated with the word “MAN”.

Pressing enter will give access to the main menu.

Pressing escape will give access to the alarm screen.

If the MyK does not recognize that it is con-

nected to an EIM 336, it will beep to indicate

that it is in alarm.

On the main screen press enter and go to

“Parameters-> MyK setup-> System”.

Under “Active EIM Addr”, set the correct ID of

the EIM 336 you want to connect to. Under

“Serial baud rate (MB)” set the baud rate to the

Setting up the MYK to

specic EIM 336 unit

address.

correct baud rate (default for EIM is 192 i.e. 19200

Baud) then after set the correct serial settings

under “Serial settings (MB)”, (default value for EIM

336 is 8E1 i.e. 8 data bits, even parity and 1 stop

bit). The MyK should now able to connect with

the EIM 336.